Abstract

The current study compares hydrogen permeation through 20 μm thick Pd–Cu40% membranes in cylindrical (CR) and plate (PR) reactors under heating and plasma experiments. Pure hydrogen gas was fed into the reactors at 0.1–5 l min−1 and the dielectric barrier discharge plasma was ignited at a plasma voltage range of 10–18 kV. The hydrogen permeability Arrhenius plot versus the inverse temperature showed a small increase at low reactor temperatures. Furthermore, the permeability results indicated a non-linearity trend by applying plasma due to the high electron mobility. The heating only results showed that the permeation rate of the CR was much higher than the PR. In addition, the peak values of CR and PR were 32.6% and 4.21% at reactor temperatures of 150 °C and 200 °C, respectively. Moreover, it was found that the H2 permeation was increased by applying plasma to reach maximum values of 100%.

Export citation and abstract BibTeX RIS

1. Introduction

Hydrogen fuel is considered the strongest contender to overcome the environmental issues caused by fossil fuels. Different hydrogen production technologies methods have been developed.1,2) Most commercially available hydrogen gas is produced by steam reforming and water electrolysis methods.3–9) Palladium and its alloys can provide an ideal method to obtain pure hydrogen gas from chemical gas mixtures due to their high hydrogen permeability and selectivity. Palladium-based membranes can be used to separate hydrogen in reforming reactors.10–12) Furthermore, palladium-based membranes have been used for commercial production of hydrogen for decades. Membrane technologies have significant economic potential in many industries such as chemical industry, pre-combustion carbon dioxide capture, and the production of ultrapure hydrogen.13–16)

Palladium-based membranes and those of its alloys are currently used for hydrogen separation from chemical gas mixtures because of their high hydrogen permeability, selectivity, and durability.17–21) Generally, palladium alloy membranes are utilized rather than pure palladium membranes,22) with the most usable palladium alloy membranes being comprised of Pd–Ag and Pd–Cu alloys.23,24) The palladium alloys are manufactured using α−β phase processes to reduce surface poisoning and to enhance hydrogen permeation.25) Palladium-copper alloy membranes are considered the most promising membranes owing to their low cost, resistance to H2S poisoning, and high permeability compared to pure Pd membranes.17,26–32)

Hydrogen permeation through Pd-based membranes has been studied by several methods, and is enhanced by the following parameters: (i) the atomization of H2 molecules, (ii) the gas partial pressure difference across the membrane, (iii) hydrogen ion beam injection, and (iv) plasma-driven permeation (being exposed to hydrogen plasma).33) The hydrogen permeation processes under gas-driven permeation through Pd-based membranes can be summarized by: (1) H2 adsorption from the membrane feed side surface, (2) dissociation of hydrogen molecules into atoms on the same membrane surface, (3) hydrogen diffusion to the membrane permeate side, (4) hydrogen molecules formation on the hydrogen permeate side, and (5) hydrogen molecules desorption from the permeate side.34) The hydrogen permeation mechanism when applying plasma may be decreased to a single step due to the plasma dissociating the hydrogen molecules into H atoms without requiring adsorption on the Pd-based membrane upstream surface. Hydrogen enters the membrane with excess energy under plasma exposure, while in gas-driven permeation, the hydrogen molecules are thermally dissociated into the Pd-based membrane.35,36)

This paper compares the hydrogen permeation of a 20 μm thick Pd–Cu40% membrane in cylindrical (CR) and plate (PR) reactors, for different H2 input flow rates and temperatures. Pure hydrogen gas (99.999%) was fed into the reactors at atmospheric pressure. Firstly, the hydrogen flux and permeability for both reactors under heating only and under plasma were determined. The atmospheric pressure plasma or dielectric barrier discharge (DBD) plasma was ignited at a voltage range of 10–18 kV. The effects of partial pressure difference and residence time on H2 permeability were investigated. Furthermore, the hydrogen permeation rate and energy efficiency versus the reactor temperatures were determined. Additionally, the hydrogen permeation rates through the Pd–Cu membrane in both reactors were compared for heating (gas-driven) and plasma experiments.

2. Experimental methods

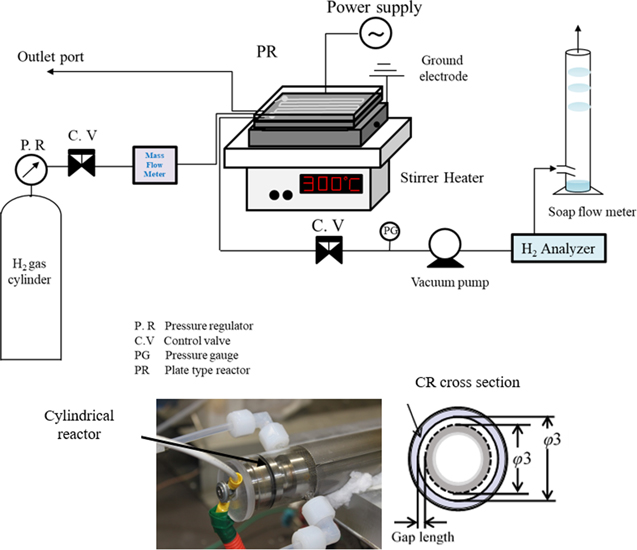

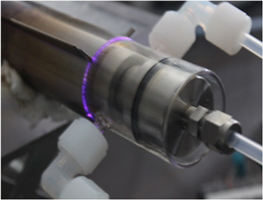

In the present work, the hydrogen permeability was measured for a CR and PR. The hydrogen permeation experiment was carried out using pure hydrogen gas and a Pd–Cu40% membrane. Pure hydrogen gas can be obtained from the palladium-based membranes with a high permeability and good mechanical stability, especially the Pd–Cu40% membrane type. A 20 μm thick membrane was installed in both reactors. The DBD plasma was ignited at a sinusoidal frequency of 10 kHz, applied voltage of 10–18 kV, and plasma input power range of 76–112 W. The hydrogen permeation was determined for both reactors under heating only and under plasma. The electrode gap volume of both reactors is presented in Table I. A schematic diagram of the experimental equipment is shown in Fig. 1. The equipment comprised a PR or CR, high voltage electrode, ground electrode, input H2 gas cylinder, pressure regulator, mass flow controller, vacuum pump, H2 gas analyzer, and soap flow meter. The reactor temperature was controlled by the stirrer heater. A vacuum pump (N820.3FT.18, KNF Company) was connected directly to the reactor at the permeation line. The H2 input flow rate was controlled by a digital mass flow controller on the input line. Moreover, the partial pressures on the feeding and permeate sides were monitored using digital pressure gauges. A hydrogen gas analyzer was installed directly after the vacuum pump to measure the permeated hydrogen gas concentration, while the permeated hydrogen gas flow rate was measured using the soap flow meter. The plasma ignition test was performed using argon gas. The DBD plasma type reactor has many advantages such as ease of control and plasma generation at low H2 gas temperatures and typical atmospheric gas pressure. Moreover, the high electron energy generated provides new radicals, atoms, and excited particles. The CR under plasma firing conditions of 10 kV and H2 input flow rate of 1 l min−1 is shown in Fig. 2.

Table I. Characteristics of Pd–Cu membrane reactors.

| Reactor type | Thickness [μm] | Reactor volume [cm3] |

|---|---|---|

| Cylindrical | 20 | 51.6 |

| Plate | 20 | 1.176 |

Fig. 1. (Color online) Schematic diagram of permeation experiment setup.

Download figure:

Standard image High-resolution imageFig. 2. (Color online) Cylindrical type reactor at DBD plasma firing.

Download figure:

Standard image High-resolution image3. Results and discussion

The hydrogen permeation through the cylindrical and plate type reactors was measured at different flow rates and heating temperatures. The effect of heating only and plasma on the hydrogen permeation through the 20 μm thick Pd–Cu40% membrane were investigated. The effects of different parameters such as temperature, partial pressure, etc on the hydrogen permeation through the Pd–Cu membrane were determined. The most important parameters to evaluate the H2 permeation through the Pd–Cu membrane are the H2 flux and permeability. The hydrogen flux is governed by the combination of Fick's and Sievert's laws as follows:37)

where  is the hydrogen gas flux (mol m−2 s−1) and the difference between hydrogen partial pressure on the feed and permeate sides had n-exponent of 0.5. The hydrogen flux (

is the hydrogen gas flux (mol m−2 s−1) and the difference between hydrogen partial pressure on the feed and permeate sides had n-exponent of 0.5. The hydrogen flux ( ) is a function of the H2 permeability, Pe (mol m−1 s−1 Pa−0.5), × (m) is the Pd–Cu membrane thickness,

) is a function of the H2 permeability, Pe (mol m−1 s−1 Pa−0.5), × (m) is the Pd–Cu membrane thickness,  (Pa) is the upstream partial pressure, and

(Pa) is the upstream partial pressure, and  (Pa) is the downstream or permeate side partial pressure of the Pd–Cu membrane. The permanence term or the pressure-normalized flux can be defined as the ratio of the H2 permeability to the membrane thickness. The dependence of the H2 permeability on temperature is typically presented in an Arrhenius relationship between the H2 permeability and the inverse absolute temperature (K−1). Additionally, it can be determined from the following expression: Pe = Peo exp(−ED/RT), where ED is the activation energy and the pre-exponential constant is Peo.

(Pa) is the downstream or permeate side partial pressure of the Pd–Cu membrane. The permanence term or the pressure-normalized flux can be defined as the ratio of the H2 permeability to the membrane thickness. The dependence of the H2 permeability on temperature is typically presented in an Arrhenius relationship between the H2 permeability and the inverse absolute temperature (K−1). Additionally, it can be determined from the following expression: Pe = Peo exp(−ED/RT), where ED is the activation energy and the pre-exponential constant is Peo.

3.1. Hydrogen permeation through cylindrical-type reactor

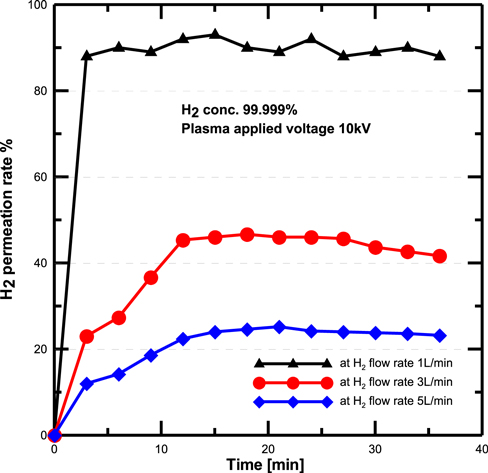

The permeation through the Pd–Cu40% membrane in the CR was investigated with conditions of 10 kV plasma voltage and H2 input flow of 1–5 l min−1; the upstream or feeding side was at atmospheric pressure and the permeate side pressure was controlled by the vacuum pump. In the CR plasma experiment, the operating temperature was controlled by the plasma ignition. Figure 3 shows the hydrogen permeation rate% at different H2 input flow rates with time. The hydrogen permeation rate% can be defined by the following relation: H2 permeation rate % = (Permeated H2 flow rate [l min−1]/Input H2 flow rate [l min−1]) × 100. It is seen that the hydrogen permeation rate% increased with time for all tested H2 input flow rates. In addition, the hydrogen permeation results of H2 input flow rate of 1 l min−1 were much higher than that obtained at flow rates of 3 and 5 l min−1.

Fig. 3. (Color online) Comparison of the H2 permeation rate% at different H2 flow rates.

Download figure:

Standard image High-resolution image3.1.1. Hydrogen permeability determination

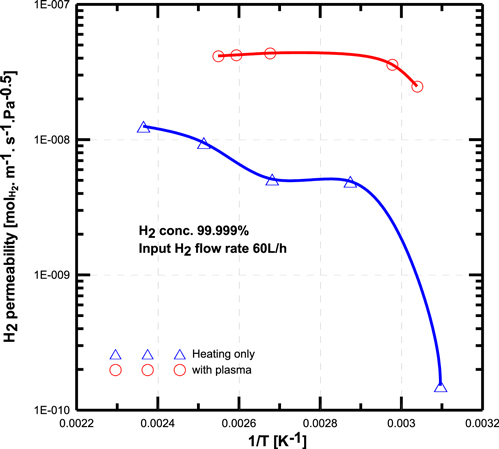

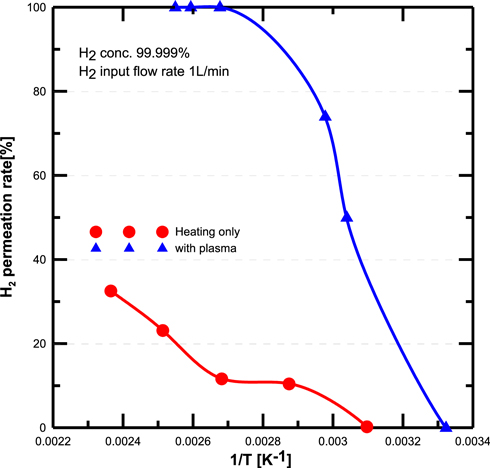

The effects of plasma and heating on the hydrogen permeation were investigated. Figure 4 presents the Arrhenius plot of the H2 permeability versus the inverse temperature for the plasma and heating experiments. It was clear that the permeability increased with the reactor temperature in both experiments. The permeability of hydrogen molecules was improved by applying plasma and the permeation result was higher than that obtained from the heating only experiment. To clarify the effect of the DBD plasma on the hydrogen permeation through the Pd–Cu40% membrane, the hydrogen permeation rate% was determined. Figure 5 shows the hydrogen permeation rate% for the plasma and heating experiments at the H2 input flow rate of 1 l min−1. One of the most interesting results was the permeation rate% of the plasma experiment which reached 100% at a temperature of 100.7 °C, while the peak value of the heating experiment was 32.6% at 150 °C. It was seen that the plasma raised the electron mobility, which subsequently caused the hydrogen dissociation through the Pd–Cu membrane to increase.

Fig. 4. (Color online) Effect of plasma and heating on H2 permeability.

Download figure:

Standard image High-resolution imageFig. 5. (Color online) Comparison of CR H2 permeation rate for plasma and heating experiments.

Download figure:

Standard image High-resolution image3.1.2. Effect of partial pressure on H2 permeation

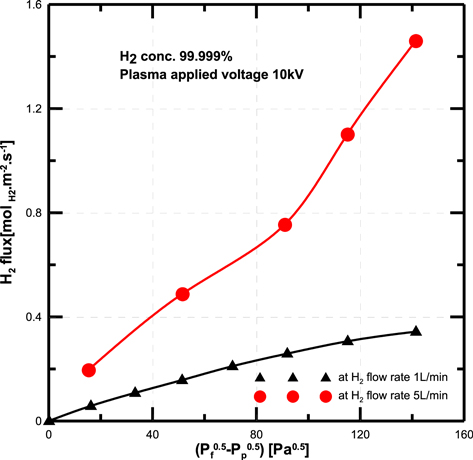

The partial pressure difference between the feeding and permeate side was considered the driving force of the hydrogen permeation processes. According to Fick's and Sievert's laws, the hydrogen flux increased with the partial pressure. Figure 6 shows the hydrogen flux of pure H2 gas versus the partial pressure difference with power n-exponent of 0.5. Two different H2 input flow rates were injected into the CR at applied plasma voltage of 10 kV. It was found that the hydrogen flux increased with partial pressure difference. In addition, the hydrogen flux for an input flow rate of 5 l min−1 was higher than for a flow rate of 1 l min−1. The results were in agreement with the hydrogen flux relation and the previous literature.38) The hydrogen permeability linear Arrhenius relations versus inverse temperature are given in Fig. 7. The plasma discharge voltage was maintained at 10 kV and the input voltage frequency was 10 kHz. Furthermore, the plasma increases the hydrogen diffusivity and caused a non-linear slight increase in hydrogen permeability versus the reactor temperature. In addition, it was seen that the plasma experiments did not change or destroy the membrane properties.

Fig. 6. (Color online) Effect of partial pressure on hydrogen flux.

Download figure:

Standard image High-resolution imageFig. 7. (Color online) Typical Arrhenius plot of H2 permeability versus inverse temperature.

Download figure:

Standard image High-resolution image3.1.3. Effect of residence time on H2 permeation

To clarify the permeation processes through the Pd–Cu membrane, the residence time was determined for the different H2 input flow rates and applied plasma voltage of 10 kV. It can be determined from the following expression: Residence time [min] = Reactor reaction volume [l]/H2 input flow rate [l min−1]. Figure 8 shows the hydrogen permeation rate% versus the residence time at different reactor heating temperatures. It was found that the hydrogen permeation rate was slightly increased with residence time at low CR heating temperature, whereas at high CR temperature, the permeation rate continuously increased and appeared to be near to each other with the residence time. However, the hydrogen permeability is influenced by the membrane thickness and the partial pressure difference between the upstream and the downstream sides; the residence time is also considered an important factor for the adsorption process of the hydrogen molecules from the membrane upstream surface.

Fig. 8. (Color online) Residence time effect on H2 permeation rate%.

Download figure:

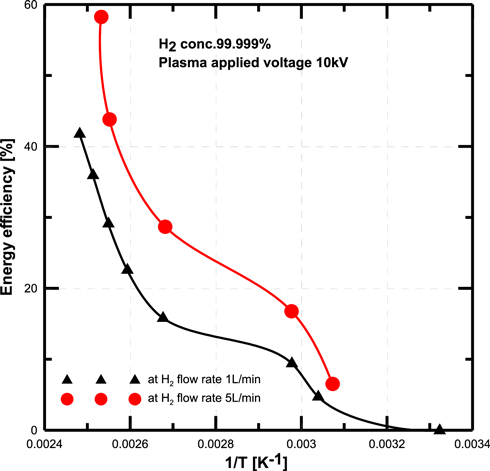

Standard image High-resolution imageTo evaluate the permeation process through the Pd–Cu membrane, the energy efficiency was determined according to the following expression: Energy efficiency [%] = [HHV × permeated H2 flow rate [l min−1]/(total power consumption + HHV × H2 input flow rate [l min−1])] × 100. Where HHV is the hydrogen gas higher heating value. Figure 9 shows the effect of CR heating temperature on energy efficiency at H2 input flow rates of 1 and 5 l min−1. It was found that energy efficiency increased with the reactor temperature for both flow rates. Moreover, it was observed that maximum measured energy efficiency was 41.80% and 58.30% for H2 input flow rates of 1 and 5 l min−1, respectively. It was also clear that the hydrogen permeation process through the palladium membrane surface was rapid but it was still limited due to the membrane thickness and partial pressure effect.

Fig. 9. (Color online) Energy efficiency versus inverse temperature.

Download figure:

Standard image High-resolution image3.2. Hydrogen permeation through plate type reactor (PR)

Hydrogen permeation through the 20 μm thick Pd–Cu40% membrane was investigated using pure hydrogen gas in a PR over a temperature range of 423–573 K and applied plasma voltage of 10–18 kV. The plasma discharge was ignited at a sinusoidal frequency of 10 kHz. The hydrogen permeation was measured in the PR under heating only and plasma heating experiments. The concentrations of the permeated hydrogen gas were measured by the H2 gas analyzer, while the permeated H2 gas flow rate was monitored by the soap flow meter. The hydrogen permeability results were compared for both experiments. Figure 10 shows the Arrhenius plot of the H2 permeability versus the inverse temperature for the plasma and heating experiments at H2 input flow rate of 0.1 l min−1. It was clear that the permeability was improved by applying plasma. In addition, the permeability when using plasma was higher than when only using heating. Furthermore, the hydrogen permeability was slightly increased with the plasma discharge voltage due to the increased electron density and high mobility. The permeation results showed good agreement with the permeability results, such that the maximum values are obtained at a PR temperature of 573 K.

Fig. 10. (Color online) Arrhenius plot of H2 permeability versus inverse temperature.

Download figure:

Standard image High-resolution image3.2.1. Effect of plasma applied voltage on H2 permeability

The effect of plasma discharge voltage on the hydrogen permeation process was investigated at different reactor heating temperatures, and is shown in Fig. 11. The H2 permeability did not continuously increase with the applied plasma voltage due to the non-linearity effect of high voltage that appeared in the hydrogen molecules reverse reaction.39,40) Moreover, the most interesting result is that the permeability of H2 molecules decreased at applied plasma voltage of 18 kV; furthermore, it was observed that the solubility decreased and a small increase in the hydrogen diffusion leads to the H2 permeability non-linearity increase at different applied plasma voltages.

Fig. 11. (Color online) Effect of plasma applied voltage on H2 permeability.

Download figure:

Standard image High-resolution image3.2.2. Effect of residence time on the permeation rate

The effect of residence time on the hydrogen permeation rate% was investigated for the PR heating temperature range of 423–573 K, under heating only. Figure 12 demonstrates the hydrogen permeation rate change at different residence times and PR heating temperatures. It was found that the hydrogen permeation rate increased linearly with residence time due to the reaction time inside the PR plasma ignition gap increasing. In addition, it was clear that the PR hydrogen permeation rates have a similar trend to those obtained from the CR experiment.

Fig. 12. (Color online) Residence time effect on hydrogen permeation rate.

Download figure:

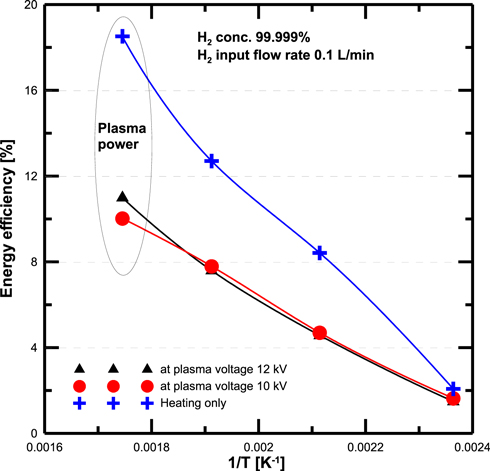

Standard image High-resolution imageThe hydrogen permeation through the Pd–Cu membrane in the PR type was investigated by comparing the energy efficiency results of the heating and plasma-heating experiments. The operating conditions were hydrogen input flow rate of 0.1 l min−1, and plasma voltage range of 10–12 kV. Figure 13 shows the energy efficiency plot results for the heating only and plasma experiments versus the PR heating temperature. It was observed that the energy efficiency of heating only was much higher than for plasma-heating due to the plasma electric power consumption being high compared to the permeated hydrogen molecules flow rate. In addition, it was indicated that energy efficiency increased with the PR heating temperature.

Fig. 13. (Color online) Energy efficiency of plasma and heating for PR type.

Download figure:

Standard image High-resolution image3.3. Comparison between H2 permeation rate% for CR and PR type reactors

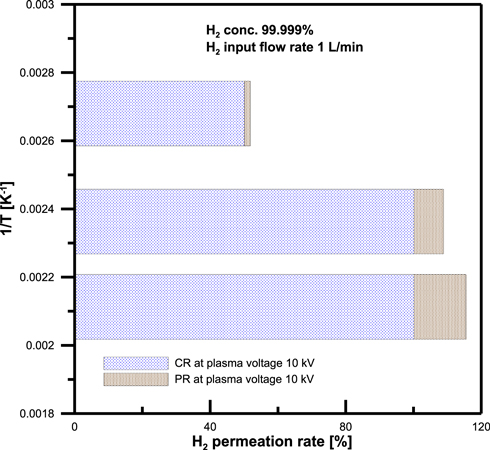

The hydrogen permeation rate% through the Pd–Cu40% membrane in the CR and PR type reactors was compared. The hydrogen gas was fed into the upstream side at a flow rate of 1.0 l min−1 and applied plasma voltage of 10 kV. The measurements were taken for both reactors under heating only and plasma conditions. Figure 14 shows the column plot of the hydrogen permeation rate versus the reactor heating temperature for both PR and CR reactors. It was found that the hydrogen permeation rates obtained from the CR type were higher than those obtained from the PR type at the same operating conditions. In addition, low H2 permeation values were obtained at low reactors heating temperatures. The maximum hydrogen permeation value for the CR type was 32.6% at a temperature of 150 °C, while the peak value of PR type for the heating only experiment was 4.21% at a temperature of 200 °C. The hydrogen permeation rates for both reactors under plasma driven conditions are compared in Fig. 15. It was found that the hydrogen permeation rate of the CR type reached a maximum value of 100% at a reactor temperature of 100.7 °C, whereas the maximum permeation value of the PR type was 15.34% at a temperature of 200 °C. In addition, it was clear that the hydrogen permeation rate through the Pd–Cu membrane improved by applying plasma in both reactor types. Additionally, it can be concluded that the hydrogen permeation results through the Pd–Cu membrane in CR were better than those obtained from the PR type in both experiments.

Fig. 14. (Color online) Comparison of permeation rate under heating only for CR and PR type.

Download figure:

Standard image High-resolution imageFig. 15. (Color online) Comparison of permeation rate under plasma-heating for CR and PR type.

Download figure:

Standard image High-resolution image4. Conclusions

The permeability of the 20 μm thick Pd–Cu40% alloy membrane to pure hydrogen gas was determined at atmospheric pressure under heating and plasma-heating in plate (PR) and cylindrical (CR) reactors. The measurements were performed for various input H2 flow rates, reactor temperatures, and applied plasma voltages. The effects of heating only and plasma were determined for both reactors. It was found that the H2 permeability when using plasma was much higher than when only using heating. Additionally, the permeability Arrhenius plot showed a non-linearity effect and a small increase under plasma experiments in both reactor types. Furthermore, the results showed that the H2 flux and permeation rate were influenced by the partial pressure difference on the upstream and downstream sides. Moreover, the permeation residence time effect on the hydrogen permeation indicated that the permeation increased with residence time in both experiments. The hydrogen permeation rate and energy efficiency were determined for both reactors at different reactor heating temperatures and H2 flow rates. It was found that the permeability increased as the temperature increased for both reactors, while the permeability for the PR at different applied plasma voltages showed a small increase with temperature. In addition, the permeability decreased at high applied plasma voltages, due to the quick increase in the hydrogen diffusion which appeared in the non-linear trend of permeability. The permeation rate through the Pd–Cu membrane for H2 input flow rate of 1 l min−1 and at different reactor temperatures was compared for the CR and PR. The heating only experiment showed that the permeation rate of CR was higher than the PR type. The maximum permeability of the CR type was 32.6% at a temperature of 150 °C, while the maximum H2 permeation of the PR type was 4.21% at a temperature of 200 °C. Furthermore, the permeability of the plasma experiment was measured for both reactors at a plasma voltage of 10 kV. It was found that the H2 permeation rate improved by applying plasma to reach the maximum values of 100% and 15.34% in the CR and PR, respectively.

Acknowledgments

The authors would like to thank Prof. Shinji Kambara (Environmental and energy systems department-Gifu University-Japan) for his continuous support.