Abstract

In this work, we have experimentally demonstrated the ultrafast laser in Erbium-doped fiber laser using MoS2 as saturable absorber. The MoS2 SA in this work is prepared by bottom-up method. A three-electrode configuration is used to perform the electrodeposition to coat the MoS2 onto conductive film. The MoS2 saturable absorber is incorporated into the fiber laser system to induce mode-locking operation centered at 1560.8 nm. The proposed saturable absorber has achieved pulse width of 1.47 ps, with highest average pulse energy of 0.44 nJ and repetition rate of 1.88 MHz. The venture of electrodeposition coated MoS2 thin film as saturable absorber is potentially to pave the foundation toward the sustainable industry, innovation and infrastructure.

Export citation and abstract BibTeX RIS

Original content from this work may be used under the terms of the Creative Commons Attribution 4.0 licence. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

Introduction

In year 2023, the Nobel Prize in Physics has been awarded to Pierre Agostine, Ferenc Krausz and Anne L'Huillier for their contributions in creating ultrafast pulses of light that can give a snapshot of changes within atoms [1]. Undoubtedly, ultrafast phenomena play an important role for current and future technologies. In current industrial application ultrafast lasers are used for high-precision micromachining and surface structuring of emerging materials [2], particularly in semiconductor and electronics industries for cutting and drilling microstructures [3]. In medical applications, ultrafast lasers are employed in laser eye surgery and dental treatments. Their ability to remove tissue with minimal thermal damage makes them suitable for delicate surgical procedures [4]. Toward the future technologies, ultrafast lasers continue to drive the advancement in attosecond science, which open new possibilities for understanding and manipulating electronic processes at the atomic and subatomic levels [5].

The generation of ultrafast laser in fiber laser system are relied on saturable absorber (SA). The SAs can be made by emerging materials or formation of optical components that function as artificial SA. The formation of artificial SAs are including nonlinear polarization rotation (NPR) [6], nonlinear amplifying loop mirror (NALM) [7] and nonlinear optical loop mirror (NOLM) [8]. The emerging materials that had been reported as SA are including carbon nanotube (CNT) [9], topological insulators (TIs) [10], transition metal dichalcogenides (TMDs) [11] etc. Among the emerging materials, many of the TMD members have presented their potential in ultrafast laser generation, such as MoS2 [12], MoSe2 [13], MoTe2 [14], WS2 [15], WSe2 [16] NbxRe(1-x)S2 [17], PdSe2 [18], and SnS2 [19]. The fabrication methods of TMD SA in fiber laser system are normally using top-down methods, such as liquid phase exfoliation (LPE) [20] and mechanical exfoliation [21]. LPE method required complicated and costly chemical processes, whereas mechanical exfoliation method is difficult to achieve homogenous layer SA [11]. Therefore, alternative fabrication method of saturable absorber is one of the highlighted research direction.

In this work, we have experimentally demonstrated the ultrafast laser in Erbium-doped fiber laser (EDFL) using MoS2 as SA. Owing to the exceptional optical properties, MoS2 has proven its potential in ultrafast laser generation, including vector soliton [22] and dissipative soliton [23]. Unlike the typical top-down method, the MoS2 in this work is prepared by bottom-up method. A three-electrode configuration is used to perform the electrodeposition to coat the MoS2 onto conductive film. As compared to top-down methods, the proposed electrodeposition is more cost effective and more feasible to control the thickness by control the deposition time. From the ultrafast laser performance using the proposed MoS2 SA, pulse width of 1.47 ps, with highest average pulse energy of 0.44 nJ and repetition rate of 1.88 MHz has recorded.

MoS2 thin film preparation & characterization

For the preparation of MoS2 thin film, a mixture of molybdic acid H2MoO4 in ammoniacal solution of pH 9.3 ± 0.2 having concentration of 0.5 M with sodium thiosulphate pentahydrate Na2S2O3 . 5H2O is used as electrolyte ions precursors. For the synthesis of MoS2 , the electrolyte mixture ratio between the precursor solution of H2MoO4 and Na2S2O3 . 5H2O is selected to be 1:2 following its stoichiometry. The electrodeposition of MoS2 is carried out using Admiral Squidstat potentiostat. A three-electrode configuration is used for the cyclic voltammetry analysis and electrodeposition of the thin film as shown in figure 1. The electrolysis cell consists of ITO-coated conductive film been assigned as the working electrode (WE) where the MoS2 thin film is to be deposited. On the other hand, graphite rode work as the counter electrode (CE) while a saturated calomel electrode (SCE) with Ag/AgCl reference system work as the reference electrode. For precaution, the spacing among these 3 electrodes must be carefully positioned to get maximum deposition. The working electrode and counter electrode are placed with 1 cm distance, and both the surfaces facing each other were kept parallel so that the released ions will be attracted and deposited exactly perpendicular to the substrate surface. The function of the reference electrode (SCE) is used to measure the potential of the working electrode and placed very close to the working electrode so that the exact potential at the surface will be monitored and unaffected by the solution resistance (internal resistance of the cell). The deposition of thin film is carried out for 15 s with temperature of 40±1 °C. It is worth to note that the thickness is sensitive to deposition time. Thus, the MoS2 SA using electrodeposition method is highly reproducible with precise deposition time control. Based on the Scanning Electron Microscopy (SEM) analysis as shown in figure 2, we confirm the MoS2 has coated onto the conductive film in small flakes structure. From the Energy dispersive x-ray (EDX) analysis, both Mo and S are tangibly appeared on the conductive film with the approximate ratio of 1:2. As saturable absorption is the most crucial optical characteristic to induce mode-locking operation in laser system, we have conducted a twin-detector method to confirm the saturable absorption as shown in figure 3. Based on the obtained results, the saturable absorption is measured as 3.4%, which are comparable to other fabrication techniques [11].

Figure 1. MoS2 thin film preparation.

Download figure:

Standard image High-resolution imageFigure 2. SEM and EDX analysis.

Download figure:

Standard image High-resolution imageFigure 3. Modulation depth analysis.

Download figure:

Standard image High-resolution imageExperimental setup

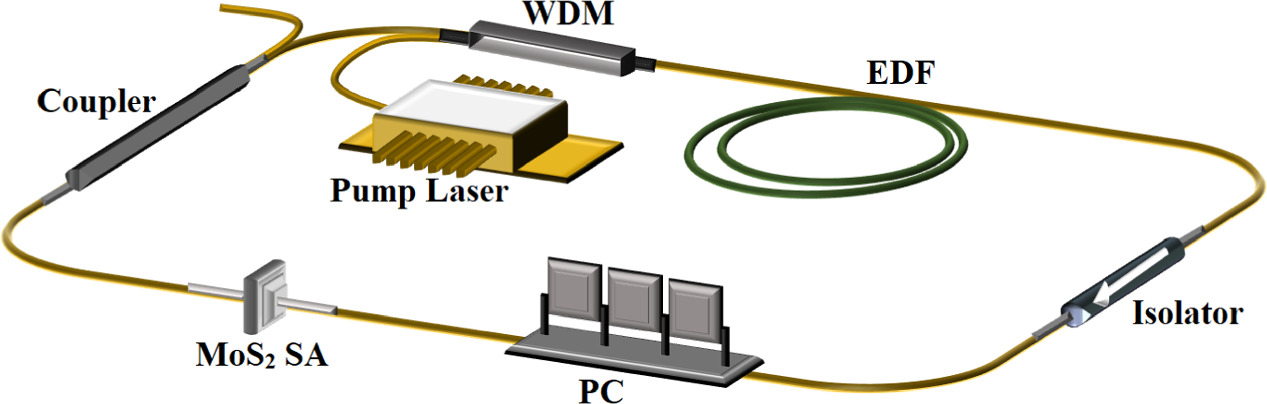

The ultrafast laser is experimentally visualized in a typical ring Erbium-doped fiber laser (EDFL) as shown in figure 4. A 980 nm butterfly laser diode is used as a pump laser to induce population inversion in the gain medium. A wavelength division multiplexer is used to combine 980 nm and 1550 nm lasing to circulate in the ring cavity. A 1 m EDF is used as a gain medium to absorb 980 nm light spectrum and to produce ∼1550 nm lasing. An isolator is connected to the EDF to eliminate the bi-directional photon emission from the gain medium. A polarization controller in the cavity is used to adjust the polarization state of light circulation that favourable for pulse optimization. The MoS2 thin film with insertion loss of 2.86 dB is incorporated into the ring cavity using sandwiched technique. A coupler is used to tap 10% of light out from the ring cavity for further investigation. The wavelength domain, frequency domain and time domain are investigated using optical spectrum analyzer (OSA, Anritsu MS9710C), RF spectrum analyzer (MS2830A) and oscilloscope (GW Instek GDS-3352) respectively. Due to the constrain of the oscilloscope, an autocorrelator (Alnair Labs HAC-200) is used to investigate the pulse width in pico/femtosecond region.

Figure 4. Experimental setup of mode-locked EDFL.

Download figure:

Standard image High-resolution imageResults and discussion

Initially, the ring laser cavity is operated in continuous wave (CW) region. With the increase of pump power to 78.5 mW, the laser cavity self-started into the mode-locking operation. The cavity is stably operated in mode-locking operation with the increase of pump power between 78.5 mW to 142.8 mW (limited by maximum pump power of the laser diode). The spectrum of the mode-locked laser is centered at 1560.8 nm, with 3 dB spectral bandwidth of 2.4 nm as illustrated in figure 5. As the ring EDFL is operated in anomalous dispersion, the typical soliton characteristic [24], Kelly's sideband [25] is tangibly observed in the optical spectrum.

Figure 5. Optical spectrum of mode-locked EDFL at pump power of 142.8 mW.

Download figure:

Standard image High-resolution imageThe mode-locking operation is more observable in time domain, as shown in figure 6(a). The repetitive pulse train is captured in the oscilloscope, with pulse repetition rate of 1.88 MHz. The round trip time of 532 ns is well tallied with the cavity length of 103 m. The pulse width was not able to measure accurately due to the limitation of oscilloscope. Therefore, an oscilloscope is used to perform the autocorrelation based on Sech2 fitting to measure the pulse width. As illustrated in figure 6(b), the measured pulse is well fitted with Sech2 fitting, and to obtain the pulse width of 1.47 ps.

Figure 6. (a) Mode-locked pulse train and (b) autocorrection trace for mode-locked pulse width.

Download figure:

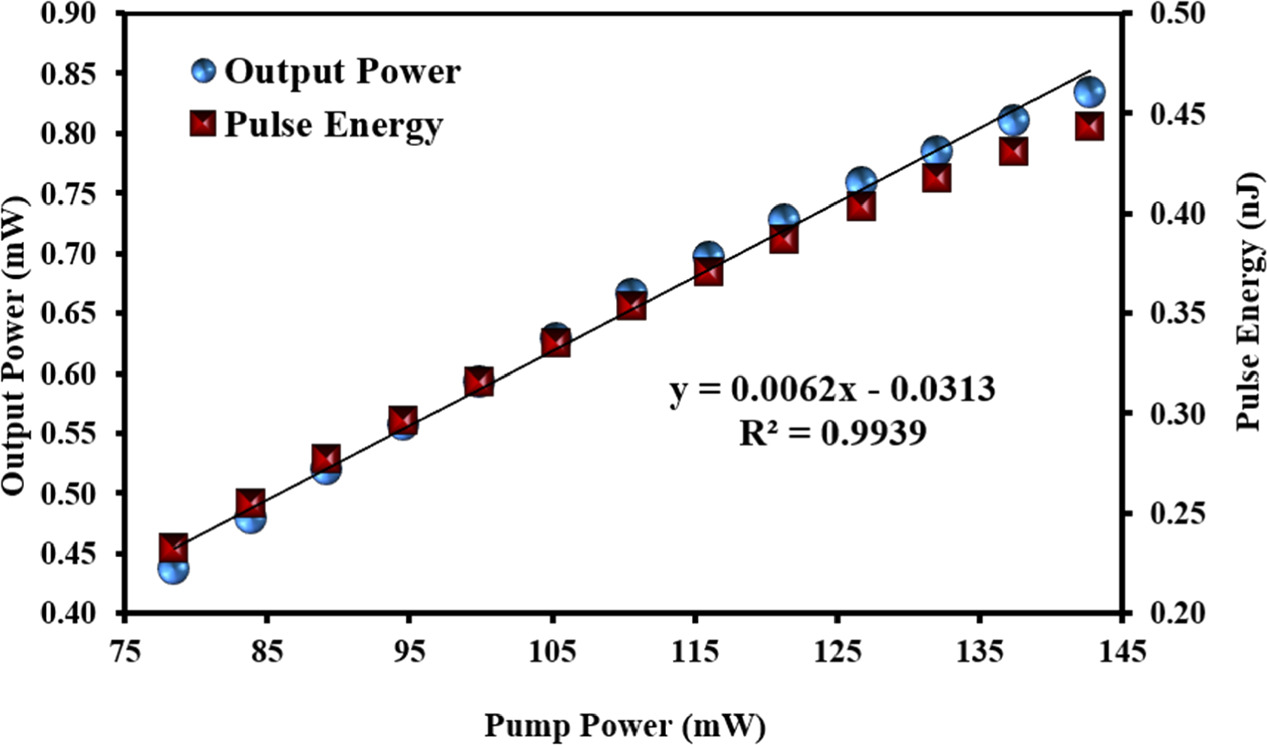

Standard image High-resolution imageThe output power and average pulse energy are further analyzed as shown in figure 7. With the increase of pump power from 78.5 mW to 142.8 mW, both output power and average pulse energy increase linearly, with R2 value of 0.9939. Along the pump power tuning range, the output power is recorded from 0.44 mW to 0.83 mW, which gives the laser efficiency of 0.62%. Besides, the highest average pulse energy is recorded as 0.44 nJ at pump power of 142.8 mW. The mode-locking operation is constrained by the maximum power of the pump laser diode, the SA are highly potential to operate at pump power beyond 142.8 mW.

Figure 7. Output power and average pulse energy analysis with the increase of pump power.

Download figure:

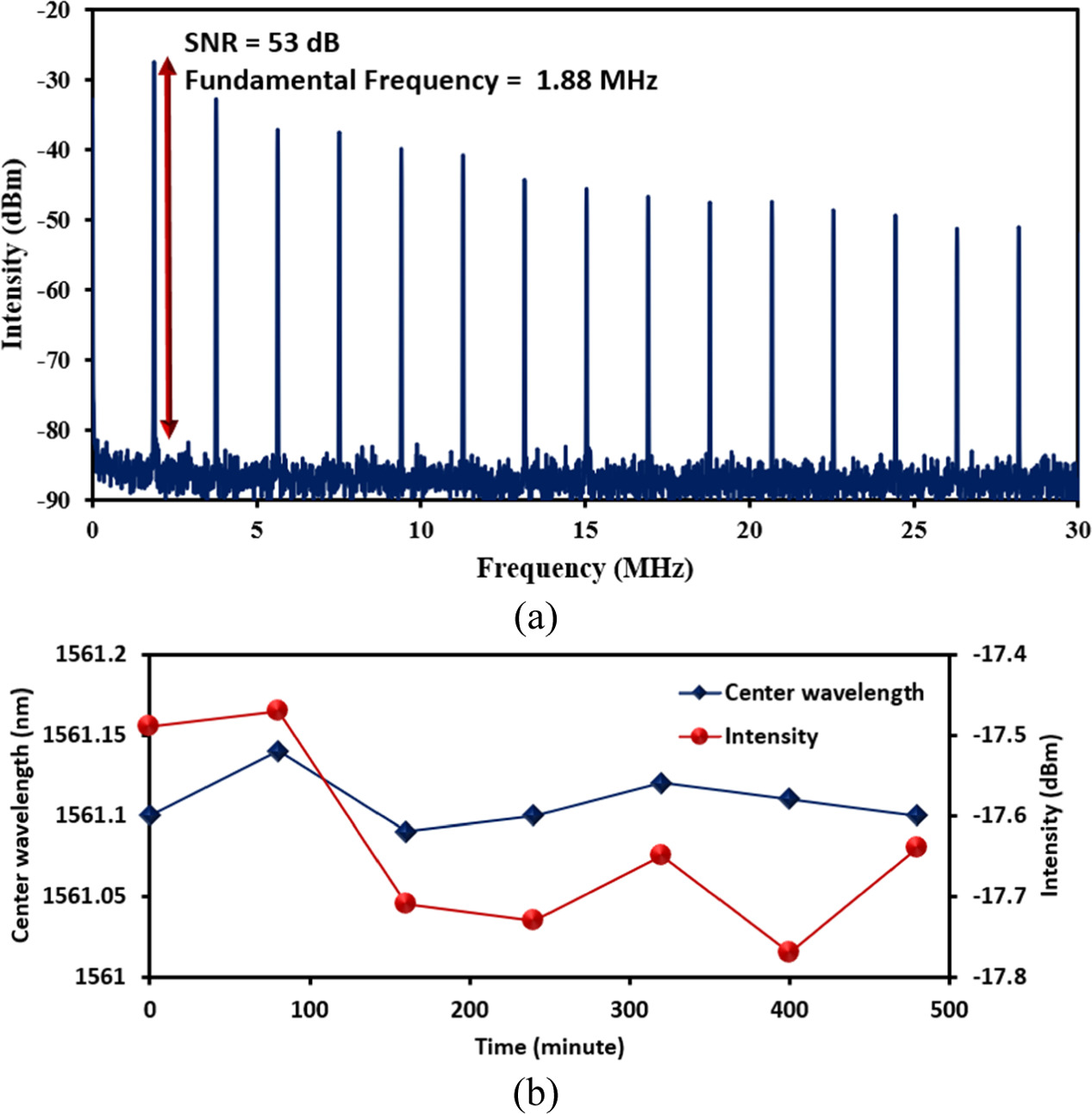

Standard image High-resolution imageOn the other hand, the stability of the mode-locked laser is investigated in frequency domain as shown in figure 8(a). The fundamental frequency is recorded as 1.88 MHz, which is well agreed with the pulse repetition rate in time domain. The signal-to-noise ratio is recorded as 53 dB, indicating the mode-locked laser is highly stable. The mode-locked laser has been continuously operated in laboratory environment for about 8 h, there is no significant wavelength shift (<0.5 nm) or intensity degradation (<0.3 dB) along the operation period as shown in figure 8(b).

Figure 8. (a) RF spectrum of the mode-locked laser and (b) stability test based on optical spectrum.

Download figure:

Standard image High-resolution imageConclusion

In this work, we have achieved the mode-locking operation in Erbium-doped fiber laser using MoS2 as saturable absorber. The MoS2 SA in this work is prepared by electrodeposition method. A three-electrode configuration is used to perform 15 s electrodeposition to coat the MoS2 onto conductive film. The saturable absorption of MoS2 saturable absorber is reported as 3.4%. The MoS2 saturable absorber is incorporated into the fiber laser system to induce mode-locking operation centered at 1560.8 nm. The proposed saturable absorber has achieved pulse width of 1.47 ps, with highest average pulse energy of 0.44 nJ and repetition rate of 1.88 MHz.

Data availability statement

The data cannot be made publicly available upon publication because they contain commercially sensitive information. The data that support the findings of this study are available upon reasonable request from the authors.