Abstract

The ever-increasing energy consumption has been projected to burden renewable energy sources. It is imperative to look for high-performance clean energy storage systems to sustain future energy demands. Among all the environmentally friendly and efficient energy storage options, supercapacitors are one of the most researched devices. Supercapacitors possess excellent electrochemical properties such as high-power density, superior cyclic stability, fast charging-discharging rates, and high specific capacitance that makes them a fascinating candidate. To improve the energy storage capacity, the two-dimensional counterpart of the supercapacitors is being investigated extensively and manifested unique electrochemical properties. This article thoroughly summarizes the synthesis and characterization techniques adopted for the most recent two-dimensional supercapacitor electrode materials. We focus on the family of carbon-based materials, transition metal oxides and hydroxides, MXenes, and transition metal dichalcogenides that can be employed for clean energy storage applications. The performance of these materials is discussed and compared based on their synthesis technique.

Export citation and abstract BibTeX RIS

This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 License (CC BY, http://creativecommons.org/licenses/by/4.0/), which permits unrestricted reuse of the work in any medium, provided the original work is properly cited.

With the increasing global population and its dependence on depleting natural energy resources, the scientific community is focusing its attention on managing future energy demands. According to the International Energy Agency (IEA), a typical U.S. home has doubled its energy consumption since 1980, with projections that energy consumption will double by 2022 and triple by 2030. 1 The situation is critical as energy sources such as wind, solar power, and other renewable sources cannot sustain the ever-increasing future demands. Energy generation and storage are some of the most critical challenges of the 21st century. The continuous development of technological advances and global economic growth can be sustained only through the evolution of energy generation as well as energy storage systems.

Additionally, with environmental concerns, exploring clean energy sources is imperative for the development of human society. Pertinent to this, high-performance energy conversion and storage devices are essential to enable efficient, versatile, and environmentally friendly uses of energy. Among all the available options, lithium-ion batteries and supercapacitors are the two most critical devices being researched extensively for energy storage applications.

The fundamental differences between batteries and electrochemical capacitors regarding materials, structure, and mechanism drive their functions. While the battery stores energy chemically with higher energy density than a capacitor, it undergoes physical changes during the transitions between charged and discharged states. Contrary to that, a capacitor stores charge physically and do not undergo any significant physical change during transitions. This fundamentally results in different charge/discharge times for batteries and capacitors. The other key difference between these two technologies is based on the energy storage mechanism. Lithium-ion batteries are an established choice due to their superior performance, such as high energy density, high power density, long cycling time, low memory effect, and low self-discharge. 2–5 However, the development of lithium-ion batteries has attained a bottleneck due to multiple hurdles such as safety concerns, poor utilization of Li metal, high cost, convoluted chemical reactions, poor cyclic performance, and low rate capability. 6–11 Supercapacitors have gathered more attention than lithium-ion batteries due to their faster charge/discharge rates, higher power density, and longer lifetimes. 12,13 The advantages and disadvantages of supercapacitors and lithium ion batteries has been listed in Table I. 14 Although most of the cutting-edge research has been performed recently, Hermann von Helmholtz was the first to introduce the phenomenon of supercapacitors in 1879. 15 This phenomenon did not gain popularity until the General Electric Corporation patented the carbon-based electrolytic capacitors in 1957. 16 The technology developed furthermore with Standard Oil Company of Ohio patenting the first electric double layer capacitor for commercial purposes in 1966. 17 Finally, in 1978, it was marketed as a "supercapacitor" for applications in memory for computers. 18 Since then, many efforts have been made to develop this technology for multi-fold applications. Supercapacitors are highly reliable, as manifested by their use in state-of-the-art aerospace applications in Airbus 380, back-up power systems, digital communications, pacemakers, airbags, and hybrid electric vehicles. 11,19,20

Table I. Advantages and disadvantages of supercapacitors and lithium ion batteries.

| Category | Advantages | Disadvantages |

|---|---|---|

| Supercapacitors | High power density | Low energy density |

| Long cycle life | ||

| Fast charging speed | ||

| Good low temperature performance | ||

| High current discharge ability | ||

| Super low temperature characteristics | ||

| Simple charging and discharging circuit | ||

| Convenient detection | ||

| Lithium ion battery | High working platform | High cost |

| High energy density | Cannot discharge large current | |

| Long cycle life | Need over-charge and over-discharge protection | |

| Fast charge and discharge | ||

| Good safety performance, no pollution, and no memory effect | Line control | |

| Small self-discharge | ||

| Large temperature range |

Over the past few years, extensive studies have been performed reflecting on the importance of supercapacitor devices for future energy storage systems. Figure 1 shows the number of published articles on the topic of supercapacitors in the past decade.

Figure 1. The number of published articles on supercapacitors in the last decade. The data was collected from google scholar by searching the keyword "supercapacitor."

Download figure:

Standard image High-resolution imageElectrochemical capacitors (ECs), also known as ultracapacitors or supercapacitors, can be classified as pseudocapacitors and electrochemical double-layer capacitors based on the energy storage mechanism. Capacitance generation in a supercapacitor results from two occurrences, the formation of an electrical double layer at the electrode/electrolyte interface or the near-surface Faradaic charge transfer between electrolyte ions and electrode materials. 1 As a result, charge storage is fast in supercapacitor. However, the major drawback of supercapacitors is their inherent low energy density due to the use of electrode surface or near-surface only.

These limitations are the foundation for driving research interests to develop novel electrode materials with high energy density. Besides high energy density, it is also essential to consider rate capability and cycle stability in designing high-performance supercapacitor electrodes. Besides, the toxicity and cost of the electrode material are also crucial factors to consider. Overall, to realize a high-performance supercapacitor electrode, factors of paramount importance are as follows:

- (1)Surface area—Since supercapacitors store charge on the surface of the electrode, superior specific capacitance can be achieved using an electrode with a higher surface area. The surface area of the electrode material can be engineered using nanostructures.

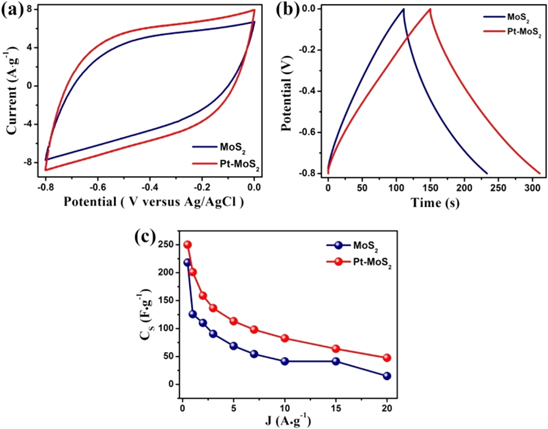

- (2)Conductivity—Electronic and ionic conductivities influence the specific capacitance and rate capability. A high electronic and ionic conductivity will also ensure the rectangular nature of cyclic voltammetry curves and symmetric galvanostatic charging-discharging curves. Electronic and ionic conductivities can be enhanced by precise electrode design and pore size control.

- (3)Stability—The electrode material's mechanical and chemical stability significantly affects the cycle stability. Along with the investigation of new electrode materials, the electrode designs with nanostructures pave a robust foundation for accomplishing high-performance supercapacitors.

While a plethora of materials has been investigated, recently, two-dimensional (2D) materials have gained significant attention as supercapacitor electrode materials due to their extraordinary physicochemical properties. The intrinsic high surface area and unique electrical properties of atomically thin sheets of 2D materials are attractive for capacitive energy conversion and storage. 21–23 2D materials hold high potential for applications in electronic devices, sensors, catalysts, energy conversion, and energy storage due to their excellent electrical, optical, chemical, and thermal properties. 24–27 Extensive efforts are being made to develop 2D materials, focusing on the design and fabrication of effective electrode materials for energy conversion and storage. Additionally, the capability of engineering 2D materials with unique morphologies and properties makes them attractive candidates to tune the supercapacitor performance.

Carbon-based materials such as graphene, carbon nanotubes, carbon nanosheets, activated carbon, and non-porous carbon have continued to fascinate scientists for energy storage over the past decade. 28–32 Graphene analogous boron carbon nitride (BCN) nanomaterials with high surface activity and tunable electrochemical properties have emerged as next-generation energy storage materials with high specific capacitance, excellent rate capability, and outstanding durability. 33–36 Two-dimensional transition metal oxides and hydroxides (TMOs and TMHs) are revolutionizing the field of energy storage owing to their high theoretical specific capacitance, abundant in nature, a plethora of active electrochemical sites as well as the feasibility of forming hierarchical structures by integrating with other materials such as graphitic carbon. 37 Even though TMOs/TMHs have intrinsically low conductivity, their atomic thickness shortens the ion diffusion path and reduces the ion diffusion resistance, making them inept for high-rate performance. However, designing TMOs and TMHs in the form of 2D nanostructures allow a significant transformation to their inherent properties. These nanostructures have resulted in high conductivity, effortless ion diffusion, and enhanced mechanical integrity. 38–40 Additionally, hierarchical structuring of TMOs/TMHs with other low dimensional materials can overcome the agglomeration of nanosheets and improve the performance of different electrode materials to boost the overall performance of the supercapacitor device.

MXenes, which belongs to the family of 2D metal carbides, nitrides, or carbonitrides, has evolved as a promising candidate for transparent supercapacitor electrode material. This has been primarily associated with its remarkable electrical conductivity due to its electrochemically active surfaces, fast ion diffusivity due to its stacked morphology, good hydrophilicity due to the presence of surface hydroxyl groups, and large interlayer spacing. 41–43 MXene proves to be a unique member of the 2D family of materials since the interlayer spacing can be effectively controlled and the possibility of insertion of spacers to avoid restacking of the MXene sheets. 44 Furthermore, MXenes are environmentally friendly and exhibit outstanding biocompatibility for electrochemical biosensors. The synthesis technique and the method incorporated to fabricate the MXene sheets considerably impact its properties. 45

Beyond graphene, there is a broad spectrum of 2D materials with a primary focus on 2D transition metal dichalcogenides, as evidenced by the literature's publication record. 46 Unlike graphene, many 2D TMDs are semiconducting and can be designed into ultra-small and low power transistors in the state-of-the-art ever-shrinking silicon technology. 47 2D TMDs display unique electrical and optical properties that emerge due to the quantum confinement and surface effects during the transition from indirect to direct bandgap when bulk materials are scaled down to monolayers. 48 What makes TMDs distinctive is the van der Waals gap between each neighboring layer, the large surface area, and variable oxidation states make them highly attractive for both EDL and Faradaic charge storage mechanisms. 49,50 The properties of TMDs are determined by their phases, which are different bonding and configurations. Phase engineering has resulted in extraordinary electrochemical performance and high operational voltage windows. 51

Many reviews have been published on supercapacitor electrode materials in the past decade. These articles mainly reviewed the electrode material properties and applications, with a majority of articles focusing on carbon electrodes such as carbon nanotubes, graphene and C/metal oxides. However, these reports lack a comprehensive analysis of the influence of synthesis techniques on the performance of supercapacitor electrodes. With the increasing demand for supercapacitor devices, it is crucial to understand the influence of synthesis techniques to identify the uniqueness of electrode materials, which will expose novel properties leading to additional innovations. As a result, this article mainly focuses on the synthesis and characterization techniques of recent 2D materials, which show exceptional potential for supercapacitor applications. Contemporary 2D materials belonging to the families of carbon, TMOs/TMHs, MXenes, and TMD are summarized with strategies in design and synthesis for optimizing the electrochemical performance of these electrodes for energy storage applications. The performance of supercapacitor electrode materials and their stability are reported and compared based on the synthesis technique adopted.

Carbon Based Electrodes

Activated carbon

Carbon is one of the most frequently used materials for energy storage applications. The flexibility of manufacturing carbon electrodes in several morphologies ranging from 0D to 3D nanostructures as spheres, rods, sheets, and foams, respectively, makes them widely popular for tuning their properties based on the structure. Even though the general trend is that the specific capacitance is directly proportional to electrode surface area, the case with carbon electrodes is notably different. Carbon morphologies with a lower surface area are reported to exhibit higher specific capacitance than morphologies with a larger surface area. 52,53 Numerous efforts have been dedicated to producing tailored porous carbon electrodes, including activated carbons, 54,55 carbon aerogels, 56,57 graphene, 58,59 carbon nanotubes, 60–63 carbon nanofibers 64–67 and nano carbons for enhancing the energy storage mechanism. 68,69 Activated carbon is one of the critical materials explored for supercapacitor applications owing to its high specific surface area between 1000–2000 m2g−1 and relatively low cost. 13,31 In recent years, many researchers have successfully synthesized activated carbon for electrochemical energy storage systems from bio-waste for sustainable development. 70–72

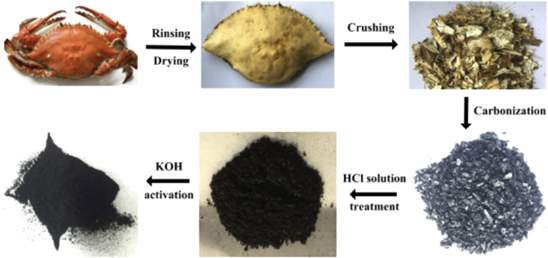

For high-performance supercapacitors, it is not only essential to design activated carbon with a large number of pores to accumulate the electrolyte ions, but it is equally essential to make the porous structure compatible with the electrolyte ion. In recent years, there has been rapid development of activated carbon electrodes from bio-waste materials towards environmentally friendly synthesis. Fu et al. attempted to synthesize high-performance activated carbon electrodes from economic and green abandoned seafood waste. 73 They reported a multi-hierarchical porous activated carbon electrode using the crab shell as a precursor, which exhibited specific capacitances of 322.5 F g−1 and 223.4 F g−1 at current densities of 1 and 10 A g−1, respectively. These supercapacitors showed remarkable cyclic stability with less than 1% capacitance fading over 10000 cycles at 1 A g−1. Figure 2 shows the synthesis process of activated carbonized carbon shells synthesized in this study. The crab shell was subjected to cleaning to remove impurities, followed by drying, crushing, grinding, and carbonization. The ground crab shell was heated at 500 °C for 1 h in a tube furnace in the presence of high purity nitrogen gas. The dark solid product obtained, shown in Fig. 2, was denoted as carbonized crab shell (C-CS). To remove traces of MCO3, the product was mixed with 10% HCl solution, stirred for 2 h, and finally washed with ultra-pure water till neutralization. This process was followed by drying the product at 80 °C. Subsequently, the sample was subjected to KOH treatment for 24 h and dried at 100 °C overnight. Finally, the mixture was heated to 600 °C, 700 °C, 800 °C for 1 h in the presence of nitrogen gas to achieve the activated C-CS (A-C-CS).

Figure 2. Illustration of the synthesis process of activated carbonized crab shell.

Download figure:

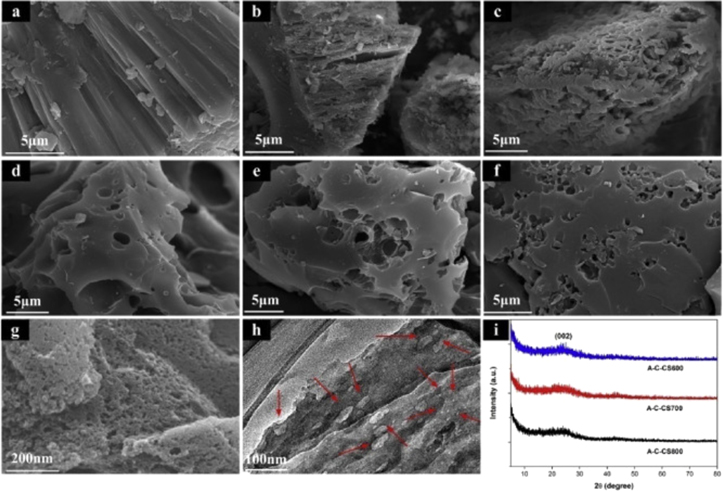

Standard image High-resolution imageSEM, TEM, and XRD were performed to identify A-CS samples' morphology and crystalline structure obtained at different heating temperatures. The morphology of the samples displayed a strong correlation with the activation temperature, indicating evidence of increased porous structure. Figure 3h shows that the samples displayed macropores and micropores, and mesopores. Figure 3i shows that all samples demonstrated a single diffraction peak at 25° and no trend in crystallinity with an increase in activation temperature. The superior electrochemical performance of these activated carbon electrodes was attributed to the formation of macropores, micropores, and mesopores, resulting in a larger surface area and shorter ion diffusion paths.

Figure 3. SEM images of (a) CS, (b) C-CS, (c) HCl treated C-CS, (d) A-C-CS obtained at 600 °C, (e) A-C-CS obtained at 700 °C, (f) A-C-CS obtained at 800 °C, (g) high magnification SEM image of A-C-CS obtained at 700 °C, (h) high magnification TEM image of A-C-CS obtained at 700 °C, (i) XRD patterns of A-C-CS.

Download figure:

Standard image High-resolution imageMultiple reports have emphasized sweet corn husk as a promising precursor for high operating voltage supercapacitors. 74,75 Activated carbon electrodes devised from a corn husk precursor in a two-step carbonization process and activation exhibited higher energy density than conventional supercapacitors. 76 The carbonization was performed by heating the dried corn husk at 1000 °C for 1 h in an inert atmosphere. This was followed by activation using varying amounts of KOH (1:1 and 1:4 wt ratio) solutions. The resultant mixture was sonicated for 2 h, dried in a hot air oven at 105 °C, and exposed to heat treatment at 800 °C for 2 h in an argon atmosphere. The activated carbon materials were washed with DI water and dried overnight in the oven at 60 °C. The electrochemical studies were performed using an organic electrolyte (1 M tetraethylammonium tetrafluoroborate (TEABF4) in acetonitrile (AN)) in an operating voltage window of 0V–2.7V. The resulting activated carbon electrodes displayed a specific capacitance of 80 F g−1 at 1 A g−1 current density, good cyclic stability of 90% capacitance retention after 5000 cycles, high energy density of 20 Wh kg−1, and power density 681 W kg−1. This superior performance of activated carbon electrode was associated with a high specific surface area of 1378 m2 g−1, increase in the mesoporous volume due to the two-step synthesis process, and formation of layered morphology due to the exfoliating nature of KOH.

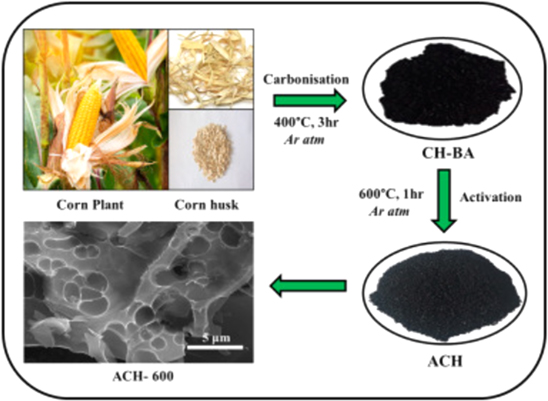

Surya et al. also successfully attempted to synthesize novel hierarchical porous activated carbon electrodes from corn husk, which exhibited using chemical activation of KOH, which revealed and measured the electrochemical performance in acid electrolytes. 77 The preparation steps are shown in Fig. 4 adopted carbonization of dried corn husk in a furnace at 400 °C for 3 h in argon ambiance. The carbon powder obtained from the carbonization process was then chemically activated using KOH in a 1:3 weight ratio by mixing the additives at 600 °C for 1 h in the presence of argon. The activation temperature for the carbonized sample was set to 500 °C, 600 °C and 700 °C to understand the disparity in electrochemical performance. The activated corn husk processed at 600 °C exhibited a specific capacitance of 314.83 F g−1 at 1 mV s−1 in 0.5 M H2SO4, with high stability over 2000 cycles. The high specific capacitance values of activated corn husk up to 600 °C was accredited to fast ion transfer in well-developed micro and mesoporous electrode structure. These symmetric capacitors also displayed high energy and power density of 9.85 Wh kg−1 and 7185 W kg−1, respectively, thus verifying its potential as a cheap, abundant, and green electrode material for supercapacitors.

Figure 4. The synthesis process of activated carbon electrodes for supercapacitor from corn husk precursor.

Download figure:

Standard image High-resolution imageRoy et al. demonstrated a facile method to fabricate activated carbon nanosheets (ACNSs) comprised of hierarchical porous carbon materials by using banana leaves as a precursor. 78 Activated carbon was extracted from banana leaves using the pyrolysis technique, as shown in the figure. The naturally dried banana leaves were cleaned with DI water and dried at 80 °C for 24 h in an electric oven followed by pulverization in a blender. The dried mass was mixed with an activating agent (K2CO3) in a ratio of 1:2. This mixture was subjected to various steps of pyrolization. The mixture was first heated to 750 °C at a rate of 10 °C min−1, maintained at this temperature for 5 h, and then cooled at the rate of 5 °C min−1 in a tube furnace in the presence of nitrogen gas. The carbonized samples were then cleaned with 0.5 M HCl and DI water, followed by further drying in an electric oven at 80 °C for 12 h to obtain activated carbon nanosheets. Figure 5 shows the steps adopted during the pyrolysis technique to obtain activated carbon from banana leaves. These ACNSs exhibited a maximum specific capacitance of 190 F g−1 in ionic liquid 1-butyl-3-methylimidazolium hexafluorophosphate electrolyte. The specific capacitance values of ACNSs from banana leaves were higher than the specific capacitance values of ACNSs obtained from other natural sources such as rice husk, 79 cauliflower, 80 and orange peel. 81 This high specific capacitance value was attributed to the well-organized porous structure of the electrode saturated by the electrolyte ions for facilitating the electric double layer formation.

Figure 5. Preparation of activated carbon nanosheets from banana leaves using pyrolysis technique.

Download figure:

Standard image High-resolution imageFurthermore, these ACNSs demonstrated high specific energy and specific power of 59 (Wh kg−1) and 750 (W kg−1), respectively. It is sporadic to see such outstanding results from activated carbon-based electrodes synthesized from biomass precursors. As a result, ACNSs developed from banana leaves offer attractive prospects for industrial energy storage applications.

Boron carbon nitride (BCN)

2D sheet of carbon popularly known as graphene, discovered by Andre Geim and Konstantin Novoselov in 2004, has been a major fascination of the scientific community for energy storage applications. 82,83 Graphene attains extraordinary properties due to its sp2 carbon hybridization, such as astounding strength, unprecedented thermal conductivity, and high electrical conductivity. Graphene has been widely explored for energy storage applications with a theoretical maximum specific surface area of 2600 m2g−1 and maximum specific capacitance of 550 F g−1. 84 Analogous to graphene, 2D layered nanostructures of boron carbon nitride (BCN) materials have gained considerable attention over the past decade owing to their unique electrical and physical properties. 85 With graphene exhibiting excellent properties for energy storage, the curiosity led to research and development on graphene analogous BCN nanomaterials. Typically, graphene is doped with N and B heteroatoms to form BCN structures with tunable electronic and electrochemical properties. 86,87 BCN nanomaterials have proven to be multifunctional with applications in supercapacitors, 88–91 lithium-ion batteries, 92,93 electrolytic and photocatalytic catalysts, 94–96 nano-biotechnology, and nanomedicine field. 97–99 Recently, several efforts have been made to synthesize clean 2D BCN structures for energy storage applications.

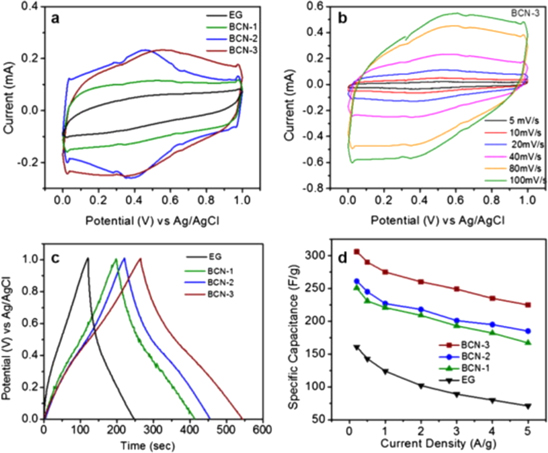

2D BCN structures are synthesized using many techniques such as solid-state reaction, 100 microwave plasma CVD, 101 thermal catalytic reactions. 102 Sreedhara et al. reported the synthesis of BxCyNz nanosheets by reacting a few layers of exfoliated graphene with boric acid and urea at 900 °C in the presence of nitrogen. 86 The proportion of boric acid and urea was varied to obtain different compositions of BxCyNz. The molar ratio of boric acid and urea was varied from 1:100 to 1:25, while the exfoliated graphene was maintained constant. Using this technique, the composition of the resulting BCN was recorded to be B0.06 C0.73 N 0.21 (BCN-1), B0.13 C0.49 N0.38 (BCN-2), B0.26 C0.22 N0.52 (BCN-3) using XPS characterization. BCN-1, BCN-2, and BCN-3 samples' electrochemical performance was performed using cyclic voltammetry, galvanostatic charge-discharge curves, and electrochemical impedance spectroscopy. Figure 6 shows the cyclic voltammetry curves of BCN samples measured at 40 m V s−1. BCN-3 exhibited the largest curve area due to high contents of N and B. It is important to note that BCN-3 also displayed excellent electrochemical stability over a wide scan range of 5–100 mV s−1. The discharge time of BCN-3 was significantly longer than the other samples, thus showing remarkable energy storage capability. The specific capacitance of exfoliated graphene, BCN-1, BCN-2 and BCN-3 was measured to be 162, 251, 261 and 306 F g−1 at 0.2 A g−1. Figure 6d shows that BCN-3 exhibited good stability and higher specific capacitance of 225 F g−1 at a current density of 5 A g−1 which was the highest observed in this study, thus demonstrating potential applications in energy devices.

Figure 6. (a) Cyclic voltammetry of BCN samples (b) CV curves of BCN-3 sample at scan rates between 5–100 mV s−1 (c) galvanostatic charge-discharge curves at a current density of 1 A g−1 (d) specific capacitance of BCN-1, BCN-2, and BCN-3 samples in comparison with exfoliated grapheme.

Download figure:

Standard image High-resolution image2D BCN synthesized by facile one-step pyrolysis method from orange peel extract exhibited immense potential as a supercapacitor electrode for energy storage and as an electrochemical sensor material to detect L-3,4-Dihydroxyphenylalanine (Levodopa, L-DOPA), which is used in Parkinson's disease treatment. 103 Orange peel wastes were dried at 60 °C in an oven for 24 h, followed by heat treatment in argon at 600 °C in a tube furnace, and pyrolyzed at 800 °C in the presence of carbon dioxide to achieve activated carbon. Synthesis of BCN was performed using a stoichiometric ratio of activated carbon, urea, and boric acid in DI water. The mixture was heated, dried, and then carbonized for 3 h from 700 °C to 900 °C in an argon atmosphere. Finally, BCN was obtained after treatment with HCl and overnight drying at 60 °C in the oven. Figure 7 shows the detailed mechanism of the synthesis process of BCN used in this study. The BCN electrodes displayed a specific capacitance of 391 F g−1 at a scan rate of 5 mV s−1. The BCN electrode retained its specific capacitance of 45 F g−1 even at a high scan rate of 200 mV s−1, thus exhibiting good stability. This stability was attributed to the complete release of electrochemical capacitance upon activation. The modified BCN electrode exhibited linear response over 0.2–160 μM of L-DOPA concentrations up to a detection limit of 0.14 μM in pharmaceutical formulations and spiked human urine. Thus, BCN electrodes developed from orange peel precursor attract multipurpose applications in supercapacitors and detect Levodopa in commercial formulations and human urine.

Figure 7. Mechanism of synthesis of BCN from the orange peel as a precursor.

Download figure:

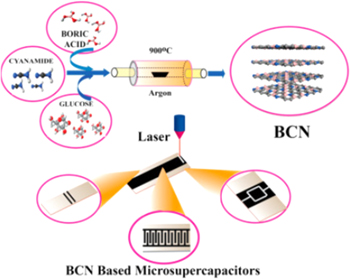

Standard image High-resolution imageThe growing demand for miniaturized and wearable electronic devices has led to the rapid development of flexible microelectronics. Hybrid electrodes are more popular for micro-supercapacitors (MSCs) applications as they offer mechanical stability and high energy density. Traditional techniques of fabricating planar MSCs such as photolithography and wet etching are not compatible with flexible substrates. Karbhal et al. reported laser scribed BCN microelectrode on flexible ITO/PET (Indium Tin Oxide/Polyethylene Terephthalate) sheet to overcome this limitation PVS-H2SO4 electrolyte. 104 BCN was synthesized from a solution of boric acid, glucose, and cyanamide (1:1:1) dissolved in distilled water. The solution was heated to 70 °C to form a thick paste and then further exposed to heat treatment at 900 °C for 3 h in an argon atmosphere in a tube furnace. To compare the electrochemical performance of varying doping levels, multiple BCN samples were prepared by varying the molar ratio of boric acid, glucose, and cyanamide. The ITO/PET substrate was coated with a slurry consisting of 80 wt% BCN electrode, 15 wt% of conducting carbon, 5 wt% of polyvinylidene fluoride as a binder and N-methyl-2-pyrrolidone. The slurry was dried at 100 °C in a vacuum oven overnight. The as-prepared film was scribed on the substrate using a CO2 laser to form interdigitated electrodes. Figure 8 shows the schematic of the synthesis of BCN electrodes and fabrication of a flexible MSC device. The BCN MSC device thus fabricated exhibited a specific capacitance of 72 mF cm−2, which is higher than that reported for graphene or CNT-based MSCs. The BCN-MSCs also displayed excellent stability up to 80000 cycles with intermittent bending performed ∼1500 times at an angle of 150°. BCN-MSCs show extraordinary potential towards next-generation flexible energy storage devices with their unique chemical and physical properties.

Figure 8. Schematic representation of BCN synthesis from boric acid, glucose, and cyanamide, and fabrication of flexible BCN MSC.

Download figure:

Standard image High-resolution imageTowards developing high-performance MSCs for future energy storage devices, Zhang et al. synthesized a novel 2D BCN nanomesh (BCNN) from a gel precursor of milk powder and boron oxide. They achieved an increase in aerial capacitance by tailoring defects and atomic contents of BCNN. 105 30g of boric acid was stirred with 200 ml hot DI water for 1 h before adding milk powder. The solution was heated at 90 °C to form a milk-boric acid sol-gel. The sol-gel was heated to remove residual water. The dried sol-gel was sintered at 700 °C to 900 °C for 1 h in the presence of nitrogen to obtain activated carbon. It was further refluxed thrice with DI water to remove excess of boric acid from the carbonized material. The achieved samples were designated at BCNN700, BCNN800, and BCNN900 based on the carbonization temperatures. The MSC fabrication was performed by first obtaining BCNN film by vacuum filtering 50 ml BCNN solution on cellulose paper and drying it in an oven at 60 °C. The BCNN film was coated with a 20 nm gold layer. The microelectrodes were formed using laser cutting and assembled on thin PET films to form BCN-MSCs. By tailoring defects and atomic contents of BCNN through the synthesis process, the BCNN900 exhibited remarkable capacitance and energy density of 80.1 mF cm−2 and 67.5 mWh cm−3, respectively. These values are considerably higher than the commercially used on-chip lithium thin-film batteries and most other carbon-based MSCs. This performance boost was attributed to the synergistic effect of pores, boron, and nitrogen doping and defects of BCNN.

The final mixture annealing time and temperature have been indicated in the Table II.

2D Transition Metal Oxides (TMOs) and Transition Metal Hydroxides (TMHs)

Although supercapacitor electrodes were designed initially using carbon-based materials due to their excellent electric conductivity, large surface area, and easy accessibility, they suffer from the low specific capacitance in the range of 62.2–347 F g−1. 106–115 The performance of supercapacitors is governed by ion diffusivity occurring at the separator and electrode interface, which is clarified using equation 116

Where τ denotes the diffusion time, λ signifies the ion/electron diffusion length, and Di represents the ion diffusion coefficient. Diffusion time can be significantly reduced by slicing the bulk material into its 2D counterpart, promoting a faster and shorter diffusion path for ions enabling higher specific capacitance. 117 It is imperative to shift towards new generation 2D active pseudo capacitor materials like TMOs and TMHs, 118–120 which show promising advantages like large specific surface area, reduced ion diffusion time, high specific capacitance, excellent mechanical flexibility, and better electrochemical performance as compared to the bulk form. 37,121 In the following section, the most commonly used supercapacitor electrode materials like noble (Ruthenium Oxide), low cost and widely available TMOs and TMHs (Manganese Oxide, Nickel Oxide, and Hydroxide, and Cobalt Hydroxide) have been discussed.

2D Ruthenium Oxide (RuO2)

RuO2 has been one of the first TMOs used as supercapacitor electrodes due to its high theoretical specific capacitance (1450 F g−1) with an exceptional life cycle, high electron conductivity, and superior electrochemical reversibility. 122,123 However, the use of RuO2 in its pristine form as the electrode material has deteriorated in recent years due to the following reasons. Firstly, due to continuous charging and discharging cycles, oxides accumulate at the grain boundaries, which easily peel off from the electrode surface. 124 This significantly reduces its gravimetric capacity over time. Secondly, since ruthenium is scarce and costly, the use of RuO2 in its pure form as the electrode material finds few practical applications in supercapacitors. 125 To mitigate the problems mentioned earlier, RuO2 based metal oxide nanocomposites, RuO2 based Carbon nanotube (CNT) nanocomposites, RuO2 based graphene binary composites, RuO2 based conducting polymer nanocomposite have been discovered. 124,126

RuO2 based metal oxide nanocomposites

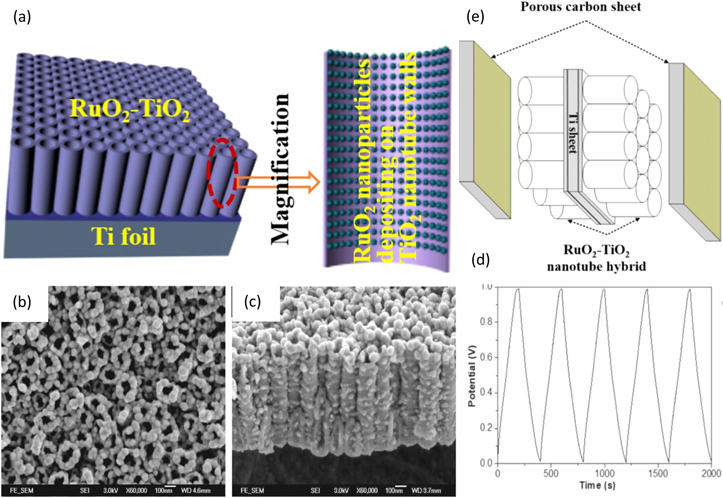

Amongst all the metal oxides, Titanium Oxide (TiO2) is preferred due to its abundance, low-cost nature, and high chemical stability. To improve the cost and utilization efficiency of RuO2, Xie et al. have made use of a porous, highly-ordered, and high surface area TiO2 nanotube array as the electrode substrate material, as shown in Fig. 9a. 127 FESEM images shown in Figs. 9b, 9c depict the TiO2 nanotube array grown on the Ti foil that supplies a large surface area to promote electrochemical activity. RuO2 nanoparticles are grown on the walls of the nanotube array. Electrochemical anodization of Ti metal was first carried out in a mixture containing ammonium fluoride, ethylene glycol, and phosphoric acid, which was further calcinated to prepare TiO2 nanotubes. RuO2 nanoparticles were filled into the TiO2 nanotube array by differential pulse and cyclic voltammetry. This was followed by electro-reduction, electro-oxidation, and heating to promote electro-activity of RuO2 and ultimately prepare the RuO2-TiO2 nanotube array. The galvanostatic charge-discharge curves of the RuO2-TiO2 nanotube array, shown in Fig. 9d, conducted at 0.2 mA cm−2 in 1.0 M H2SO4 electrolyte, showed a high specific capacitance of 39.6 mF cm−2 denoting exceptional electroactivity. The supercapacitor arrangement shown in Fig. 9e consists of RuO2-TiO2 nanotube array used as the cathode, porous carbon used as the anode, and an electrolyte consisting of a mixture of H2SO4 and polyvinyl alcohol polymer gel used as an electrolyte was able to achieve a high specific capacitance of 16.06 mF cm−2, a high energy density of 0.029 mW h cm−2, and capacitance retention of 78.9 % of the initial value after 1000 cycles.

Figure 9. (a) Schematic diagram of the microstructure of RuO2-TiO2 nanotube hybrid on Titanium foil, (b) Schematic diagram of RuO2-TiO2 supercapacitor assembly, (c), (d) FESEM images of RuO2-TiO2 nanotube hybrid, and (e) GCD curve of RuO2-TiO2 nanotube hybrid.

Download figure:

Standard image High-resolution imageLeng al. have combined the advantages of a conductive matrix of flexible and porous graphene, excellent conductivity, chemical and thermal stability of RuO2, and high surface area of TiO2 to synthesize graphene–RuO2–TiO2 nanocomposites using a hydrothermal process. 128 RuCl3 and TiCl3 with Ru/Ti = 3/1 as the mole ratio were dissolved in water. The resultant solution was then mixed with graphene oxide dispersion, named GRT1. Samples prepared using the same procedure but different molar ratios of Ru/Ti (1:1 and 1:6) were named GRT2 and GRT3, respectively. The synthesis process has been illustrated in Fig. 10a. Reduced graphene oxide (RGO), graphene-TiO2 (GT), and graphene-RuO2 were also prepared using the same procedure for comparison purposes. The XRD patterns of GRTs are shown in Figs. 10b, 10c. The peaks labeled 1 belong to rutile RuO2, and those labeled 2 belong to anatase TiO2. It is quite evident that GRT1 has low-intensity TiO2 peaks suggesting slow TiO2 crystal growth due to adsorption of Ru on the Titanium Hydroxide (TiH4O4) surface. As the molar ratio was increased, the Ti content in the GRT increased, thereby noticeably increasing the anatase peak intensities. C=C (sp2 hybrid C) peak from graphene can be seen across the FTIR spectra of the GRTs at 1621 cm−1. The O–H bond at 3425 cm−1 was more prominent for GRT2 and GRT3, suggesting stronger hydroxyl vibration. This suggested the increased presence of hydroxyl groups on the TiO2 surface and comparatively less existence on the RuO2 surface. Minor peaks pertaining to the C–O peak at ∼1000–1260 cm−1 and C=O peak at 1715 cm−1 were also present. The SEM images are shown in Figs. 10d, 10e suggested the presence of RuO2-TiO2 nanodots on the graphene surface. The prominence of these nanodots increases with the Ti content in the molar samples. The curved veil-like morphology of graphene is consistent with all the GRTs.

Figure 10. (a) Schematic representation of the formation of GRT, (b) XRD pattern of GRT, (c) FTIR pattern of GRT, SEM image of (d) GRT1 and (e) GRT2, (f) CV curve of GRT, (g) GCD curve of GRT, and (h) cycle performance of GRT.

Download figure:

Standard image High-resolution imageGRT1 and GRT2 showcased better reversibility, superior mass transport, and smooth electron conduction, which can be inferred from Fig. 10f based on their close to ideal CV curves encompassing a larger area. Since GRT3 had a comparatively higher TiO2 content, the CV curve of GRT3 deviates from the ideal behavior. This resulted in larger equivalent series resistance. From the GCD curves shown in Fig. 10g, it was noticed that GRT1 exhibited the highest specific capacitance of 396.5 F g−1, followed by GRT2 at 282.4 F g−1, and finally, GRT 3 manifested a specific capacitance of 216.7 F g−1. GRT1 and GRT2 take advantage of their extremely low internal resistance by demonstrating ∼95% capacitance retention after 1000 cycles at 0.1 A g−1, as shown in Fig. 10h.

RuO2 based conducting polymer nanocomposite

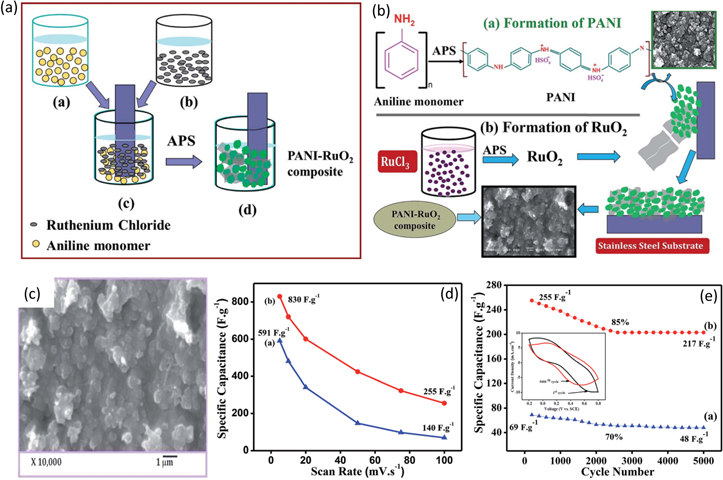

The incorporation of polymers into RuO2 has recently attracted a lot of attraction owing to enhanced supercapacitor performance. 126 Conducting polymers are known to be a good candidate for supercapacitor electrode material. However, their application is restricted by short cycling life. Conducting polymer composites demonstrates unique physiochemical properties, which can be used as an electroactive material that exhibits exceptionally high specific capacitance. The chemical bath deposition (CBD) method was carried out by Deshmukh et al. to deposit polyaniline-RuO2 (PANI-RuO2) composite thin films on stainless steel substrate. 129 The polymerization process obtained PANI solution by mixing H2SO4 solution, aniline monomer, and ammonium persulphate (APS). Stainless steel substrate was immersed in PANI, aqueous RuCl3, and APS solutions. Thin layers of RuO2 with a thickness of 0.12 mg cm−2 covering PANI clusters were deposited on the substrate. This growth mechanism has been schematically illustrated in Figs. 11a, 11b.

Figure 11. (a) Schematic illustration of CBD method for synthesis of PANI-RuO2 thin films, (b) schematic illustration of the growth mechanism of PANI-RuO2 thin films, (c) SEM image of PANI-RuO2 thin films, (d) variation of specific capacitance with a scan rate of PANI (blue curve) and PANI-RuO2 (red curve), and (e)specific capacitance retention over 5000 cycles for PANI (blue curve) and PANI-RuO2 (red curve).

Download figure:

Standard image High-resolution imageAgglomerated and globular morphology of PANI was seen over the entire surface of the stainless-steel substrate, evident in the SEM images shown in Fig. 11c. A thin layer of RuO2 covered the dense cluster of PANI. To analyze the performance of PANI-RuO2 as a supercapacitor electrode material, the cyclic voltammetry study was conducted in 1.0 M H2SO4 solution at a scan rate of 5mV s−1 within the potential window of −0.2 to +0.8V. The CV curves revealed an enhanced specific capacitance of 830 F g−1 obtained for the PANI-RuO2 composite electrode for a scan rate of 5mV s−1 superior to 591 F g−1 at the same scan rate obtained for the PANI electrode material. The CV response of PANI-RuO2 thin-film electrodes at various scan rates shows that as the scan rate was increased, the current under the curve slowly increased, asserting the pseudocapacitive behavior of the composite. The redox peaks do not show at higher scan rates due to limited proton diffusion migration. The scan rates for both the electrode materials exhibited an inverse relationship with specific capacitance. The galvanostatic charging-discharging study conducted for both the electrodes revealed asymmetric curves due to the redox reaction or electrochemical adsorption/absorption occurring at the electrode and electrolyte interface, demonstrating typical pseudocapacitive behavior. The galvanostatic plot further asserts that due to the low internal resistance of the composite electrode, the potential drop for the PANI-RuO2 composite electrode is less than that of the PANI electrode material. The specific power, specific energy, and coulombic efficiency for the PANI-RuO2 composite electrode were obtained as 4.16 kW kg−1, 260 W h kg−1, and 95%, respectively. The difference in the specific capacitance and the capacitance retention between PANI and PANI-RuO2 composite electrodes has been shown in Figs. 11d, 11e.

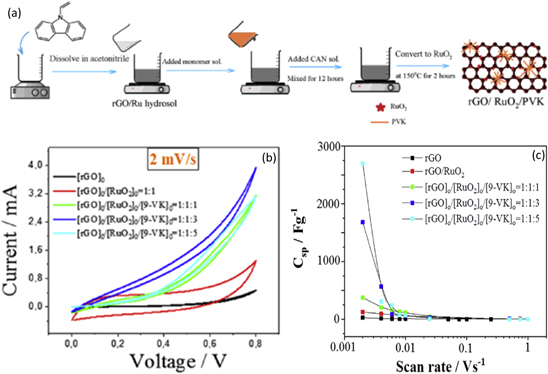

Ternary nanocomposite comprising reduced graphene oxide/RuO2/polyvinylcarbazole (rGO/RuO2/PVK) prepared by polymerization technique was used as supercapacitor electrode material by Ates et al. 130 Initially, 9-vinylcarbazole monomer and acetonitrile (ACN) solution were mixed, then added to rGO/Ru hydrosol. This solution was then added to a mixture of ammonium cerium nitrate (NH4)[Ce(NO3)6] and ACN solution. The resultant solution was mixed for 12 h to complete the polymerization process. The mixture was then filtered, and the residue of Ru/rGO was heated for 2 h at 150 °C. The heating process converts Ru to RuO2, and finally, ultrafine rGO/RuO2/PVK nanocomposite is obtained. The synthesis procedure of the nanocomposite has been illustrated in Fig. 12a. The authors have performed electrochemical measurements and analysis of different feed ratios of rGO/RuO2/PVK nanocomposite, out of which ([rGO]o/[RuO2]o/[9-VK]o = 1:1:5) showed the best results.

Figure 12. (a) The synthesis procedure of rGO/RuO2/PVK nanocomposite, (b) CV plots for different molar concentrations of PVK in the nanocomposite, and (c) variation of specific capacitance with scan rate for different molar concentrations of PVK in the nanocomposite.

Download figure:

Standard image High-resolution imageThe SEM image of [rGO]o/[RuO2]o/[9-VK]o = 1:1:5 showed the granular structure of PVK and RuO2 covering the rGO nanosheets indicating well-distributed rGO in the polymer matrix. This crystalline structure resulted in better charge carrying capacity and good conducting channels in the ternary nanocomposite. All the components of the ternary nanocomposite coexist well together due to good physical adsorption between them. The electrolyte used for the CV study is a 1 M H2SO4 solution which shows that the highest specific capacitance of 2698 F g−1 was obtained for [rGO]o/[RuO2]o/[9-VK]o = 1:1:5 at a scan rate of 2 mV mV s−1 as depicted in Fig. 12b. The variation in specific capacitance with the scan rate has been shown in Fig. 12c. The galvanostatic charge/discharge (GCD) study showed symmetric charging and discharging patterns across all the initial feed ratios for the nanocomposites. A high energy density of 11.31 Wh kg−1 and a high power density of 22625 W kg−1 were obtained at 50 mA for the nanocomposite electrode. A 100% Coulombic efficiency was obtained for all the nanocomposite films. The stability test for the nanocomposites to be used as supercapacitor electrodes, carried out using CV methods for 1000 cycles, confirmed 45.62% stability/charge retention capability for [rGO]o/[RuO2]o/[9-VK]o = 1:1:5.

RuO2/Carbon-based nanocomposite

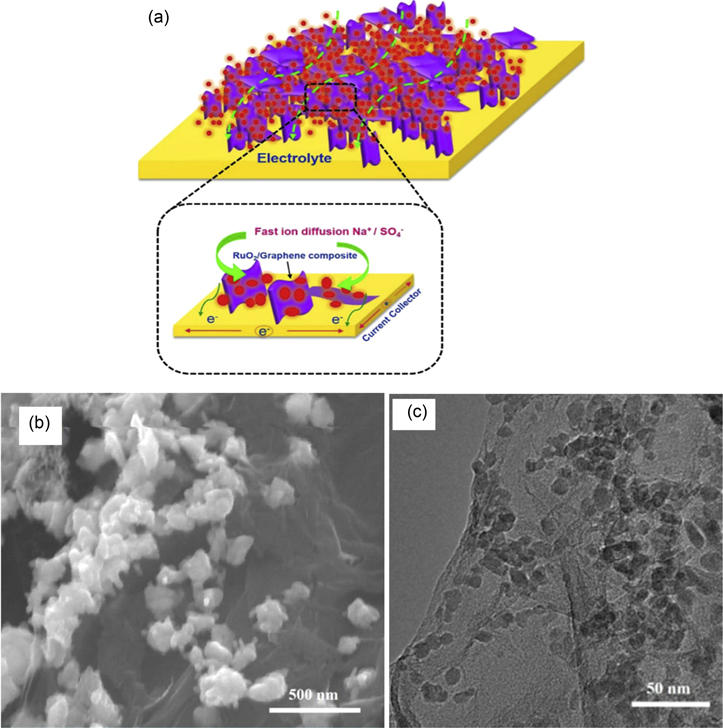

Carbon-based materials such as graphene, 131–133 carbon nanotube (CNT), 134–137 and carbon nano-onions (CNOs) 138 have been found to elevate the supercapacitor properties of ruthenium oxide. In recent years, RuO2/Carbon-based nanocomposites are becoming increasingly popular due to the low cost and abundance of carbon materials. RuO2/graphene (RuO2/G) nanocomposite was prepared by Thangappan et al. for supercapacitor applications using the hydrothermal method. 139 Graphene oxide (GO) suspension was added to the ruthenium chloride hydrate, citric acid, and DI water mixture. The mixture was ultrasonicated, transferred to a Teflon-lined stainless-steel autoclave, and was heated for 24 h at 180 °C. The black powder collected by centrifugation was dried in a vacuum for 24 h at 60 °C. The authors have compared the experimental results of RuO2/G with pure RuO2 synthesized using the same procedure. The structure of the nanocomposite is shown in Fig. 13a.

Figure 13. (a) schematic structure of RuO2/G nanocomposite, (b) SEM image, and (c) TEM image of RuO2/G nanocomposite.

Download figure:

Standard image High-resolution imageThe SEM image of RuO2/G nanocomposite shown in Fig. 13b manifested the RuO2 nanoparticles homogeneously distributed on the surface of the graphene sheets, which confirmed the formation of RuO2/G nanocomposite. The same phenomenon was also observed through the TEM image shown in Fig. 13c. The cyclic voltammetry (CV) conducted in 1 M of Na2SO4 electrolyte indicated high-rate capability due to the nanoporous structure of the nanocomposite with large void spaces. The specific capacitance measured from the Galvanostatic charging/discharging (GCD) curves indicated a high specific capacitance of 441.17 F g−1 due to the easy and abundant availability of highly conducting RuO2 nanoparticles on the surface of graphene nanosheets. The nanocomposite showed a high energy density of 61.2 Wh kg−1 and a higher power density of 1838.2 W kg−1. RuO2/graphene, when used as supercapacitor electrode material, was capable of ∼100% retention of its original capacitance at a high specific capacitance even after 1000 cycles.

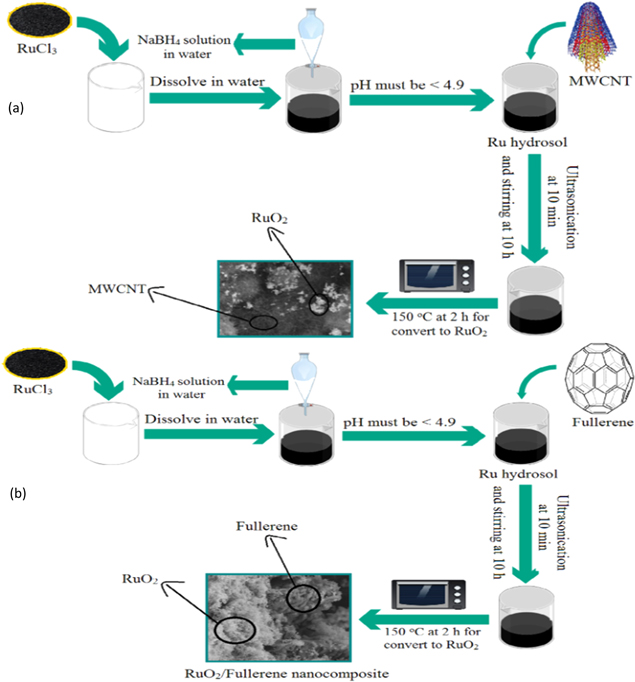

Fullerene and MWCNT are preferred in energy storage applications due to their rich electron carbon source and exceptional thermal, electrical, and mechanical properties. Two different RuO2 based hybrid supercapacitor electrode materials, RuO2/Multi-walled CNT (MWCNT) and RuO2/Fullerene, were synthesized by Ates et al. using the electrobath deposition technique. 140 To prepare RuO2/MWCNT, aqueous sodium borohydride (NaBH4) acting as an initiator was added to RuCl3 solution with a constant check on pH value to be less than 4.9. This was followed by the addition of MWCNT. RuO2 hydrosol/MWCNT was obtained through a centrifuge process. Finally, RuO2/MWCNT nanocomposites were obtained by heating RuO2 hydrosol/MWCNT at 150 °C for 2 h. To prepare RuO2/Fullerene, fullerene nano-material was added to the previously prepared Ru hydrosol solution. The mixture was then left in an ultrasonic bath and was stirred magnetically. To convert the obtained RuO2 hydrosol/Fullerene to RuO2/Fullerene, the mixture was heated at 150 °C for 2 h. The preparation of the two supercapacitor electrode materials have been shown in Figs. 14a, 14b

Figure 14. The synthesis procedure of (a) RuO2/MWCNT nanocomposite and (b) RuO2/Fullerene nanocomposite.

Download figure:

Standard image High-resolution imageRuO2/MWCNT and RuO2/Fullerene with varying initial feed ratios were prepared. Amongst them, [RuO2]o/[MWCNT]o = 3:1 and [RuO2]o/[Fullerene]o = 2:1 showed the best electrochemical behavior. The SEM images of the obtained RuO2/MWCNT and RuO2/Fullerene showed that RuO2 had a crystalline polymorphic structure, whereas fullerene had a porous spherical form. It also showed the existence of RuO2 on the surface of MWCNT and fullerene. Cyclic voltammetric (CV) measurements carried out demonstrated an exceptionally high specific capacitance of 3952.21 F g−1 and 1662.19 F g−1 for [RuO2]o/[Fullerene]o = 2:1 and [RuO2]o/[MWCNT]o = 3:1 respectively at 1 mV s−1. In comparison, the highest specific capacitance obtained by the authors for the pure RuO2 was 331.18 F g−1 at 1 mV s−1. Such high specific capacitance for RuO2 nanocomposites was obtained due to ions' adsorption on the inside and outside surfaces of electrode material for a lower scan rate. Comparatively lower specific capacitance was obtained for the nanocomposites at a higher scan rate due to the ions getting adsorbed only on the outside surface of the electrode.

A high energy density of 44.09 Wh kg−1 at 0.004 V s−1 and 74.41 Wh kg−1 at 0.002 V s−1 was obtained for [RuO2]o/[Fullerene]o = 3:1 and [RuO2]o/[MWCNT]o = 3:1 respectively. A high power density of 5964.18 W kg−1 at 1 V s−1 and 28695.27 W kg−1 at 0.5 V s−1 was obtained for [RuO2]o/[Fullerene]o = 3:1 and [RuO2]o/[MWCNT]o = 3:1 respectively. In comparison, the highest energy density and highest power density obtained for pure RuO2 was 2.07 Wh kg−1 at 0.001 V s−1 and 717.65 W kg−1 at 1 V s−1, respectively. The coulombic efficiency has been calculated to be ∼100% for both the nanocomposites.

The stability tests performed on the nanocomposites indicated 79.34% of initial capacitance being preserved for [RuO2]o/[MWCNT]o = 1:1 and 2:1. However, it dropped to 79.34% for [RuO2]o/[MWCNT]o = 3:1. On the other hand, ∼85%, ∼100%, and ∼59.54% of initial capacitance was retained for [RuO2]o/[Fullerene]o = 1:1, 2:1, and 3:1 respectively.

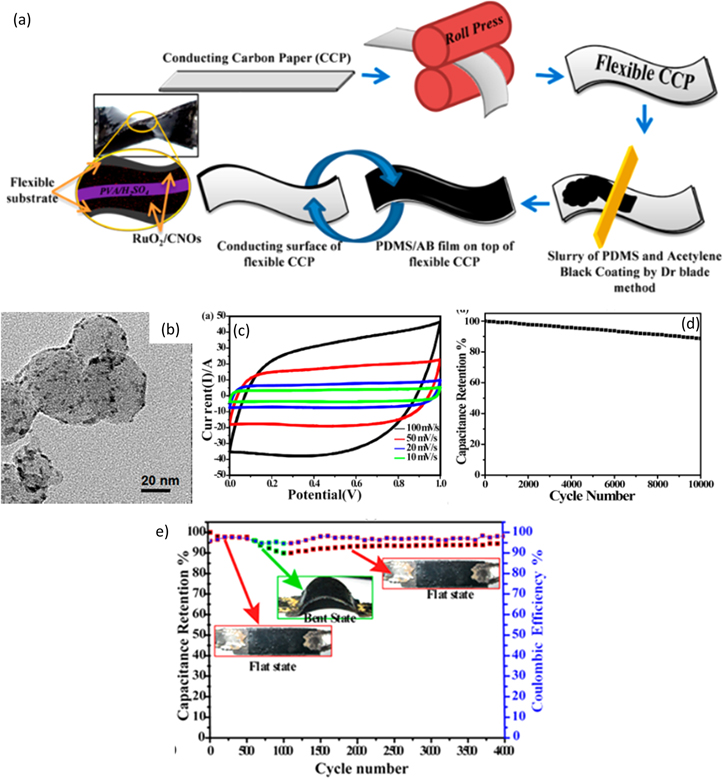

Since carbon nano-onions demonstrate lower resistance and better electrochemical performance than other carbon nanostructures, RuO2/carbon nano-onion (CNO) nanocomposite was synthesized by Muniraj et al. using a sol-gel method. 138 RuCl3.3H2O was added to a solution containing CNOs dispersed in DI water. NaOH was used to control the pH level of the mixture and was maintained neutral. RuO2 nanoparticles are formed on the CNO surface due to the reaction between NaOH and RuCl3.3H2O. The solution was stirred continuously for 6 h, dried at room temperature, and underwent calcination at 150 °C for 6 h. Conducting carbon paper was used as the substrate, which was hot-pressed by a rolling machine to make it less brittle and flexible. To hold its flexibility, one side of the carbon paper was coated with a paste of polydimethylsiloxane (PDMS), curing agent, and acetylene black in 10:1:2 proportion. The single-sided coated carbon paper was then dried at 95 °C for 10 min. The synthesis procedure is depicted in Fig. 15a. HRTEM image shown in Fig. 15b of the RuO2/CNO nanocomposite showed that the functional groups of oxygen present in CNOs promote the formation of RuO2 on the surface of CNOs in a highly dispersed manner. The RuO2/CNO nanocomposite was analyzed further using a CV study in a 0.5 M H2SO4 solution and PVA/H2SO4 gel. The corresponding cyclic voltammetry plot shown in Fig. 15c suggestsed that the area under the curve is directly proportional to the scan rate indicating good pseudocapacitive behavior, which is essential to be used as a supercapacitor electrode material. The highest specific capacitance of 1110 F g−1 was obtained for the RuO2/CNO hybrid electrode in 0.5 M H2SO4 solution as the electrolyte, tested at 1 A g−1 current density.

Figure 15. (a) Schematic illustration of the preparation of RuO2/CNO electrode separated by H2SO4 gel electrolyte, (b) HRTEM image of RuO2/CNO nanocomposite, (c) CV curve, (d) capacitance retention, and (e) capacitance retention after bending stress.

Download figure:

Standard image High-resolution imageFigure 15d shows an excellent life cycle of 88.7% of initial capacitance even after 10,000 cycles for the RuO2/CNO tested in 0.5 M H2SO4, confirmed by the cyclability test conducted at 15 A g−1 current density. The coulombic efficiency achieved was 100%. The RuO2/CNO tested in PVA/H2SO4 gel exhibited 88.9% retention of original capacitance tested with bending of the flexible electrode, as shown in Fig. 15e. The coulombic efficiency achieved was 96%. The energy and the power density obtained for the nanocomposite in PVA/H2SO4 gel were 10.59 Wh kg−1 and 4.475 kW kg−1, respectively. In the case of 0.5 M H2SO4 solution as the electrolyte, the energy density and the power density obtained were 19.75 Wh kg−1 and 4.782 kW kg−1, respectively.

2D Manganese Oxide (MnO2)

Since MnO2 is a cheap and familiar material, it serves as a suitable replacement for RuO2. However, similar to pure RuO2, pure MnO2 as the supercapacitor electrode material is not used due to the following problems. Firstly, MnO2 suffers from capacitance degradation during charging cycles due to the dissolution of MnO2 in the electrolyte over time. Secondly, MnO-based materials suffer from poor electrical conductivity and low surface area. 126,141 The aforementioned problems can be solved by synthesizing MnO2 based carbon, oxides, and polymer nanocomposites.

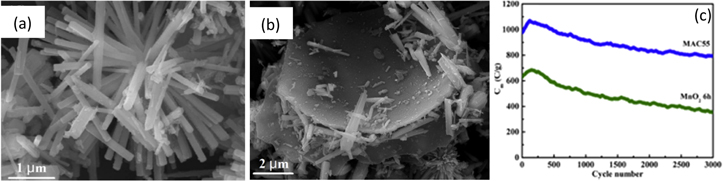

As compared to the other well-known crystalline forms of MnO2, α-MnO2 revealed better transmission of cations and superior electrochemical behavior. α-MnO2, in conjunction with activated carbon, facilitates higher electric conductivity that promotes the use of the composite as a supercapacitor electrode material. α-MnO2/activated carbon (MAC) composite was synthesized by Shen et al. by hydrothermal method. 142 The AC was prepared by mixing solid KOH and carbonized rice husk and heating the mixture at 800 °C for 2 h. The MAC nanocomposite was prepared by mixing MnSO4.H2O, KClO3, and DI water. HNO3 solution was added into ultrasonically treated MAC solutions which were eventually transferred to a Teflon-lined autoclave and heated and dried to obtain the final nanocomposite. Out of the different compositions of MnO2/AC nanocomposite, the nanocomposite obtained with equal proportions of MnO2 and AC (MAC55) exhibits the highest electrochemical activity. For comparison, the authors have also prepared single α-MnO2 without AC.

Irregular rod structures of varying sizes of MnO2 were formed during the initial 1 h of heating due to incomplete hydrothermal reaction. However, more uniformly shaped aggregated three-dimensional actiniaria structures were observed for 3 h and above heating times. With heating, the diameter of the rod structure varied from ∼100 nm (6 h), ∼200 nm (9 h), and ∼400 nm (12 h). The FE-SEM images of MAC55 nanocomposite showed that the porous morphology of AC gets eventually converted into MnO2 actiniaria structure dominance as the proportion of MnO2 content in the nanocomposite increases. This is shown in Figs. 16a, 16b.

Figure 16. FE-SEM image of (a) α-MnO2, (b) MAC55, and (c) comparison of capacitance retention of α-MnO2 and MAC55 supercapacitor electrodes.

Download figure:

Standard image High-resolution imageThe supercapacitance behavior of α-MnO2 was confirmed from the GCD study. The specific capacitance values of 629.2 C g−1 for α-MnO2 were synthesized at 6 h, and a large specific capacitance of 1062.7 C g−1 for MAC55 was obtained. It was noted that the presence of AC improved the surface area and the conductivity of the nanocomposite. The CV study indicated that as MnO2 is added to AC, redox peaks were observed in the rectangular CV curves of AC which confirms the supercapacitive behavior of the nanocomposite. Figure 16c observed that after 3000 cycles, capacity retention of 56.2% for α-MnO2 and 81.3% for MAC electrode tested in 0.5 M K2SO4 electrolyte was confirmed.

Singhal et al. have found that the introduction of GO to MnO2 nanorods resulted in an improved electrochemical performance. 143 To carry out a comparative analysis, the performance of the MnO2-GO electrode was compared to the MnO2 electrode prepared by the centrifuge process. The precipitate was obtained by centrifuge process by adding KMnO4 to an ultrasonicated mixture of GO, ethanol, and DI water was dried for 24 h at 80 °C in an oven to obtain MnO2-GO nanocomposite. The TEM study showed the nanorod morphology of MnO2 with an average diameter of 15 nm. This nanorod morphology significantly changed to nono-powder-like morphology upon GO inclusion in the nanocomposite. CV analysis of the MnO2-GO electrode was conducted at scan rates from 1 to 300 mV s−1. The nanocomposite electrode exhibited good charge storage behavior, which was evident from the increase in the CV curve area as the scan rate increased. The highest specific capacitance exhibited by the MnO2 electrode was 650 F g−1, and the MnO2-GO electrode was 850 F g−1 at a scan rate of 10 mV s−1. The charge storage capacities of the MnO2 electrode improved by the addition of GO in the nanocomposite. A high energy density of 4.58 Wh kg−1 and a high power density of 5.0 kW kg−1 were calculated for the nanocomposite electrode.

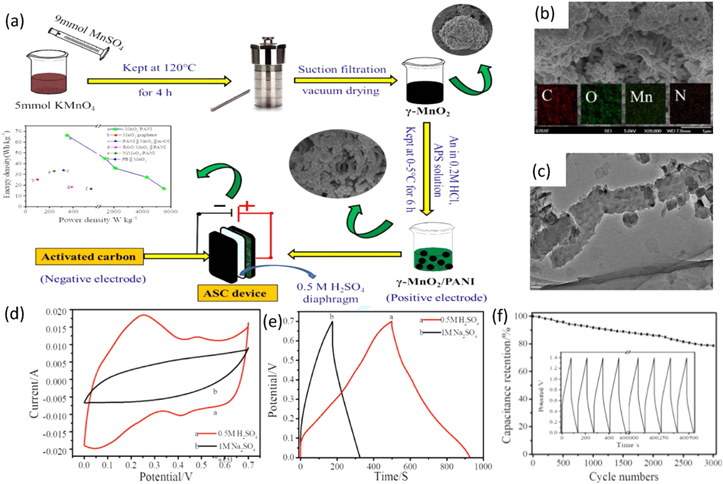

Since γ-MnO2 has superior supercapacitor behavior than its other forms due to high electrochemical performance and higher catalytic oxidation activity, γ-MnO2/PANI composite was synthesized by Zhu et al. by in situ polymerization for supercapacitor applications. 144 An aqueous solution of γ-MnO2, H2SO4, and aniline was prepared to which ammonium peroxodisulfate (APS) dissolved in distilled water was added gradually. To complete the polymerization process, the resultant mixture was refrigerated overnight at ∼0 °C–5 °C to complete the polymerization process. The synthesis procedure adopted is shown in Fig. 17a.

Figure 17. (a) Illustration of synthesis of γ-MnO2/PANI electrode and assembly of asymmetric supercapacitor device, (b) SEM image (c) TEM image, (d) CV curve, (e) GCD curves in different electrolytes, and (f) cyclic stability over 3000 cycles of γ-MnO2/PANI electrode.

Download figure:

Standard image High-resolution imageThe SEM and TEM images of the nanocomposite shown in Figs. 17b, 17c indicates evenly distributed clusters of γ-MnO2 around the rod-like morphology of PANI, indicating the successful compound formation of γ-MnO2/PANI composite. This resulted in an increased surface area and improved electrochemical performance of the nanocomposite. The electrochemical performance of the γ-MnO2/PANI electrode in both 0.5 M H2SO4 and 1.0 M Na2SO4 electrolytes was tested. The results are shown in Fig. 17d, indicating rectangular CV curves with redox peaks integrating more area when testing in 0.5 M H2SO4 electrolyte. This demonstrated better electrochemical performance in acid electrolytes. Improved pseudocapacitance and better stability of γ-MnO2 in the acid electrolyte confirmed from the GCD analysis shown in Fig. 17e led to a higher specific capacitance of 580.2 F g−1 was almost double than what was observed when tested in the neutral electrolyte (216 F g−1). Due to the molar conductivity of H+-SO4 2− being lower than Na+-SO4 2−, the charge transfer resistance of γ-MnO2/PANI nanocomposite in 0.5 M H2SO4 was 1/5 of what was obtained in 1.0 M Na2SO4. The nanocomposite showed an excellent rate capability of 70.5% at a current density of 5 A g−1, as shown in Fig. 17f.

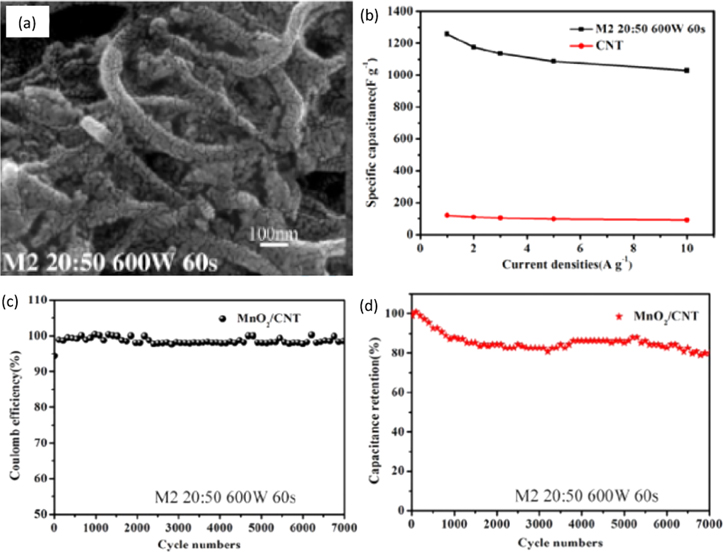

To improve the electrical conductivity of MnO2 and enhance its electrochemical activity in the electrolyte, Tan et al. prepared the MnO2/CNT nanocomposites using the solid-state microwave method. 145 In this method, CNT mixed with manganese nitrate tetrahydrate [Mn(NO3)2.4H2O] in the proportion of 20:50 was grounded using mortar. The hybrid was placed in a crucible and subjected to 600 W of microwave power for 60 s. The SEM micrograph of the resultant product shown in Fig. 18a revealed uniform dispersion of MnO2 on the CNT surface. This morphology helped in electrolyte ion transport. Figure 18b shows that the highest specific capacitance obtained was 1250 F g−1 for the nanocomposite. It was observed that the right amount of microwave power was necessary to complete the nanocomposite formation reaction. If the power was too low, the CNTs could not absorb enough energy and complete the reaction. If the power was too high, partial products formed flock and were distributed unevenly, resulting in reduced specific capacitance. A good capacitance behavior and electrochemical reversibility were confirmed from the higher integral area of the CV curve exhibited by the MnO2/CNT nanocomposite. The coulombic efficiency was maintained at ∼100 % for the nanocomposite all through 700 cycles at 5 A g−1 current density, as shown in Fig. 18c. After 7000 cycles of continuous charging and discharging, high capacitance retention of ∼80 % was observed for the nanocomposite, as seen in Fig. 18d.

Figure 18. (a) SEM image of MnO2/CNT nanocomposite, (b) comparison of specific capacitance of CNT and MnO2/CNT nanocomposites, (c) charge and discharge cycle of the nanocomposite, (d) variation of capacitance retention of the nanocomposite electrode over 7000 cycles.

Download figure:

Standard image High-resolution image2D Nickel Oxide (NiO)

Due to the low cost, environmental friendliness, high theoretical specific capacitance (3750 F g−1), and high chemical and thermal stability, NiO often finds its use as an electrode material for supercapacitor electrode applications. 122 However, poor ionic conductivity and low electrically active sites restrict its use as a supercapacitor electrode material. 146,147 To mitigate these problems, different morphology of NiO nanostructures such as nanobelts, nanowires, nanorods, and nanoflowers have been synthesized. The electrochemical performance of NiO nanobelts decorated with gold (Au) nanoparticles were synthesized by Tan et al. 148 Ni(OH)2 powder, DI water, and HAuCl4 were mixed and treated ultrasonically for 30 min. After evaporation of H2O molecules by heating at 100 °C, the residual powder was calcinated at 500 °C for 2h in a muffle furnace.

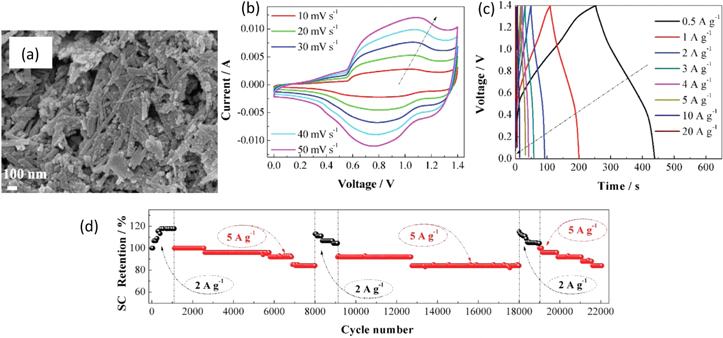

Characterization by SEM confirmed the nanobelt structure of NiO–Au nanoparticles (NiO–AuNP), as seen in Fig. 19a. Redox peaks in the CV curves shown in Fig. 19b confirmed the capacitive behavior of the nanostructure. The high specific capacitance of 597 F g−1 at a current density of 0.5 A g−1 was calculated through the GCD curves exhibited in Fig. 19c. An assembly of NiO–Au as the positive electrode, AC as the negative electrode, and 2 M KOH as the electrolyte was used to study the supercapacitor behavior. As seen from Fig. 19d, NiO–Au nanoparticles demonstrated a maximum energy density of 18 Wh kg−1 and capacitance retention of 100% and 84% at 2 A g−1 and 5 A g−1 scan rates, respectively, after 22,000 cycles of charging and discharging.

Figure 19. (a) SEM image of NiO–Au nanoparticles, (b) CV curves, (c) GCD curves, and (d) cycle life of NiO–Au∣∣AC supercapacitor.

Download figure:

Standard image High-resolution imageTaking advantage of the increased ion diffusion path provided by the NiO nanowires and fast electron transportation rendered by Ag, Ag-doped NiO nanowires on Ni foam were prepared by Hussain et al. using the hydrothermal method. 149 Ni(NO3)2.6H2O, AgNO3, CO(NH22222)2, ethanol, and DI water were mixed and stirred for 30 min. Ni foam immersed in the mixture was heated in the autoclave at 110 °C for 15 h and then brought down to room temperature. The rinsed and dried sample was again annealed at 350 °C for 2 h to obtain Ag-doped NiO nanowires on Ni foam. High magnification SEM and TEM images revealed porous nanowire formation that provided a short ion diffusion path speeding up the charge transfer process. The average diameter of the nanowires was ∼20 nm. Pseudocapacitive property and fast electron conduction can be attributed to the composite electrode tested through the CV curves evaluated in a 2 M KOH electrolyte. A high specific capacitance of 570.7 F g−1 at a discharge current density of 1 A g−1 was obtained. Direct contact of the NiO nanowires with the Ni foam and Ag doping facilitated achieving a high specific capacitance of 570.7 F g−1 at a current density of 1 A g−1, and good capacitance retention of ∼92.5 % tested for 3000 cycles. These results indicate Ag-doped NiO nanowires on Ni foam, a promising supercapacitor electrode material.

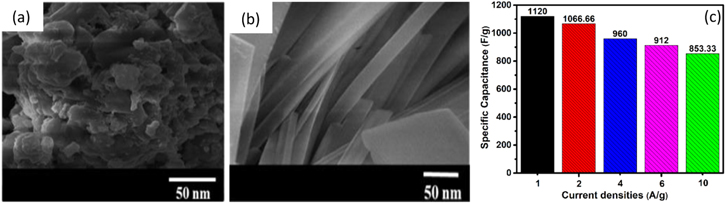

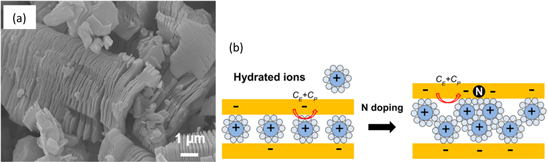

The use of Cr-doped NiO nanorods prepared using the hydrothermal method for use as supercapacitor electrode material was investigated by Ahmed et al. 150 A mixture of chromium chloride (CrCl2) and nickel chloride (NiCl2) in DI water was mixed gradually. The pH level was maintained at 8.0 using NaOH solution. After adding PVP and urea, the mixture was heated at 180 °C for 18h, dried at 80 °C for 4h, and eventually, Cr-doped NiO nanorods were obtained after calcination at 550 °C for 3h. SEM technique employed to study the nanostructure morphology confirmed that the initial spherical superfine morphology gets slowly converted to nanorod structure upon Cr doping which is evident in Figs. 20a, 20b. The nanorods possessed an average diameter of 20 nm and hundreds of nm in length. The CV studies were conducted in 3 M KOH electrolyte in a potential window of −0.2V to 0.55V at a scan rate of 5 mV s−1. Due to the reversible redox reactions of Ni and Cr occurring on their surface, redox peaks signifying good pseudocapacitive behavior were observed. It was also seen that Cr doping plays an essential role in the electrochemical behavior of the nanostructure. The high specific capacitance of 1132.64 F g−1 was obtained for Cr doping of 6 % owing to decreased crystallite size, increase in the active sites for charge storage due to oxygen vacancies developed during the calcination process, and change from nanoparticles to nanorods morphology. The variation of specific capacitance with the current density for Cr–NiO nanorods is shown in Fig. 20c. Highly symmetric GCD curves for the nanorods displayed superior reversible redox reaction between the potential range of −0.2 to 0.55 V. The GCD test over 2000 cycles conducted at 1 A g−1 showed that the Cr-doped NiO nanorods could retain 90.44 % of its initial capacitance, signifying an excellent candidate for supercapacitor electrode material.

Figure 20. SEM image of (a) pure NiO sample, (b) Cr-NiO sample, and (c) variation of specific capacitance with current densities of Cr-NiO sample.

Download figure:

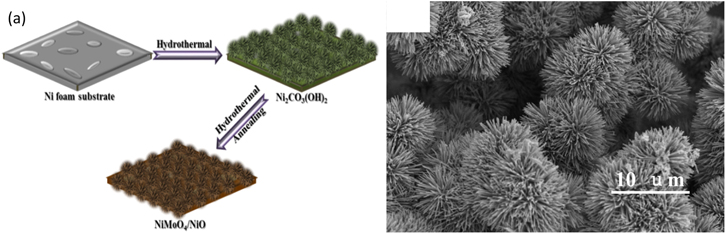

Standard image High-resolution imageTo overcome the shortcoming of the low energy density of supercapacitor materials, Xu et al. developed NiMoO4/NiO nanoflowers to be used as asymmetric pseudocapacitive electrode material for supercapacitor applications using the hydrothermal method. 151 NiCl2.6H2O, urea, and DI water were mixed and hydrothermally processed with as-prepared Ni foam at 130 °C for 20 h. (NH4)2MoO4 solution with the as-prepared precursor solution were placed in the autoclave at 160 °C for 10 h. The nanoflowers synthesized on the surface of Ni foam were then ultrasonically rinsed, dried, and annealed at 300 °C for 2 h. The schematic illustration of the synthesis procedure is shown in Fig. 21a. Figure 21b shows the FESEM image of the NiMoO4/NiO nanoflowers indicating agglomerated rod clusters that led to the formation of nanoflower morphology with an average diameter of ∼100 nm. This type of morphology assisted in electron transfer and ion diffusion at the interface due to the nanoflowers' large surface area and high pore volume. The CV curves enclosed a large area signifying high specific capacitance due to the nanoflower morphology and reversible Faradaic redox reactions of Ni(II)/Ni(III). An excellent specific capacitance of 1982.3 F g−1 at a current density of 11 mA cm−2 was obtained from the GCD curves for the nanoflowers. The highly conductive Ni-foam used as the substrate along with a large number of active sites and fast electron transport in the nanoflower morphology led to such high specific capacitance. The cyclic stability tests confirmed outstanding electrochemical stability, evident from 98.6% retention of the initial capacitance after 3000 cycles. When used as the supercapacitive electrode material, the nanoflowers exhibited an energy density of 38 Wh kg−1 and a power density of 96.2 W kg−1.

Figure 21. (a) Scheme for synthesizing NiMoO4/NiO nanoflowers on Ni foam and (b) FESEM image of NiMoO4/NiO nanoflowers.

Download figure:

Standard image High-resolution image2D Nickel Hydroxide [Ni(OH)2]

Thanks to the high redox behavior and superior theoretical specific capacity, Ni(OH)2 finds its implementation in energy storage applications. 152 When Ni(OH)2 is used as the positive electrode material for supercapacitor applications, the reversible Faradaic reaction takes place according to, 122

However, p-type semiconductor electrode material of Ni(OH)2 suffers from poor electrical conductivity, short cycle life under high current density charging and discharging, and poor rate performance. 153 Hence, nanostructured Ni(OH)2 are gaining popularity as the pseudocapacitive electrode material for supercapacitor applications.

The nanostructured α-Ni(OH)2 phase was grown using the electrodeposition method on Ti plate by Aguilera et al. 154 The galvanostatic deposition process was carried out for 30 min at a current of −2.0 mA in a three-electrode glass cell arrangement comprising of Ag/AgCl as the reference electrode, Ti substrate as the working electrode, and platinum plate as the counter electrode present in 0.1 mol l−1 Ni(SO4)2.6H2O electrolyte. The SEM image shown in Fig. 22a revealed agglomerated nanorods with space between the adjacent clusters that gave cabbage-like morphology. A closer look at one of these clusters indicated smaller nanoparticles forming nanorods which increased the access of active sites to the electrolyte ions improving the capacitive performance. The CV curves for α-Ni(OH)2 showed symmetric anodic and cathodic peaks resulting from reversible transfer between Ni2+ and Ni3+ ions. As the scan rate increased, the CV curves maintained their shape. They integrated more area, suggesting faster redox reactions at the surface of the α-Ni(OH)2 electrode material. The discharge curves indicated two sloping potential regions resulting from the pseudocapacitive behavior of the α-Ni(OH)2 nanosize cabbage structure. Since most of the active material is available for the ions in the electrolyte for the diffusion and migration process at a low current density, a high specific capacitance of 1907 F g−1 for α-Ni(OH)2 at a current density of 3 mA cm−2 was obtained from the GCD curves. The variation of specific capacitance with the current density is shown in Fig. 22b. The cyclic stability of the nanostructure was tested after 1000 cycles and 3000 cycles. A 99.3 % and 90.15 % capacitance retention after 1000 cycles and 3000 cycles, respectively, was observed from Fig. 22c, indicating long-term cycle stability of α-Ni(OH)2 electrode. A high energy and power density of 42.31 Wh kg−1 and 430 W kg−1 were calculated.

Figure 22. (a) SEM image, (b) specific capacitance as a function of current density, and (c) specific capacitance as a function of cycle number of α-Ni(OH)2 films.

Download figure:

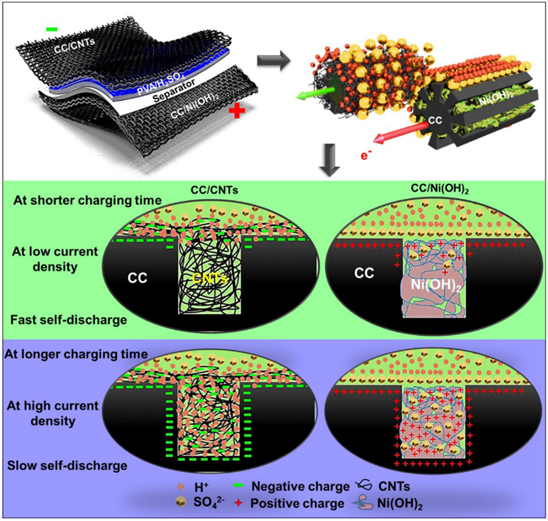

Standard image High-resolution imageBenefitting from the high compatibility of Ni(OH)2 and carbon cloth (CC), carbon cloth/Ni(OH)2 (CC/Ni(OH)2) was synthesized by the electrochemical deposition technique by Ovhal et al. 155 Ag/AgCl was used as the reference electrode, Pt wires were used as the counter electrode, and 3 M NiCL.6H2O.Ni(OH)2 was used as the electrolyte. The low magnification FESEM images showed that the diameter of CC fibers was 15–17 μm. Grooves with sizes of 200–400 nm and crests with dimensions of 1.5–2.0 μm started to show on higher magnification on the surface of each carbon fiber. These grooves and ridges promoted the growth of Ni(OH)2 by providing greater surface area. Porous Ni(OH)2 nanoparticles with 10–12 nm particle size covered most of the grooves of the carbon fibers upon the synthesis of CC/Ni(OH)2. The schematic diagram illustrating the ion adsorption and self-discharge mechanism of CC/CNT and CC/Ni(OH)2 electrodes has been shown in Fig. 23. Ni(OH)2 on the grooves and crests of carbon fibers facilitated efficient charge transport and high charge storage, which led to obtaining a high specific capacitance of 3987 F g−1 at a current density of 0.5 mA cm−2. Due to the reversible Faradaic reactions at the electrode and electrolyte interface, non-linear GCD curves are obtained for the CC/Ni(OH)2 electrode. The CV curves showed symmetric anodic and cathodic peaks indicating the reversible nature of Ni(OH)2 electrochemical deposition.

Figure 23. Schematic diagram illustrating the ion adsorption and self-discharge mechanism of CC/CNT and CC/Ni(OH)2 electrodes.

Download figure:

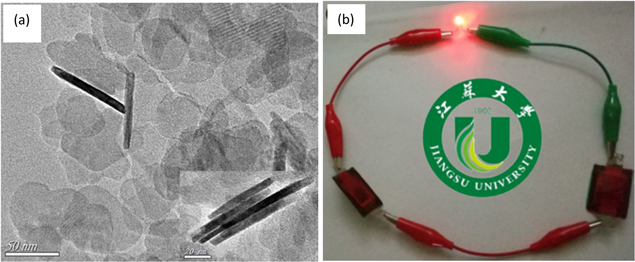

Standard image High-resolution imageTo further increase the energy storage capacity of Ni(OH)2, the hydrothermal method was employed by Ji et al. to synthesize nitrogen-doped carbon dots (NCDs) on Ni(OH)2 nanosheets. 156 Ni(Ac)2.4H2O, NCDs, and DI water were mixed, and a 3 M NaOH solution was used to maintain the pH level of the mixture at 11. After heating at 180 °C for 24h, the solid residue obtained through centrifugation was dried in a vacuum oven at 60 °C for 24h. The Ni(OH)2/NCDs obtained through 20 mg of NCDs show the highest electrochemical performance among all the initial feed ratios. Figure 24a shows the FESEM image, which reveals the platelet-like morphology of Ni(OH)2/NCDs. The width of these nanosheets is ∼35.1 nm which was confirmed from the TEM analysis. However, the width and thickness of Ni(OH)2 nanosheets were restricted as NCDs were added. The width and thickness of the composites were at 87.0 nm and 9.8 nm, respectively. The CV study indicated a direct relationship between the loop area and the specific capacitance of the electrode material.

Figure 24. (a) TEM image of Ni(OH)2/NCD nanosheets and (b) LED-lighted by the assembled device.

Download figure:

Standard image High-resolution imageIn comparison, it was found that there is a significant increase in the specific capacitance when NCDs are added to Ni(OH)2. The exact specific capacitance for the Ni(OH)2/NCDs nanosheets was calculated from GCD curves and was found to be ∼1711.2 F g−1 for a current density of 1 A g−1. A supercapacitor device based on Ni(OH)2/NCDs nanosheets as the positive electrode and graphene as the negative electrode exhibited high energy and power density of 34.6 Wh kg−1 and 700 W kg−1, respectively. Two of these supercapacitor devices can be combined to deliver a voltage of 2.2 V to efficiently power a LED, as seen in Fig. 24b.

2D Cobalt Hydroxide [Co(OH)2]

Among other hydroxide-based supercapacitor electrodes, Co(OH)2 has attracted much attention due to its layered structure offering a large surface area, large interlayer spacing, high conductivity, and long-term stability. 122,126 β-Co(OH)2/CNT composite was prepared by Aghazadeh et al. using the electrodeposition method. 157 The stainless-steel grid was used as the cathode, and graphite plates were used as the anode. A mixture of CNTs, DI water, and an aqueous cobalt chloride solution was used as the electrodeposition bath. The electrodeposition was carried out for 30 min at 25 °C. The CNTs were electrophoretically moved towards the cathode surface as soon as the electrodeposition process started. At the same time, cobalt cations were also transferred onto the cathode surface. After the deposition of CNTs, the electrochemical growth of Co(OH)2 started immediately. The final Co(OH)2 composite morphology comprised the platelet-like Co(OH)2 around CNTs. The CV and GD tests were performed with Ag/AgCl as the reference electrode, Pt wire as the counter electrode, and the deposited nanocomposite on the steel grid as the working electrode in the presence of 1 M KOH electrolyte solution. The CV curves showed a pair of redox peaks both in the anodic and cathodic directions, which increased as the scan rate increased. The CV curves calculated the maximum specific capacitance of 1354 F g−1 at a scan rate of 2 mV s−1. The GCD profiles exhibited an excellent charge storage capability and pseudocapacitive behavior of the β-Co(OH)2/CNT composite. High capacitance retention of 89.4 % and 80.5 % after 5000 cycles of charging/discharging measured at a current rate of 0.5 A g−1 and 2 A g−1 respectively was demonstrated by the β-Co(OH)2/CNT composite.

Co(OH)2-rGO nanocomposite was prepared by Rahimi et al. using the environmentally friendly preparation route of the electrodeposition method. 158 A mixture of GO powder, an aqueous solution of CoCl2, and DI water was used as the electrolyte for the electrodeposition. The electrode system comprised a stainless steel plate used as the cathode, sandwiched between two graphite plates acting as the anode. The synthesis procedure adopted for the electrodeposition process of Co(OH)2-rGO nanocomposite is shown in Fig. 25. Among the different composites prepared, Go: CoCl2.6H2O with a w/w ratio of 1:4 gave the best electrochemical results. From the SEM study, the porous intertwined structure with nanosheet morphology of Co(OH)2-rGO nanocomposite was confirmed to have more potential to preserve charge. The porous intertwined structure and the synergistic interaction between Co(OH)2 and rGO gave rise to a specific capacitance of 734 F g−1 at a current density of 1 A g−1 and capacitance retention of 95% after 1000 cycles. The nanocomposite's average energy and power densities were 60.6 Wh kg−1 and 3208 W kg−1, respectively.

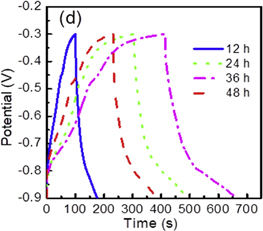

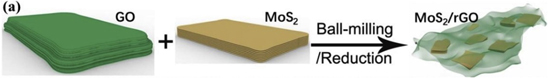

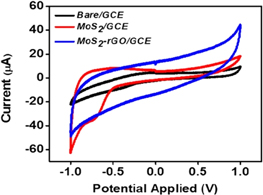

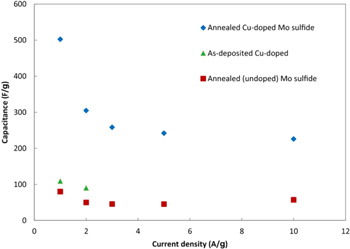

Figure 25. Electrodeposition process of Co(OH)2-rGO nanocomposite in a two-electrode system.