Abstract

Substitution of wood for more fossil carbon intensive building materials has been projected to result in major climate mitigation benefits often exceeding those of the forests themselves. A reexamination of the fundamental assumptions underlying these projections indicates long-term mitigation benefits related to product substitution may have been overestimated 2- to 100-fold. This suggests that while product substitution has limited climate mitigation benefits, to be effective the value and duration of the fossil carbon displacement, the longevity of buildings, and the nature of the forest supplying building materials must be considered.

Export citation and abstract BibTeX RIS

Introduction

Forest ecosystems represent important stores of global terrestrial carbon and are the focus of possible climate mitigation strategies [1–3]. Along with that stored in forest ecosystems, carbon can be stored in wood products in-use and after disposal [4, 5]. Another way forests could mitigate climate change is through product substitution, a process whereby products from the forest substitute for others (i.e. concrete and steel) which, if used, would result in more fossil carbon release to the atmosphere [6–16]. While wood-based building materials generally embody less fossil-derived energy in their manufacture than steel and concrete, resulting in a net displacement of fossil carbon, its effectiveness as a climate mitigation strategy depends on the amount of carbon displaced and its duration. Current estimates of climate mitigation benefits of product substitution are generally based on three critical, often unstated assumptions: (1) the carbon displacement value remains constant [8–16], (2) the displacement is permanent and therefore of infinite duration [12–16] which implies no losses via cross-sector leakage, and (3) there is no relationship between building longevity and substitution longevity [10]. Below, each of these assumptions is reviewed.

Although most analyses of product substitution benefits implicitly assume a constant displacement value over time [8–16], it is subject to change. Schlamadinger and Marland [12] hypothesized energy substitution displacement values increase over time because of increased efficiencies. For product substitution, I hypothesize it will likely move in the opposite direction for three reasons. First, changing manufacturing methods impact embodied energy: for example, as long as it is available, the addition of fly ash could lead to a 22%–38% reduction in embodied energy required for concrete reducing the displacement value [17]. At the same time, increased processing of wood to create materials suitable for taller buildings (e.g. cross laminated timbers) would likely lead to a lower displacement value given laminated beams have 63%–83% more embodied energy than sawn softwoods [9, 17]. Second, the increases in energy efficiency hypothesized by [12] related to rising energy costs and recycling [9, 18, 19] and as noted by [8, 16] would also result in a decrease in product substitution displacement because the key relationship involves the difference in emissions and not the ratio as in energy substitution [20] (see supplemental information is available online at stacks.iop.org/ERL/14/065008/mmedia for detailed analysis of the displacement formula). Finally, changing the mix of fossil fuels used to generate energy can also substantially change the amount of carbon released per unit energy consumed and if natural gas continues to increase relative to coal, as has been observed [21], then the displacement value would likely decline in the future. The same is true if non-fossil energy sources such as solar, wind, or hydropower are increasingly used as projected [22].

One possible mechanism leading to permanent displacement is that fossil carbon not used by the building sector is also not used in any other sector in the future. However, this seems unlikely given carbon leakage [20, 23–25]. While the rate of product substitution-related leakage is difficult to estimate (in part because the form and location of the fossil carbon is not specifically known), it is unlikely to be zero given fossil carbon-based fuels are expected to be depleted in the next 107–235 years [26, 27] (see supplemental information). Even if these depletion time estimates are off by centuries, the duration of the displacement is not infinite and the claim that 'saved fossil emissions are forever' [12] is untenable. I hypothesize that without a mechanism to prevent its use, that fossil carbon displaced by product substitution will gradually be released by other sectors and will not be excluded from depletion as implied by [10, 12].

The key assumption of no relationship between product longevity and product substitution longevity has been asserted [10], but not fully explained. If there always is a preference for non-wood building materials, then avoiding their use avoids fossil carbon emissions, hence the displacement would continue to accumulate [20]. However, if wood is preferred then the use of wood does not necessarily increase cumulative displacement [20]. Despite differences in regional preferences for wood [28], most if not all assessments of product substitution tacitly assume wood is not preferred and that preferences never change. As a consequence, the product substitution store never saturates and implying there is no negative feedback in the net cumulative displacement. In all other forest-related carbon pools, a negative feedback exists between pool size and output (i.e. they are donor controlled systems): the larger the pool size, the larger the output flow. This causes these pools to saturate in time as long as the input remains constant. It is striking that this behavior is true for wood products, but not for product substitution (see supplemental information). In [12] product and energy substitution are treated the same. However, I believe they are quite different. In the case of energy, once energy is used it does not have a lifespan or store per se. However, in the case of wood products when the product lifespan is exceeded it has to be replaced with either wood-based or some other materials. If it is the former, the fossil carbon displacement continues, but does not necessarily increase [20] (see supplemental information). If it is the latter, the fossil carbon that was displaced is released to the atmosphere [20]. I therefore hypothesize that when wood is or becomes the preferred building material the product substitution pool has a negative feedback directly related to building longevity.

The objective of this study is a sensitivity analysis of these three assumptions and their impact on projected climate mitigation benefits. In addition to examining each assumption separately, I examined how they might work together to determine whether product substitution carbon benefits eventually become as large relative to the forest ecosystem and harvested materials as previous analyzes suggest [10–15]. To perform this analysis I used a relatively simple landscape model assuming an idealized, regulated system and focused on conditions in which product substitution benefits would be highest (i.e. clear-cut harvest, high manufacturing efficiency, and maximum use of products in buildings). The cases examined are therefore illustrative of the kinds of behavior the assumptions create, but not an exhaustive analysis of all forest ecosystems, management or manufacturing systems. Nor does the analysis try to identify the most likely values of displacement factors, carbon leakage, or product lifespans: e.g. [29, 30].

Methods

Each of the three assumptions was examined individually and then jointly for three contrasting initial conditions using a simple landscape model1 that tracks the stores for the live, dead, and soil carbon pools in the forest ecosystem, the products in use and disposal, and the virtual carbon stores associated with product substitution. Each of these pools was modeled as a simple input–output, donor controlled sub-model following first order dynamics in which the output was regulated by a rate-constant describing the fraction lost per year. For product substitution, the fossil carbon displaced was the input, and losses were associated with use of fossil carbon by other sectors (hereafter called leakage losses) and those associated with the replacement of wooden buildings (hereafter called replacement losses). All simulations were conducted for a 300 year period as in [8] using a 50 year harvest cycle.

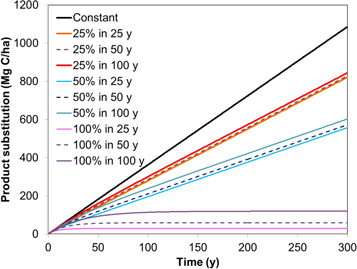

Displacement decline

In this set of simulations I assumed no losses associated with leakage or building replacement. The initial displacement value of 2.1 Mg C per 1 Mg C wood use [20] was reduced by 25%, 50% and 100% over either a 25, 50, or 100 year period. The 100% decline represents the possibility that fossil carbon will be completely replaced as a source of energy in the location of manufacture. As a control, the displacement value was assumed to not decline.

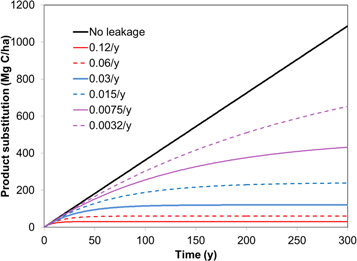

Leakage losses

In this set of simulations I assumed the displacement value remained 2.1 Mg C per 1 Mg C wood use and there were no losses associated with building replacement. To examine the sensitivity of substitution benefits to cross-sector leakage, I simulated five possible scenarios: (1) no leakage, (2) 12%, (3) 6%, (4) 3%, (5) 1.5%, (6) 0.75, and (7) 0.375% yr−1. In these scenarios leakage via other sectors was assumed to be continuous and not a one-time phenomenon. While expressed as a constant percentage lost per year, these values imply depletion times ranging between 25 and 800 years, which are 71%–340% of the currently estimated range of 35–235 years [26, 27].

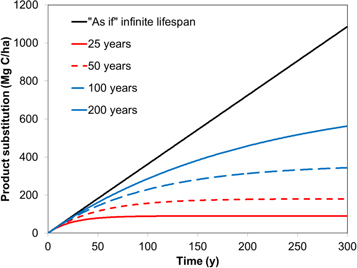

Replacement losses

In this set of simulations I assumed the displacement value remained 2.1 Mg C per 1 Mg C wood use and there were no losses associated with cross-sector leakage. I varied the average building life-span to be 25, 50, 100, and 200 years, which bracket current estimates2 . To provide a comparison to past studies, I reduced replacement losses to zero since this parameterization mimics the consequences of assuming no relationship between building longevity and product substitution longevity (see supplemental information).

Overall effect

To assess the overall effect of product substitution assumptions I examined a clear-cut system for three possible initial conditions: (1) an old-field planted to a production forest, (2) a production forest that originated from an old-growth forest landscape that began conversion 100 years ago, and (3) an old-growth forest converted to a production forest. In each case I assumed that 65% of the live carbon would be harvested, that 75% of that harvest would be converted into buildings. To explore the sensitivity of the assumptions on their overall impact I used the displacement and leakage loss parameter values that gave the minimum, median, and maximum effect based on the earlier simulations. In the case of replacement losses, I assumed an average building lifespan of either 50 years, 100 years, or an infinite number of years. The various combinations resulted in 47 simulations per initial condition. The model parameterization was based on a productive forest in the Pacific Northwest, a major source of wood building materials and US carbon stores [31].

Results

Displacement decline

There was a direct relationship to the total product substitution virtual store and the degree displacement declined, although the faster the decline in the displacement, the lower the final value (figure 1). For example, a 25% decline in 25, 50, and 100 years led to a final reduction in the product substitution virtual store of 24.3%, 23.6%, and 22.3%, respectively. This suggests that while the timing of the decline had an effect, the major response was to the level. The product substitution virtual store saturated only for the cases in which displacement went to zero and even if this took 100 years, product substitution stores estimates at 300 years were reduced by ≈89%.

Figure 1. Accumulation of product substitution carbon when displacement is reduced 25%–100% over a 25–100 year period for a 50 year clear-cut harvest interval. For these simulations losses via leakage and replacement were zero3.

Download figure:

Standard image High-resolution imageLeakage losses

Regardless of the time required for cross-sector leakage to occur, this process substantially limited the product substitution virtual store relative to the case without leakage (figure 2). With a leakage as low as 0.375% yr−1 (≈one-third the current estimate of the minimum depletion rate [27]) the store at 300 years was ≈40% lower than when there was no leakage. If the leakage rate-constant was 12% yr−1, then ≈97% less would be stored relative to the no leakage scenario. Moreover, if the current range of depletion times (i.e. 35–235 years) is correct, then cross-sector leakage would reduce the estimates by 78%–96%. This indicates that leakage via other sectors may substantially undermine any attempt to displace fossil carbon using product substitution.

Figure 2. Accumulation of product substitution carbon when the time for displacement to be lost via leakage varies from 25 to 800 years for a 50 year clear-cut harvest interval. Displacement was assumed constant and replacement losses zero3.

Download figure:

Standard image High-resolution imageReplacement losses

For an average building longevity of 50 years the product substitution store at 300 years was ≈17% of that of the case in which product substitution behaved as if it had infinite lifespan (figure 3). Even when average building lifespan was 200 years, this store at 300 years was ≈52% that of when product substitutions behaved as if they had an infinite lifespan. This indicates that assuming no relationship between product substitution lifespan and building lifespan overestimates benefits.

Figure 3. Accumulation of product substitution carbon when the average longevity of building varies for a 50 year clear-cut harvest interval. For these simulations displacement was constant and there were no leakage losses3.

Download figure:

Standard image High-resolution imageOverall effect

Product substitution, estimated using past assumptions regarding displacement decline, leakage, and relationship to building longevity, increased for each initial condition; increasing the most when old-growth forests were harvested (figure 4). When alternative assumptions about product substitution were used, the shape of the product substitution accumulation curve varied: generally increasing for the old-field conversion to an asymptote, decreasing or increasing to an asymptote for the plantation system depending on replacement assumptions, and for most combinations reaching a peak at 10–40 years for the old-growth forest converted to a plantation scenario. This analysis indicates that to increase the overall amount of carbon stored in the system, that conversions of old-growth forests in the Pacific Northwest to plantations should be avoided, whereas creation of plantations on old-fields should be encouraged. Moreover, existing plantation systems are unlikely to increase their carbon stores unless building longevity is substantially increased (figure 4(e)).

Figure 4. Accumulation of ecosystem, products in-use and disposed, and product substitution carbon stores for a 50 year clear-cut harvest interval in the Pacific Northwest for three possible scenarios: a plantation forest established on an agricultural field (A), (D); a production forest system that is continued (B), (E); an old-growth forest replaced by a forest plantation (C), (F). For past assumptions there was no decline in displacement value, there was no leakage, and buildings were assumed to have an infinite lifespan3,4.

Download figure:

Standard image High-resolution imageRegardless of the initial conditions, product substitution was lower when alternative assumptions regarding displacement decline, leakage, and relationship to building lifespan were used, ranging from virtually zero to 80% of the past assumptions at year 300 depending on the parameter values assumed (tables S-2 to S-4). At the very least this suggests product substitution estimates are extremely uncertain. However, 85% of the 141 combinations examined were <50% than currently estimated. Those few exceeding 50% involved the assumption that substitution replacement losses were zero (i.e. an infinite lifespan) and had either an unrealistically low rate of leakage (i.e. less than one-third that indicated by the maximum depletion time) or a minimal decline in displacement. Moreover, although past assumptions would indicate product substitution forms a large share of carbon stores at year 300 (74%–80% depending on the initial conditions), 90% of the alternative combinations examined indicated it was less than 50%. The combinations in which product substitution stores comprise the majority share of stores assumed an infinite lifespan and either minimal displacement decline or extremely low cross-sector leakage rates (tables S-2 to S-4).

Discussion

Past analyses suggest product substitution benefits at the landscape level continue to increase at a constant rate into the future [6–16]. Moreover, they imply that while a carbon debt can be created in some situations (e.g. harvest of primary forests), that this debt is eventually paid back via product substitution [10, 12, 32]. While I examined only a few illustrative cases, in the case of product substitution, these debts would not be paid back if the displacement declines or there are losses via cross-sector leakage or related to product replacement. That is because negative feedbacks associated with losses can prevent product substitution from accumulating forever. These negative feedbacks could exist regardless of the forest ecosystem, the harvest system, and the efficiency of processing harvests into products as well as the proportion allocated to buildings. Thus, while I did not examine the effect on a wide range of ecosystems, or alternative harvest systems, or systems in which buildings are minor faction of harvested carbon, these underlying relationships would not be altered for these new situations4.

The assumption that the product substitution benefit has no losses (e.g. [10]) results in at least two sets of untenable predictions: (1) if fossil fuel carbon is stored each time a wooden building is constructed, then theoretically it would be possible for fossil fuel carbon to be stored long after this carbon has been depleted by other sectors; hence this assumption may violate the conservation of mass; (2) this assumption also views the following as the same: (a) harvest that completely replaces wood building losses, (b) harvest that does not replace wood building losses, (c) harvest that exceeds wood building losses leading to more wood buildings, and (d) wood buildings that are not replaced. These cases clearly differ [20] (see supplemental information). This assumption also introduces a logical inconsistency: products appear to have different lifespans depending on whether their direct carbon (finite) or substitution carbon (infinite) effects are being considered (figure S-4).

Although displacement decline over time influences the accumulation of product substitution benefits, its effect is smaller than leakage or replacement losses. In contrast, leakage loss has as dramatic effect as longevity even if it occurs at a very slow rate implying the effect of product substitution is to delay eventual fossil carbon release, but not to stop it altogether. This may be important because it buys time, but this is not the same as the displaced fossil carbon never being released as suggested by [10, 12].

Collectively the past assumptions commonly used to assess the mitigation benefits of product substitution lead to a carbon pool that does not saturate causing the product substitution pool to eventually exceed the carbon stores in the forest ecosystem and in the associated wood products. Moreover, because there are no losses from the products substitution pool, its highest rate of increase occurs for the harvest interval providing the highest yield, typically a very young age relative to the forest ecosystem carbon maximum [32]. With no relationship to building longevity, there is no relationship to the size of the wood products pool despite the fact that more wooden buildings would imply more success in displacing fossil carbon. Finally, this set of assumptions makes product substitution benefits relatively insensitive to the initial conditions of the forest ecosystem because product substitution benefits always increase over time.

The alternative set of assumptions explored here suggests that the highest overall climate mitigation may not necessarily be achieved by maximizing the harvest yield using short rotation forestry [33]. Moreover, if product substitution is the primary climate mitigation strategy, wood building materials need to keep their carbon advantage by maintaining or increasing their displacement value. This suggests that while wood can be used in buildings taller than the general current practice, this may have less mitigation value than anticipated if these materials embody more fossil energy than current wood-based materials. Given the strong potential relationship between building and product substitution longevity, increasing the life-span of buildings or reusing building materials could potentially help meet future demand and increase mitigation benefits. Without a policy to assure that fossil carbon displaced by one sector is not used by another sector, product substitution benefits could be quite limited. While it is unlikely any policy could completely eliminate cross-sector leakage, designating long-term reserves might delay releases until their climate impacts are reduced to acceptable levels.

Conclusions

Despite its general and limited nature, this sensitivity analysis found that product substitution benefits have likely been overestimated for many scenarios and are generally smaller than those related to the forest ecosystem and their derived products. This new analysis suggests that if product substitution is to be used as part of a climate mitigation strategy, then more attention will have to be paid to maintaining the amount of carbon displaced, reducing the rate of carbon cross-sector leakage, and increasing the longevity of buildings. This new analysis also suggests that the best strategy for forest-related climate mitigation for an important timber region, the Pacific Northwest, is largely determined by the initial conditions of the management system. Afforestation leads to an increase in carbon stores in the ecosystem, wood products, and substitution benefits for many decades. On existing production forests, substitution benefits could be maintained by continuing the current system or increased by harvesting more (but only as long as ecosystem carbon stores do not decline) and/or increasing the longevity of buildings. Conversion of older, high carbon stores forests to short rotation plantations would over the long-term likely lead to more carbon being added to the atmosphere despite some of the harvested carbon being stored and production substitution occurring [33].

Acknowledgments

This research was funded by the Kaye and Ward Richardson endowment to the College of Forestry, Oregon State University and grant from the National Science Foundation (DEB-0823380 and DEB-1440409) to the Andrews LTER. I thank Drs Darius Adams, Thomas C Maness and the anonymous reviewers for their valuable insights.

Footnotes

- 1

A more complete description of the model and parameters are available as supplemental information online.

- 2

Estimates of housing longevity are highly variable with exponential rate-constants ranging from 0.0069/y to 0.03/y [12–16]. In some cases building longevity has been modeled as a step function, with rapid losses after 80 years [10–11]. These estimates give an average lifespan or turnover time of 33–144 years. I explored a range of 25 to 200 years to bracket this uncertainty. Note that the average lifespan is not the same as the maximum lifespan of buildings: for an average lifespan of 50 years, the maximum lifespan would be over 230 years.

- 3

See figures S-7 to S-10 for detailed view of the first 50 years.

- 4

See supplemental text and figure for similar results for a productive Southeastern US forest.