Abstract

All-electric or hybrid electric aircrafts, wherein batteries are key components, are promising to reduce CO2 emissions. Knowing a battery's behavior over a broad range of different conditions, mainly temperature and load changes, is crucial for efficient usage of a battery, especially in aircrafts. Therefore, a model that can predict the battery behavior in relation to electric airplanes was developed. For this contribution, a model using an equivalent circuit with a voltage source, one R and two RC parts was used to have a good trade-off between accuracy and computation time [1]. Due to the short computation time, it is possible to combine the model with a whole aircraft model or even integrate it into the battery management system. The model was done for three different commercial lithium ion batteries planned for aviation applications:

The 20 Ah HP602030 LFP cylindrical cell was chosen due to good thermal stability and safety of LFP [2][3] which is crucial for aviation.

The 10 Ah HE 341440 NCA cylindrical cell was chosen since NCA has a high specific energy due to a high specific capacity and high voltage vs lithium [4]. This high specific energy leads to lower weight which is another important aspect for aviation.

The 12 Ah SLPB065070180 NMC pouch cell was chosen, since NMC has a good trade-off between energy density, costs and safety [4].

The open circuit voltage (OCV) of each battery was determined by measuring a charging and discharging curve with low current of C/40. The medium of these two curves had a good accordance to galvanostatic intermittent titration technique measurements and therefore was assumed to correspond to the open circuit voltage over state of charge (SOC). The SOC is calculated by coulomb counting based on the usable capacity dependent on temperature and current. To calculate the resulting battery voltage at the current collectors, the OCV is reduced by voltage drops due to the equivalent circuit resistances and capacitances using typical equations for electrical circuits. These resistance and capacitance are dependent on current, temperature and SOC. To determine these dependencies, cycles at different currents and temperatures were performed. To keep temperature and humidity constant, the batteries were placed in a climate chamber. The two main heat sources for batteries are considered in the simulation. Joule heat is calculated by power losses. The reversible heat is calculated with the entropic potential. Heat distribution is considered to be equal over the whole cell.

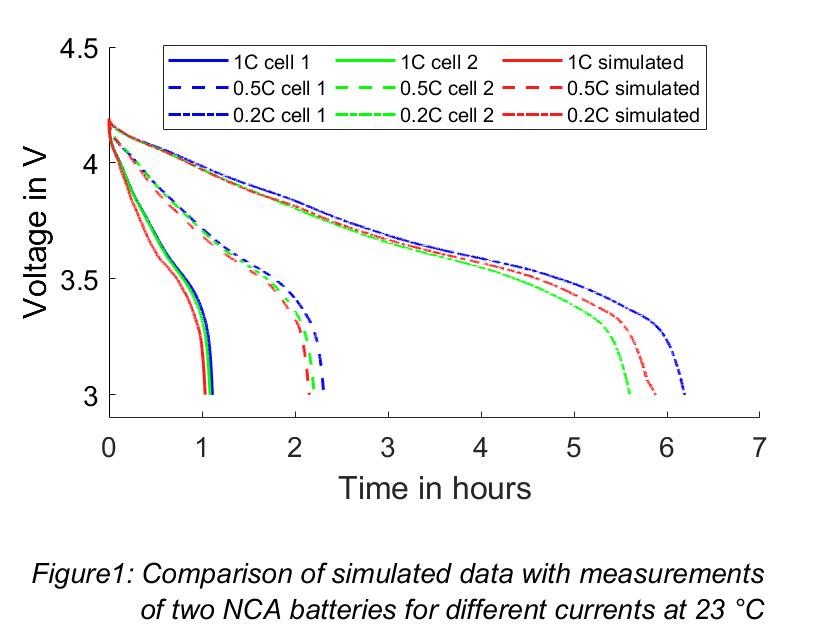

Figure 1 shows the comparison of first simulation results with measured data of two NCA battery cells. The simulated data for 2 A is in between the two battery measurements. The comparison at 5 and 10 A shows a good agreement at high SOC. At low SOCs, there is some deviation which is tolerable since the batteries will only be discharged up to approximately 80% SOC in the aircraft due to safety considerations. Additionally, the 5 and 10 A simulation values are below the measured values which means the real battery would at least be capable of powering the aircraft load. Therefore, the described model is suitable to predict the behavior of the mentioned batteries for aircraft applications.

A battery system model is formed by connecting the battery model in series and parallel and this in turn is coupled to a model describing the drive train of an aircraft for example a hybrid electric aircraft powered by fuel cell and battery like the HY4 [6]. This tool analyzes the unique system behavior of novel drive trains, improved system designs, control strategies, flight profiles and the overall efficiency of an aircraft to reach the goal of emission-free flight.

References

[1] M. Chen et al., "Accurate electrical battery model capable of predicting runtime and I-V performance," IEEE Trans. Energy Convers., vol. 21, no. 2, pp. 504–511, Jun. 2006, doi: 10.1109/TEC.2006.874229.

[2] A. K. Padhi et al., "Phospho‐olivines as Positive‐Electrode Materials for Rechargeable Lithium Batteries," J. Electrochem. Soc., vol. 144, no. 4, pp. 1188–1194, Apr. 1997, doi: 10.1149/1.1837571.

[3] M. Brand et al., "Electrical safety of commercial Li-ion cells based on NMC and NCA technology compared to LFP technology."

[4] N. Nitta et al., "Li-ion battery materials: Present and future," Materials Today, vol. 18, no. 5. Elsevier B.V., pp. 252–264, Jun. 01, 2015, doi: 10.1016/j.mattod.2014.10.040.

[5] A. Barai et al., "A comparison of methodologies for the non-invasive characterisation of commercial Li-ion cells," Progress in Energy and Combustion Science, vol. 72. Elsevier Ltd, pp. 1–31, May 01, 2019, doi: 10.1016/j.pecs.2019.01.001.

[6] H2Fly, "HY4." https://h2fly.de (accessed Jan. 07, 2021).

Figure 1