Abstract

High-albedo white and cool roofing membranes are recognized as a fundamental strategy that dense urban areas can deploy on a large scale, at low cost, to mitigate the urban heat island effect. We are monitoring three generic white membranes within New York City that represent a cross section of the dominant white membrane options for US flat roofs: (1) an ethylene–propylene–diene monomer (EPDM) rubber membrane; (2) a thermoplastic polyolefin (TPO) membrane; and (3) an asphaltic multi-ply built-up membrane coated with white elastomeric acrylic paint. The paint product is being used by New York City's government for the first major urban albedo enhancement program in its history. We report on the temperature and related albedo performance of these three membranes at three different sites over a multi-year period. The results indicate that the professionally installed white membranes are maintaining their temperature control effectively and are meeting the Energy Star Cool Roofing performance standards requiring a three-year aged albedo above 0.50. The EPDM membrane shows evidence of low emissivity; however this had the interesting effect of avoiding any 'winter heat penalty' for this building. The painted asphaltic surface shows high emissivity but lost about half of its initial albedo within two years of installation. Given that the acrylic approach is such an important 'do-it-yourself', low-cost, retrofit technique, and, as such, offers the most rapid technique for increasing urban albedo, further product performance research is recommended to identify conditions that optimize its long-term albedo control. Even so, its current multi-year performance still represents a significant albedo enhancement for urban heat island mitigation.

Export citation and abstract BibTeX RIS

1. Introduction

The concept of 'albedo', or fraction of incident solar radiation diffusively reflected from a surface or body, broadly defined, (e.g., clouds, planetary atmosphere, natural landscape), is fundamental to climate science and science in general. Since planetary energy balance is ultimately achieved by equilibrium between absorbed incoming solar radiation and outgoing longwave radiation, planetary albedo is receiving increasing scientific, public and policy attention as a potential adaptation strategy to long-term global warming [1].

Recent terminology refers to albedo enhancement as a 'geoengineering' scheme or 'solar radiation management' [1]. In some cases, most notably those involving altering atmospheric albedo, such schemes will not be without controversy and, indeed, may trigger unintended consequences. In other cases, such as those that replace anthropogenic dark, non-vegetated surfaces with lighter surfaces will be relatively uncontroversial. Candidates here include surfaces at grade, such as road pavements and sidewalks, building facades and rooftops.

Maximizing rooftop albedo, or alternatively using cool colors [2, 3], is now recognized as preferred to conventional dark membranes. The motivations include reduced warm-season building energy demand and greenhouse gas emissions for cooling, urban heat island mitigation and associated air quality and urban energy peak demand benefits [4]. The present study will not address energy impacts as it would require modeling heat flow and need additional structural roof data. We performed such an analysis in a prior study of white roofs [5] where we had the needed data.

In this letter we report on and evaluate small-scale performance data from three monitored white roof projects in New York City. Such data are important for validation of urban albedo modeling assumptions, understanding urban heat island mitigation effectiveness at the building scale, and, germane to this letter, identifying product performance differences between various membrane material technologies.

The three membranes (table 1) include one asphaltic (with an acrylic top coating), one rubberized (ethylene–propylene–diene monomer (EPDM)), and one thermoplastic (thermoplastic polyolefin (TPO)). They represent a cross section of the major flat roof membranes installed within the US, with approximately 60% of the market being multi-ply asphaltic and 40% being single-ply EPDM and TPO (see the appendix). Each membrane was located on one of three separate buildings within the New York City borough of Queens. Because each of the sites for this study were institutional buildings and each owner had prior specific interests and preferences for their white roof selection, it was not possible for the present study to study the three membranes in a side-by-side arrangement under identical atmospheric conditions.

Table 1. Location, membrane specifications and installation costs per square foot (/sq. ft) for test sites.

| Location | Membrane type | Product/manufacturer | Installation costa ($/sq. ft) | Initial solar reflectanceb | Age (yrs) |

|---|---|---|---|---|---|

| MoMA Queens | Asphaltic membrane painted with elastomeric acrylic | APOC® 247 sun-shield white reflective roof coating | $0.50c (+ cost of underlying membrane) | 0.87 | 2 |

| Con Edison | EPDM rubber membrane | Carlisle sure-white FleeceBACK | $15–18c $25–28d | 0.76 | 3 |

| Queens Botanical Garden | TPO membrane | Carlisle sure-weld TPO membrane | $15–18c $25–28d | 0.79 | 4 |

aCosts include materials and labor; material costs are roughly 15% of the total installation cost. bUsing test method ASTM C-1549. Cool Roof Rating Council (CRRC). cNon-union labor. dUnion labor.

The main national cool roof program that defines minimum performance standards for cool roofs is the EPA Energy Star Reflective Roof program. To qualify for the Energy Star rating, a cool roof must have an initial 'solar reflectance' greater than or equal to 0.65 and a three-year solar reflectance greater than or equal to 0.50. Such cool roofs are also generally assumed to have high thermal emissivity as well (e.g., 0.90 or above) but a performance standard does not appear to have been defined yet for emitted longwave radiation.

As was discussed in Bretz et al [6], a precautionary note is needed concerning the terminology of albedo versus solar reflectance. Often the two terms are used interchangeably [7] even though they should not. Given that natural sunlight conditions differ everywhere on Earth with time of day and season, including atmospheric variability from clouds and aerosols, standardizing a field measurement for albedo may by definition be impossible. As an alternative a laboratory measurement using a spectrophotometer to simulate visible light is often applied. Cool roof ratings for solar reflectance should therefore be regarded cautiously as proxies for actual albedo performance in the field. References to albedo below will refer to a true outdoor field measurement whereas reflectance will refer to a laboratory measurement.

2. Summary of previous related white roof monitoring studies

Many studies have looked at the surface energy balance properties of white acrylic roof coatings applied to various substrates and have reported on temperature, albedo, solar reflectance and/or emissivity performance. Fewer studies have examined the cooling performance of single-ply TPO, EPDM or PVC membranes, which are the dominant white roof professional membranes in the US.

Considering first some prior studies on acrylic coatings, Bretz et al [6] examined the albedo performance of a number of elastomeric acrylic coatings on an outdoor field site using a pyranometer and exposed rooftop surfaces in the state of California. Most of the multi-year albedo decline occurred within the first year, with an average albedo loss of 0.15, starting from an average initial albedo of 0.65. After that the incremental decreases in albedo were small. Washing returned the albedo values close to initial. Berdhal et al [8] measured spectral reflectance and total solar reflectance in a lab-setting for a number of commercial white elastomeric coatings applied to smooth substrate using a spectrophotometer. Fresh total solar reflectance for these samples was in the range 0.74–0.85. In a parallel study, Akbari et al [9] studied a building in Sacramento, California to evaluate its thermal and energy savings from a white coating and compared this to simulations using a DOE-2 building model. They found significant energy savings from the experimental data, which were underestimated by the model. Akridge [10] monitored the temperature effect of white acrylic coating applied to a 1200 m2 metallic galvanized roof on a single story building outside Atlanta, Georgia. The fresh acrylic coating resulted in an immediate peak surface temperature drop of ∼33 °C (60°F). The long-term data showed little loss in this temperature performance for the following year. Synnefa et al [11] monitored the temperature, albedo and emissivity performance of 14 types of commercially available reflective coatings. However the goal of the study was to evaluate the temperature benefits of such coatings as if they were applied to concrete sidewalks, pavements, parking lots and vertical building facades so the data are not readily comparable to this letter on rooftop coating. Parker et al [12] performed building field temperature and albedo studies on nine buildings in South, Central and West Florida, in which white elastomeric paint coatings were applied to various shingle, gravel and metallic roof surfaces, including black, white and gray shingle systems. The pre-coated shingles had albedos mostly in the range of 0.15–0.30 and after coating this albedo jumped to a range of 0.60–0.73. For a site with an albedo increase of 0.22–0.73, peak surface temperatures dropped from 74 to 43 °C. Long-term performance was not evaluated in this report.

With respect to single-ply professional white membranes, Konopacki et al [13] and Rose et al [14] studied a white PVC thermoplastic membrane in Austin, Texas and found a modest roof reflectance drop from 0.83 to 0.75 over three years. Roodvoets et al [15] studied long-term albedo, emissivity and temperature performance for a number of PVC, EPDM and TPO membranes in an East Tennessee climate, on what appears to be a non-urban test location. They found a 30–50% loss of reflectance after three years with most loss within the first two years.

We conclude that there are fewer academic studies of single-ply membranes than of acrylic membranes and that our study is distinguished from prior research by comparing these two broad categories of white roofs. Moreover our study is the first for white roofing performance in New York City.

3. Project site descriptions and performance data

3.1. Museum of Modern Art Queens—elastomeric acrylic paint applied to asphaltic membrane

The youngest white roof test site we are monitoring is located on a Museum of Modern Art Queens (MoMA Queens) facility in Long Island City, New York. The project site is adjacent to a busy urban thoroughfare—Queens Boulevard—and also to an elevated subway train line, which may be creating elevated atmospheric pollution or soot conditions.

This white roof consists of coating white elastomeric acrylic paint as a 'retrofit' on top of an existing standard dark asphaltic membrane. The paint, 'APOC®-247' [16] is manufactured by APOC, Inc. According to the manufacturer, this product expands and contracts during daily thermal cycles to resist cracking and damage and provides good adhesion to a variety of roofing substrates.

The product is characterized by the manufacturer as delivering an initial solar reflectance value of 0.87, using the American Society for Testing and Materials (ASTM) test method C-1549, and emissivity between 0.90 and 0.93 [16]. The ASTM C-1549 method measures solar reflectance at four wavelengths: 380, 500, 650 and 1220 nm. These performance metrics will be evaluated in this report for this specific project and application.

The acrylic paint approach comprises one of the flagship urban heat island initiatives being undertaken in New York City by the Mayor's Office of Long Term Planning and the New York City Department of Buildings [17]. The advantages of this approach are many: (i) it can be applied as a retrofit to existing dark roofing membranes that are in good condition and therefore do not require reroofing at high cost; (ii) it can be applied by the building owner themselves to achieve the lowest costs; and (iii) in New York City a low-tech volunteer organization trained in the application [18], will apply the paint for a building at the relatively inexpensive total cost of $0.50/square foot (table 1) (or $5.38/square meter) [35]. These advantages mean the method offers the most rapid technique for whitening urban albedo on a large scale. On the other hand, as a retrofit, it does require the building owner to pay an additional expense over what they paid for their existing and already functional roofing membrane (table 1). The program has been in existence for approximately three years. The strategic plan for the initiative aims to create 250 million square feet of such white roofing—which is approximately 25% of all available New York City rooftop area—by 2020. The program represents the first deliberate attempt to significantly increase New York City's albedo in its history.

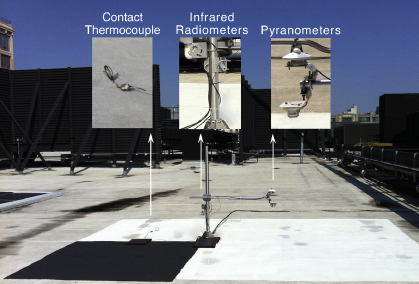

Instrumentation at this site includes the following sensors: (i) two narrow-field-of-view infrared radiometers from Apogee Instruments (model number SI-121 [19]) measuring surface temperatures on the white and black test membranes with a reported accuracy of ±0.2 °C; (ii) two back-to-back solar spectrum Kipp and Zonen pyranometers (model number CMP3 [20]) that measure incident and reflected shortwave radiation in the spectral band of 310–2800 nm and have view factor of 180° and (iii) one contact type-E thermocouple (Campbell Scientific Instruments (CSI) model number CS-220 [21]) measuring the white surface contact temperature. According to the CSI specification documents, this thermocouple has an accuracy of ±0.3 °C for the built-in reference junction temperature range of −25–50 °C.

The pyranometer boom arm was lowered to approximately 45 cm above the surface (figure 1) to minimize, and ideally eliminate, far field non-test surface light contamination. We acknowledge the possibility that not all far field contamination was eliminated. In addition, with a low boom arrangement, the risks of instrument related shadowing of the test surface increases.

Figure 1. White elastomeric acrylic paint surface, black asphaltic control membrane and instrumentation at the MoMA Queens test site (Long Island City, New York, NY). The surrounding gray area is the aged white roof that had darkened significantly in the two years before the sensor deployment began.

Download figure:

Standard image3.1.1. Temperature performance.

During the summer, peak black membrane temperatures often reach 70 °C (158°F) (figure 2). During a record-breaking heat wave on 22 July 2011 the peak black rooftop temperature exceeded 76.5 °C (170°F). Electric power load was the highest in the City's history at 13 189 MW [22]. Clearly under such conditions a preponderance of black urban rooftops is contraindicated as it is contributing a significant heat burden onto the city's atmosphere, buildings and energy demand.

Figure 2. Comparative white and black roof temperatures at the MoMA Queens site,where white acrylic paint was applied to a black asphaltic substrate. Data are shown for the meteorological summer June–August 2011.

Download figure:

Standard imageDaytime peak black temperatures were on average 23.6 °C (42.5°F) warmer than the test white surface. The temperature difference is most strongly a function of sunlight as seen by looking at cloudier days, with cooler temperatures, when the temperature differences decrease markedly.

Another interesting feature is the very low nocturnal temperature achieved on both test surfaces, to well below ambient air temperatures. This is a basic surface radiation balance effect wherein, on calm, clear nights, energy balance is largely being achieved between upward longwave radiation from the surface and downward longwave radiation from the atmosphere. On such clear nights, downward radiation is emanating from very high altitudes in the troposphere with correspondingly low temperatures. The surface therefore continually loses net longwave energy and cools as it seeks to match the high-altitude atmospheric radiating temperatures.

Extremely large temperature cycles are a significant factor in rooftop deterioration over time (e.g., [23, 24]). The uncoated black membrane is undergoing a cycle roughly double in amplitude to the white membrane. This implies greater material expansion and contraction cycles that will result in a greater membrane stresses and more rapid degradation over time. Thus the simple procedure of applying a white coating is likely to significantly increase rooftop membrane service lifetime, partially offsetting the additional costs for the coatings. UV radiation is also known to be a strong factor in physical and photo-degradation of organic materials, including roofing membranes [23, 24] and manufacturers accordingly include light-stabilizers to reduce this effect. It is possible the acrylic paint is reducing UV exposure as well but we cannot assess this with the present instrumentation.

In terms of the long-term climate impact of white roofing surfaces, the average daily temperature difference between black and white may be more germane. Table 2 shows the statistics for the peak and average temperature differences both for the meteorological summer and during a heat wave date that summer. The average diurnal temperature differences are more moderate than the peak differences, of course, and average 6.6 °C. Urban heat island mitigation studies and strategies aim to reduce urban temperatures by a few degrees Celsius [4].

Table 2. Average (Avg) peak and average daily temperature differences observed on the MoMA Queens site for the two test surfaces during the summer 2011 (left) and peak temperatures, difference and average daily difference for the hottest day of that summer (right).

| MoMA Queens summer 2011 | (°C) | MoMA Queens 22 July 2011—heat wavea | (°C) |

|---|---|---|---|

| Avg peak black (B) temp | 63.3 | Peak black temp | 76.5 |

| Avg peak white (W) temp | 39.7 | Peak white temp | 53.1 |

| Avg B and W peak temp diff | 23.6 | Peak temp diff | 23.4 |

| Avg B and W daily temp diff | 6.6 | Avg B and W daily temp diff | 8.6 |

3.1.2. Albedo performance.

Although this project is recent, the roof was originally treated with the paint coatings two years prior to the data collection in the present study (sequential photos in figure 3).

Figure 3. White roof conditions during the summers of 2010 and 2011 showing albedo loss effects over time. The original black membrane was first coated in summer 2009. (a) Surface conditions one year later after a fresh test patch was applied in summer 2010. (b) Surface conditions two years later just before sensor deployment began. (c) Surface conditions at the start of data collection after a second recoating.

Download figure:

Standard imageInspection of the surface (figures 3(b) and (c)) shows that rainwater ponding is a significant contributor to darkening. Also runoff from rooftop infrastructure (figure 3(c)) appears to lead to darkening. In addition, it may be that the technical approach itself—applying white paint coating on top of a black asphaltic surface—is at a disadvantage because over time, with large temperature cycling, the granulated asphalt surface may be beginning to become partially exposed itself or may be emitting oils that surface [23]. It was noted above that the building is located adjacent to a busy urban thoroughfare. Such transportation arteries may be creating a local air pollution or soot load that could be contributing to the rooftop darkening as well. Sorting out which of these factors is dominant, if any, will require further research such as locating possible air pollution readings for the area. Our impression from multiple visits, however, leads us to believe the granular dark substrate is a primary factor. On the other hand, Cheng et al [25] compared solar reflectance declines between urban and rural test sites and found larger declines in the urban setting leading them to conclude air particulates was the dominant effect.

Albedo data for the site before and after a fresh recoating, which took place on 25 May 2011, displays a pronounced step function (figure 4). The data clearly shows that after two years, the surface had experienced roughly a 0.30 albedo decline from a presumed initial albedo of 0.65, representing almost a 50% albedo loss in two years. The field-measured fresh albedo is also lower than the rated performance for fresh solar reflectance from the product manufacturer of 0.87—an example of the possible inaccuracy of the solar reflectance methods as a proxy for field albedo.

Figure 4. Observed albedo data for the MoMA Queens site before (at two years of age) and after a fresh acrylic paint recoating, which took place on 25 May 2011.

Download figure:

Standard imageHourly averaged albedo gives an indication of the change in albedo during the daily solar cycle (figure 5). In a dense urban setting like New York City, early morning and late evening shadowing is almost unavoidable as the ubiquitous building and infrastructure on the horizons will impact the incident light during sunrise and sunset. Such shadowing can result in a lowering of albedo if the shadow falls on the test membrane, or an elevation of albedo if it falls on the skyward sensor. These interference effects arose with the current deployment and are noted by dashed line in figure 5. As is well-known (e.g., [26, 27]) albedo is generally a strong function of solar incidence angle, and is usually higher during early morning and late evening hours at high incidence angles [28]. Ignoring the shadowing effect, albedo on the membrane surface shows a characteristic U-shaped profile (figure 5).

Figure 5. Hourly averaged albedo data for the MoMA Queens site during the summer of 2011 showing the change during the daily solar cycle. Dashed lines indicate interference by rooftop infrastructure, which cast shadows on the sensors during sunrise and sunset.

Download figure:

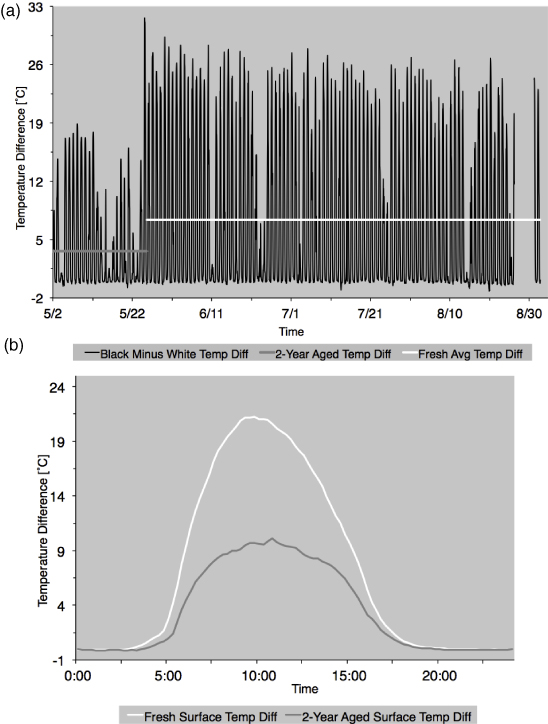

Standard imageThe albedo losses over time do have a significant impact on temperature. Temperature difference plots between the black and white surfaces (figures 6(a) and (b)) show that the aged white surface does warm considerably relative to black. The hourly average difference plots for the fresh and aged surfaces (figure 6(b)) show that after two years the white surface has lost roughly half of its cooling performance, consistent with its 50% decline in albedo.

Figure 6. (a) Hourly black minus white temperature differences measured over summer 2011 at the MoMA Queens site. Also shown are the average pre-recoating difference value (horizontal gray line) and post-recoating difference value (horizontal white line). (b) Black minus white surface temperature differences averaged over the diurnal cycle for the fresh coating (white line) and also for the two-year aged surface (gray line) at the MoMA Queens site. The aged surface lost approximately half its temperature control, consistent with an approximately 50% albedo loss.

Download figure:

Standard image3.1.3. Emissivity performance.

We installed a contact thermistor to the white surface in addition to the infrared (IR) radiometric temperature sensor (shown in figure 1) in order to provide an estimation of the emissivity, as an alternative method to using an emissometer, which was not available for this project. The infrared sensor is programmed with an assumed emissivity of 0.95, which is appropriate for many organic-based materials and many other natural surfaces. If there is a difference between the contact temperature, which measures true temperature, and the IR sensor reading, it means there is an emissivity difference from the assumed value of 0.95. The actual emissivity can then be determined using the following formula:

where TIR and Tactual represent the IR sensor temperature and contact sensor temperature, respectively, with both expressed in Kelvin.

The emissivity as calculated using equation (1) (figure 7) is close to the assumed 0.95 value, at around 0.97 and this represents a trivial temperature correction as far as the IR sensor data is concerned. We observe however an interesting diurnal cycle with the emissivity dropping slightly during the daytime and rising at night (figure 7). We are not able to evaluate the exact cause of this cycle but speculate that it could be an effect of dew formation at night where the water at the surface slightly increases the surface emissivity and then evaporates during daytime. It may also be a direct temperature effect on material emissivity. The literature on time-varying emissivities is not extensive as such data may be difficult to obtain in field experiments.

Figure 7. Average hourly emissivity values at the MoMA Queens site, calculated using data for equation (1), over the diurnal cycle are shown by the upper fluctuating line. The constant dashed line is the assumed infrared sensor emissivity of 0.95 that was programmed into the datalogger.

Download figure:

Standard image3.2. Con Edison Learning Center—EPDM membrane

The second monitoring site is located on an educational facility belonging to the New York City electric utility company, Con Edison, Inc., and is also located in Long Island City, New York. In contrast to the MoMA Queens site, this building is located adjacent to the East River and in a low traffic area with no major transportation arteries nearby.

The white and black roof test membranes installed at this site are both single-ply ethylene–propylene–diene monomer (EPDM) materials. We therefore had an opportunity to compare black and white surface membranes made of the same material at this site. The black membrane ('FleeceBACK') and the white membrane ('Sure-White FleeceBACK') are manufactured by Carlisle Syn Tech Incorporated. Installation costs for this membrane range from $15–$28/square foot ($161–$301/square meter) including materials and labor (table 1). The manufacturer's specification sheet rates the initial solar reflectance at 0.76 initially, using the same ASTM C-1549 test method mentioned above, and 0.64 after three years without cleaning. The emissivity is similarly rated at 0.90 initially and 0.87 after three years.

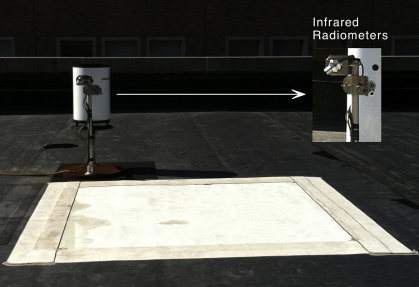

Monitoring at this site began in October 2008. Only infrared surface temperatures are being measured at this site (figure 8), not albedo nor emissivity, because of project budget constraints. The white and black membranes are approximately three years of age at the time of the photograph (figure 8) and have not been cleaned during that time. Some data communication problems led to lost temperature data for portions of the monitoring period as seen in figure 9.

Figure 8. Black and white EPDM membranes and surface IR temperature sensors (the white bucket in the background is a rain gauge) at the Con Edison study site. The membranes are three years old at the time of this photograph and the white membrane has not been cleaned during that time.

Download figure:

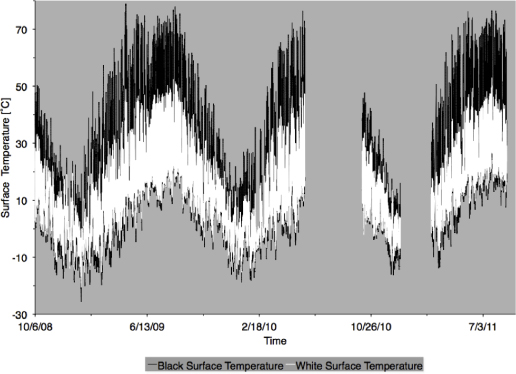

Standard imageFigure 9. Nearly three years of average hourly black and white membrane temperatures observed for the black and white EPDM single-ply membranes at the Con Edison site (October 2008–August 2011).

Download figure:

Standard imageThe dramatic warm-season temperature differences are evident at the Con Edison site. The black membrane temperature cycles are vastly greater and, as noted with the MoMA site, will create greater material thermal stresses and degradation over time. Indeed during the summer, black membrane temperature cycles have an amplitude approaching 70 °C (126°F) in a single day.

In contrast, extraordinary cold nocturnal winter surface temperatures were also observed. At one point the black and white membrane temperatures reached a low of −25.6 °C (−14°F) and −20.7 °C (−5°F), respectively. Such temperatures are comparable to wintertime low air temperatures in coastal Antarctica. As discussed, they are the result of extremely weak downward longwave radiation on clear winter nights, emanating from very high-altitude temperatures in the atmosphere. The importance of the nocturnal greenhouse effect for nocturnal surface temperatures can be contemplated in this regard.

Another feature is the persistent nocturnal warmth on the white membrane as compared to the black. Indeed this warmth was strong enough to result in the counterintuitive and unexpected observation that this white membrane is actually slightly warmer in wintertime than the black membrane [5]. A rooftop wintertime heat flow energy analysis for this site [5] showed there was no building 'winter heat penalty' from this white surface because, in effect, it was slightly warmer than the black membrane in the winter. Our explanation is that this must be due to a lower field emissivity on this white membrane that may not have been recognized by the manufacturer (emissivity rated at 0.90). An informal handheld sensor measurement by the authors suggested an emissivity of 0.48 but the test is difficult to do with spot sampling [5]. However this raises the interesting question as to whether a lower emissivity white membrane might be desirable in cold climate zones.

The multi-year data (figure 9) do not suggest a significant loss in temperature control by the white EPDM membrane relative to black over the three-year period. Indeed comparing tables 2 and 3, for meteorological summer 2011, the EPDM membrane and acrylic paint membrane show very similar temperatures. As the specification sheet for the EPDM indicated a three-year aged albedo of 0.64 and figure 4 indicates the acrylic surface also had an albedo of approximately 0.64, our data are consistent with a three-year aged EPDM albedo in the range of 0.64. Thus the aged EPDM membrane is performing as well as the new acrylic membrane.

3.3. Queens Botanical Gardens—TPO membrane

The oldest of our monitored sites is located on the rooftop of the Queens Botanical Garden (QBG) in Flushing, Queens. The building was one the first Leadership in Energy and Environmental Design (LEED) Platinum-rated projects in the New York City area and was completed in 2008 and is thus currently four years old. As a botanical garden, the location is a heavily urban-vegetated region without adjacent transportation arteries.

The white roofing membrane installed at this site is a thermoplastic polyolefin (TPO) membrane and was supplied and installed by Carlisle Inc. roofing. Installation costs for this membrane range from $15–$28/square foot ($161–$301/square meter), including materials and labor (table 1). The manufacturing company rates the initial solar reflectance of this membrane at 0.88.

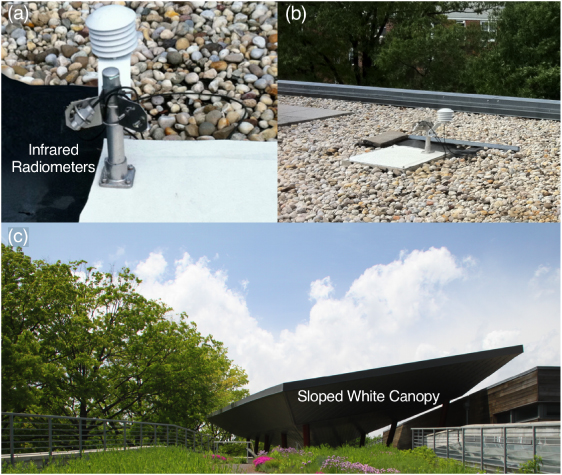

The membrane was installed on a sloping canopy intended for stormwater runoff control (seen in figure 10(c)) and was thus not suitable for a horizontal temperature analysis. Therefore, we installed a test sample of the membrane horizontally next to an exposed black geotextile cloth (figure 10(a)). The experimental arrangement is thus not ideal but the best available substitute to acquire performance data at this site. Due to project budget constraints, only black and white IR surface temperatures are being monitored here (table 4).

Figure 10. Sensor and test surfaces set up ((a) and (b)) on the Queens Botanical Garden. The building TPO membrane is actually a sloped canopy (c) requiring the use of a small horizontal test membrane.

Download figure:

Standard imageFigure 11. Hourly black and white membrane temperatures at the Queens Botanical Garden site (2008–2011). The test site roof experienced severe storm weather damage during the summer 2010.

Download figure:

Standard imageWe found that the difference in temperature between the two surfaces decreases over time (figure 11). This is mainly due to black membrane cooling, especially during summer 2010. That season was a particularly stormy one for the location. There were high winds early in the season that overturned the rain gauge and damaged the roof and spread debris widely, including over the membranes. Later in the season, a highly anomalous tornado touched down nearby and inflicted severe damage to trees in the area. These events and debris likely affected the temperature readings during summer 2010. The black surface dust and debris may have lightened its color over time, leading to the observed cooling over the years. Judging just the white TPO membrane cycles however, it appears that the white temperature performance has been relatively stable over the three years and that the albedo has not declined markedly.

Table 3. Summary of average (Avg) peak and average daily temperature differences observed on the Con Edison Learning Center for the two test surfaces for meteorological summer 2011 (left) and peak temperatures, difference and average daily difference for the hottest day of that summer (right).

| Summer 2011 | (°C) | 22 July 2011—heat wavea | (°C) |

|---|---|---|---|

| Avg peak black (B) temp | 65.4 | Peak black temp | 77.4 |

| Avg peak white (W) temp | 41.7 | Peak white temp | 53.4 |

| Avg B and W peak temp diff | 23.7 | Peak temp diff | 24.0 |

| Avg B and W daily temp diff | 5.1 | Avg B and W temp diff | 6.7 |

Table 4. Summary of average (Avg) peak and average daily temperature differences observed on the Queens Botanical Garden site for the two test surfaces for meteorological summer 2011 (left) and peak temperatures, difference and average daily difference for the hottest day of that summer (right).

| Summer 2011 | (°C) | 22 July 2011—heat wavea | (°C) |

|---|---|---|---|

| Avg peak black (B) temp | 51.0 | Peak black temp | 64.0 |

| Avg peak white (W) temp | 39.4 | Peak white temp | 53.1 |

| Avg B and W peak temp diff | 11.6 | Peak temp diff | 10.9 |

| Avg B and W daily temp diff | 3.3 | Avg B and W daily temp diff | 3.7 |

4. Discussion and concluding remarks

Table 5 shows a synopsis of the temperature data for the three projects for the overlapping time period of summer 2011. Overall, we found very similar white roof temperature performance for the three test membranes (table 5). The key point however is that the retrofitted paint membrane is new while the professional EPDM and TPO membranes are three and four years old, respectively. This succinctly proves that the professional membranes are maintaining their high-albedos more effectively. We also conclude that the three membranes have a similar albedo in the 0.65 range, since this was directly measured on the acrylic paint membrane. The emissivity performance appears more variable and we argue here and in prior publications that the EPDM membrane we are monitoring has a lower emissivity than reported from the product specification information. It has been shown in Gaffin et al [5] that in colder climates during winter, lower emissivity may actually be a positive attribute for white roofs with respect to avoiding any possible winter heat energy penalty. If a performance standard for emissivity is set for roof membranes, the possibility that a low emissivity may be desirable in cold climates to avoid any winter heat penalty, should be considered.

Table 5. Average (Avg) black and white temperature values and average difference for the three test sites over summer 2011.

| Site | MoMA Queens | Con Ed | QBG |

|---|---|---|---|

| White membrane type | Fresh acrylic paint | Three-year old EPDM | Four-year old TPO |

| Avg black temp (°C) | 31.8 | 31.5 | Naa |

| Avg white temp (°C) | 24.4 | 26.4 | 25.1 |

| Avg temp diff (°C) | 7.3 | 5.1 | Naa |

aBlack geotextile cloth not comparable to waterproof membranes.

The better performance of the professional membranes is perhaps to be expected as the application of acrylic paint onto a very dark asphaltic substrate risks substrate exposure effects. Our results for the painted membrane most closely compare with those of Bretz et al [6] although we observe a stronger continued albedo decline with age. Nevertheless, our two-year aged acrylic surface albedo still represents a significant boost in albedo over the original black surface, which likely has an albedo in the vicinity 0.05 [26].

Further research into the dominant causal factor (e.g., air pollution, substrate exposure, infrastructure runoff), if any, for the observed albedo decline of the acrylic surface, will be important for improving the technique and should be undertaken. The acrylic program in New York would greatly benefit from improved maintenance guidelines, including best washing methods. Recoating is unlikely to be a viable option, despite the relatively low costs of $0.50/square foot ($5.38/square meter) because it would require repeated costs of hundreds to thousands of dollars even for relatively small building owners, who are unlikely to do this for an already functioning roof membrane. One policy implication is that at the time of roof replacement for any urban building, only white membranes should be considered given that they are the same costs as dark membranes and they outperform painted surfaces.

Location may also strongly affect white roof performance in various ways, including some that are surprising. For example, our experience with the white membrane in a relatively well-forested area, a botanical garden, showed evidence that leaf litter and vegetation debris from tree canopy can quickly impact surface exposure and thus affect albedo and temperature performance. More data could be brought into the analysis such as differences between site sky view and windspeeds, for example. Our informal investigator assessment of the sky view for these rooftops is that they have fairly unobstructed sky views in each case as they all reside in low-building height neighborhoods. Windspeed differences have not been assessed here but may in a future study.

Urban climate models are increasingly studying white and other roofing scenarios for the impacts on local, regional and global climate (e.g., [29–34]). The data in this letter may be of use to such models that seek to simulate building roofing scenarios using various albedo parameters. Moreover, the field data shown in this report may help validate building façade temperature cycles simulated in urban climate models.

The challenges of installing and maintaining a distributed network of surface energy balance monitoring equipment in an urban environment for many years are evident and significant. Equipment and sensor problems increase over time, storm damage and building owner interference occurs and, as the example of shadowing of the albedometer shows (figure 5), ideal siting conditions, even on rooftops, are very difficult to ensure. However we believe the benefits of observing product performance on actual urban buildings, in an array of locally different environments, provides important field data and the lessons learned are worth the challenges.

Acknowledgments

We thank two anonymous reviewers for detailed comments that significantly improved the letter. We also thank Curtis Maughan at Campbell Scientific Instruments for technical assistance with our sensor installations and Tom Taylor at GAF for general roof membrane information. We thank Chris O'Karma at Con Edison for allowing us to study their project and installing the test sample white EPDM membrane for our study. We thank Nicole De Feo, Jennifer Souder and Gennadyi Guran for their support of our project at the Queens Botanical Garden.

Appendix.: Summary of general roofing industry classifications for waterproof membrane types [36]

The two broad categories of flat roof membranes are (i) single-ply and (ii) multi-ply asphaltic systems (modified bitumen, mod-bit, and built-up roofing (BUR)). Single-ply systems can be categorized as EPDM black, EPDM white, TPO and PVC. EPDM market share has been flat or declining in recent years, while TPO share has been growing fairly rapidly. Approximately 99% of the TPO membranes today are white. EPDM white membranes are available but generally are not cost competitive. TPO and PVC are heat weldable whereas EPDM uses adhesive seaming.

PVC membranes were the first heat weldable single-ply system. There is some consumer concern about the chemical impacts of PVCs including their incorporation of chlorinated polyvinyls and their use of phthalate plasticizers.

Built-up multi-ply roofs use multiple layers of glass mat that is then saturated with asphalt and topped off with sand, gravel or larger river rock. A second category of such roofs are modified bituminous roofs having either 1 or 2 base sheets with a smooth or granulated cap sheet. Mod-bit membranes are typically polyester mat based.

Urban roofs tend to be asphaltic and hence low albedo because of the heterogeneous geometry and multiple roof penetrations for infrastructure. Such roofs are more labor intensive in their installation. Suburban commercial flat roofs, like big-box stores, are almost exclusively TPO or EPDM. The simple geometry of such structures and relative lack of rooftop penetrations allows them to be installed rapidly. Green roofs now are increasingly being underlain with TPO because of the welded seam structure, which has great strength and resists root migration very well.

In general, older roofs tend to be BUR, while newer roofs are increasingly becoming TPO membranes.