Abstract

It has been difficult to detach smaller abrasive nano-particles from polished surfaces. In this article, we observed the behaviors of Ø50, 70, and 300 nm SiO2 particles on a silica surface in an inevitable liquid nano-scale shear flow field as a rinse cleaning by using an evanescent light. These results implied that larger-sized particles were detached because the quantitative moment in the shear flow acting on the particle is considerably higher than those of the sub-100 nm particles. The acting moment would be able to describe the detachability of the nano-particles on the surface.

Export citation and abstract BibTeX RIS

In recent years, residual particles on the polished film surface or near the wiring of dozens of nanometer width/pitch can be a killer defect, which can lead to lower large-scale-integration circuit yield. 1) Definitely, removing smaller nano-particles (abrasive particles, cleaning waste, etc.) from the polished surfaces has been a significant challenge in the post-CMP (Chemical Mechanical Polishing) wet cleaning process. 2)

However, cleaning phenomena are not already clearly known because the residual contamination on the wafer surface has been usually inspected only after the cleaning process in dry conditions, not in wet conditions due to the surface scanning methods. Eventually, it is indispensable to investigate the cleaning mechanisms by observing the cleaning phenomena that are considered as the detachment of the nano-particle from the surface to be cleaned, and the occasional reattachment to the surface.

Thus, we have established a direct observation method of cleaning phenomena that occurred within the few hundred nanometers range from the surface by applying an evanescent light localized near the surface to be cleaned.

In this article, we have directly observed various-sized (Ø50, 70, and 300 nm) SiO2 nano-particle behaviors near the SiO2 surface by using developed evanescent wave microscopy in the inevitable shear flow field in a near parabolic velocity distribution with known velocity VH to duplicate the rinse cleaning as shown in Fig. 1. After obtaining the evidence of each particle size that can be detached only by the rinse cleaning (shear flow), drag force and the moment (torque) acting on the nano-particles in the shear flow is also calculated to investigate quantitatively the size-dependent particle detachment from the surface.

Fig. 1. Detachment behaviors of nano-particles during the rinse cleaning process in the shear flow within a few hundred nanometers from the surface.

Download figure:

Standard image High-resolution imageEvanescent light is generated in the range of a few hundred nanometers from the substrate surface when the total internal reflection occurs between the liquid that has a low refractive index (e.g., particle suspension, solution) and the substrate/thin film that has a higher refractive index in the incident angle θi condition above the critical angle θc (θi > θc = arcsin[nL /nH ]). 3–5)

Particle detachment behaviors near the surface in wet conditions are observed in the shear flow with high contrast due to the limited scattering of the evanescent wave beam. 6–9) Also, evanescent light can determine the nano-particle size which is attached to the surface by characterization of scattering light intensities. 7,8) Thus, the cleaning phenomena can be observed in the shear flow after the particle size is determined.

Figure 2 shows the lab-made experimental setup, and Table SI (in the supplementary information) shows the experimental parameters. In this rinse cleaning experiment, a centrifugal force by practical rotation could be neglected, since the centrifugal force acting on the nano-particles is obviously less than 1% compared to the fluid drag force. A liquid flow cell was placed on the silica glass surface to observe nano-particle behaviors in the pulseless shear flow. We duplicated the flow velocity vx (z) = z VH /H, where z is the height from the surface, VH = vx (H) (≒ 70[μm/ms] at H = 1 μm) as shear flow during rinse cleaning. An evanescent field is generated by a laser to observe the nano-particle behavior near the surface as accumulated scattering light by an objective lens with a CMOS optical area sensor.

Fig. 2. Experimental setup to observe the nano-particle behaviors in the shear flow by using the evanescent light.

Download figure:

Standard image High-resolution imageØ50, 70, and 300 nm standard SiO2 particles attached by drying the suspension (Table SII shows that sample condition in detail), and the behaviors were observed near the silica glass surface as shown in Fig. 3 (sequentially observed images were shown in Fig. S1 in the supplementally information). It was recorded with an exposure time of 10 milliseconds in 100 frames per second. It showed the larger particle scatter higher light intensities, and detachment and remaining behaviors were quantitatively evaluated on a time axis. In practical rinse cleaning, it is well known that the residue particles were more detached from a SiO2 surface, in high pH solution. However, it was difficult to detach residual sub-100 nm SiO2 particles from the surface. The Ø300 nm SiO2 particle was detached within 0.2 s.

Fig. 3. Various-sized silica nano-particle behaviors near the silica surface in the shear flow.

Download figure:

Standard image High-resolution imageThese results were also confirmed by surface contamination scanning inspection before and after the cleaning process by the imec group. 10) It was implied that smaller particles did not receive enough detach energy. Hence, the magnitude of the drag force and moment acting on the residual particle on the surface were analyzed in the shear flow with a particle spherical curve. Previously, a shear flow as the Stokes flow 11) or a shear flow without particle spherical curve 12) were widely calculated.

The drag force Fdrag acted on the residual particle in the shear flow field with a linearly proportional velocity distribution with height z [μm] from the surface. The drag force acting on the differential sectional projected area dA was determined (Fig. S2 in the supplementally information),

![$\,d{F}_{\mathrm{drag}}=\frac{1}{2}\rho {C}_{d}(z){[{v}_{x}(z)]}^{2}dA$](https://content.cld.iop.org/journals/1347-4065/62/SH/SH8004/revision2/jjapacde87ieqn1.gif)

where ρ is the density of the solution, ν is the viscosity of the solution, Cd (z) is the drag coefficient, and vx (z)[μm/ms] is the velocity distribution in the flow direction with height z [μm]. Integrating this over all the particle projection planes yields, Fdrag is

Also, the moment action to particle was estimated as follows,

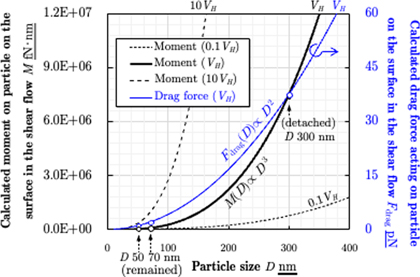

For various constants given in the case of water, ρ = 1000 [kg m–3], ν = 1.0 × 10−6 [m2 s–1], VH = 70 [μm/ms], H = 1 [μm] is determined to calculate the absolute hydrodynamic drag force Fdrag and moment action M as shown in Fig. 4,

Fig. 4. Calculated hydrodynamic drag force and moment acting on the nano-particle on the surface in the shear flow with the velocity vx (z) = (z/H)VH , where VH = vx (H) (≒ 70 [μm/ms] at H = 1[μm]).

Download figure:

Standard image High-resolution imageThe magnitude of the acting moment in the shear flow considerably increases compared with the increase in the magnitude of acting force, to be able to describe the detachability of the nano-particles on the surface. For this reason, the Ø300 nm particles were considered to be detached in the shear flow.

Acknowledgments

This work was also partially supported by KAKENHI 16K06015, 21J14543 from the Japan Society for Promotional Science.

Supplementary data (0.5 MB DOCX)