Abstract

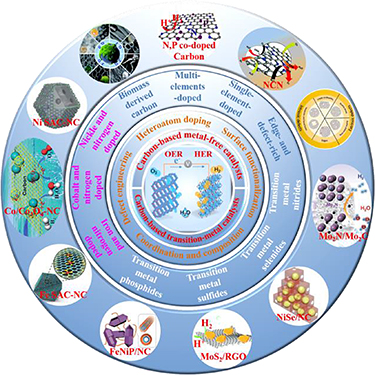

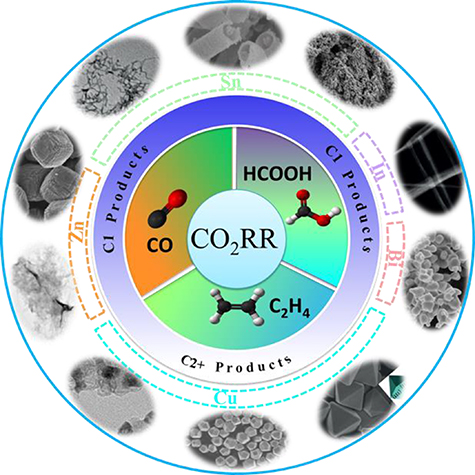

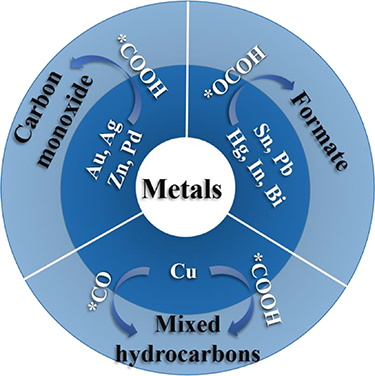

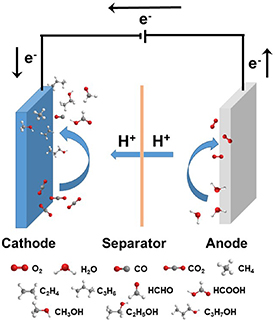

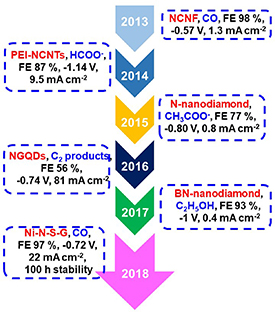

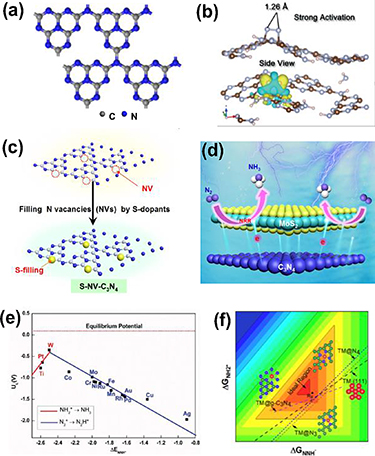

Serious challenges in energy and the environment require us to find solutions that use sustainable processes. There are many sustainable electrocatalytic processes that might provide the answers to the above-mentioned challenges, such as the oxygen reduction reaction (ORR), water splitting, the carbon dioxide reduction reaction (CO2RR), and the nitrogen reduction reaction (NRR). These reactions can enhance the value added by producing hydrogen energy through water splitting or convert useless CO2 and N2 into fuels and NH3. These electrocatalytic reactions can be driven by high-performance catalysts. Therefore, the exploration of novel electrocatalysts is one of the important electrocatalytic fields. In this paper, we aim to systematically discuss a variety of electrocatalysts used for sustainable processes and to give further insights into their status and associated challenges. We invited many famous research groups to write this roadmap with topics including platinum (Pt) and its alloys for ORR, oxides for ORR, chalcogenides for ORR, carbon-based hollow electrocatalysts for ORR, carbides for ORR, atomically dispersed Fe–N–C catalysts for ORR, metal-free catalysts for ORR, single-atom catalysts (SACs) for ORR, metal boride (MB) electrocatalysts for water splitting, transitional metal carbides (TMCs) for water splitting, transition metal (TM) phosphides for water splitting, oxides for water splitting, sulfides for water splitting, layered double hydroxides for water splitting, carbon-based electrocatalysts for water splitting, Ru-based electrocatalysts for water splitting, metal oxides for CO2RR, metal sulfides for CO2RR, metals for CO2RR, carbon for CO2RR, SACs for CO2RR, heterogeneous molecular catalysts for CO2RR, oxides for NRR, chalcogenides for NRR, C3N4 for NRR, SACs for NRR, etc. Their contributions enabled us to compile this 2020 roadmap on electrocatalysts for green catalytic processes and provide some suggestions for future researchers.

Export citation and abstract BibTeX RIS

Original content from this work may be used under the terms of the Creative Commons Attribution 4.0 license. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

Introduction

Jiandong Liu1, Jianmin Ma1 and Zhicheng Zhang2

1 School of Physics and Electronics, Hunan University

2 Tianjin Key Laboratory of Molecular Optoelectronic Sciences, Department of Chemistry, School of Science, Tianjin University and Collaborative Innovation Center of Chemical Science and Engineering (Tianjin)

A potential energy crisis and increasing environmental problems drive us to explore sustainable energy that can replace fossil energy. Many interesting reactions inspire the study of sustainable processes, such as those of the hydrogen evolution reaction (HER), CO2RR, and the nitrogen reduction reaction (NRR) [1–4]. These sustainable reactions can provide H2 energy, gas, or liquid fuels and ammonia (NH3), and can be driven by solar energy, electricity or their combination (i.e. photoelectrocatalytic processes). Among these, electrocatalytic processes can be continuously carried out without insolation. Therefore, they are preferred from the perspective of the stability of reaction processes. Also, the oxygen evolution reaction (OER) is coupled with the HER to form so-called water splitting and is thus considered to be an important reaction [5]. The oxygen reduction reaction (ORR) is another reaction involving O2 [6], which is an important reaction for fuel cells and metal-air batteries.

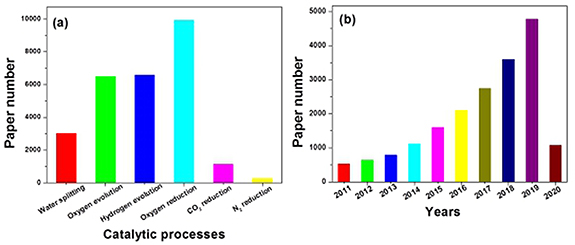

Electrocatalysts play crucial roles in determining the performance of the sustainable processes mentioned above. Various strategies have been employed to improve the catalytic performance of electrocatalysts such as doping, defect design, hybridization, single-atom active centers, and their combinations [7–12]. Figure 1(a) presents the materials published up until 26 March 2020 that are relevant to different electrocatalytic processes. The numbers of papers reported are: 3016, 6495, 6573, 1132, 9927, 4147 for water splitting, OER, HER, CO2RR, ORR, and NRR, respectively. It can be seen that ORR is an extremely active field of study. We also studied the trend of electrocatalysts over the last decade. Figure 1(b) illustrates the number of papers relevant to electrocatalysts that were published each year from 2011 to 2020. The active trend is very clear: the number of papers published has risen from 524 in 2011 to 4777 in 2019, which is a nine-fold increase. From the start of 2020 to 26 March 2020, 1070 papers were published, which is near the total number for 2014 (1119). This also indicates that the field of electrocatalysis is active and strongly pursued by scientists.

Figure 1. (a) The number of papers published relevant to different electrocatalytic processes up tountil 26 March 2020. Here, the papers were searched for on the Web of Science using the topic 'electrocatalyst' and the search results were refined by a further keyword termn (i.e. water splitting, oxygen evolution, hydrogen evolution, oxygen reduction, CO2 reduction, N2 reduction) for all document types on 26 March 2020. (b) The number of papers relevant to electrocatalysts undefinedpublished each yearundefined from 2011 to 2020; here, the papers were searched for on the Web of Science using the topic 'electrocatalyst' for all document types on 26 March 2020.

Download figure:

Standard image High-resolution imageAlso, we studied the different kinds of material used as electrocatalysts. Figure 2 shows the numbers of papers published up until 26 March 2020 that are relevant to different kinds of electrocatalyst. In those papers, some important kinds of electrocatalyst, such as oxides, sulfides, carbides, phosphides, carbons, platinum, ruthenium, and single atom, were analyzed. Metal-free carbon electrocatalysts were popular targets. Moreover, oxides and ruthenium have also been very actively studied.

Figure 2. The number of papers published relevant to different kinds of electrocatalyst up until 26 March 2020. Here, the were papers were searched for on the science Web of Science using the topic 'electrocatalyst' and further filtered using byusing a second term (i.e. oxide, sulfide, carbide, phosphide, carbon, platinum, ruthenium, single atom) for all document types on 26 March 2020.

Download figure:

Standard image High-resolution imageThis roadmap gives a comprehensive overview of the electrocatalysts used for ORR, water splitting, CO2RR and NRR. The main kinds of electrocatalyst shown in figure 2 will be comprehensively discussed in the following sections, which will include statuses, challenges, and concluding remarks. We invited some active researchers to give their views on different kinds of electrocatalyst. It is strongly expected that this roadmap will provide guidance for future research.

1. Pt and its alloys for ORR

Yuchen Qin

College of Sciences, Henan Agricultural University

Status

Platinum (Pt) is regarded as an excellent electrocatalyst for the ORR and represents a benchmark for ORR catalysts. The effects of the particle size, structure and shape of Pt nanocrystals (NCs) on ORR performance have been deeply explored. However, the unsatisfactory activity, high cost, and insufficient reserves of Pt limit its large-scale application. Therefore, minimizing the quantity of Pt required in catalysts and further improving the ORR's performance are essential for its extensive commercial deployment [13].

Initially, noble metals were generally employed in alloys with Pt, owing to their matching lattice parameters. Many Pt–noble metal alloys with various structures such as Pt–Au nanowires [14], Pt–Pd hollow nanostructures [15], Pt–Ag nanowires [16], etc, have successfully been prepared and have exhibited enhanced catalytic activity and stability in the ORR. This enhancement of catalysis can be attributed to the modification of Pt's electronic structure due to synergies between the metals. However, the improvement to the ORR's performance is limited. In particular, alloying Pt with noble metals cannot effectively reduce the cost. Therefore, it is desirable to alloy more suitable metals with Pt to further boost the ORR's performance and significantly reduce the cost.

Pt–transition metal (TM) alloys have attracted much attention, owing to the lower proportion of Pt required and their superior catalytic performance when they are used in the ORR. The enhanced catalytic property of Pt alloys originates from the TMs [17]. Thus, the type of TM plays a significant role in improving the ORR's performance. Alloys of Pt and late TMs have been widely studied for many years, and the main factors that may be responsible for the high ORR activity include the strain effect, the ligand effect and the surface structure [18, 19]. The strain and ligand effects can modify the d-band center or vacancy of Pt, resulting in a weakening of the adsorption of oxygen-containing species, which is crucial for the improvement of ORR performance [20]. Rough and Pt-skin surfaces are formed owing to the dissolution of TMs during ORR measurement in an acid environment or with initial acid treatment. More dissoluble TMs generally lead to higher ORR activity, but lower stability [21]. Thermal annealing is often carried out on Pt–late TM alloys to cause the segregation of Pt atoms on the surface, resulting in a Pt-skin surface and excellent ORR performance. The increased degree of ORR activity after thermal annealing is slightly different, following the sequence Pt < Pt3Ti < Pt3V < Pt3Fe < Pt3Ni < Pt3Co [22]. Apart from Pt–late TM alloys, alloys of Pt with early TMs and rare earths can also improve the activity and stability of the ORR, and are even superior to Pt–late TM alloys. Theoretical calculations demonstrate that the excellent catalytic properties of Pt–early TM alloys or Pt–rare earth alloys can be attributed to the ligand effect from the non-noble metals in the sublayers [23].

Since the start of the twenty-first century, many Pt intermetallic (ordered) alloys such as PtCo, PtFe, PtNi, PtZn, PtFeCo have successfully been synthesized through high-temperature annealing. These ordered Pt alloys usually deliver superior catalytic activity and stability, compared to disordered alloys, due to their stronger structural stability [24]. Even after ORR testing, the ordered structure was able to be maintained and only a few surface atomic layers became a Pt-like skin. According to theoretical calculations, the stronger Pt–metal covalent bond and more negative formation heat of ordered Pt alloys resulted in a superior ORR performance.

Another important development of Pt alloy catalysts is the fabrication of thin film structures. Distributing Pt alloy NCs on a nanostructured polymer thin film can not only effectively eliminate carbon corrosion and contact resistance between NCs and carbon but also reduce the proportion of low-coordination-number atoms. These factors all contribute to the much higher ORR activity of Pt alloy catalysts with a thin film structure, compared to that of carbon-supported Pt alloys.

Current and future challenges

Over the past decade, many notable advancements have been made in the development of Pt and Pt alloy ORR catalysts. The surface structure, electronic structure, strain, size, morphology and supporting material all play significant roles in improving the ORR's performance [25]. However, many challenges and opportunities still remain.

The D-band center plays an important role in the adsorption energies of intermediate species, and determines the catalytic activity of the ORR. Tuning the surface strain of Pt alloys can effectively influence the position of the d-band's center [26]. In Pt alloys, tensile strain can upshift the d-band's center, leading to stronger interaction with adsorbates, whereas compressive strain downshifts the d-band's center, weakening the adsorption energy (figure 3). Therefore, an effective and simple method for accurately controlling the surface strain of Pt alloys has shown great promise for catalytic enhancement.

Figure 3. A schematic diagram of the relationship between surface strain and the d-band center of Pt.

Download figure:

Standard image High-resolution imageDefect engineering is a hot spot in the field of catalysis and nanomaterials. The construction of defect sites (including vacancies), doping, and the amorphization of Pt alloys exhibit great potential for the enhancement of ORR activity. However, the preparation of Pt alloys with ordered defect sites is an enormous challenge. Porous Pt alloys can improve the catalytic property of ORR due to an increase in the numbers of active sites and boundary atoms. The dealloying method is the most common method for generating a porous structure. However, the resulting pores are disordered and cannot maximize the nanoconfinement effect required for the enhancement of catalytic performance. Therefore, the exploration of an effective strategy for preparing Pt alloys with an ordered porous structure is important for increasing the ORR's performance and decreasing the amount of Pt used.

The mechanistic investigation into ORR performance using Pt alloy catalysts at the atomic level has fallen behind synthetic studies. In this respect, advanced in-situ characterization techniques including in-situ Raman spectroscopy, in-situ Fourier-transform infrared spectroscopy (FTIR), in-situ transmission electron microscopy (TEM) and in-situ x-ray absorption spectroscopy (XAS) should be employed to detect transient states in the ORR process and directly reveal the reaction pathway and mechanism. Currently, the understanding of the relationship between the electronic structure and the ORR activity of Pt alloys is that it is a 'volcano-type' relationship [27]. Thus, balancing the adsorption energies of reactive intermediates and available reactive sites on the surface is essential for the improvement of ORR performance. Also, increasing the interaction between the catalyst's support and the Pt alloys is significant for realizing an effective distribution of Pt-based NCs on the support, which is beneficial for the enhancement of activity and stability.

According to the United States Department of Energy (DOE), the target for catalysts in proton-exchange membrane fuel cells (PEMFCs) is to reduce the total Pt loading to 0.125 mgPt cm−2 and increase the mass activity (MA) to 0.44 mA  at 0.9 V in an actual fuel cell device. Although the ORR performance of advanced Pt alloy catalysts reported previously was far higher than the DOE target, most of them were measured by a rotating disc electrode (RDE) system. There is a great difference between the catalytic property of Pt alloys as confirmed by RDE systems and practical performance achieved in an actual fuel cell device; therefore, a novel, fast, and low-cost catalyst evaluation technology should be explored to replace RDE systems. Until now, it has been rare for Pt alloy catalysts to exhibit such an excellent performance that they can be transferred into real fuel cell devices. Therefore, the design and preparation of Pt alloys with high activity and long-term stability that have been tested in real fuel cell devices remains a great challenge.

at 0.9 V in an actual fuel cell device. Although the ORR performance of advanced Pt alloy catalysts reported previously was far higher than the DOE target, most of them were measured by a rotating disc electrode (RDE) system. There is a great difference between the catalytic property of Pt alloys as confirmed by RDE systems and practical performance achieved in an actual fuel cell device; therefore, a novel, fast, and low-cost catalyst evaluation technology should be explored to replace RDE systems. Until now, it has been rare for Pt alloy catalysts to exhibit such an excellent performance that they can be transferred into real fuel cell devices. Therefore, the design and preparation of Pt alloys with high activity and long-term stability that have been tested in real fuel cell devices remains a great challenge.

Concluding remarks

This field has been regarded as a research hot spot for many years and has achieved significant advances. Although some scientific and technological problems remain, Pt alloy catalysts have exhibited great potential for widespread application.

Acknowledgments

This study was financially supported by the National Natural Science Foundation of China (21706074, 21972038), Natural Science Foundation of Henan Province (2023000410209), Key Research and Promotion Project of Henan Province (202102210261, 202102310267) and Top-notch Personnel Fund of Henan Agricultural University (30500682).

2. Pt-based electrocatalysts for ORR

Yan-Jie Wang

School of Materials Science and Engineering, Dongguan University of Technology

Status

With the exploration of clean and sustainable energy sources, the large-scale implementation of PEMFC technology that generates electricity from the electrochemical conversion of hydrogen and oxygen into water has been urgently demanded for use in commercial, residential, and transport applications. However, electrochemical conversion suffers greatly from certain issues, notably the sluggish speed of the ORR and the use of costly Pt-based catalysts at the cathode, which account for over 55% of the total PEMFC cost [17, 28]. Currently, Pt-based catalysts are undoubtedly the most active electrocatalysts for the ORR in PEMFCs, delivering the highest catalytic contribution to the ORR. Due to the scarcity and high price of Pt, reducing the Pt loading (particularly in the cathode catalyst layer), as well as improving its catalytic activity and stability to meet the requirements of PEMFC commercialization have become hot topics of widespread concern [29, 30].

In an effort to develop an optimum Pt-based ORR catalyst over the past few decades, significant progress has been made in the design and fabrication of nanostructured Pt-based catalysts using advanced materials science and nanotechnology, in which the size and morphology of the catalysts have been considered as critical factors for improving the catalytic activity and stability [17, 31]. For Pt-based nanostructures, it is well known that when the size of the catalysts is controlled in the nanoscale regime, especially over the small range of 3–5 nm, the attractive physical and/or chemical properties that do not emerge in the bulk state can afford excellent opportunities to obtain a large electrochemically active area and a high degree of catalytic activity. Meanwhile, for the structural morphology to enhance the catalytic performance, important insights into the nature of the active sites and their involvement in the ORR have shifted from traditional empirical trial-and-error methods to rational structural design and fabrication at the molecular or atomic levels, corresponding to the surface electronic structure of the catalysts and based on an understanding of the ORR catalytic mechanism. Both molecular catalysts (e.g. the molybdenum-doped hyperoctahedral Pt3Ni NCs with high-index facets) and atomic catalysts (e.g. single-atom Pt-based catalysts with good architectures) with well-designed geometric morphologies can favor high ORR activity and stability [32, 33]. Given the rapid development of advanced Pt-based ORR catalysts, a great need for updated design concepts has emphasized Pt-based nanostructures (figure 4) in three main trends: (a) Pt-based nanoparticles (NPs), (b) Pt-based nanotextures, and (c) Pt-based branched or anisotropic elongated nanostructures. Depending on their unique morphologies and nanoscale dimensions, these nanostructured Pt-based catalysts are preferred for precise control of structural reactivity, resulting in improved catalytic performance and electrochemical/physicochemical stability [31]. Also, insights into the relationship between structure and property, including the effects of Pt's facets, geometric architectures, compositional profile, and support, on the ORR's performance, have been significantly highlighted by the development and creation of advanced Pt-based nanostructured catalysts for practical PEMFC applications.

Figure 4. Various nanoscale Pt-based electrocatalysts.

Download figure:

Standard image High-resolution imageTo obtain low-Pt-content fuel cell electrodes with high Pt utilization efficiency, research advances in surface engineering strategies (figure 5) have been made using Pt-based nanostructured catalysts. Based on surface facet technology, coupled with composite engineering and a doping strategy, Mo-doped Pt3Ni (Mo–Pt3Ni) octahedral NPs [33] exhibit excellent ORR performance (i.e. an MA of 6.98 mA µgPt −1 and a specific activity (SA) of 10.3 mA cmPt −2 as measured by RDE at 0.9 V versus a reversible hydrogen electrode, RHE) compared to commercial Pt/C catalysts (i.e. 96 mA mgPt −1 and 0.127 mA cmPt −2, respectively). After 8000 potential cycles between 0.6 and 1.1 versus RHE at a sweep rate of 50 mV s−1, the Mo–Pt3Ni octahedral NPs display decreases of only 6.2% and 5.5% from the initial SA and MA, respectively, suggesting very good stability. Meanwhile, the combined surface strategy of composite engineering and defects demonstrates validity in the preparation of ultrafine jagged Pt nanowires (J Pt NWs) [34] with the best present-day ORR performance (i.e. an MA of 13.6 mA µgPt −1 and an SA of 11.5 mA cmPt −2 at 0.9 V versus RHE). The accelerated durability test (ADT) at a sweep rate of 100 mV s−1 between 0.6 V and 1.0 V showed that after 6000 potential cycles, the SA and MA only dropped by 5.5% and 12%, respectively, indicating the strong stability of J Pt NWs. Thanks to their excellent thermal and chemical stability, unique surface coordination states, and faster electron and mass transport, ultrathin NWs not only favor high catalytic activity but also cause less Pt dissolution and Ostwald ripening in a realistic fuel cell.

Figure 5. Surface engineering strategies for enhancing ORR performance.

Download figure:

Standard image High-resolution imageHowever, to avoid large crystallites in shaped Pt-based NPs with insufficient oxygen contact in the electrode during ORR, an ultralow concentration of Pt alloy supported on platinum-group-metal (PGM)-free materials (denoted by LP@PF-2) [36] was fabricated from engineered active sites with a combination of Pt and PGM-free catalytic sites, providing synergistic catalysis over the LP@PF-2 with improved activity (an MA of 12.36 mA µgPt −1 in the RDE test at 0.9 V versus RHE) and stability. The measured MEA at an internal resistance-corrected (iR-free) voltage of 0.9 V demonstrated that LP@PF-2 can achieve an MA of 1.77 mA µgPt −1, which is the best ORR performance of a membrane electrode assembly (MEA) measurement in the current technical landscape. In particular, after the standard durability test, the LP@PF-2 demonstrated stability comparable to the benchmark required by the DOE 2020 targets [37]. Moreover, at a very low Pt cathode loading of 0.033 mgPt cm−2, the rated power density reached 0.37 W cm−2, suggesting the excellent potential of LP@PF-2 for use in real fuel cells.

Current and future challenges

For Pt-based catalysts operating in PEMFCs, it is desirable to conduct the ORR through a four-electron pathway due to its direct energy efficiency. An experimental explanation of the electrochemical reaction mechanism in PEMFCs, required to clearly understand the details of the ORR, is challenging during the development of advanced Pt-based catalysts, because many intermediates of the ongoing ORR, depending on the nature of electrode material, catalyst, and electrolyte, are not easily probed via in situ characterization [38]. This often makes the ORR mechanism controversial, even though density functional theory (DFT) can provide theoretical help by modeling the electrochemical reactions of Pt-based catalysts. Moreover, in the recent single-atom Pt-based catalysts that provide enough atomic utilization and active sites to improve catalytic performance, isolated single atoms often prefer a two-electron pathway to catalyze ORR [39], which may result in difficulties in the theoretical understanding of the electrocatalytic mechanism, and thereby, in improving electrocatalytic activity.

Besides, other major technological challenges exist in the utilization of nanoscale Pt-based catalysts in real fuel cell operation: (a) as opposed to limited-scale laboratory fabrication, large-scale synthesis procedures for consistent, reliable, and reproducible NP quality need to be developed, in which the size and morphology should be controlled to maintain high activity and stability; (b) in the preparation of highly active Pt-based catalysts (e.g. facet-dependent Pt-alloy NCs), more reliable and controlled strategies are needed for the removal of surfactant(s) so that the size and morphology of NPs can be effectively controlled; (c) Pt-based nanostructured catalysts usually exhibit a large performance discrepancy between rotating disk electrode (RDE) screening and membrane electrode assembly (MEA) testing, because the polymer electrolyte membrane used, coupled with the electrode configuration, often results in an MEA with limited proton and oxygen transport as well as waterflooding within the cathodic electrode, which does not exist in the RDE. More systematic studies could be expected to clarify the correlation between changes in operating conditions and electrocatalytic properties; (d) for Pt-based nanostructured catalysts, in which the Pt or Pt-alloy NPs are generally deposited on conductive support materials (e.g. carbon) with high surface areas to prevent their agglomeration, more detailed analysis of the interaction between Pt and its support should be sufficiently addressed to clarify the influence of the support material on the activity and stability of Pt-based catalysts. More importantly, carbon corrosion at high potentials can make Pt-based NPs coalescent and detachable in long-term fuel cell operation, which requires more durable support candidates, such as modified carbon or noncarbon support materials with high surface areas and good conductivities.

Concluding remarks

Advances in surface engineering have created an important insight into improving the ORR activity and stability of Pt-based nanostructured catalysts in PEMFCs. Based on surface engineering strategies for building nanoscale structures and morphologies, there are new opportunities to make a big breakthrough and resolve the research bottleneck in the development of highly catalytic Pt-based ORR catalysts, while theoretical studies are still needed to uncover the cause of the catalyst's performance discrepancy when used with RDEs versus MEAs.

Acknowledgments

This work was supported by the Startup Grant of High-level Talents (GB200902-30, No. 196100041018) and the Foundation of Regular Research Team (TDYB2019007, No. 196100043028) at the Dongguan University of Technology.

3. Oxides for ORR

Yao Wang

State Key Laboratory of Heavy Oil Processing, College of Chemical Engineering and Environment, China University of Petroleum

Status

PEMFCs and metal–air batteries have been investigated for several decades due to their high efficiency, ease of operation, zero emission and most importantly, their unlimited renewable source of reactants. However, the sluggish kinetics of ORRs limit their large-scale commercial application [30, 40–42]. Transition-metal oxides (TMOs), such as cobalt oxides, nickel oxides, iron oxides, and manganese oxides are arousing enormous attention as promising alternatives to noble-metal-based electro-catalysts for ORRs, due to their intrinsic activity and sufficient stability in an oxidative electrochemical environment [43–48].

On one hand, extrinsic methods for enhancing the electrical conductivity of TMO catalysts to eventually achieve high ORR activity are based on combining them with other foreign components. Graphene, as the most promising conductive substrate, has been widely used to support TMOs to enhance ORR performance, due to its superior electrical conductivity [49]. This hybrid possesses enhanced electrical conductivity and fast electron transfer, thus accelerating the ORR's kinetics. Additionally, there is a synergistic effect between TMOs and graphene, which is beneficial to the ORR's performance. Furthermore, the doping of graphene with nitrogen inspires further development of the superior performance of TMO catalysts. In addition to increased activity, the introduction of graphene also enhances durability by anchoring the TMO components, which can be attributed to the strong effect of the interaction between the support and the TMOs. In general, the size of TMOs is always large, which is detrimental to rapid electron transfer. Micrifying the sizes of TMO particles not only greatly increases the contact interface between TMOs and conductive materials but also strongly promotes electron transfer.

On the other hand, the electrical conductivity of TMOs changes remarkably, from that of a semi-conductor to a metal-like conductor, through the introduction of other cations or the construction of desired oxygen vacancies. Firstly, doping another metal cation (Ni2+, Co2+, Fe2+ et al) into the lattice of TMOs can modify their electrical conductivity [50, 51]. However, the introduction of massive metal cations into bulk TMOs would probably form a new material. In this case, the crystal structure and composition of the pristine materials would be changed, thus affecting the adsorption/desorption energy of the intermediates. Secondly, constructing defects, especially oxygen vacancies, is regarded as the most effective method for altering the intrinsic conductivity of TMOs by strongly tuning their bandgaps. Some reports have shown that oxygen vacancies can be formed by a simple heat treatment. The existence of oxygen vacancies induces the bandgaps to become smaller, enhancing the intrinsic conductivity. Thus, rational control of the oxygen vacancies enhances the metallic characteristics of TMOs.

In a basic solution, the details of the ORR's performance are complex and are under investigation. It is generally accepted that O2 is reduced to OH− or HO2 − through the 4e− or 2e− pathways, respectively. In terms of TMO catalysts, it has been reported that the 2e− plus 2e− process is the dominant pathway for the alkaline ORR process. However, the adsorption energy between the catalyst's surface atoms and the reactant is not just related to the crystal facets, but also to the valance state of the surface metal atoms of TMOs. According to the associative pathway, the O–O bond will be be further cleaved to produce an O* intermediate after the OOH* intermediate is formed, and then an electron will transfer from the surface metal atoms to the adsorbed O* intermediate to form M(M+1)+–O2−. Based on the strategies discussed above, it is important to construct a tight relationship between TMO catalysts and ORR performance to guide the process of catalyst design (figure 6).

Figure 6. The advantages, challenges and fabrication strategies of TOM catalysts.

Download figure:

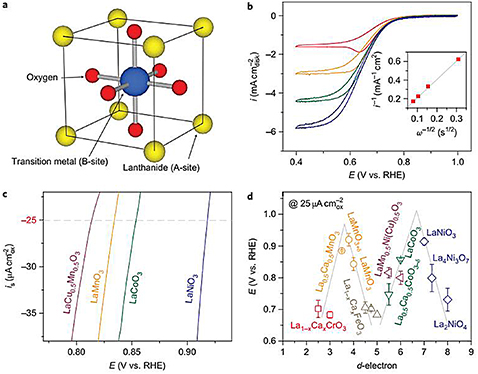

Standard image High-resolution imageApart from the previously discussed examples of TMO-type catalysts, other special materials, such as perovskite-type materials, spinel-type materials, and other ternary TMOs are widely used for ORRs. Firstly, the perovskite-type ORR catalysts usually consist of rare earth metals or alkaline earths (A) and TMs (B) in the form of ABO3. Implanting foreign cations into the bulk of perovskite to replace the A-site and B-site could greatly improve the ORR's catalytic performance. In the past, perovskite catalysts showed an enhanced ORR performance, which can be traced back to the 1970s. Matsumoto and co-workers documented that LaNiO3 perovskite material possessed an intrinsic activity, phase structure, and specific surface and electronic conductivity in the ORR [52]. It was reported that a so-called 'star' material based on perovskite oxide catalysts showed unprecedented ORR performance. In 2011 [35], Yang Shan-horn and coworkers reported that ORR activity for oxide catalysts was primarily correlated with σ*-orbital (eg) occupation and the extent of B-site transition-metal–oxygen covalency, which reflects the critical influences of the surface electron structure and metal–oxygen covalency on the competition between O2 2−/OH− displacement and OH− regeneration of surface transition-metal ions, demonstrating the importance of electron structure in controlling ORR catalytic performance, as shown in figure 7.

Figure 7. ORR activity of perovskite transition-metal-oxide catalysts. (a) ABO3 perovskite structure. (b) Oxygen-reducing activity of an LaCu0.5Mn0.5O3 electrode in O2-saturated 0.1 M KOH at a 10 mV s−1 scan rate and rotation rates of 100, 400, 900 and 1600 r.p.m. Koutecký–Levich analysis (inset) of the limiting currents (0.4 V) indicates a 4e− transfer reaction. (c) Specific activities of LaCu0.5Mn0.5O3, LaMnO3, LaCoO3, and LaNiO3. The potential at 25 μA cm2 ox is used as a benchmark for comparison. (d) Potentials at 25 μA cm2 ox of the perovskite oxides have an M-shaped relationship with the d-electron number. Data symbols vary with the type of B ion (Cr, red; Mn, orange; Fe, grey; Co, green; Ni, blue; mixed compounds, purple), where x ¼ 0 and 0.5 for Cr, and 0, 0.25 and 0.5 for Fe. Error bars represent standard deviations of at least three measurements [35].

Download figure:

Standard image High-resolution imageBesides, spinel-type ORR materials can be denoted by AB2O4 with specific proportions of A and B, where A stands for a divalent metal ion (such as Co, Ni, Mg, Zn etc) and B represents a trivalent metal ion (such as Co, Mn, Ni, Fe, Al etc). General methods for boosting the ORR performance of spinel-type materials include adjusting the composition and valence, designing the morphology and structure, and introducing defects and vacancies, the same as for ample TMO-type catalysts. Finally, some other ternary TMOs have also been explored, such as double perovskites, pyrochlore-type oxides, Ruddlesden–Popper-type oxides, LiCoO2-related oxides and Mn-based mullite oxides. It should be noted that the synergistic effect plays an important role in enhancing ORR activity due to the amount of intimate interfaces of different TMO components.

Current and future challenges

As is known, for the ORR, high-conductance materials are needed during the catalytic process, while the semiconductor characterizations of TMOs limit their ORR activity. Several strategies have been developed, such as combining TMOs with other components by in/ex situ methods, doping modifications and introducing defects and vacancies, and developing new materials and fabrication methods, among which, combining TMOs with other superior conductive support materials, such as pure metal NPs, carbon materials (graphene and carbon nanotubes (CNTs)), and other conductive polymers, is considered a high-efficiency method for improving the conductivity of bulk materials [35]. This strategy is based on the fact that introducing foreign components into TMOs by in-situ or ex-situ methods limits the margin of ORR performance enhancement. Another method is to optimize the intrinsic electrical conductivity of TMOs by atomic-level regulation, for example, by doping them with other metal atoms and developing oxygen defects [53]. This strategy can essentially convert TMO catalysts from semiconductors into metallic-type conductors, thus improving their intrinsic activity for the ORR.

Apart from the conductivity, the specific crystal structure and facets are other factors that affect ORR performance [54–56]. TOMs contain ordered but specific crystal and amorphous structures, which possess distinctly catalytic behaviors. Thus, exploring the detailed relationships between these structures and ORR performance is necessary for the rational design of the desired TMO catalysts. Also, TOMs with different facets exhibit different adsorption/desorption abilities and electrical conductivities. According to the Sabatier principle, the interactions between the catalyst surface atoms and the reactant should be neither too strong nor too weak, demonstrating the presence of maximum catalytic activity to some extent. The regulation of crystal facets of TOMs is an efficient strategy for improving ORR performance.

Concluding remarks

In recent years, research in the emerging fields of energy storage and conversions based on TMOs has been demonstrated at the atomic level. The development of the ORR in PEMFCs and metal–air batteries has been obtained by improvements in TMOs. Several strategies discussed in this paper have been elaborated to improve the activity and stability of TMO catalysts. Therefore, a deep exploration of the underlying relationships between TMOs and ORR performance is the key viewpoint for the rational design and construction of TMO catalysts in the future.

4. Chalcogenides for ORR

Rou Tan and Xiaochuan Duan

Pen-Tung Sah Institute of Micro-Nano Science and Technology, Xiamen University

Status

To solve the growing energy and environmental crisis caused by fossil fuels, much research effort has been devoted to clean energy systems, such as fuel cells and rechargeable metal–air batteries. ORR is a key fundamental electrochemical reaction involved in the energy systems mentioned above, which relies heavily on high-performance electrocatalysts to meet its practical applications. In general, the precious metal Pt and its complexes are the most common catalysts in commercial use for the ORR. Unfortunately, the high cost and scarcity of Pt-based catalysts severely limits their large-scale application. Therefore, there is an urgent need to develop alternative highly active low-cost ORR catalysts. To this end, more economical and competitive ORR catalysts that are not based on precious metals have been developed in succession [57–59]. In particular, layered transition-metal dichalcogenide (TMD)-based catalysts have attracted much interest because of their diverse and tunable catalytic properties [60, 61]. Previous studies have revealed that TMDs with well-defined structures exhibit superior catalytic activity for HER and OER, while their ORR performance is unsatisfactory due to their sluggish kinetics, including low conductivity and weak adsorption of ORR intermediates. Thus, the pursuit of high-performance TMD-based catalysts is conducive to the realization of trifunctional catalysts that are simultaneously efficient for HER, OER, and ORR, which can fulfill the needs of highly efficient renewable energy systems [62].

Current and future challenges

Layered TMDs possess a common chemical formula MX2 (M = transition metal, X = chalcogen) with a sandwich structure (X–M–X) held together by strong intralayer bonding (covalent bonding) and weak interlayer bonding (van der Waals interaction). According to the M–X arrangement, there are three known phases for MX2, namely one-layer tetragonal (1 T), two-layer hexagonal (2 H) and three-layer rhombohedral (3 R). Generally, in the 1 T phase, the TM atomic coordination is octahedral, while the 2 H and 3 R phases are trigonal prismatic (figure 8) [63]. The catalytic performances of layered MX2 nanosheets that expose the prismatic edges and basal planes can be tuned by reducing their size and phase transitions. On one hand, reducing the size of trilayer X–M–X to the atomic level endows MX2 ultrathin nanosheets with low-coordination step edges (metallic edge states) and corner atoms that are usually considered to be the active center in catalytic processes such as HER and ORR. On the other hand, the catalytic activity of MX2 can be adjusted by a phase transition that influences its electronic conductivity. For instance, the metallic 1 T phase of molybdenum disulfide (MoS2) exhibits higher activity compared with the semiconducting 2 H phase due to improved electron density, and thus favors fast electronic transport in the electrocatalytic process [64].

Figure 8. Illustration of TMDs and three typical 1 T, 2 H and 3 R phases with different metal coordinations and stacking sequences of MX2 structural unit cells. Reproduced with permission [63]. Copyright 2018, The Royal Society of Chemistry.

Download figure:

Standard image High-resolution imageCurrently, TMDs are used as a potential catalyst for the ORR based on the four-electron path. However, their sluggish kinetics restrict further application in clean energy-based devices. To improve the catalytic performances of TMDs for the ORR, various strategies have been applied: (a) atomically thin MX2 nanosheets manifest an ORR performance that is comparable to that of commercial Pt/C catalysts, especially in their methanol tolerance and stability. However, ultrathin MX2 nanosheets with high surface energy are inclined to restack together under the van der Waals attraction between their interlayers, thus reducing the density of exposed catalytic active sites. To improve the structural stability of ultrathin MX2 nanosheets and avoid agglomeration, highly conductive carbon-based frameworks such as CNTs, graphene or reduced graphene oxide (rGO), carbon fiber cloth, etc, have been used for hybridization with MX2 nanosheets. Moreover, considering the intrinsic ORR activity of carbon materials, a synergistic effect between the MX2 nanosheets and the abovementioned conductive carbon framework can provide more active sites for ORR and also facilitate electron transfer. Song et al reported a high-performance ORR catalyst consisting of ultrathin MoS2 nanosheets (∼5 nm) on carbon nanotube forest-covered graphite foam (GF-CNT@MoS2) made using the atomic layer deposition method (figure 9(a)) [65]. Benefiting from an integrated structural advantage, this composite catalyst exhibited high catalytic activity for both the ORR and the OER, and was successfully applied in a Li–O2 battery. (b) Given that the sluggish kinetics of TMDs in the ORR mainly originate from the unfavorable adsorption of oxygen-containing intermediates, especially in the case of the X-terminated layer of TMDs, the replacement of an X atom by other heteroatoms can significantly reduce the energy barrier for ORR intermediate adsorption on TMD surfaces, which is conducive to the reaction kinetics of the ORR. Singh et al systematically examined the effects of nitrogen (N) and phosphorus (P) doping on TMD catalysts for the ORR using first-principle calculations, and indicated that the substitution of X (S or Se) in the MX2 monolayer by N or P atoms induced a high spin density on the MX2 basal plane with improved chemical activity for O2 activation and adsorption. Thus, N-doped MX2 catalysts manifest efficient catalytic performance for the ORR based on the four-electron reduction mechanism, whereas over-strong binding by oxygen-containing intermediates in P-doped MX2 catalysts blocks the ORR (figure 9(b)) [66]. Also, the defect types and sites of heteroatom doping also greatly affect the ORR performance of TMDs. For pristine surfaces and surfaces with point defects in TMDs, large overpotentials (>1.0 V) are needed to activate the ORR, while the ORR overpotentials at edge defects are very low (0.66 V), corresponding to high activity, close to that of a prototypical Pt catalyst (overpotential ∼0.45 V) [67]. (c) Heterointerface tailoring has proven to be an efficient strategy for promoting the electrocatalytic properties of TMDs. The introduction of additional chalcogenides leads to an interfacial charge redistribution in the heterointerfaces that effectively reduces the adsorption energies of ORR intermediates, leading to the generation of more active catalytic sites and the promotion of electron transfer [68]. In the case of ultrathin Ni3S2/MoS2 heterostructured nanosheets (figure 9(c)), the presence of abundant heterointerfaces provides numerous highly active sites based on Mo edges and Mo–Ni–S sites [69]. Furthermore, the heterointerfaces in Ni3S2/MoS2 accelerate electron transport and enable the binding of more oxygen-containing intermediates for the ORR.

Figure 9. (a) Schematics of the preparation of GF–CNT@MoS2 catalysts. Reproduced with permission [65]. Copyright 2019, Wiley–VCH. (b) Scaling relation between adsorption-free energies of oxygen-containing intermediates on N-doped and P-doped MX2 monolayers. Reproduced with permission [66]. Copyright 2018, Wiley–VCH. (c) Schematics of the synthetic protocol for ultrathin Ni3S2/MoS2 nanosheets. Reproduced with permission [69]. Copyright 2019, The Royal Society of Chemistry.

Download figure:

Standard image High-resolution imageConcluding remarks

Layered TMDs have been considered as promising trifunctional electrocatalysts for the HER, OER, and ORR. However, the unsatisfactory ORR performance of TMDs that stems from their sluggish kinetics limits their further application in highly efficient clean energy systems. Thus, it is necessary to develop modification strategies to improve the ORR performance of TMD-based electrocatalysts. Comprehensive strategies including heteroatom doping, hybridization with conductive carbon materials, and heterointerface tailoring need to be considered to achieve optimal catalytic activity for the ORR. Although much progress has been made, the field of high-performance TMD-based catalysts for the ORR is still challenging. A deep understanding of the ORR mechanism of TMDs will be of great assistance in the realization of superior TMD electrocatalysts with high activity and stability. Through rational design and the fabrication of TMDs with well-defined structures, TMD-based multifunctional electrocatalysts hold great promise for the energy-related field in the near future.

Acknowledgments

This study was supported by the National Natural Science Foundation of China (Grant No. 21601148) and the Natural Science Foundation of Fujian Province (Grant No. 2017J05090).

5. Carbon-based hollow electrocatalysts for ORR

Tong Zhen Tian, Cai Hong Zhang, Wen Wen Xie, Nian-Wu Li and Le Yu

State Key Lab of Organic-Inorganic Composites, Beijing University of Chemical Technology

Status

With the current surge in energy consumption, energy storage systems such as lithium-ion batteries are approaching their performance limits. New energy technologies, such as PEMFCs and metal–air batteries, with higher energy densities and lower production costs, have attracted tremendous research attention as promising candidates to address this problem [70–72]. The operation of both PEMFC and metal–air devices relies on a series of electrochemical processes at both electrodes. Amongst these, the most critical reaction is the ORR at the cathode, which determines the performance of the whole device [73]. The ORR can proceed through two pathways: one is the direct four-electron transfer pathway, and the other is the indirect four-electron pathway containing a two-step two-electron reaction route. In energy storage systems, the direct four-electron pathway is the first choice for realizing high efficiency [74–76]. Large-scale commercialization of the PEMFCs and metal–air batteries requires highly efficient, durable and low-cost ORR catalysts. In catalytic design, there are two main strategies for improving electrochemical performance. One is to increase the apparent activity through structural optimization, increasing the number of exposed active sites per gram and enhancing the utilization of the active sites by an improved mass transfer of electrolytes. The other is to improve the intrinsic catalytic activity per active site by the introduction of heteroatoms [77]. The heteroatoms change the oxygen-binding ability of the active site, altering the proton–electron transfer to diverse intermediates (OOH*, OH*, O*). Currently, the most widely used commercial ORR catalyst is Pt/C, which has excellent half-wave potential and limit current, showing its excellent intrinsic catalytic activity and apparent catalytic activity, respectively. However, the widespread commercial application of precious metals has been greatly hindered by the scarcity of reserves, high cost, carbon monoxide poisoning and methanol cross-reaction issues. Therefore, it is necessary to explore new low-cost and highly efficient catalysts to replace or reduce the use of noble metals. Carbon-based materials have been considered as promising alternates due to their abundance in nature, corrosion resistance, high conductivity and controllable surface properties [78]. Benefitting from large specific surface areas, defined active sites, limited voids and adjustable mass-transfer rates, hollow nanostructures have proved themselves in advanced electrocatalyst designs [79]. When applied to carbon materials, hollow structured carbon electrocatalysts can further optimize mass and electron transport, maximizing the usage of active sites. Here, we focus on recent research progress in the design of carbon-based hollow electrocatalysts for the ORR (figure 10). Based on their composition, hollow carbon-based catalysts are divided into three categories: metal-free catalysts, carbon with single-atom active sites, and carbon-based composites.

Figure 10. The design of carbon-based hollow electrocatalysts for ORR.

Download figure:

Standard image High-resolution imageCurrent and future challenges

For metal-free catalysts, the introduction of heteroatoms (such as N, B, S) is the approach most widely studied to effectively increase catalytic activity. The heteroatomic doping of carbon-based catalysts induces charge transfer between the doping site and the adjacent carbon atoms, so that the electron distribution can be rearranged. In particular, carbon atoms accompanied by more electronegative N or B atoms can improve the chemisorption of oxygen atoms. Also, N atoms bound in pyridinic sites or graphitic sites may enhance the electrochemical performance. B sites can also act as electron donors for the reduction reaction. Moreover, S doping can increase the spin density of graphene. The appearance of local states in the electron band structure enables the generation of active sites in the inert carbon atomic network, but there is still some doubt about the specific role of the doping species. Therefore, it is highly important to investigate the contribution of intrinsic carbon defects to the ORR. Conceptually, these intrinsic defects (vacancies, pentagon and/or heptagon formation, Thrower–Stone–Wales (TSW) defects, etc) are regarded as topological deviations that do not destroy the graphitic lattice. However, these structural changes can modify the atomic orbitals to create localized electronic states, which can induce improved ORR activity. For example, the hollow nanocages (figure 11(a)) designed by Hu and co-workers [80] had three kinds of defective carbon structure: (a) pentagon defects at the corners, (b) edge defects at the broken fringes of the shells, and (c) hole defects from micropores (figure 11(b)). DFT calculations further revealed that pentagon and zigzag edge defects were the catalytic active sites (figure 11(c)). Due to their defect engineering and unique hollow structures, these defective nanocages demonstrated an ORR performance comparable to that of N-doped carbon in an alkaline solution (figure 11(d)). A deep understanding of the inherent defects of carbon is helpful for the further defect engineering of carbon catalysts.

Figure 11. (a) High-resolution TEM (HRTEM) image of carbon nanocages. (b) Three typical defect locations within the carbon nanocages. (c) DFT calculations for the ORR activities of different defects. (d) ORR performances of carbon nanocages annealed at different temperatures. (e) Schematic illustration of the formation of hollow carbon spheres with single Co atoms. (f) Corresponding EXAFS fitting curves in R space. (g) ORR polarization curves. (h) Schematic illustration of the formation of a single-holed Co/NC hollow particle. (i) Field-emission scanning electron microscopy (FESEM) image of single-holed Co/NC hollow particles. (j) Tolerance test at 0.5 V in O2-saturated 0.1 m KOH solution with the addition of methanol after 2000 s. Panels (a)–(d) reproduced from [80] with permission. Copyright 2015, American Chemical Society. Panels (e)–(g) reproduced from [84] with permission. Copyright 2017, John Wiley and Sons. Panels (h)–(j) reproduced from [86] with permission. Copyright 2017, John Wiley and Sons.

Download figure:

Standard image High-resolution imageFor hollow carbon-based ORR catalysts containing metal species, the investigation of metal-based active sites at the atomic level on the carbon substrate is a hot research topic. Single-atom catalysts (SACs) have a theoretical 100% utilization of metal sites, thus significantly reducing the use of metal. Therefore, the combination of an SAC and a hollow carbon-based catalyst can largely control the production cost of ORR catalysts. As a typical example, Li et al [84] synthesized a catalyst with isolated single Co atomic sites fixed to hollow carbon spheres through a template-assisted pyrolytic (TAP) method (figure 11(e)). SiO2 and Co-TIPP were selected as the template and the cobalt source, respectively. As confirmed by the Fourier-transformed (FT) k3-weighted extended x-ray absorption fine structure (EXAFS) spectrum, the single Co atoms were atomically dispersed on the hollow carbon spheres with a coordination number of four (figure 11(f)). As an ORR catalyst, the hollow material displayed excellent catalytic activity, comparable to that of Pt/C in acidic media (figure 11(g)). The authors then compared this kind of hollow sphere with the same hollow sphere without an isolated single atom of Co and a solid ball with a single atom of dispersed Co. It was concluded that both the hollow structure and the single point gave the catalyst excellent ORR performance. A subsequent stability test showed that the hollow spherical catalyst had good cyclic stability due to the strong interaction between the single atomic Co site and the carbon substrate, and that the hollow spherical substrate was able to maximize the exposure of the active site and enhance the mass transfer of the catalyst.

Owing to the diversity and controllability of the structure and the composition of the precursors, hollow carbon-based composites obtained by the pyrolytic method using other organometallic complexes are another hot research direction. As an example, metal-organic frameworks (MOFs) are ideal precursors for the synthesis of many carbon-based functional materials with versatile morphologies and chemical compositions [85]. For example, Guan et al [86] synthesized a single-hole Co/N doped carbon hollow sphere from MOF precursors (figure 11(h)). Polystyrene (PS) spheres were selected as hard templates for the self-assembly of ZIF-67 NPs. The subsequent annealing treatment consumed the inner PS core and transformed the ZIF-67 into Co/N-doped carbon. The fast release of the gaseous product left a single hole in the sphere (figure 11(i)). An electrochemical test in 0.1 M KOH showed that the single-holed Co/N-doped hollow carbon spheres had a comparable ORR performance to that of Pt/C, with a half-wave potential of 0.87 V, and better tolerance for methanol (figure 11(j)). The reason for the excellent catalytic performance and stability is that the single-holed hollow structure greatly improves the mass transfer of the catalyst, while the active Co sites and N species are highly separated within the carbon shell.

Concluding remarks

The development of cheap and efficient ORR catalysts that can replace Pt/C is crucial to the commercialization of the related energy technologies. Carbon-based hollow materials have been widely investigated as promising ORR catalyst materials. In this review, we briefly discussed three potential research directions for the design of carbon-based hollow catalysts. However, there are still many problems with hollow carbon-based materials. The large consumption of templates is a big issue in the preparation of hollow structures. Besides, reaching a balance between the conductivity and the mechanical strength of carbon-based catalysts is critical, especially for hollow structures. Nevertheless, with progress in hollow materials and surface engineering, the performance of hollow materials will be improved, and the use of precious metals will be further reduced.

Acknowledgments

LY acknowledges the National Natural Science Foundation of China (Grant No. 51902016) and the financial support of the Fundamental Research Funds for the Central Universities (Grant No. buctrc201829). NWL acknowledges the financial support of the Fundamental Research Funds for the Central Universities (Grant No. buctrc201904).

6. Carbides for ORR

Chenhuai Yang and Zhicheng Zhang

Tianjin Key Laboratory of Molecular Optoelectronic Sciences, Department of Chemistry, School of Science, Tianjin University and Collaborative Innovation Center of Chemical Science and Engineering (Tianjin)

Status

Among green energy conversion technologies, fuel cells can directly and efficiently convert chemical energy into electrical energy, giving rise to water only, and not pollution. For fuel cells, the cathodic ORR is the rate-limiting reaction, due to its naturally complex and sluggish kinetics during electron transfer [87–89]. The mechanism of the ORR is rather complicated and mainly depends on the nature of the electrode and electrolyte, which has a crucial effect on the catalytic performance [90]. Hence, the rational design and synthesis of efficient ORR electrocatalysts with high onset potentials, low overpotentials, and high catalytic currents are important to the development of fuel cells. Currently, platinum (Pt) electrocatalysts still exhibit unparalleled catalytic performance for the ORR. However, scarcity of resources, high cost, sluggish ORR kinetics, and inferior operational stability due to deactivation by CO poisoning and the crossover effect hamper the commercial application of fuel cells. Therefore, it is desirable to replace Pt-based catalysts with new materials to make fuel cells useful for practical applications. Among various candidates, transition metal carbides (TMCs) have attracted intense interest for use as ORR electrocatalysts, which may be due to the following advantages: benefiting from an interstitial alloy structure, TMCs have advantageous properties such as high melting points, high electronic conductivity, excellent chemical stability and good corrosion resistance [91, 92]. Moreover, the group IVB-VIIIB TMs can alloy with carbon to form TMCs; these normally have formulas such as MC, M2C, and M3C and are made by controllable synthesis methods (e.g. carbothermal reduction, templates, MOF-assisted strategies, and so on), which greatly expand the number of TMCs [93].

Some bimetallic carbides such as Co6Mo6C and Fe2MoC have also been successfully prepared, enriching the range of TMCs available for use in ORRs [94]. Most importantly, their noble-metal-like electronic structures allow them to manifest a Pt-like nature in electrocatalysis, which ensures and even improves the catalytic efficiency of the ORR [95]. To improve their electrocatalytic activity and stability, TMCs have been encapsulated in carbon-based materials (e.g. CNTs, graphene). The introduction of these conductive supports is critical to improve the dispersity of downsized TMCs and strengthen the active sites via physicochemical coupling with TMCs. For instance, Wen et al reported a facile, scalable, cost-effective method to prepare core–shell structured N–Fe/Fe3C@C nanorods (Fe/Fe3C nanorods as the core and graphitic carbon as the shell) as electrocatalysts for ORR. The stability of the catalyst increased in neutral phosphate buffer solution (PBS) due to the complete enclosure of the (Fe/Fe3C) core by the graphitic carbon [96]. Moreover, the one-dimensional structure of the catalyst provided increased ORR active sites and exhibited a high ORR performance with a positive onset potential of 0.21 V. Yang et al reported a one-step soft-template-induced strategy for the controlled synthesis of bamboo-like carbon nanotube (b-CNT)/Fe3C nanoparticle hybrids (BCNFNHs) [97]. The BCNFNHs formed were highly active and stable catalysts for the ORR in both alkaline and acidic solutions. Specifically, the halfwave potential of the ORR using BCNFNHs reached 0.861 V vs. RHE in 0.10 M KOH, which is more positive than that of 20 wt% Pt/C (0.812 V vs. RHE). Furthermore, the BCNFNHs showed an ORR onset potential comparable to that of a Pt/C catalyst in an acidic solution. The BCNFNHs also exhibited outstanding stability and methanol tolerance, showing no ORR polarization curve shift and no cyclic voltammetric (CV) current changes in the presence of 1.0 M MeOH under both alkaline and acidic conditions.

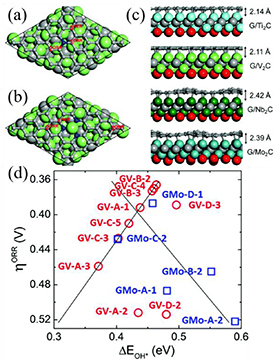

Furthermore, TMCs can serve as versatile backbones/supports for other active materials, thereby forming multicomponent composites for the ORR. Based on first-principle DFT calculations, Zhou et al investigated the electrocatalytic properties of the heterostructures of N-doped graphene supported by TMCs (G/Ti2C, G/V2C, G/Nb2C and G/Mo2C monolayers) (figures 12(a)–(c)) [98]. Graphitic sheets hybridized with V2C and Mo2C monolayers showed enhanced ORR activity. Hollow-site C atoms located close to pyridinic N dopants were the most active sites and exhibited low overpotentials of 0.36 V (G/V2C) and 0.39 V (G/Mo2C) in the ORR (figure 12(d)). Considering their low cost, high stability, good activity, and Pt-like electronic structure, the use of TMCs instead of carbon to support Pt metal can effectively improve metallic stability and reduce Pt loading. Furthermore, because of the large binding energy of Pt-TMC, supporting Pt on TMCs hampers metal particle agglomeration. Xie et al reported that Pt combined with Ti3C2Tx was able to boost ORR activity with improved durability [81]. After 10 000 cycles, the half-wave potentials of the Pt/Ti3C2X2 did not visibly decrease, signifying the high electrochemical stability of the Pt/Ti3C2T2 catalyst.

Figure 12. (a), (b) Top views of N-doped graphene supported by the V2C MXene monolayer, with N dopants in the graphitic and pyridinic forms, respectively. The red numbers indicate the active sites for the ORR and HER. (c) Side views of N-doped graphene on Ti2C, V2C, Nb2C and Mo2C MXene monolayers, respectively. The interlayer distances are shown for each system. The C, N, O, Ti, V, Nb, and Mo atoms are shown in grey, blue, red, cyan, green, dark green and turquoise colors, respectively. (d) Volcano plots of ORR overpotential vs. OH* binding energy [99]. 'GV' and 'GMo' are abbreviations for G/V2C and G/Mo2C, respectively.

Download figure:

Standard image High-resolution imageCurrent and future challenges

Considering the significant advantages of TMCs, they will become a potential replacement for costly Pt-based catalysts. However, research into TMC-based electrocatalysts is in the early stages, and the future development of highly efficient TMCs still involves huge challenges, as follows.

- (a)Highly active TMCs with controlled/specific structures and crystal planes are normally obtained via solid-state reactions in a multistep process and using high-temperature treatments, which limit their large-scale controllable synthesis. Therefore, efficient, low-cost, and green methods should be explored for the facile synthesis of enhanced-performance TMCs.

- (b)For practical applications, it is vitally important to reduce the cost of TMC-based electrocatalysts and carbide loading and produce carbide under mild conditions. Hence, it is desirable to develop TMC-based electrocatalysts that have multiple functionalities and are highly compatible with the ORR in chemical environments with complicated species and highly variable parameters.

- (c)The surfaces of TMCs are easily oxidized, which limits their application in the ORR. Efficient strategies (e.g. metal functionalization) should be developed to enhance the stability of TMC-based electrocatalysts and improve OER performance by avoiding the oxidation of TMCs. Moreover, most of these emerging catalysts are completely inactive in acidic solutions. Extensive studies are required to understand the reason for this.

- (d)The electrochemical reaction mechanisms of ORRs based on TMCs are not well understood from the perspectives of thermodynamics and kinetics. The active sites of metal carbides are not clearly known. Hence, a methodology for the real-time precise monitoring of the dynamic variation of reaction intermediates on a catalyst's surface needs to be established, by combining advanced in situ operando techniques (such as in situ Raman spectroscopy, x-ray photoelectron spectroscopy (XPS), and synchrotron x-rays) to understand the mechanisms involved.

Concluding remarks

We described the current bottleneck of traditional Pt-based catalysts and highlighted the recent trends and great effort invested in TMC-based electrocatalysts for the ORR. We demonstrated that TMCs can be used as electrocatalysts or supports to improve the catalytic performance of the ORR. Despite the various challenges mentioned above, the field of carbide-based electrocatalysts for ORRs is a new frontier in research, with unlimited prospects and opportunities.

7. Atomically dispersed Fe–N–C catalysts for ORR

Yanyan Zhao

Rowland Institute at Harvard University

Status

The electrochemical ORR has attracted extensive attention due to its application in fuel cells [82]. The precious‐metal‐group (PMG) materials, such as Pt and Pd, are generally efficient electrocatalysts for ORR, however, their high prices and poor CO tolerance have hindered their large‐scale application. Therefore, it is necessary to replace the PMG materials with earth‐abundant catalysts but without sacrificing stability and activity. Currently, Fe–Nx –Cy catalysts are considered to be the most promising ORR catalysts due to their superior catalytic performance and are regarded as promising substitutes for PMG catalysts [100–102].

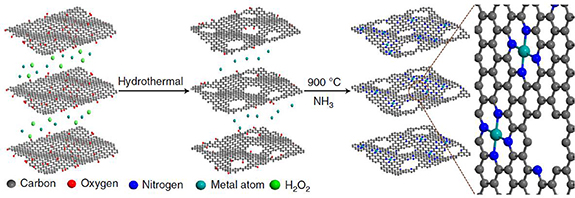

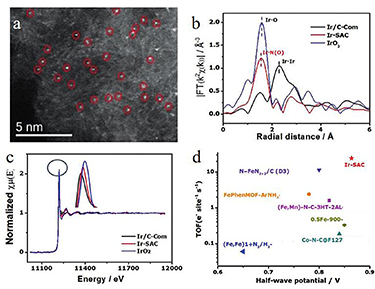

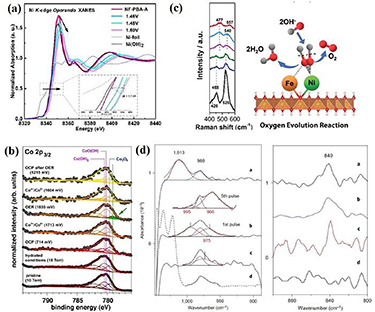

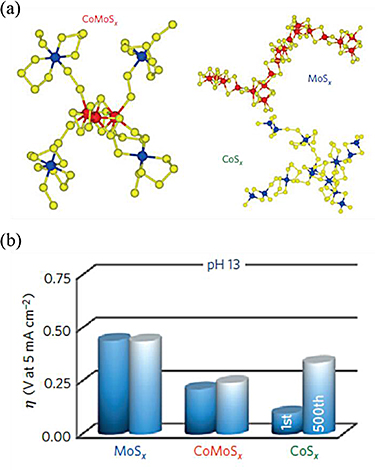

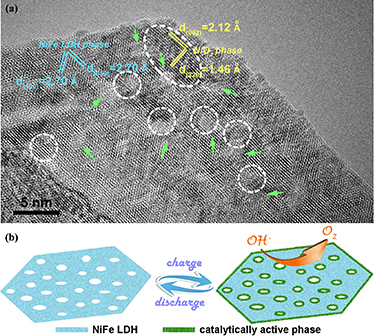

The sum of the existing knowledge inspires the researcher to recognize the importance of catalysts with well-defined structures. To meet this need, researchers first aimed to prepare an atomically dispersed catalyst with Fe metal centers within N or C frameworks. For instance, such a catalyst can be prepared by mixing the metal precursor and graphene-based materials using a sequential annealing process (figure 13) [83]. To get a clear picture of the prepared motif at the atomic level, microscopic and spectroscopic techniques are coordinated (figure 14). For the characterization of the Fe metal, the most direct evidence is obtained by high-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) [103]. The bright spot highlighted in the background usually represents the metallic center. However, the microscopic data usually serves as a platform for the identification of the location. To further explore the local chemical information of the metal center, HAADF-STEM can also be combined with electron energy loss spectroscopy (EELS) to detect the coordination environment of target metal sites. For instance, Zelenay and co-workers applied high-resolution EELS to confirm the presence of adjacent N atoms around an Fe center [103]. Also, quantification of the Fe-to-N ratio from the EELS data helps to confirm an average composition. However, in some cases, the resulting catalysts might not exhibit adequate stability for high-resolution characterization. When studied by high-intensity experimental tools such as STEM, an atomically dispersed motif might undergo structural evolution, rendering structural information at the atomic level elusive. To partially address this challenge, spectroscopic studies such as X-ray absorption spetroscopy (XAS), including X-ray absorption near edge structure (XANES), and Extended X-ray absorption fine structure (EXAFS) spectra have also been developed to explore the average coordination environment of Fe [104]. XANES can help to identify the chemical valence state and spatial configuration, while EXAFS serves as a tool to identify the coordination numbers of Fe–N (first shell) and Fe–C (second shell). While Fe–Nx–Cy have been shown to be active in the ORR, there is still a debate about whether Fe2+ or Fe3+ is the active species. The answer to this will require XAS coordinated with Fe Mösbauer spectroscopy based on the recoil-free absorption of γ rays from Fe57 nuclei [82, 105]. A change in the coordination environment leads to a difference in isomer shift and quadrupole splitting. What is more, during the reaction, the valence state switch could also be observed by in-situ XAS and the atomic state could be monitored by in-situ STEM. Besides a detailed exploration of the coordination environment of the Fe center, the other key information is the chemical environment of the N. Similarly, when the researchers examined the performance of the ORR, the ratios of different kinds of N resulted in a divergence in terms of activity and selectivity. This observation begs the question: which N is necessary to achieve high performance? X-ray photoelectron spectroscopy (XPS) can be used to confirm the N species in the catalyst, such as pyridinic N, pyrrolic N, or graphitic-like N. Also, the dynamic state of N during the reaction can be monitored by an in-situ technique such as in-situ XPS or XAS. By combining these multiple pieces of information, a clear picture can be obtained of the detailed structure, oxidation state, and spin states of the Fe–Nx–Cy active sites.

Figure 13. A typical method for preparing a well-defined MNx Cy (M=Fe, Co or Ni) atomic motif. A graphene oxide (GO) solution was mixed with H2O2 and an Fe precursor. The mixture was hydrothermally reacted to form graphene hydrogel. By sequent thermal annealing in an NH3 atmosphere, an atomically dispersed M–Nx–Cy motif was prepared. Reprinted and reused with the permission from [83], Copyright © 2018, Huilong Fei et, Springer Nature.

Download figure:

Standard image High-resolution imageFigure 14. A clear picture of the prepared motif at the atomic level, obtained by microscopic and spectroscopic techniques.

Download figure:

Standard image High-resolution imageCurrent and future challenges

Fe–Nx–Cy catalysts have usually been prepared through the pyrolysis of molecular or polymeric precursors which contain metal centers, N– and C–containing ligands. Due to the heterogeneity of the prepared catalysts, the metal centers have a variety of chemical valences and C or N atoms are embedded in a diversified coordination environment [106]. The lack of a clear atomic picture of Fe–NX–Cy and the absence of an understanding of the ORR mechanism at the molecular level are the main challenges in expediting the development of this catalyst [107]. Although significant progress in terms of ORR performance has been reported in a large number of published works, these efforts face an important caveat: the active sites are not well defined. Because of this, enhancement of the performance mainly relies on trial and error. A variety of reasons are the cause of this issue [82, 83]:

- (a)The difficulty of preparing Fe–Nx–Cy catalysts free of metal nanoparticles, especially under annealing conditions.

- (b)Lack of comprehensive and accurate characterization tools for determining the structural details of the active sites, including both metal sites and N- or C-containing ligands.

- (c)The difficulty in distinguishing the individual role of N-doped C structures and metal sites. Moreover, the synergistic effect is not clearly understood at present.

Concluding remarks

Detailed structural information about active sites would make it much easier to capitalize on the molecular identities of catalysts to systematically study their mechanisms, which is critical to further performance optimizations. Moreover, knowledge about the dynamic nature of the active sites obtained by in-situ methods would help to unveil the whole catalytic process.

8. Metal-free catalysts for ORR

Hamna Zia and Farhat Nosheen

SA-CIRBS, International Islamic University Islamabad, Pakistan and Department of Chemistry, Division of Science and Technology, University of Education

Status

For important industrial processes, catalysts of metals and metal oxides are used for clean energy storage, energy generation, and material production. However, due to the high cost, poor durability, and low selectivity of these catalysts, certain problems must be solved. They also suffer from CO deactivation, are highly susceptible to gas poisoning and time-dependent drift, and have various harmful impacts on the environment. Furthermore, the worldwide commercial large-scale application of these renewable energy technologies has been hindered by the scarcity of precious metals [108–110]. Currently, fast and dynamic development is underway to replace metal-based catalysts with abundant, cheap, and high‐performance ORR electrocatalysts [111]. Up until now, various metal-free electrocatalysts have been synthesized, among which, carbon‐based metal-free catalysts have been reported to exhibit outstanding ORR electrocatalytic activity due to their high stability and good tolerance. Moreover, the constituents of these metal-free catalysts are highly abundant [99], and they also have the advantages of high energy conversion efficiency, low energy consumption, good corrosion resistance, and a wide application range. Therefore, they are considered as potential alternatives to metal-based catalysts [112].

Since the discovery of these metal-free catalysts, the overall cost has been dramatically reducedand the efficiency of renewable technologies has increased. These renewable technologies can alter our daily lives by providing us with very clean, renewable and efficient energy from water and sunlight [113]. Since the 1960s, research has been carried out to find effective alternatives to replace platinum catalysts [114]. Alloying platinum with some non-precious metals such as iron, cobalt, nickel, etc, was found to be a promising approach, but it was still not very effective for practical applications, due to the cost, scarcity, and limited reserves of platinum [78]. Stable, efficient, and low-cost catalysts are highly desirable to cater to large-scale applications. After intensive research efforts for over half a century to develop a metal-free catalyst for ORR, finally, the overall cost was dramatically reduced when vertically aligned nitrogen-doped carbon nanotubes (VA-CNTs) arrays were discovered in 2009 [6]. They exhibited a three-fold increase in electrocatalytic activity and high stability in comparison with commercially available platinum/C electrodes for ORRs in alkaline media and did not suffer from CO deactivation and methanol crossover. Later, several carbon-based metal-free heteroatom-doped catalysts were reported due to rapid development in the field of metal-free catalysis, for example: sulfur-doped graphene, boron-doped CNTs, phosphorus-doped graphite, edge-halogenated doped graphene nanoplatelets, iodine-doped graphene layers, phosphorous and nitrogen co-doped VA-CNTs, boron and nitrogen co-doped graphene, sulphur and nitrogen co-doped CNTs, nitrogen-doped ordered mesoporous graphitic arrays, quantum dots (QDs) supported by graphene nanoribbons, phosphorus-doped graphite layers, and nitrogen and sulfur co-doped graphene QDs [115].

Current and future challenges

Metal-free catalysts have seen great progress and development during the last decade. However, until now, the development of a carbon-based metal-free catalyst for ORR catalysis (defect-induced) is in the premature stage; therefore, further research is required to understand the overall mechanism. Metal-free catalysts will not be able to compete with metal-based catalysts until the following challenges have been resolved:

- (a)For alkaline solutions, some of the carbon-based metal-free ORR catalysts show similar or even better ORR activity compared to Pt/C, but in acidic media, most of these carbon-based catalysts show poor ORR activity compared to Pt/C.

- (b)The literature hardly explains the reduction of carbon dioxide by carbon-based metal-free catalysts. Up until now, no standard evaluation protocol has been applied using practical devices to check the long-term durability of metal-free catalysts, which can cause a hindrance for the commercial application of metal-free catalysts.

- (c)The multi-doping of sp2 carbon materials to achieve high ORR activity is a promising approach. To benefit from synergistic effects that are aroused by the multi-doping of carbon materials, the configuration of the dopants must be regulated and studied thoroughly by paying attention to all possible aspects. This may be helpful to the electrocatalytic performance of carbon materials in ORRs.

- (d)Surface active sites have a significant role in the reduction of current density and are the place where the ORR proceeds. There are huge numbers of topological defects present in active sites, giving a better onset potential, and thus making them highly active for the ORR. Moreover, a severe difficulty occurs for the ORR due to the low electron conductivity that is caused by large active sites. Hence, to optimize the performance of carbon‐based ORR electrocatalysts, a good balance between surface active sites and electron conductivity is necessary. Since the ORR involves multiple steps, and many intermediate species are formed, the handling of multiple defects and doping configurations becomes more complex and complicated.

- (e)The fabrication and design of catalytic materials and electrodes require structural evaluation and control at the molecular and macroscopic levels to form appropriate multi-scale hierarchical structures for optimized catalytic performance.

- (f)Novel doping or synthetic methods should be developed to control the location, distribution and content of dopants in heteroatom-doped carbon catalysts precisely.

- (g)The development of combined experimental and theoretical approaches is essential to understand the kinetics, mechanism and structure of the catalytic center.

- (h)The application of these catalysts in gas-phase reactions (for example, to the oxidative dehydrogenation of alkanes) has been very limited; their application in other new reaction systems must be expanded on an urgent basis.

- (i)Several basic factors are still unclear, for example, the exact role of the interface, the reaction mechanism, and the nature of the active sites during catalytic processes. A reliable identification method is needed that must identify functional groups and their structural defects and properties.

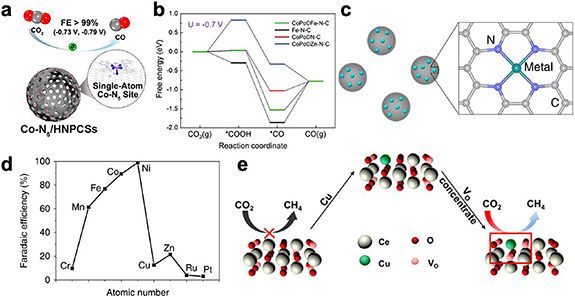

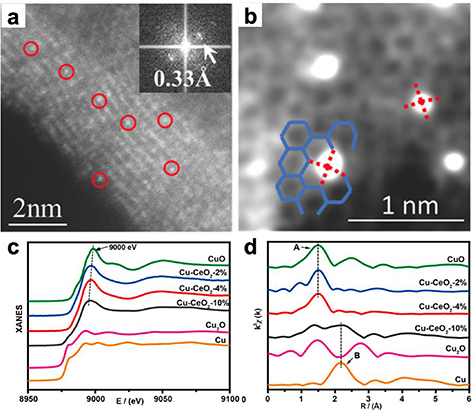

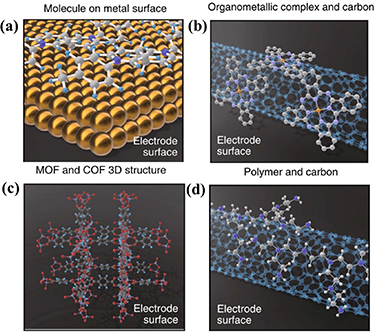

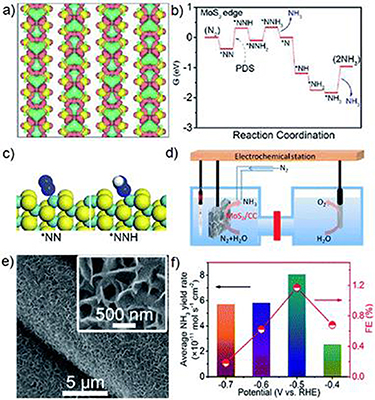

- (j)The impact of metal impurities on catalytic activity is still unknown. These metal impurities are present in trace amounts in the reaction mixture.