Abstract

Rhombohedral Bi(Mg0.5Ti0.5)O3-modified BiFeO3-BaTiO3 ceramics were successfully textured along the nonpolar 〈100〉 direction using the templated grain growth process for the first time. The textured 0.90(0.33BaTiO30.67BiFeO3)0.10Bi(Mg0.5Ti0.5)O3 (33BTBF-10BMT) ceramics were fabricated by a 33BTBF-10BMT matrix with BT templates. The degree of orientation was investigated by various sintering temperatures, and the 80% oriented 33BTBF-10BMT along the 〈100〉 direction was achieved at a relatively high sintering temperature. However, the degree of orientation abruptly decreased at the highest sintering temperature of 1100 °C due to the large pores and low relative density. Based on the analysis of the unipolar strain measurements, the highest strain and d33* values were observed in the textured ceramics with 80% orientation. These textured ceramics exhibited approximately 0.3% strain and a d33* exceeding 400 pm V−1, representing approximately 1.5 times higher values compared to the nontextured ceramics.

Export citation and abstract BibTeX RIS

1. Introduction

Pb-free BiFeO3-BaTiO3 (BFBT)-based piezoelectric ceramics are strong candidates for replacing Pb-based piezoelectric ceramics, owing to their relatively large piezoelectric response with a high Curie temperature. 1–4) Among them, we investigated the various ferroelectric and relaxor ferroelectric-like piezoelectric and ferroelectric properties in Bi(Mg0.5Ti0.5)O3 (BMT)-modified BFBT systems through a chemical composition dependence. 2) Specifically, the composition range of (1−y){xBT(1−x)BF}yBMT, where x = 0.25, 0.30, 0.33, and 0.40, and y = 0.01, 0.03, 0.05, and 0.10, was explored. Among the various investigated solid solution ceramics, the composition with x = 0.33 and y = 0.10 (referred to as 33BTBF-10BMT, hereafter), displayed relatively large piezoelectric and ferroelectric properties, despite exhibiting a pseudo-cubic symmetry as confirmed by high energy synchrotron X-ray diffraction. The origin of ferroelectricity in pseudo-cubic BMT-modified BFBT and pure BFBT ferroelectrics was proposed by the A-site Bi ion off-centering mechanism. 5–7) However, the piezoelectric response of the 33BTBF-10BMT ceramics is approximately two-thirds that of common Pb-based piezoelectric ceramics, such as lead zirconate titanate. 8) Furthermore, it is widely believed that piezoelectric materials such as BF-based ceramics possessing a high Curie temperature have low piezoelectric properties. 9,10) Consequently, such conventional belief should be challenged through the application of other concepts rather than chemical composition dependence or morphotropic phase boundary strategy to achieve high-performance Pb-free piezoelectric materials with high Curie temperature.

To ensure the development of alternative high-performance Pb-free piezoelectric ceramics, it is crucial to achieve comparable properties in polycrystalline ceramics as those found in piezoelectric single crystals, which exhibit excellent piezoelectric and ferroelectric properties by their strong anisotropy. 11–13) Ultrahigh piezoelectric properties and strain response, such as piezoelectric charge constant d33 over 2500 pC/N, strain over 1.7%, and hysteresis-free strain, were achieved in [001]-poled rhombohedral Pb(Zn1/3Nb2/3)O3-PbTiO3 (PZN-PT) and Pb(Mg1/3Nb2/3)O3-PbTiO3 (PMN-PT) single crystals. 13) In general, higher piezoelectric performance is expected when an external electric field is applied along a polar direction. However, in PZN-PT rhombohedral crystals, which possess 〈111〉 polar vectors, the application of an electric field along the nonpolar direction such as [001] yields unexpectedly excellent results compared to general wisdom. This result suggests that a new engineered domain configuration represents a powerful technique for achieving ultrahigh piezoelectric performance with hysteresis-free strain curves. Regarding the piezoelectric single crystals through the engineered domain configuration, various literature has been extensively reported on Pb-based and Pb-free piezoelectric single crystals. 11–20) Despite their high performance of piezoelectric properties, piezoelectric single crystals are burdened with high production costs and difficulties in processing methods. For this purpose, it should be developed polycrystalline ceramics to apply the engineered domain configurations.

Polycrystalline ferroelectric ceramics typically exhibit randomly oriented polarization directions with numerous grains. In order to attain performance levels comparable to piezoelectric single crystals, it is crucial to align all the grains within polycrystalline ceramics along specific directions, thereby enhancing their anisotropy. The concept of grain orientation, commonly referred to as "textured ceramics," has emerged as a technique for aligning grains along specific crystallographic directions. 21–24) By employing textured ceramics along nonpolar directions, the piezoelectric properties of textured ceramics could be significantly enhanced compared to their nontextured counterparts.

In this study, we fabricated the highly oriented rhombohedral BMT-modified BFBT piezoelectric ceramics along the nonpolar 〈100〉 direction for the first time. Common textured processes and templates such as the templated grain growth (TGG) process and BT templates were chosen in this research. The effect of various sintering temperatures on the degree of orientation and various dielectric, ferroelectric, and piezoelectric properties was systematically studied. The textured ceramics exhibited approximately 1.5 times higher piezoelectric strain response compared to the nontextured ceramics.

2. Experimental methods

2.1. Synthesis of matrix powder

The chemical compositions, 0.90{0.33BaTiO3-0.67BiFeO3}0.10Bi(Mg0.5Ti0.5)O3 (33BTBF-10BMT), were prepared using BaCO3, Fe2O3, Bi2O3, MgO, and TiO2 powders. The starting powders were first mixed through ball milling for 24 h and then calcined at 800 °C for 6 h. Next, the calcined powder and 0.1 wt% of MnO2 were performed through second ball milling to reduce leakage current and create a large size difference between the matrix powder and templates, aiding the TGG process. 3,25) The average size of the matrix powder was less than 500 nm.

2.2. Synthesis of templates

The BaTiO3 (BT) templates were synthesized using the three-step molten salt method. A bismuth-based layered structure of Bi4Ti3O12 (BiT) precursor, which formed an aurivillius-type layered structure, was prepared through the molten salt method. Initially, Bi2O3, TiO2, NaCl, and KCl were used as raw powders and mixed by hand milling. The mixture was then heated at 1100 °C for 1 h, and the resulting product was washed several times with hot deionized water. In the second step, the synthesized BiT precursor was mixed with BaCO3, TiO2 powders in a molar ratio of 1:1.1:1.1 by magnetic stirring. An equal amount of NaCl and KCl was added, and the mixture was heated at 1080 °C for 1 h. The powder was washed with hot deionized water several times to remove the remaining flux, resulting in the formation of BaBi4Ti4O15 (BBiT). Lastly, the synthesized BBiT precursor was mixed with BaCO3 powder in a molar ratio of 1:4 by magnetic stirring. Equal amounts of NaCl and KCl were also added, and the mixture was heated at 950 °C for 3 h. The resulting powder was washed several times with hot deionized water and then with dilute HNO3 to obtain high-quality BT templates without remaining Bi2O3. The average size of the BT templates was a length of 10–20 μm and a thickness of 0.5 μm.

2.3. Preparation of textured ceramics

For the tape-casting process, the slurry was prepared by mixture with the calcined 33BTBF-10BMT with 0.1 wt% of MnO2 matrix powder, 7 vol% BT templates, binder, and solvent. The mixing process was conducted by ball milling for 20 h at a speed of 40 rpm. The slurry was tape casted with a doctor-blade thickness of 200 μm. After drying, the green sheets were cut as square sheets of 20 × 20 mm2, stacked, and uniaxial pressed under 60 MPa at 80 °C for 10 min. The green compact after pressing was cut into a size of 6 × 6 mm2, and then the binder was burnt out at 600 °C 5 h. At last, the textured ceramics were obtained by sintering process at 1000 °C–1100 °C for 4 h. The nontextured ceramics were sintered at 1000 °C for 4 h using a conventional solid-state synthesis. 2) Relative density was measured by the Archimedes method.

2.4. Characterization of crystal structure, microstructure, and degree of orientation

The crystal structure was investigated using an X-ray diffractometer (XRD; Ultima IV, Rigaku) with Cu Kα radiation. For microstructure observation through scanning electron microscopy (SEM; JSM-6510, JEOL), the ceramics with cross-sectional areas were mirror polished and chemically etched using a 1 N HCl solution for 10 min. The average grain size for the textured ceramics was estimated using the linear intercept method. The degree of orientation was determined by the Lotgering method, and the degree of orientation along the 〈100〉 direction, F100, was calculated by the following formula:

where I and I0 represent the peak intensities of textured and nontextured ceramics, respectively.

2.5. Dielectric, ferroelectric, and piezoelectric properties measurements

The sintered pellets were polished and cut into dimensions of 2 mm (length) × 2 mm (width) × 0.4 mm3 (thickness). The prepared samples were annealed at 800 °C for 1 h and then quenched in water. The continuous thermal annealing and water-quenching processes enhanced the ferroelectric and piezoelectric properties by recovering surface-damaged layers and domain wall depinning. 26–28) Gold electrodes were coated on the sample surfaces and heated at 300 °C for 10 min. The temperature dependence of the dielectric constant and loss was measured using an LCR analyzer (6440B, Wayne Kerr Electronics) in the temperature range of 20 °C–500 °C. Bipolar polarization electric field loops and unipolar strain electric (SE) field curves were determined using a ferroelectric and strain measuring system (JP005-SE, Kitamoto Denshi) with a displacement meter (Millitron 1202IC, Mahr). The measurements were conducted at 0.1 Hz at 22 °C.

3. Results and discussion

3.1. Fabrication of 〈100〉-oriented BMT-modified BFBT piezoelectric ceramics

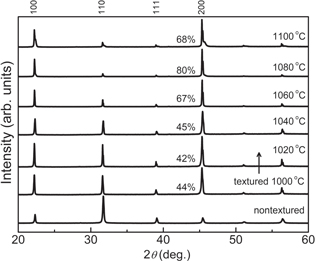

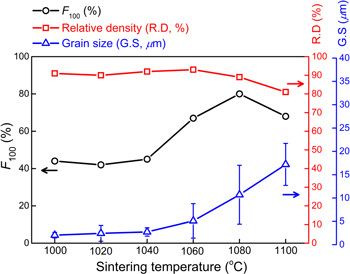

A nonpolar 〈100〉 direction is a target direction for engineered domain configuration owing to the rhombohedral symmetry of the 33BTBF-10BMT matrix. 2,5–7) The degree of orientation (F100) of 33BTBF-10BMT textured ceramics with 7 vol% BT templates was examined as a function of sintering temperature (Ts). Since BFBT-based solid solutions typically achieve dense ceramics when sintered around 1000 °C, the evaluation of F100 began from a Ts of 1000 °C, as shown in Fig. 1. Interestingly, textured 33BTBF-10BMT ceramics using BT templates exhibited the orientation along the 〈100〉 direction even at 1000 °C, with an F100 of 44%. The similar lattice parameter between the BT template and the 33BTBF-10BMT matrix may contribute to a less lattice mismatch between them, resulting in epitaxial growth of oriented grains by a coherent interface between the template and matrix. 21,23,24) Similar F100 results were achieved at 1020 °C and 1040 °C. Beyond 1060 °C, higher F100 results were attained, reaching a maximum orientation of 80% at 1080 °C. However, the F100 gradually decreased after 1080 °C, and the degree of orientation at 1100 °C was similar to that at 1060 °C. To comprehend these results, the microstructural characteristics of the samples within the Ts range from 1000 °C–1100 °C were carried out, as shown in Fig. 2. The microstructure profiles were obtained using SEM from the cross-sectional surfaces of the samples, which were prepared through a mirror-polishing and a chemical etching process. From 1000 °C–1040 °C, small grains of approximately 2 μm and the presence of templates were clearly observed. On the other hand, at 1060 °C, templates inside brick-like grains and larger grains around 5 μm were observed. It should be noted that some templates were not properly aligned along the casting direction, indicating the need for further optimization by processing techniques such as BT template contents, doctor-blade thickness, casting speeds, and others. 24,29) At 1080 °C, even larger grains of approximately 10 μm were observed, and a higher level of grain homogeneity was observed compared to Ts below 1060 °C. The different F100 results obtained from XRD, comparing relatively low Ts (1000 °C, 1020 °C, and 1040 °C) with high Ts (over 1060 °C), may be closely related to the volume of large oriented grains, as shown in Fig. 3. It is known that the growth of oriented grains contributes to an enhanced degree of orientation. 21) This result indicates that larger oriented grains at relatively high Ts are important for achieving a high degree of orientation. At 1100 °C, however, the lower F100 appears to be correlated with the low relative density, although large oriented grains were observed around 17 μm. The distinct phenomenon such as round-shaped grains and large pores were observed, suggesting decomposition caused by excessively high Ts for the matrix composition. It should be noted here that additional analysis, such as electron backscattered diffraction, is required to confirm the exact volume of oriented grains across a wide range of samples. The tendencies of F100, relative density, and grain size as a function of Ts are shown in Fig. 3. The relative density exhibited above 90% from 1000 °C–1060 °C, 90% at 1080 °C, and 80% at 1100 °C. The relative density started to decrease from 1080 °C, while large oriented grains increased from 1060 °C. The result of the degree of orientation as a function of Ts indicates a trade-off relationship between the volume of large oriented grains and relative density. The low relative density at high Ts of 1100 °C may be related to the presence of large pores due to the decomposition issue in the matrix. This result is consistent with the expectation that it may be due to the large gap of Ts compared to typical nontextured BFBT-based piezoelectric ceramics, which are commonly sintered at around 1000 °C. Thus, selecting an optimized Ts is critical for achieving a significant number of oriented grains without pores caused by decomposition.

Fig. 1. XRD patterns for nontextured and textured ceramics as a function of Ts.

Download figure:

Standard image High-resolution imageFig. 2. Cross-sectional surfaces of textured ceramics by SEM as a function of Ts.

Download figure:

Standard image High-resolution imageFig. 3. Tendencies of F100, relative density, and grain size for textured ceramics as a function of Ts.

Download figure:

Standard image High-resolution imageIt should be noted that SEM images revealed the presence of non-reacted BT templates after the sintering process. This indicates that BT templates do not react with the 33BTBF-10BMT matrix, particularly similar to the case of Pb-based textured ceramics produced by BT or SrTiO3 (ST) templates. 21) The diffusion issue and interaction between templates and matrix are important factors in the TGG process. Thus, additional analysis, such as energy dispersive spectroscopy (EDS), is required to confirm the diffusion issue across a wide range of samples.

3.2. Dielectric, ferroelectric, and piezoelectric properties

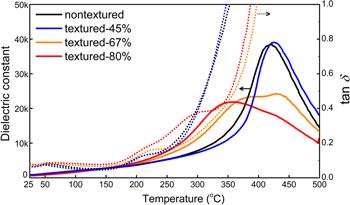

A Ts of 1060 °C and 1080 °C represent a promising candidate for achieving high degrees of orientation (67% and 80%, respectively) as well as dense ceramics (relative densities over 90%), as supported by the Lotgering factor and microstructure analysis. Thus, two textured ceramics were compared to their nontextured counterpart. It should be noted that the results of other textured ceramics with different Ts can be seen in Table I. Figure 4 and Table I show the temperature dependence of the dielectric constant and loss of nontextured and textured ceramics at 1 kHz. Dielectric constant peaks were observed at 425 °C for nontextured ceramics, while relatively low dielectric constant peaks were observed for both textured ceramics at Ts of 1060 °C and 1080 °C. Furthermore, the dielectric constant peak significantly declined at higher Ts, especially at 1100 °C, as shown in Table I. The decrease in the maximum temperature (Tmax) might be associated with two reasons in this research. One is the decreased relative density when increasing the Ts. The other reason is the partial diffusion of Ba ions into the interface between the BT template and matrix 33BTBF-10BMT regions at higher Ts. On the other hand, the dielectric constant peak was not significantly changed up to a Ts of 1040 °C as shown in Fig. 4. This means that BT templates may be related to less chemical reaction with the 33BTBF-10BMT matrix at relatively low Ts. Once again, the analysis of EDS is required to investigate the diffusion issue. The dielectric constant of textured ceramics shows a high dielectric constant compared to their nontextured counterparts at 23 °C with 1 kHz, except for textured ceramics sintered at 1100 °C due to the low relative density. The increased dielectric constant in textured ceramics might be related to the presence of BT templates, owing to their larger dielectric constant compared to any BMT-modified BFBT composition. 30) The dielectric loss (loss tangent) for all nontextured and textured ceramics does not drastically increase until 150 °C, while a dramatic increase in large dielectric loss at high temperature may be associated with the relaxation of defect dipoles. 2,3)

Table I. Summary of various parameters of nontextured ceramics and textured ceramics as a function of Ts.

| Samples | Ts (°C) | Relative density (%) | F100 (%) | Grain Size (μm) | εr (1 kHz) | tan δ (1 kHz) |

|---|---|---|---|---|---|---|

| Nontextured | 1000 | 94 | — | 1.7 ± 0.4 | 590 | 0.069 |

| Textured | 1000 | 91 | 44 | 2.0 ± 0.6 | 687 | 0.067 |

| Textured | 1020 | 90 | 42 | 2.4 ± 1.7 | 710 | 0.068 |

| Textured | 1040 | 92 | 45 | 2.7 ± 0.9 | 722 | 0.072 |

| Textured | 1060 | 93 | 67 | 5.1 ± 3.7 | 716 | 0.081 |

| Textured | 1080 | 90 | 80 | 10.7 ± 6.3 | 652 | 0.084 |

| Textured | 1100 | 81 | 68 | 17.2 ± 4.5 | 542 | 0.082 |

| Samples | Ts (°C) | Pr (μC cm−2) | Tmax (°C) | Unipolar Smax (%) | d33* (pm V−1) | Strain hysteresis (%) |

|---|---|---|---|---|---|---|

| Nontextured | 1000 | 31.2 | 425 | 0.19 | 273 | 10 |

| Textured | 1000 | 29.7 | 448 | 0.21 | 301 | 15 |

| Textured | 1020 | 30.1 | 421 | 0.22 | 312 | 15 |

| Textured | 1040 | — | 424 | 0.22 a) | 310 a) | — |

| Textured | 1060 | 27.1 | 405 | 0.28 | 405 | 15 |

| Textured | 1080 | 24.2 | 358 | 0.29 | 410 | 16 |

| Textured | 1100 | 18.2 | 252 | 0.25 | 361 | 22 |

Fig. 4. Temperature dependence of dielectric constant and loss for nontextured ceramic and textured ceramics with 45% (Ts: 1040 °C), 67% (Ts: 1060 °C), and 80% (Ts: 1080 °C) orientations.

Download figure:

Standard image High-resolution imageFigure 5 shows the bipolar P–E hysteresis loops of the nontextured and textured ceramics at 22 °C with 0.1 Hz. All measurements were conducted after the poling cycles. The remanent polarization (Pr) of textured ceramics with 80% orientation is 24.1 μC cm−2, which is clearly lower than that of nontextured ceramics (31.2 μC cm−2). The decrease of Pr in textured ceramics might be attributed to the grain orientation along the nonpolar direction and the presence of BT templates. For the former case, a gradual decrease of Pr is due to the increase of orientation degree along the nonpolar direction. For rhombohedral crystals, a lower Pr is observed when an electric field is applied along the 〈001〉 direction due to the 〈111〉 spontaneous polarization direction of the perovskite rhombohedral crystal. 13) Most of the grains are aligned along the nonpolar 〈100〉 direction through the grain orientation process in the rhombohedral BMT-modified BFBT system. Hence, Pr gradually decreases when the degree of orientation is increased, as shown in Fig. 5 and Table I. For the latter case, the presence of non-reacted BT templates acts as a composite in the BMT-modified BFBT system, resulting in relatively low Pr in the textured ceramics. The lower Pr in the textured ceramics was attributed to the lower Pr and coercive field (Ec) of the BT ceramics. 30) It should be noted that the textured ceramics sintered at 1100 °C show the lowest Pr despite the degree of orientation not being maximum, which may be related to the lowest relative density.

Fig. 5. Bipolar polarization—electric field (P–E) hysteresis loops for nontextured ceramic and textured ceramics with 67% (Ts: 1060 °C) and 80% (Ts: 1080 °C) orientations.

Download figure:

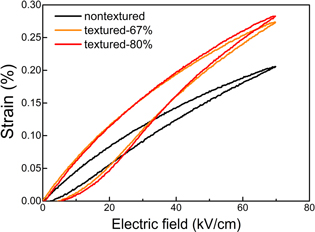

Standard image High-resolution imageThe unipolar S–E curves for the nontextured and textured ceramics are shown in Fig. 6. Enhanced maximum strain (Smax) was observed in textured ceramics compared to nontextured ceramics. The highest Smax is observed in textured ceramics with 80% orientation, measuring 0.29%, while Smax of nontextured ceramics is 0.19%. The d33

* (calculated by Smax/Emax) exhibits trends analogous to the results of Smax. The highest d33

* (410 pm V−1) was achieved by textured ceramics with 80% orientation, while d33

* for nontextured ceramics is 270 pm V−1. Furthermore, the textured ceramics with 67% orientation achieved a comparable value of d33

* (405 pm V−1) to textured ceramics with 80% orientation. These values represent an approximately 1.5 times higher value compared to nontextured ceramics. A similar enhancement of piezoelectric strain response has been observed in other Pb-free piezoelectric textured ceramics. BT-based textured ceramics, for instance, show approximately 1.4 times higher d33

* than their nontextured ceramics.

31) Over d33

* of 600 pm V−1 has been attained, but its application is limited due to the lower Curie temperature, around 90 °C. Similar tendencies have been observed in other Pb-free (K,Na)NbO3 (KNN) and (Bi0.5Na0.5)TiO3 (BNT)-based piezoelectric textured ceramics, which show high d33

* but lower Curie temperature, typically below 300 °C.

32,33) The textured ceramics in this study sintered up to 1060 °C exhibit a Tmax of 400 °C with d33

* of 300 pm V−1. The only textured ceramic with 67% orientation shows a d33

* of over 400 pm V−1 and a Curie temperature of 400 °C, as shown in Fig. 7. The highest d33

* (410 pm V−1) was achieved by textured ceramics with 80% orientation, but it shows a Tmax of 358 °C. Despite the relatively low Tmax in textured ceramics with 80% orientation, it is still higher than other Pb-free piezoelectric ceramics.

31–34) It should be mentioned here that the significant enhancement of piezoelectric strain response in the textured ceramics is attributed to the high orientation factor rather than the presence of BT templates. The decrement of positive strain in BT/BMT-modified BFBT composite was reported.

30) In unipolar S–E curves, open hysteresis can be observed in textured ceramics. The strain hysteresis of nontextured ceramics is 10%, while it shows 15% for most textured ceramics, as shown in Table I and Fig. 6. Ideally, hysteresis-free strain should be expected in highly 〈100〉-oriented rhombohedral perovskite ceramics. In [001]-poled rhombohedral crystals, there are only four ferroelectric domains along the [111], ![$[1\bar{1}1],$](https://content.cld.iop.org/journals/1347-4065/62/SM/SM1002/revision2/jjapace1dcieqn1.gif)

![$[\bar{1}11],$](https://content.cld.iop.org/journals/1347-4065/62/SM/SM1002/revision2/jjapace1dcieqn2.gif)

![$[\bar{1}\bar{1}1]$](https://content.cld.iop.org/journals/1347-4065/62/SM/SM1002/revision2/jjapace1dcieqn3.gif) directions since 〈111〉 is the polar direction, as observed in PZN, PZN-PT, and PMN-PT single crystals.

13) Thus, hysteresis-free strain can be easily expected due to the absence of domain wall movement caused by energetically equivalent domains under the electric field along the [001] direction. In the case of 〈100〉-oriented BMT-modified BFBT piezoelectric ceramics, however, the oriented grains are not exactly aligned along the nonpolar direction, resulting in open hysteresis. Another plausible reason for open hysteresis in textured ceramics along the nonpolar direction might be associated with internal stresses from the presented BT templates embedded within the oriented grains. Internal local stresses of up to 8 MPa were observed in the vicinity between ST templates and the PMN-PT matrix, and this may be related to the poor stability of the domain state due to the possibility of ferroelastic switching of domains.

21,35) Hence, this could account for open hysteresis observed in textured ceramics even along nonpolar directions. Alternatively, it could also be due to the low relative density in this research caused by large porosity at higher Ts. Changes in the movement of domain walls can occur due to any of these reasons under the applied electric field and mechanical stresses.

directions since 〈111〉 is the polar direction, as observed in PZN, PZN-PT, and PMN-PT single crystals.

13) Thus, hysteresis-free strain can be easily expected due to the absence of domain wall movement caused by energetically equivalent domains under the electric field along the [001] direction. In the case of 〈100〉-oriented BMT-modified BFBT piezoelectric ceramics, however, the oriented grains are not exactly aligned along the nonpolar direction, resulting in open hysteresis. Another plausible reason for open hysteresis in textured ceramics along the nonpolar direction might be associated with internal stresses from the presented BT templates embedded within the oriented grains. Internal local stresses of up to 8 MPa were observed in the vicinity between ST templates and the PMN-PT matrix, and this may be related to the poor stability of the domain state due to the possibility of ferroelastic switching of domains.

21,35) Hence, this could account for open hysteresis observed in textured ceramics even along nonpolar directions. Alternatively, it could also be due to the low relative density in this research caused by large porosity at higher Ts. Changes in the movement of domain walls can occur due to any of these reasons under the applied electric field and mechanical stresses.

Fig. 6. Unipolar S–E field curves for nontextured ceramics and textured ceramics with 67% (Ts: 1060 °C) and 80% (Ts: 1080 °C) orientations.

Download figure:

Standard image High-resolution imageFig. 7. Summary of d33 *, Smax, and Tmax for textured ceramics as a function of Ts. Note that the symbol "*" represents the nontextured ceramic.

Download figure:

Standard image High-resolution imageFor further enhancement of the piezoelectric strain response, there are possible strategies for the future, such as exploring other BMT-modified BFBT systems and increasing the degree of orientation and relative density. For the former case, the 40BTBF-BMT systems exhibit the highest d33 *, relatively low strain hysteresis, and a comparable Tmax compared to other 25, 30, and 33BTBF-BMT systems reported in previous literature. 2) Thus, it is expected that further enhancement of the piezoelectric strain response, low hysteresis, and maintaining a high Tmax can be achieved by applying grain orientation along the 〈100〉 direction. On the other hand, for the latter case, achieving over 80% orientation and high relative density simultaneously remains a challenge. The use of sintering aids, longer Ts time, the need for further optimization of BT template contents, doctor-blade thickness, casting speeds, and other processing techniques, are required to promote TGG and densification at relatively lower Ts. 24,29)

4. Conclusions

In conclusion, we successfully fabricated the 33BTBF-10BMT textured ceramics with an 80% orientation along the nonpolar direction using the TGG process for the first time. The use of BT templates resulted in a 44% orientation along the 〈100〉 direction at a sintering temperature of 1000 °C, which is the same sintering temperature of the nontextured ceramics. As the sintering temperature increased beyond 1060 °C, higher degrees of orientation were achieved, reaching a maximum of 80% at 1080 °C. However, the degree of orientation abruptly decreased at a sintering temperature of 1100 °C due to the large pores, as confirmed by microstructure profiles. The dielectric constant peak above 400 °C did not show a significant decline up to a sintering temperature of 1060 °C. The textured ceramics with 80% orientation exhibited the highest Smax value of approximately 0.3% and a d33 * value exceeding 400 pm V−1, which are approximately 1.5 times higher values compared to the nontextured counterparts. These findings indicate the potential for enhanced piezoelectric strain response in the Pb-free textured ceramics with a high Curie temperature. This study shows the high potential of 〈100〉-oriented BMT-modified BFBT textured ceramics for high-temperature actuator applications.

Acknowledgments

The author would like to thank the Graduate Program for Power Energy Professionals, Waseda University, of the Japanese Ministry of Education, Culture, Sports, Science, and Technology (MEXT) WISE Program for its partial support of this work.