Abstract

Thermal electricity generation is a major consumer of freshwater for cooling, fuel extraction and air emissions controls, but the life cycle water impacts of different fossil fuel cycles are not well understood. Much of the existing literature relies on decades-old estimates for water intensity, particularly regarding water consumed for fuel extraction. This work uses contemporary data from specific resource basins and power plants in Texas to evaluate water intensity at three major stages of coal and natural gas fuel cycles: fuel extraction, power plant cooling and power plant emissions controls. In particular, the water intensity of fuel extraction is quantified for Texas lignite, conventional natural gas and 11 unconventional natural gas basins in Texas, including major second-order impacts associated with multi-stage hydraulic fracturing. Despite the rise of this water-intensive natural gas extraction method, natural gas extraction appears to consume less freshwater than coal per unit of energy extracted in Texas because of the high water intensity of Texas lignite extraction. This work uses new resource basin and power plant level water intensity data to estimate the potential effects of coal to natural gas fuel switching in Texas' power sector, a shift under consideration due to potential environmental benefits and very low natural gas prices. Replacing Texas' coal-fired power plants with natural gas combined cycle plants (NGCCs) would reduce annual freshwater consumption in the state by an estimated 53 billion gallons per year, or 60% of Texas coal power's water footprint, largely due to the higher efficiency of NGCCs.

Export citation and abstract BibTeX RIS

Content from this work may be used under the terms of the Creative Commons Attribution-NonCommercial-ShareAlike 3.0 licence. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

1. Introduction

1.1. Background

Coal and natural gas are depletable fossil fuels commonly used to generate electricity, each with operational advantages and environmental impacts. In the United States, costs and emissions from the coal and natural gas fuel cycles in particular have received significant public attention, especially as new long-lived generation assets replace older power plants. Concern about greenhouse gas and other air emissions—and the associated compliance costs that coal plants increasingly face—has raised the question of whether policy makers should promote a shift from coal to natural gas or other generation.

Simultaneously, new water-intensive extraction methods for natural gas have created concern regarding water consumption and pollution for natural gas, historically considered a clean fuel. The trend toward more natural gas-fired electricity, the rapid expansion of hydraulic fracturing for natural gas extraction, and recent major droughts have publicly highlighted energy-related water consumption, withdrawal needs and contamination (see e.g. [1]). While the air and solid waste impacts of coal- and natural gas-fired electricity have been well characterized [2], the relative water intensity of coal and natural gas fuel cycles has received less attention. Despite recent specific attention to natural gas' impacts on water resources [3], both coal- and natural gas-fired electricity use large amounts of water for fuel extraction and power plant operations, and decision makers can benefit from a quantitative comparison of the two.

This work's main objective is to quantify in-state water consumption associated with Texas' coal- and natural gas-fired electricity, then to assess the potential impacts of coal to natural gas fuel switching on Texas' freshwater systems. Major contributions of this analysis include higher resolution data on the water intensity of coal and natural gas extraction than have previously been published. In particular, this work derives water intensity factors using resource basin-specific data and including major second-order sources of water consumption. Notably, the water intensity of unconventional natural gas production via hydraulic fracturing is quantified for 11 separate basins. Many previous studies have relied on 1993 average estimates of water consumed during natural gas and coal extraction [4–6], largely due to a lack of data. This contemporary analysis builds on the literature to provide new quantitative results relevant to policy makers addressing energy, water and major related infrastructures.

The ability to quantitatively compare the water intensity of coal- with natural gas-fired electricity is relevant to state and national policy. Natural gas' share of the Texas and US fuel mixes has increased since 1990 (due to decreasing coal-fired generation and steady natural gas share in Texas and steady coal-fired generation and increasing natural gas share in the US) [7, 8]. In 2010, coal and natural gas provided 36 and 45% of Texas' roughly 400 TWh of electricity, respectively [7]. As more coal-fired power plants retire due to age and/or regulatory compliance costs, a more explicit shift from coal to natural gas could begin, especially given today's historically low natural gas prices.

Environmental considerations are an important driver for coal to natural gas fuel switching in Texas and other regions. Burning natural gas instead of coal generates lower levels of sulfur, nitrogen and carbon oxides; heavy metals; particulates; and solid wastes like ash (figure 1). Increasingly stringent regulations on emissions and water intakes will likely favor NGCCs (natural gas combined cycle power plants) over PCs (pulverized coal power plants) [9–11]. NGCCs are also operationally more flexible than PCs [12], which could benefit power grids as renewable energy policies and economics add more nondispatchable generation capacity. However, PCs can be retrofitted to reduce emissions, and new PCs are significantly cleaner and more efficient than those in the existing fleet. Understanding how fuel mix decisions will impact water supplies can aid regionally appropriate decision making.

Figure 1. On average, Texas' coal-fired power plant fleet uses more energy and water and emits more air pollution to produce electricity than Texas' natural gas combined cycle plants (values normalized to production of 1 kWh of electricity).

Download figure:

Standard imageThis study specifically considers the potential impact of replacing existing coal-fired power plants with NGCCs in Texas on Texas' freshwater consumption, forming a basis for future analysis of fuel switching in other contexts. Texas is an appropriate case study for several reasons: its electrical grid and river basins are almost entirely within Texas, which means that state datasets are useful and readily comparable; its scale as an energy producer and consumer makes Texas a suitable miniature snapshot of the nation, with a variety of climates and a fuel mix roughly similar to that of the US as a whole; and most of the water impacts of natural gas and coal extraction for Texas electricity occur in state, as Texas produces all of its own natural gas and about a third of its coal energy (predominantly as lignite: the remainder is almost entirely subbituminous coal imported from the Powder River Basin, whose extraction consumes an estimated 3–17% as much water per unit energy as lignite extraction [4, 13]). Texas' status as an energy leader, particularly in natural gas extraction methods and grid management, means that its regulatory and policy experiences are frequently a test bed for other states and the nation as a whole.

The impact of coal to natural gas fuel switching on freshwater consumption in Texas is highly relevant to state policy. Texas' water resources are increasingly strained, evidenced by periods during 2011 when the state experienced drought over 100% of its area [14]. Drought conditions left over 11 GW (about 1%) of power generation capacity at risk of curtailment due to water limitations [15], and securing water rights has become a major challenge for new power plants [16]. This work suggests that coal to natural gas fuel switching could save 53 billion gallons of water per year, about 1% of Texas' 4900 billion gallon annual water consumption, 60% of the water Texas currently consumes for coal-fired electricity, and 10% of the state's current unsupplied need [17]. These savings are particularly attractive when combined with the potential for positive economic and air quality impacts to Texas, a major natural gas producer and coal importer. Evaluating the impact of different modes of electricity production on Texas freshwater consumption provides quantitative data that can aid decision makers, particularly during times of water stress.

1.2. Study scope

This limited life cycle analysis assesses freshwater consumption associated with fuel extraction, power plant cooling and pollution controls, which together typically account for over 95% of electricity-related freshwater consumption (based on this analysis and [4]). Included in the evaluation of water needs for pollution controls are carbon capture and storage (CCS) systems, which are not yet operating in Texas but could be installed in response to future carbon dioxide (CO2) control policies. Major second-order effects from embodied water in drilling fluid components and in limestone (used for sulfur pollution control) are included, but the small amount of water used for transportation [4] and infrastructure construction (e.g. for building power plants) is not. The Texas state line is the chosen study boundary, so out-of-state water consumption for materials used in Texas is not included. Drawing such geographical boundaries aligns better with the real-world aspects of state-based water planning and enables the use of internally consistent data. This work only addresses freshwater consumption, excluding major issues like water quality (e.g. chemical and thermal water pollution) and water adequacy, or spatial and temporal availability relative to demand (e.g. for power plant cooling withdrawal needs). The study scope is illustrated in figures 1 and 2.

Figure 2. The study scope is limited to power plant cooling, fuel extraction and emissions controls within Texas. (Note: freshwater consumption incurred outside of Texas or for transportation (e.g. dust control for coal transport by rail or pressure testing for natural gas transport by pipeline) is not considered. Important electricity-related water considerations like adequacy for cooling water withdrawals, effect of use in small areas over short time periods, and impacts on water quality and habitats are outside the scope of this work.)

Download figure:

Standard imageThis letter describes methods, data and results for estimating freshwater consumption associated with coal and natural gas power plant cooling, extraction and pollution controls. Discussions of the relative water intensity of coal and natural gas fuel cycles and routes to water savings follow. Supplementary data can be found online (available at stacks.iop.org/ERL/7/045801/mmedia).

2. Methods

This life cycle analysis of Texas coal and natural gas fuel cycles uses literature-based water consumption rates for power plant cooling, fuel extraction and pollution controls to evaluate freshwater consumption differences between NGCCs and existing PCs. These differences are evaluated at the individual power plant level, assuming that each major PC in Texas is replaced by an NGCC of equivalent output with Texas NGCC fleet-average characteristics.

The standard metric used in this work is gallons of water consumed per kilowatt-hour of electricity generated (gal kWh−1), which allows direct comparison of the water intensity of electricity from PCs and NGCCs. The water intensity of coal and natural gas extraction in Texas is calculated as gallons of water consumed per million British thermal units of fuel produced (gal/mmbtu). Data are from Nicot et al, a study of Texas oil, natural gas and mining industry water use for the Texas Water Development Board (TWDB) that surveyed Texas coal producers on 2009–10 coal production and associated water use and projected Texas natural gas-related freshwater consumption between 2010 and 2060 [18]. These figures are converted to gal kWh−1 using power plant heat rates to account for the different efficiencies of PCs and NGCCs. Power plant fleet information, including heat rate, total generation, fuel source and installed emissions controls, is compiled from King et al [19], a study of Texas power sector water use also prepared for the TWDB; United States Energy Information Administration (EIA) forms 860 and 923 [7, 8]; and the United States Environmental Protection Agency (EPA) Emissions and Generation Resource Integrated Database (eGRID) [20]. The remainder of this section presents specific data sources and analytical approaches for each major freshwater-consuming system evaluated: fuel extraction, power plant cooling, and pollution controls for coal and natural gas fuel cycles in Texas.

2.1. Freshwater consumption for fuel extraction

2.1.1. Method: water consumption for coal extraction.

The average freshwater consumed to extract a short ton of Texas lignite is calculated assuming a conservatively high energy density of 7000 btu/lb (Texas lignite heat content is typically 6500–7000 btu/lb) [21] and total 2009–10 production and water use figures from all 11 active coal mines or mine groups in Texas [18] according to equation (1):

Freshwater intensity at coal mines depends primarily on interactions between coal seams and aquifers, with central Texas mines requiring more depressurization and dewatering than east Texas mines due to their link to freshwater aquifers [18]. Water is consumed in other states to mine about two thirds of the coal energy burned in Texas [22, 23]. This out-of-state consumption is not tallied for this in-state consumption assessment but adds an estimated 2–10% to the total water consumption associated with coal extraction for Texas electricity, reflecting the much lower water intensity of imported coal versus Texas lignite [4, 13].

The major use of water at coal mines is aquifer dewatering (depressurization), a process that removes water from coal seams so that mining can proceed. Dewatering produces water that theoretically becomes available for other users, but the water is generally extracted and discharged independent of potential beneficial use [18]. At least one Texas lignite mine's depressurization water is directly designated for municipal use, and such water is not counted toward coal-related consumption here [18]. This document adopts the convention of the Texas Water Development Board that water removed from an aquifer and discharged without a designated beneficial use represents consumption, as the water is no longer available for use on demand and any downstream benefits are ad hoc [18]. Stormwater removal from mine pits is not considered consumption [18]. For clarity, this work assesses two values for freshwater consumption from coal extraction in Texas: gal/mmbtu of effective freshwater consumption, which includes depressurization water without a designated downstream user, and gal/mmbtu of direct consumption, or freshwater inputs to coal mining.

2.1.2. Method: water consumption for natural gas extraction.

The water intensity of natural gas extraction varies substantially by basin and extraction technique, and so this work separately evaluates the water intensity of conventional natural gas extraction and extraction from 11 unconventional basins in Texas. Here, unconventional refers to natural gas basins that require hydraulic fracturing for reservoir stimulation.

The freshwater intensity of conventional natural gas extraction is estimated using 10 years of data on Texas natural gas well completions [24] and drilling fluid freshwater use estimates based on surveys, borehole volume-based calculations and a literature review [18]. For the years 2000–9, water consumed per unit of natural gas is calculated by multiplying a year's oil and natural gas drilling water use by the proportion of natural gas wells and dividing by that year's production. The 10 year average provides a baseline for natural gas drilling water consumption per unit of energy, previously estimated as negligible in the literature [4]:

Texas' fairly stable historical natural gas production levels [25] enable the assumption that lifetime production from new wells is roughly equal to that year's total natural gas production. This assumption implies that wells are drilled at production replacement rate. Equation (2) is considered an appropriate proxy for the water intensity of conventional natural gas production despite the inclusion of unconventional production and byproduct natural gas production from oil wells: EIA reports 0 or unknown contribution from Texas unconventional natural gas wells through 2007 and less than 25% in 2008–9, and byproduct natural gas accounts for ∼10% of Texas' production [22].

The water intensity of extraction from Texas' main unconventional natural gas basins is also calculated as water consumed/unit energy but includes water used for hydraulic fracturing. Estimated ultimate recovery (EUR) by basin is divided by total estimated lifetime freshwater consumption for drilling and hydraulic fracturing:

Note that basin EURs are given in trillion cubic feet of natural gas equivalent (Tcfe), as some basins (like the Eagle Ford shale) produce oil and/or natural gas liquids (NGLs) in addition to natural gas. While oil can be more water intensive per unit of energy to extract than natural gas in traditional settings because of practices like waterflooding [26], the impact of high liquids content on water use in hydraulically fractured shale basins is not explicitly considered here. Additionally, the potential for technological change is not incorporated, as the goal of this calculation is to determine today's water intensity per unit of natural gas and both EUR and total water use estimates are based on existing technology. Given the current focus on alternative fluids and water recycling, near- to medium-term technological changes are likely to reduce water intensity [18].

In addition to direct water use for drilling and hydraulic fracturing, unconventional natural gas extraction uses proppants (usually sand or ceramic particles intended to hold fractures open) and chemicals whose production adds to the total water footprint of unconventional natural gas, given by equation (4):

The water footprint of proppants and chemicals depends on the production methodology. About 25% of the roughly 6 million short tons of proppant used for hydraulic fracturing in Texas in 2008 was Texas-mined industrial sand consuming an estimated 620 gal/short ton, with the remainder either imported or manufactured in Texas [18]. The freshwater intensity of manufactured ceramic proppant is assumed equal to that of mined industrial sand, based on price data from [27, 28] and output from Carnegie Mellon's life cycle analysis tool, EIO-LCA [29]. EIO-LCA provides estimates for total water withdrawal per dollar of value by industry, here using the 2002 US Bureau of Economic Analysis' commodity-by-industry model of the US economy [29]. Texas' status as a major petrochemical producer suggests that fracturing chemicals are largely manufactured in state, so this analysis uses the EIO-LCA 2002 producer price model and Jiang et al's valuation of the chemicals in hydraulic fracturing fluids to estimate associated water consumption ([30], details in supplementary data available at stacks.iop.org/ERL/7/045801/mmedia).

The water footprint of proppants is estimated to be between a low value assuming the 75% of proppants with unknown origin [18] are imported and a high value assuming all proppants used in Texas are mined or manufactured in Texas. The water footprint of chemicals is estimated to range between a low value assuming that only direct manufacturing water withdrawals are consumed and a high value assuming that in addition, all other non-power generation withdrawals and one per cent of the water withdrawn for power generation during chemical manufacture are consumed in Texas [5]. The method is illustrated in table 1. Note that this range is likely conservatively high, as some chemicals might be imported to Texas and some water recycling is likely. This conservatism is deemed appropriate due to large uncertainty about which chemical compounds and amounts are used for hydraulic fracturing, though the impact of the uncertainty is likely small since extraction accounts for a relatively small portion of total fuel cycle water consumption.

Table 1. A range of estimates for the freshwater consumption of chemical production is derived from an economic value-based life cycle analysis tool. (Note: source [29]. Based on water withdrawals for top 10 sectors contributing to 'other basic organic chemical manufacturing', 2002 purchaser price model, $1 million in activity. Low estimate assumes all withdrawal for basic organic chemical manufacturing is consumption. High estimate assumes 1% of power sector withdrawals are consumed and that all other withdrawals are fully consumed.)

| Sector | Water withdrawals (kgal) | Low estimate, water consumption (kgal) | High estimate, water consumption (kgal) |

|---|---|---|---|

| Total | 45 700 | 6430 | 32 700 |

| Grain farming | 23 600 | 23 600 | |

| Power generation and supply | 11 500 | 11 500 × 0.01= 115 | |

| Other basic organic chemical manufacturing | 6 430 | 6430 | 6 430 |

| Alkalis and chlorine manufacturing | 548 | 548 | |

| Cotton farming | 457 | 457 | |

| All other crop farming | 360 | 360 | |

| Petrochemical manufacturing | 334 | 334 | |

| Industrial gas manufacturing | 318 | 318 | |

| Paint and coating manufacturing | 282 | 282 | |

| All other basic inorganic chemical manufacturing | 225 | 225 | |

2.2. Freshwater consumption for power plant cooling

Cooling water consumption rates at Texas' 18 operating coal-fired power plants (each with 1–4 generators, with a total of 36 coal boilers powering 37 generators [20]) are derived from operational data presented in [19] (table S.1, supplementary data available at stacks.iop.org/ERL/7/045801/mmedia). About 60% of Texas' coal-fired power generation uses once through cooling, with the remaining 40% using wet recirculation [19].

NGCCs replacing coal-fired power plants in Texas are assumed to consume cooling water at a rate of 0.23 gal kWh−1, based on data and analysis in [19]. Texas' NGCC generation is overwhelmingly cooled with wet recirculating systems (over 90%), with the remainder using once through (about 5%) or air cooling [19].

2.3. Freshwater consumption for emissions controls

Of the common, commercially available emissions control systems, only sulfur oxide (SOx) controls consume significant amounts of water. Thirteen of Texas' 36 coal-fired units are equipped with wet lime or limestone scrubbers to reduce SOx emissions [20], which consume about 0.068 gal kWh−1 [31]. Wet scrubbers and the fluidized bed combustion systems at two other coal-fired units in Texas also consume approximately 0.227 pounds of lime or limestone kWh−1 [32] that, because of its weight, availability and relatively low cost, is very likely mined in Texas. Based on the estimate from [18] that crushed limestone mining consumes 36 gallons of surface or groundwater per short ton, the limestone used for sulfur scrubbing accounts for an additional embedded freshwater consumption of 0.004 gal kWh−1 for the nearly half of Texas coal-fired electricity generated by units with sulfur scrubbers [20]. Natural gas-fired power plants are not typically fitted with water-consuming pollution control systems due to their comparatively low air emissions, so water consumed for emissions controls mainly accrues to coal-fired electricity.

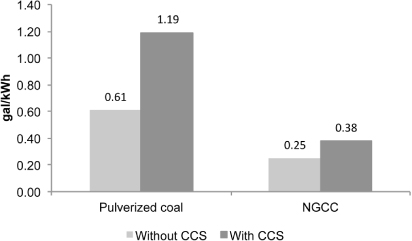

Though CCS systems have not yet been deployed in Texas, they could increase total water consumption per kWh by 80% at PCs or 70% at NGCCs ([19], table 2, figure 3). Carbon capture systems increase power plant cooling needs, and high parasitic loads lead to more fuel combustion and thus higher total upstream water use for extraction.

Figure 3. Carbon capture systems increase life cycle in-state water consumption at the Texas PC and equivalent NGCC fleets. (Note: source [19]. 'Without CCS' values are averages for the 2007 PC fleet and an NGCC fleet with Texas-average characteristics generating the same amount of electricity as the PC fleet in 2007. 'With CCS' values are averages for the 2007 PC fleet assuming all plants are fitted with post-combustion carbon capture systems and for an NGCC fleet producing the same amount of electricity and CO2 (83% of NGCCs in the 'With CCS' fleet are assumed to have CCS systems).)

Download figure:

Standard imageTable 2. Installing carbon capture systems at power plants would increase water consumption significantly, but more for PCs than NGCCs. (Note: source [19]. Values include dewatering discharge for coal and use the EUR-weighted average for natural gas. Power plants that import coal are assumed to continue to import. Water needs for non-carbon pollution controls might be higher than indicated because some types of carbon dioxide scrubbers are sensitive to sulfur and would require higher sulfur removal efficacy [36]. The increase in water use for non-carbon pollution controls includes installation of wet sulfur scrubbers at plants that do not currently use them.)

| Pulverized coal | Natural gas combined cycle | |||

|---|---|---|---|---|

| Per cent | gal kWh−1 | Per cent | gal kWh−1 | |

| Cooling water | +95% | +0.48 | +75% | +0.17 |

| Fuel extraction | +43% | +0.03 | +18% | +0.00 |

| Water for non-carbon pollution controls | +43% | +0.07 | ||

| Total | +95% | +0.58 | +71% | +0.18 |

3. Findings

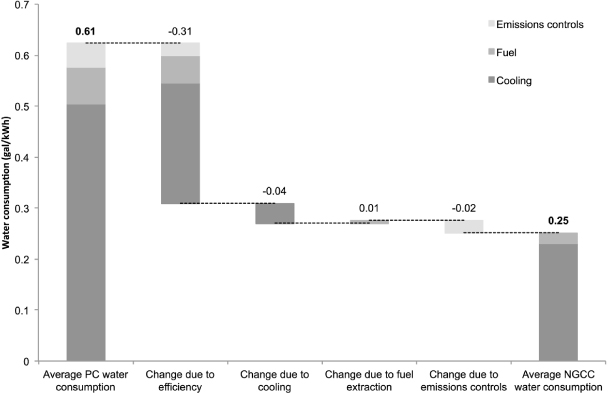

Texas coal-fired power generation accounted for an estimated 90 billion gallons of freshwater consumption in 2007 from its full fuel cycle (0.61 gal kWh−1), including about 10 billion gallons from mine dewatering. Generating the same amount of power from Texas fleet-average NGCC units would consume 37 billion gallons of Texas freshwater (0.25 gal kWh−1), a 60% reduction versus coal. These figures account for freshwater consumed for fuel extraction, cooling and emissions controls (table 3, figure 4). Higher efficiency at Texas' NGCCs versus its PCs accounts for about 80% of the water savings, mainly manifesting as reduced cooling need due to lower waste heat production. Lower inherent cooling and emissions control needs at NGCCs account for an additional 10% reduction in water consumption each, due to the air-cooled gas turbine cycle and lower emissions of NGCCs versus PCs (figure 4).

Figure 4. The greater efficiency of NGCCs is the primary driver of water savings versus PCs, mainly due to lower cooling water needs. (Note: sources: plant efficiency, [35]; cooling water needs, [19]. Efficiency effect accounts for the difference in heat rate between PCs and NGCCs and is calculated based on difference in excess btu consumed per kWh, e.g. on btu used beyond the 3412 btu kWh−1 unit equivalency. Cooling water needs are calculated assuming 15% of excess heat is lost to atmosphere through flue gases. Cooling water consumption is the generation-weighted average for Texas coal-fired power plants and the typical NGCC value described in the text. Coal extraction water intensity includes the 0 use associated with imported coal and assumes unallocated discharges from dewatering are consumed during coal mining, and natural gas extraction water intensity is the EUR-weighted average for Texas natural gas, assuming proppants and chemicals collectively add 30% to the water intensity of unconventional natural gas extraction. Water consumption for emissions controls is the average over all Texas coal-fired power plants, including 0 use at plants without scrubbers.)

Download figure:

Standard imageTable 3. Fuel switching from coal to natural gas in combined cycle power plants could save 53 billion gallons of freshwater per year in Texas, about 20% of nonagricultural water consumption. (Note: switching from coal to natural gas combined cycle generation in Texas would reduce in-state freshwater consumption by an estimated 53 billion gallons of water per year, based on 2007 generation levels. Figures might not sum perfectly due to rounding.)

| Cooling water (bgal yr−1) | Fuel extraction (bgal yr−1) | Pollution controls (bgal yr −1) | Total (bgal yr −1) | |

|---|---|---|---|---|

| Pulverized coal | 75 | 11 | 5 | 90 |

| Natural gas combined cycle | 34 | 3 | — | 37 |

| Savings from coal to gas switching | 41 | 7 | 5 | 53 |

Saving 53 billion gallons of Texas freshwater by switching from PC- to NGCC-generated electricity would increase state natural gas demand by about 1.04 Tcf, 71% of 2007 state use and 15% of production [22, 23, 25]. Generating 146 TWh at Texas' PC plants in 2007 used 1.57 quadrillion btu (quads) of coal energy (61 million tons/1.03 quads imported, 42 million tons/0.54 quads in-state), while NGCC units would consume 1.08 quads (1.04 Tcf) to generate the same amount of electricity due to higher efficiency.

3.1. Water consumption for fuel extraction in Texas

Coal extraction in Texas for use at power plants consumed an estimated 11 billion gallons of freshwater in 2007, including water discharged without an identified downstream user. Replacing both Texas-extracted and imported coal with Texas natural gas would require an estimated 3.2 billion gallons of freshwater consumption for natural gas extraction (EUR-based average). Thus, replacing all coal burned in Texas with natural gas extracted in Texas would avoid an estimated 7.3 billion gallons of freshwater consumption per year. Note that Texas coals' low energy density make extraction for export highly unlikely.

3.1.1. Water intensity of coal extraction in Texas.

Coal mining in Texas consumes an estimated 16.1 gal/mmbtu of freshwater for direct use and mine dewatering, 1.6 gal/mmbtu of which are used directly for applications like domestic water and dust control. This water use translates to 0.172 gal kWh−1 of freshwater consumption (0.017 gal kWh−1 without dewatering) at lignite-fired power plants, after accounting for prevailing energy density and conversion efficiency at power plants (table 4). Averaged across all Texas coal-fired power plants, including those that use imported coal, Texas coal extraction accounts for 0.071 gal kWh−1 of freshwater consumption (0.007 gal kWh−1 without dewatering).

Table 4. Freshwater consumption for coal and natural gas extraction in Texas varies by resource basin. (Note: source [18, 31]. Values include dewatering discharge for Texas lignite and embedded water in proppants and chemicals equal to 30% of direct water use for Texas unconventional natural gas. Without dewatering, Texas lignite extraction consumes 1.6 gal/mmbtu (0.017 gal kWh−1). The natural gas average is EUR-weighted, assuming 60 Tcf of conventional resources. Conversions from mmbtu to kWh assume the Texas generation-weighted average heat rates of 10 782 btu kWh−1 for coal-fired power plants and 7343 btu kWh−1 for NGCCs.)

| Texas fuel resource | Water consumption for extraction (gal/mmbtu) | Water consumption for extraction (gal kWh−1) |

|---|---|---|

| Natural gas average | 3.0 | 0.022 |

| Lignite | 16.1 | 0.171 |

| Natural gas by play | ||

| Conventional natural gas | 0.2 | 0.002 |

| Eagle Ford | 1.8–2.7 | 0.013–0.020 |

| Anadarko basin | 2.0 | 0.015 |

| Bossier | 2.4–3.8 | 0.018–0.028 |

| Gulf coast | 2.9 | 0.021 |

| Pearsall | 3.7 | 0.027 |

| Haynesville | 4.0–6.3 | 0.029–0.046 |

| Other Permian Basin | 4.1 | 0.030 |

| East Texas | 4.3 | 0.031 |

| Woodford/Barnett | 4.5 | 0.033 |

| Barnett | 5.1–5.9 | 0.037–0.044 |

| Haynesville West | 6.7 | 0.050 |

3.1.2. Water intensity of natural gas extraction in Texas.

On average, natural gas extracted in Texas consumes an estimated 3.0 gal/mmbtu of freshwater, including indirect water use for proppants and chemicals. This value translates to 0.022 gal kWh−1 at Texas' existing NGCC fleet and is based on expected EUR values for Texas' major natural gas basins ([18]; table 4). The water intensity of extraction varies by natural gas basin, ranging from an estimated 0.2–5.2 gal/mmbtu of direct freshwater consumption (0.002–0.038 gal kWh−1). The Haynesville West formation has the highest predicted water intensity, while conventional natural gas wells that are not hydraulically fractured have the lowest. Texas' major shale gas plays, the Haynesville and Barnett, produce natural gas with an estimated direct water intensity of 3–5 gal/mmbtu (table 4). Increased water recycling, refracturing wells for additional stimulus, and new or improved technology could change these water use estimates [18].

Embedded water in proppants and hydraulic fracturing chemicals likely adds the equivalent of between 20 and 60% of well site water consumption to natural gas extraction's freshwater consumption, with a best-guess estimate of about 30%. Total impact on the water intensity of electricity varies by shale basin but ranges from 0.003 to 0.011 gal kWh−1 assuming a 30% increase versus direct water use. At a proppant loading of one pound per gallon of fracturing water, the embodied Texas freshwater consumption in proppants is estimated at 80 000–310 000 gallons per million gallons of hydraulic fracturing fluid, depending on how much of the proppant is mined or manufactured in Texas rather than imported. The estimated Texas freshwater consumption embodied in hydraulic fracturing chemicals is similar, ranging from 76 000 to 320 000 gallons per million gallons of hydraulic fracturing fluid.

3.2. Water consumption for power plant cooling in Texas

Coal-fired power plants consumed 75 billion gallons of freshwater for cooling in 2007 (a generation-weighted average of 0.50 gal kWh−1, with a range of 0.22–2.67 gal kWh−1 at operating Texas PCs). NGCCs with the same electrical output would consume 34 billion gallons for cooling (0.23 gal kWh−1), a savings of 41 billion gallons.

3.3. Water consumption for pollution controls in Texas

Sulfur control at scrubbed coal-fired power plants in Texas consumed an estimated 5.0 billion gallons of water in 2007 (0.034 gal kWh−1 overall, including unscrubbed plant generation). NGCCs do not have significant water-consuming pollution controls and thus would have avoided 5.0 billion gallons of freshwater consumption.

Using existing post-combustion carbon capture technologies to reduce carbon dioxide emissions at Texas' existing coal-fired power plants by 85% would increase in-state freshwater consumption by an estimated 86 billion gallons per year. If the existing PC fleet were replaced by fleet-average NGCCs, the same carbon dioxide emission reduction could be achieved with 120 billion gallons per year less in-state freshwater consumption (details in supplementary data available at stacks.iop.org/ERL/7/045801/mmedia).

4. Discussion

4.1. Freshwater consumption impact of coal to natural gas fuel switching in Texas

Converting Texas' coal-fired power plants to NGCCs could reduce freshwater consumption in Texas by over 50 billion gallons per year—60% of total coal-fired electricity-related consumption and enough to supply 1 million people, assuming 140 gallons of daily consumption per person [16]. Savings are likely to be even higher if some of the 23 unscrubbed coal boilers in Texas are obliged to install water-intensive scrubber systems. Some water savings could be realized without investing in new NGCCs by improving existing PC efficiency, increasing utilization of existing NGCCs or switching to less water-intensive cooling systems at power plants, for example, though detailed implementation pathways are outside the scope of this study. Switching from Texas lignite to imported Wyoming and Montana coal could reduce both in-state and overall freshwater consumption for both extraction and sulfur control, with potential air quality benefits and unclear economic tradeoffs for Texas.

The largest single water consumption category for power generation is cooling water (∼80% of electricity generation-related freshwater consumption at PCs and ∼90% at NGCCs), which suggests that installing dry cooling systems at PCs and/or NGCCs is also a viable way to save large amounts of water from the Texas electricity system. Typical dry cooling systems at PCs and NGCCs consume 0.05 gal kWh−1 [16], a reduction of 95% at PCs and 80% at NGCCs. Switching to dry-cooled electricity would reduce current cooling water consumption from 75 to about 7.5 billion gallons per year. However, in Texas-like climates, annual average parasitic losses from switching to dry cooling from wet recirculating or open loop cooling are 2–3% for NGCCs and 11–13% for PCs [33], which translates to an increased fuel and associated extraction water demand of 2–3 or 12–14%. The additional fuel extraction-related water consumption of switching to dry cooling would be about 1.5 billion gallons per year for the PC fleet (assuming current mix of 40% wet recirculating and 60% once through cooling systems)—about 2% of the savings—or less than 0.1 billion gallons per year for a replacement NGCC fleet (assuming current mix of 90% wet recirculating and 5% once through cooling systems) [19]. However, increasing fuel use and installing dry cooling systems would also increase costs and could have other impacts.

Were post-combustion CCS systems to be deployed in Texas, the water advantage of NGCCs versus PCs would be even larger than in the base case. NGCCs produce less climate change pollution, consume less water than PCs and better accommodate intermittent renewable energy sources on grids, making them a potential tool in reducing both water and climate stress with or without CCS systems.

4.2. Water for resource extraction

The finding that on average, Texas coal extraction consumes over seven times as much freshwater per kWh as Texas natural gas extraction is somewhat unexpected (table 4), particularly given public concerns about the amount of water used for hydraulic fracturing in Texas [34]. When consumption from dewatering coal mines is excluded, Texas coal and Texas natural gas extraction consume roughly the same amount of freshwater per kWh. One major reason for the similarity is that existing NGCCs are about 30% more efficient than PCs and thus require less fuel to produce electricity. In practice, Texas' PCs (which are 31 yr old on average [35]) would likely be replaced by new, even more efficient NGCCs, amplifying this distinction.

The water intensity of natural gas extraction in Texas has attracted more attention than the water intensity of coal mining, despite the fact that Texas lignite extraction is unusually water intensive for US coal [18]. In part, this attention is because of the rapid change in water use for natural gas extraction since the commercialization of hydraulic fracturing. In parallel, concerns about water quality impacts have also drawn attention to hydraulic fracturing. Natural gas from shales can be up to about 25 times as water intensive as conventional natural gas (table 4), and the use of high volume multi-stage hydraulic fracturing for shale gas extraction is a recent but rapidly growing phenomenon, creating impacts at thousands of individual well sites. Texas' role as a natural gas exporter also means that much of this water use is for the benefit of users outside of Texas, as the presence of national markets encourages more resource intensive, more expensive extraction techniques than is required by the Texas market alone. By contrast, water use for Texas coal extraction occurs at many fewer individual sites, began at a time when Texas had a smaller population and lower drought stress, and has not changed dramatically over time. Furthermore, most of Texas' coal is imported, with no in-state freshwater consumption for extraction.

5. Conclusions

Switching from pulverized coal to natural gas combined cycle power plants in Texas would reduce in-state freshwater consumption, with savings driven by the greater efficiency of NGCCs versus PCs. While freshwater consumption for natural gas extraction in Texas has and will likely continue to increase with unconventional resource exploitation, lignite extraction is over three times as water intensive as the most water-intensive shale gas expected in Texas, primarily because of the need to dewater mines. Repeating the analysis for other regions, fuel mixes and energy systems (e.g. transportation) would likely prove helpful to decision makers seeking to balance energy and water constraints.

Acknowledgments

This research was funded by the George and Cynthia Mitchell Foundation, the US Department of Energy and the US National Science Foundation's EFRI-RESIN (Emerging Frontiers in Research and Innovation for Resilient Infrastructures) program.