Abstract

In a hydroxide exchange membrane fuel cell (HEMFC), hydroxide produced at the cathode readily reacts with CO2 in air due to its acid-base reaction. The CO2 then transports across the hydroxide exchange membrane to the anode where bicarbonates build up lowering the local pH until CO2 evolution reactions become favorable. The pH gradient across the cell results in lower voltage output; however, it can act as an effective CO2 separator from air. By focusing on CO2 separation, rather than power output, an electrochemically-driven CO2 separator (EDCS) was developed using a poly(aryl piperidinium) membrane.1 Efficient and continuous CO2 separation technologies are needed for various applications including upstream of HEMFC stacks in vehicles2 as well as life support systems in submarines3 and manned spacecrafts.4

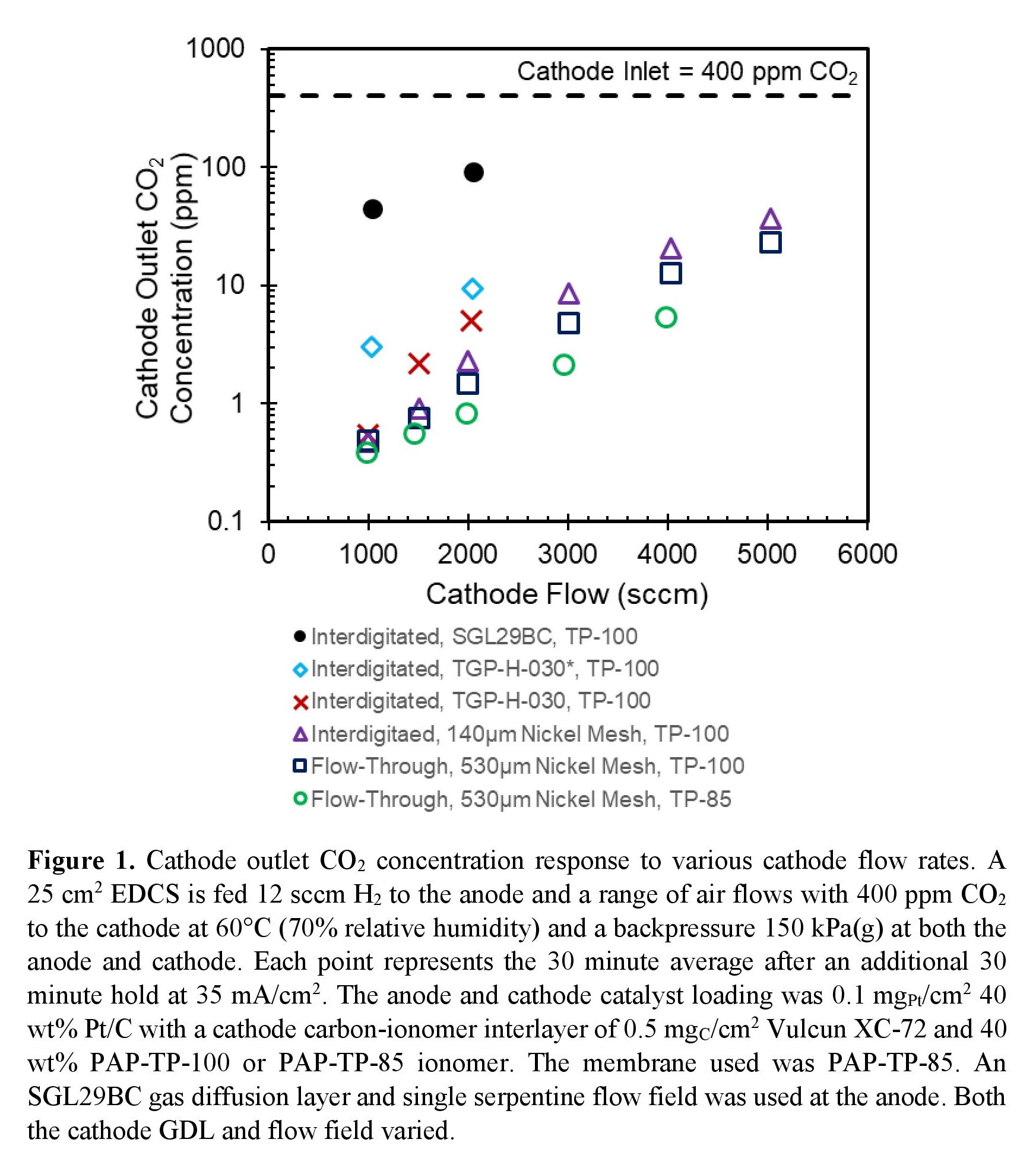

Previously, the EDCS was demonstrated as an effective and continuous method to remove CO2 from ambient air using minimal hydrogen flow to power the separation, and various operating conditions and cell build configurations were investigated.5 This work seeks to further optimize the EDCS through improvements in ionomer, flow fields, temperature, and relative humidity for various CO2 concentrations. Figure 1 shows the improvements in CO2 removal from ambient air of a 25 cm2 EDCS from the initial design inspired by fuel cells to the latest design using a nickel metal mesh as the combined flow field and gas diffusion layer at the cathode. The EDCS operating conditions and design is also evaluated for different applications as their requirements for air flow, CO2 concentrations, operating conditions, energy and size restraints differ and must be taken into account. Additionally, this work explores methods to scale the EDCS for these high throughput operations such as planar stacks or spiral wound modules.

References:

J. Wang et al., Nature Energy, 4, 5, 392-398 (2019).

N. Ziv et al., Chemsuschem, 11, 7, 1136-1150 (2018).

Raatschen, W., et al. 47th International Conference on Environmental Systems, Charleston, South Carolina, (2017).

Isobe, J., et al. 46th International Conference on Environmental Systems, Vienna, Austria, (2016).

Matz, S., et al. J. Electrochem. Soc. 168, 014501 (2021).

Figure 1