Abstract

Using isothermal micro-calorimetry, we investigate the heat generation of lithium- and manganese-rich layered oxides (LMR-NCMs) during the first cycle in which LMR-NCM exhibits a pronounced voltage hysteresis leading to a low energy efficiency (≈73%). In the first charge, LMR-NCM shows a unique voltage plateau at ≈4.5 V where irreversible structural rearrangements lead to an activation of the material as well as a large voltage hysteresis. We found that only a fraction of the lost electrical work (≈43%) is converted into waste heat. Thereby, the heat flow profile of the first charge is unique and shows considerable heat generation during the voltage plateau. With complementary electrochemical methods, contributions of conventional sources of heat, i.e., because of polarization and entropy, are determined. However, they do not cause the considerable generation of heat during the voltage plateau. Our results therefore suggest that the structural rearrangements during activation lead to a significant generation of heat. In window-opening experiments, we demonstrate that the activation is a gradual process and that the heat generated during the first discharge is directly linked to the extent of activation during the preceding charge. We also investigate the effect of the degree of overlithiation on the heat generated during activation.

Export citation and abstract BibTeX RIS

This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 License (CC BY, http://creativecommons.org/licenses/by/4.0/), which permits unrestricted reuse of the work in any medium, provided the original work is properly cited.

Lithium- and manganese-rich layered oxides (LMR-NCMs) such as Li1.14(Ni0.26Co0.13Mn0.6)0.86O2 are promising candidates for next-generation Li-ion batteries. Compared with conventional layered NCMs, they provide higher reversible capacities of up to 250 mAh g−1. This is because a part of the transition metals (TMs) in the TM layer is replaced by lithium, thereby leading to an overlithiation of the structure. By using inexpensive manganese, a low material cost compared with other state-of-the-art cathode materials, which contain high amounts of nickel and cobalt, is achieved. 1

However, the practical application of LMR-NCMs is still limited by several challenges such as voltage fading, 2 oxygen evolution, 3,4 high resistances, 5 and a pronounced voltage hysteresis. 1,6,7 The hysteresis of the voltage is still present under open-circuit conditions and is thus an intrinsic bulk property of LMR-NCM. In addition to the open-circuit voltage (OCV), other parameters show a path-dependence as a function of state-of-charge (SOC), viz., the cathode resistance, 5 the lattice parameters, 8 and the entropy curve. 9 Interestingly, all of these hysteresis phenomena occur only for an activated LMR-NCM material, i.e., after charging it to 4.8 V vs Li+/Li. Thereby, the activation of the LMR-NCM is a gradual process and the first charge occurs via a two-step voltage profile. During the initial sloping potential region, lithium (Li) is removed from the Li-sites, and the charge is compensated by the oxidation of the transition metals (TMs). In this first region (below ≈125 mAh g−1 or at ≈4.4 V vs Li+/Li), the material cycles reversibly (i.e., the coulombic efficiency is close to 100%, the peaks in the dQ/dV profile are symmetrical, 1,10 and the lattice parameters, 8 resistance, 5 and entropy 9 of the charge and discharge direction coincide). Upon further charging, the voltage curve shows a plateau at ≈4.5 V vs Li+/Li, and the charge compensation includes oxygen redox, which enables the anomalously high first-charge capacity of more than 300 mAh g−1 and leads to irreversible structural rearrangements. During the upper voltage plateau, the long-range "honey-comb" ordering disappears 10,11 and chemically available Li sites are lost, thereby leading to a large irreversible capacity loss during the first cycle. Several structural and electronic changes are associated with the activation process and discussed in the literature. These include irreversible 3,12 and reversible 13,14 oxidation of oxygen, partly reversible TM migration, 1,7,10 the formation of Li/TM dumbbells, 1,15 and the formation of dislocations. 16 All of these processes happen during the upper voltage plateau and cause a substantial hysteresis between the first charge and discharge voltage curve. This loss of voltage combined with the large irreversible capacity leads to a very low electrical energy efficiency of ≈73% for the first cycle.

The aim of the present study is to investigate the heat generated during the first cycle and to answer the following questions: (i) How much of the electrical work, which is lost during the first cycle, is converted into waste heat? (ii) What can we learn about the activation processes from the heat generation profile as a function of SOC? (iii) What effect does the activation have on the generation of heat during the subsequent discharge? (iv) How does the degree of overlithiation influence the generation of heat during activation? The lost electrical work, measured by galvanostatic cycling, can usually be directly converted into the expected waste heat of a battery when a full, reversible charge/discharge cycle is considered. However, because LMR-NCM undergoes irreversible processes during the first activation cycle, the material at the end of the first cycle clearly differs from the pristine material. The irreversible capacity loss observed and the substantially lower voltage on discharge are direct consequences. Thus, the difference between the charge and discharge energy is only a measure of lost electrical work and does not provide information about the amount of waste heat or its generation during charge and discharge. The heat generation during the activation of LMR-NCM can be analyzed only by means of calorimetry. By applying operando isothermal micro-calorimetry (IMC), we aim to analyze the generation of heat as a function of state-of-charge (SOC), thereby gaining insight into the activation processes. With the investigation of parasitic reactions, the Dahn group demonstrated that IMC is a reliable technique for precisely analyzing the thermal behavior of batteries.

17–19

In our previous IMC study,

20

we discuss the heat generation of LMR-NCMs during regular cycling and introduce a new heat source into the general energy balance model: the heat resulting from OCV hysteresis,  This term is required to describe the thermal behavior of active materials with a pronounced OCV hysteresis such as LMR-NCM. Using IMC, Assat et al.

21

investigated the heat generation of Li2Ru0.75Sn0.25O3, which serves as a model system for LMR-NCM materials. They report a large heat release during the upper voltage plateau in the first charge. This is ascribed to a chemical stabilization process correlated to the irreversible structural rearrangements during activation.

This term is required to describe the thermal behavior of active materials with a pronounced OCV hysteresis such as LMR-NCM. Using IMC, Assat et al.

21

investigated the heat generation of Li2Ru0.75Sn0.25O3, which serves as a model system for LMR-NCM materials. They report a large heat release during the upper voltage plateau in the first charge. This is ascribed to a chemical stabilization process correlated to the irreversible structural rearrangements during activation.

In the following, we use IMC to measure the heat generated during activation of LMR-NCMs in LMR-NCM/Li half-cells at C/10 and 25 °C. We also determine the irreversible heat using a galvanostatic intermittent cycling protocol. The reversible heat is calculated based on potentiometric entropy measurements. 9 However, entropic heat is shown to be negligible for the present study. Thus, from the difference between the observed heat and the expected calculated heat value, the heat resulting from activation and hysteresis is determined as a function of SOC.

Experimental

Calculation approach

When a battery is charged or discharged, heat is generated. Under isothermal conditions, the total heat flow can be expressed according to Eq. 1. In general, three main contributions to the heat generation can be identified: (i) the irreversible heat flow,  (ii) the reversible heat flow,

(ii) the reversible heat flow,  and (iii) the parasitic heat flow,

and (iii) the parasitic heat flow,

Irreversible heat originates from cell polarization, which causes the cell voltage under load,  to differ from that under open-circuit conditions,

to differ from that under open-circuit conditions,  This term, which is the first one on the right hand side of Eq. 1, is always exothermic. It can be calculated from electrochemical cycling data with an intermittent protocol explained in the section "Determination of irreversible heat by intermittent cycling". The second term, the reversible heat, is caused by the changes in the entropy of the cathode and anode as a function of SOC. Depending on the sign of the applied current,

This term, which is the first one on the right hand side of Eq. 1, is always exothermic. It can be calculated from electrochemical cycling data with an intermittent protocol explained in the section "Determination of irreversible heat by intermittent cycling". The second term, the reversible heat, is caused by the changes in the entropy of the cathode and anode as a function of SOC. Depending on the sign of the applied current,  , this contribution can be either exothermic or endothermic. For reversible processes,

, this contribution can be either exothermic or endothermic. For reversible processes,  is equal to zero if a complete charge/discharge cycle is considered. The reversible heat was determined from entropy measurements described in the section "Determination of reversible heat" belowand is discussed in more detail elsewhere.

9

The third term on the right hand side of Eq. 1 comprises all heat flow from sources other than intercalation. This can include any side reactions such as electrolyte decomposition

17–19

or SEI formation.

22

A detailed discussion of the different sources of heat can be found in our previous IMC study,

20

in which we also elucidated the necessity to add another term to the general heat equation for materials that show a significant hysteresis in their OCV, such as LMR-NCMs. We thus introduced in our previous work the heat resulting from OCV hysteresis,

is equal to zero if a complete charge/discharge cycle is considered. The reversible heat was determined from entropy measurements described in the section "Determination of reversible heat" belowand is discussed in more detail elsewhere.

9

The third term on the right hand side of Eq. 1 comprises all heat flow from sources other than intercalation. This can include any side reactions such as electrolyte decomposition

17–19

or SEI formation.

22

A detailed discussion of the different sources of heat can be found in our previous IMC study,

20

in which we also elucidated the necessity to add another term to the general heat equation for materials that show a significant hysteresis in their OCV, such as LMR-NCMs. We thus introduced in our previous work the heat resulting from OCV hysteresis,  20

For this purpose, we assume that the voltage measured under OCV conditions,

20

For this purpose, we assume that the voltage measured under OCV conditions,  , is not equal to the (hypothetical) thermodynamic equilibrium potential,

, is not equal to the (hypothetical) thermodynamic equilibrium potential,  , which cannot be measured. A potential difference and thus a similar expression as for the irreversible heat generated by polarization is created. The heat flow of LMR-NCM/Li cells is thus as follows:

, which cannot be measured. A potential difference and thus a similar expression as for the irreversible heat generated by polarization is created. The heat flow of LMR-NCM/Li cells is thus as follows:

However, this theoretical heat balance must be adjusted for the present study. For the first cycle of LMR-NCM/Li cells, the contribution from  was found to be negligible. A detailed discussion of this simplification can be found in the section "Estimate of the magnitude of other sources of heat during the first cycle activation" at the end of the Results section below. There, we also explain why the parasitic heat, which was estimated from measurements of a symmetrical Li/Li cell, is assumed to be insignificant. The heat balance used for the calorimetry study presented here thus simplifies to:

was found to be negligible. A detailed discussion of this simplification can be found in the section "Estimate of the magnitude of other sources of heat during the first cycle activation" at the end of the Results section below. There, we also explain why the parasitic heat, which was estimated from measurements of a symmetrical Li/Li cell, is assumed to be insignificant. The heat balance used for the calorimetry study presented here thus simplifies to:

The total heat generation is measured by isothermal micro-calorimetry (IMC) as described below. Thus, the additional heat term resulting from OCV hysteresis and activation,  , is determined from the difference between the total measured heat flow,

, is determined from the difference between the total measured heat flow,  , and the calculated irreversible heat. This simplification means that what we identify as

, and the calculated irreversible heat. This simplification means that what we identify as  includes contributions from

includes contributions from  and

and  In the section "Estimate of the magnitude of other sources of heat during the first cycle activation", we will demonstrate that these contributions are insignificant. Nevertheless, we still want to make clear that they are not zero, even though this is assumed for the calculation in Eq. 3.

In the section "Estimate of the magnitude of other sources of heat during the first cycle activation", we will demonstrate that these contributions are insignificant. Nevertheless, we still want to make clear that they are not zero, even though this is assumed for the calculation in Eq. 3.

Electrode fabrication and battery assembly

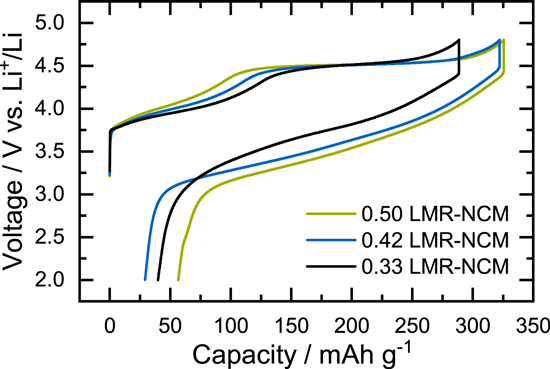

We used three different Li- and Mn-rich layered oxides (LMR-NCM) with varying degrees of overlithiation. According to the notation Li1+δ [TM]1-δ O2, BASF SE (Germany) provided us with a low-(δ = 0.14), mid- (δ = 0.17), and high-lithium material (δ = 0.20), which correspond to 0.33 li2MnO3, 0.42 li2MnO3, and 0.50 li2MnO3 when written in the notation x Li2MnO3 •(1-x) LiTMO2 that was used by Teufl et al. 3 This study focuses on the low-lithium material, which has been analyzed by means of calorimetry 6,20 and entropy. 9 Its exact composition is Li1.14(Ni0.26Co0.14Mn0.60)0.86O2 and will further on be referred to as "0.33 LMR-NCM." The LMR-NCMs with δ = 0.17 and δ = 0.20 will be referred to as "0.42 LMR-NCM" and "0.50 LMR-NCM," respectively. For electrode preparation, inks of the cathode active material (CAM) were prepared by mixing 92.5 wt% LMR-NCM, 3.5 wt% polyvinylidene-fluoride binder (PVdF, Solef 5130, Solvay, Belgium), and 4 wt% conductive carbon (Super-C65, Timcal, Switzerland) with N-methyl pyrrolidine (anhydrous, Sigma-Aldrich, Germany). The dispersion was mixed in a planetary orbital mixer (solid content ≈58 wt%; Thinky, USA), and the resulting ink was coated onto aluminum foil (≈15 μm, MTI, USA). After drying, the coatings were calendered (GK 300 L, Saueressig, Germany) to a porosity of ≈42%–45%. For electrochemical testing, the electrodes were dried for a minimum of 12 h at 120°C in a dynamic vacuum (Büchi, Switzerland). The loading of the LMR-NCM electrodes was ≈11.6 mg cm−2, which corresponds to ≈2.9 mAh/cm2 based on a nominal reversible capacity of 250 mAh/gLMR-NCM.

Coin cells (type CR2032) were assembled in an argon-filled glovebox (O2, H2O < 0.1 ppm, MBraun, Germany) with the manufactured cathodes (14 mm diameter), two glass fiber separators (17 mm diameter, glass microfiber #691, VWR, Germany), and a Li counter electrode (15 mm diameter, 450 μm thickness, 99.9%, Rockwood Lithium, USA). The electrolyte was composed of 100 μl of a 1m LiPF6 in an FEC:DEC-based (12:64 v:v) solvent with 24 vol% of an additional fluorinated co-solvent (BASF SE, Germany). All data reported here originate from constant current (CC) cycling at a C-rate of C/10, whereby the C-rate is referenced to a nominal reversible capacity of LMR-NCM of 250 mAh g−1. We use the term "state-of-charge" (SOC) to describe the nominal specific capacity (in mAh/gCAM) that was extracted from the cathode. It can hence be directly converted into the amount of Li in the cathode. With this definition, an SOC of 0 mAh g−1 means that the material is fully lithiated (Li1.14(Ni0.26Co0.13Mn0.6)0.86O2) while at an SOC of 346 mAh g−1, the LMR-NCM would be fully delithiated. Two sets of identical cells were analyzed in this study: (i) one set was cycled inside the calorimeter as described in Isothermal micro-calorimetry section; (ii) the second set of cells was used to determine the irreversible heat by intermittent cycling described in Determination of irreversible heat by intermittent cycling section. All data that is shown here was reproduced with at least two identical cells. For clarity, the figures below show data from one representative cell without error bars from the repeat measurement because the error bars are mostly smaller than the symbols in the figures.

Isothermal micro-calorimetry

The LMR-NCM/Li coin cells were transferred to the isothermal micro-calorimeter directly after assembly. A TAM IV calorimeter equipped with a 20 ml micro-calorimeter (stability ± 50 μK, accuracy ± 300 nW, precision ±100 nW, TA Instruments, USA) was used. The cells were cycled inside the IMC in a custom-made coin cell holder, which was connected by Cu-P bronze wires (Duo-Twist wire WDT-36–25, 36 AWG, Lakeshore, USA) to a potentiostat (SP200, BioLogic, France). A detailed description of the coin cell holder can be found elsewhere. 23 For clarification, the study presented here was conducted with a preceding but very similar sample holder model compared to that shown by Kunz et al., 23 which is why the setup and parameter values reported here, differ slightly from theirs.

All measurements were performed at 25 °C under isothermal conditions after internal gain calibration. On the reference side of the calorimeter, a dummy cell with the same content as the actual sample cell but without the cathode active material was used in order to ensure high measurement accuracy by having a comparable heat capacity of both cells. Before the experiment was started, we waited for the signal to reach a pre-set stability criteria (drift < 10 nW/h, standard deviation < 150 nW for 60 min). As the system identification process suggests, the calorimetric setup can be described as dynamical 2nd order system (PT2 system). Typically, such systems can be empirically characterized by the according unit step-response when a rectangular heat flow is applied as an input signal (for more details see Kunz et al. 23 ). The two time-constants T1 and T2 of the systems transfer-function we derived during the calibration process are T1 = 57 s and T2 = 131 s. This results in a time delay of 682 s until 99% of the steady-state heat flow value is detected. A positive sign in the observed heat flow indicates that heat is generated by the cell.

Galvanostatic cycling was done at C/10. First, a formation cycle was conducted between 2.0–4.8 V (all voltages are reported further on vs Li+/Li), followed by a stabilization cycle (2.0–4.7 V), which was not further analyzed, and another cycle (2.0–4.7 V) representative of the reversible cycling behavior of the LMR-NCM materials after their first-cycle activation. After each half-cycle (i.e., whenever the upper or lower cutoff was reached), the CC phase was followed by a 6 h open-circuit phase in order to enable separation of the heat flow during charge and discharge. Two identical cells were measured for each experiment in order to ensure the reproducibility of the results. The raw heat flow data obtained by IMC were normalized by the cathode active material mass and corrected for their relative y-offset by subtracting a baseline. For the charge half-cycles, a constant y-offset was determined prior to the start of the CC phase. For the discharge half-cycles, an exponential decay function fitted to the observed gradually subsiding heat flow signal was used as a baseline during the preceding OCV phase. Because the heat flow signal in the rest phase after charging did not converge to a stable value within the 6 h of relaxation, we were unable to use a simple y-offset for the discharge half-cycles. Because of the time delay, the integration of the heat flow of an individual charge or discharge half-cycle includes not only the heat signal obtained during current flow but also that obtained during the subsequent relaxation phase. Of the 6 h relaxation phase applied, we included only the first 1.5 h into the calculation. This is sufficient to obtain most of the actual heat signal, yet not so long that parasitic heat flows might be erroneously included in the calculation. A waiting time of 1.5 h might seem ineptly long considering the time delay of ≈11 min until 99% of the signal is observed in the calibration measurement. However, the determined time delay needs to be classified as a signal response of an ideal system, i.e. an electrical resistor, whose heat generation strictly follows the applied current profile. The reported value hence solely describes the time delay of the IMC instrument. When the applied current of a coin cell with a real cell chemistry is switched off at the beginning of a rest phase, equilibration processes within the electrodes occur and lead to heat generation with much longer time constants. For a reliable analysis of IMC data, it is hence crucial to critically assess how much of the rest phase will be included into the integration of the heat signal. This value should be reported to allow comparison to other reports and instruments.

Determination of irreversible heat by intermittent cycling

Complementary to the IMC measurements, electrochemical testing was performed with identical cells at 25 °C in a temperature-controlled oven (Binder, Germany) using a Biologic potentiostat (VMP300, Biologic, France). To calculate the irreversible heat according to Eq. 3, the overpotential,  , was determined by intermittent cycling. The cycling protocol applied is similar to a galvanostatic intermittent titration and was used as in our previous study,

20

in which the approach is described in more detail. The first cycle was conducted between 2.0–4.8 V, followed by a stabilization cycle (2.0–4.7 V), which was not further analyzed, and another cycle (2.0–4.7 V) representative of the reversible cycling behavior of LMR-NCMs after their first-cycle activation. All cycles were conducted at C/10. Figure 1 shows the voltage curve of a 0.33 LMR-NCM/Li cell obtained by intermittent cycling during the first charge and discharge (black solid line). The cycling procedure includes (dis)charging steps of ΔSOC = 2.5% followed by a relaxation phase of

, was determined by intermittent cycling. The cycling protocol applied is similar to a galvanostatic intermittent titration and was used as in our previous study,

20

in which the approach is described in more detail. The first cycle was conducted between 2.0–4.8 V, followed by a stabilization cycle (2.0–4.7 V), which was not further analyzed, and another cycle (2.0–4.7 V) representative of the reversible cycling behavior of LMR-NCMs after their first-cycle activation. All cycles were conducted at C/10. Figure 1 shows the voltage curve of a 0.33 LMR-NCM/Li cell obtained by intermittent cycling during the first charge and discharge (black solid line). The cycling procedure includes (dis)charging steps of ΔSOC = 2.5% followed by a relaxation phase of  = 1 h. This was repeated until the upper (lower) voltage cutoff was reached. Using this approach,

= 1 h. This was repeated until the upper (lower) voltage cutoff was reached. Using this approach,  is determined as the difference between the last voltage value at current flow,

is determined as the difference between the last voltage value at current flow,  , and the open-circuit voltage,

, and the open-circuit voltage,  , at the end of the intermittent relaxation phase, as shown in the inset of Fig. 1. The average of the final 300 s of the OCV phase are used as

, at the end of the intermittent relaxation phase, as shown in the inset of Fig. 1. The average of the final 300 s of the OCV phase are used as  The intermittent cycling method is not applicable for determining

The intermittent cycling method is not applicable for determining  for the first SOC point during charging or discharging because there is no preceding voltage relaxation in the charge (discharge) direction. By applying small ΔSOC steps, we aim to minimize the effect of this missing data point.

for the first SOC point during charging or discharging because there is no preceding voltage relaxation in the charge (discharge) direction. By applying small ΔSOC steps, we aim to minimize the effect of this missing data point.

Figure 1. Voltage curves of the first cycle of a 0.33 LMR-NCM/Li cell at C/10. During intermittent cycling, the (dis)charging was interrupted every ΔSOC = 2.5% for 1 h and when the upper or lower cutoff potential was reached. The OCV values ( ) at the end of each OCV rest phase are depicted as blue circles and the measured voltage (

) at the end of each OCV rest phase are depicted as blue circles and the measured voltage ( ) as a solid black line. A voltage curve from a continuous cycle of an identical cell is shown for comparison (dashed orange line). The inset shows voltage and current of the cell from intermittent cycling as a function of time at an SOC ≈ 180 mAh g−1 during discharge. This illustrates how the overpotential,

) as a solid black line. A voltage curve from a continuous cycle of an identical cell is shown for comparison (dashed orange line). The inset shows voltage and current of the cell from intermittent cycling as a function of time at an SOC ≈ 180 mAh g−1 during discharge. This illustrates how the overpotential,  is calculated from the difference between the last voltage point on load,

is calculated from the difference between the last voltage point on load,  and

and

Download figure:

Standard image High-resolution imageThe measurement of  after 1 h of relaxation means that slow relaxation processes that happen on the order of hours or even weeks (i.e., lithium diffusion in the solid phase) are not included into the calculation of the overpotential and hence the irreversible heat. However, prolonged relaxation phases at every ΔSOC = 2.5% would lead to severe self-discharge effects and an uncertainty in the determination of the nominal SOC. From previous experiments, we know that a 1 h OCV phase leads to reliable SOC data and a tolerable inaccuracy in the determination of

after 1 h of relaxation means that slow relaxation processes that happen on the order of hours or even weeks (i.e., lithium diffusion in the solid phase) are not included into the calculation of the overpotential and hence the irreversible heat. However, prolonged relaxation phases at every ΔSOC = 2.5% would lead to severe self-discharge effects and an uncertainty in the determination of the nominal SOC. From previous experiments, we know that a 1 h OCV phase leads to reliable SOC data and a tolerable inaccuracy in the determination of  For example, when the last discharging step in Fig. 1 is considered, the overpotential

For example, when the last discharging step in Fig. 1 is considered, the overpotential  determined after

determined after  = 1 h amounts to ≈96% of that after

= 1 h amounts to ≈96% of that after  = 6 h. Nevertheless, we want to emphasize that a longer rest phase would generally lead to higher values for

= 6 h. Nevertheless, we want to emphasize that a longer rest phase would generally lead to higher values for  Since

Since  is calculated by subtracting

is calculated by subtracting  from the total heat signal, this means that the heat because of hysteresis and activation would be slightly smaller if a longer rest phase were chosen. However, the error is small in comparison to other measurement inaccuracies.

from the total heat signal, this means that the heat because of hysteresis and activation would be slightly smaller if a longer rest phase were chosen. However, the error is small in comparison to other measurement inaccuracies.

As can be seen in Fig. 1, the charge and discharge capacities of an LMR-NCM/Li cell from constant current cycling (as applied for the IMC cells, dashed orange line) are slightly lower than from the intermittent cycling (solid black line). These deviations amount to ≈−2% for the charge capacity and ≈−4% for the discharge capacity and can be explained by the different cycling procedures. Because in the intermittent protocol, a 1 h rest phase is applied every ΔSOC = 2.5%, any concentration gradients which are formed in the cell during cycling (e.g., because of liquid or solid diffusion limitations) are continuously minimized. This means that the intercalation processes are closer to equilibrium and that more Li-ions can be (de-)intercalated during intermittent cycling compared with a constant current cycling. In addition, self-discharge phenomena might occur for the cells subjected to intermittent cycling, especially at high SOCs during charge because they spend more time at high voltages. When the upper voltage plateau is considered (SOC > 125 mAh g−1), both cell types spend ≈6 h in this region during the constant current phase. However, while for the IMC cells, only another 6 h during the subsequent OCV phase must be added, the cells from intermittent cycling go through ≈27 OCV phases of 1 h each in this region. This may enhance self-discharge phenomena and lead to a higher observable charge capacity. Because the deviations are rather small, the results from intermittent cycling can still be used to complement those from the IMC cells.

Determination of reversible heat

As shown in Eq. 2, the reversible heat is calculated as a product of the applied current, temperature, and temperature-dependent OCV value,  The latter was measured as a function of SOC after (dis)charging the cell to a certain SOC point and allowing it to relax until the change in OCV over time was less than ≈0.2 mV/h. After this relaxation,

The latter was measured as a function of SOC after (dis)charging the cell to a certain SOC point and allowing it to relax until the change in OCV over time was less than ≈0.2 mV/h. After this relaxation,  was determined by linearly varying the temperature of the cell between 5 °C and 35 °C in an Espec temperature chamber (LU114, Espec, Japan) while recording the respective OCV variation (VMP300, Biologic, France). A detailed description of the method applied and the results for the low- and high-lithium material are reported elsewhere.

9

was determined by linearly varying the temperature of the cell between 5 °C and 35 °C in an Espec temperature chamber (LU114, Espec, Japan) while recording the respective OCV variation (VMP300, Biologic, France). A detailed description of the method applied and the results for the low- and high-lithium material are reported elsewhere.

9

Results and Discussion

Heat generation during activation of LMR-NCM

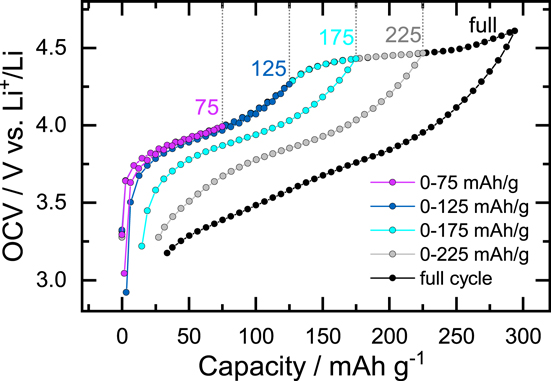

The cyclic voltage curves of the first and the third cycle of an LMR-NCM/Li cell at C/10 are shown in Fig. 2a. The second cycle is not shown because it is not representative of the continuous cycling. The first charge-discharge profile (blue curve in Fig. 2a) starts with an initial sloping region, which is associated with the oxidation of transition metals (Ni and Co), followed by a voltage plateau at ≈4.5 V during which irreversible structural changes such as transition metal migration,

1,7,10

oxygen redox,

13,14

and the loss of a honeycomb ordering

10,11

occur. The first charge of LMR-NCM thus includes unique activation processes, which cause the cell resistance,

5

the lattice parameters,

8

and the entropy curve

9

to differ from those of the following cycles. Furthermore, at high SOCs (voltage > 4.6 V), oxygen is released from the near-surface region of the material.

3,12

The voltage profile of the first charge differs significantly from that of the following cycles (black curve in Fig. 2a). In contrast, the subsequent discharge voltage curve agrees with those of following cycles. Compared with the charge, the discharge in the first cycle occurs at a much lower average potential, and the discharge capacity that can be achieved is ≈40 mAh g−1 lower because of an irreversible loss of capacity. Both factors combined lead to a significantly lower discharge energy and a considerable loss of electrical energy during the first cycle, which is shown in Table I ( ). In other words, the energy efficiency of the first cycle (≈73%) is significantly lower than that of the third cycle (≈90%).

). In other words, the energy efficiency of the first cycle (≈73%) is significantly lower than that of the third cycle (≈90%).

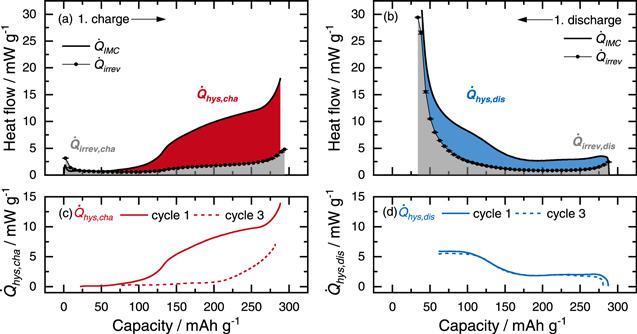

Figure 2. (a) Voltage curve of the first cycle (blue) and the third cycle (black) of a 0.33 LMR-NCM/Li cell at C/10. Panels (b) and (c) show the heat flow profiles during charge and discharge, respectively, with the heat flow of the first cycle in blue and the third cycle in black. The heat measured by IMC is shown by thick solid lines and originates from the same cell of which the voltage curves are shown in (a). The irreversible heat calculated from intermittent cycling is depicted as filled symbols connected by thin lines, with error bars from two different cells.

Download figure:

Standard image High-resolution imageTable I. Measured and calculated energy losses for a 0.33 LMR-NCM/Li cell at C/10 and 25 °C for the first and third cycle. The charge (Echa) and discharge electrical energy (Edis), the relative electrical energy efficiency (Edis/Echa) and the absolute electrical energy loss (Echa-Edis) are shown together with the total heat generation measured by IMC (QIMC,total), and the ratio of total heat/electrical energy loss for the whole cycle. Energy terms are given in mWh g−1 and ratios in %.

| Cycle |

[mWh g−1] [mWh g−1] |

[mWh g−1] [mWh g−1] |

[%] [%] |

[mWh g−1] [mWh g−1] |

[mWh g−1] [mWh g−1] |

[%] [%] |

|---|---|---|---|---|---|---|

| 1 | 1240.1 | 906.5 | 73 | 333.6 | 143.0 | 43 |

| 3 | 972.8 | 878.7 | 90 | 94.1 | 87.7 | 93 |

Table I furthermore illustrates that for the third cycle, the electrical energy lost ( ) is almost completely observed as waste heat by IMC (

) is almost completely observed as waste heat by IMC ( ). With 93%, the accuracy of this measurement is comparable to our previous study,

20

where we discuss possible error sources that might have led to the deviation observed. These include the cables connecting the coin cell holder, which might remove heat from the cell and hence the detector. Another issue is the choice of the integration limit for the calculation of the IMC heat. From the 6 h OCV phase at the end of each half-cycle, only the first 1.5 h were considered for the calculation, as explained in Isothermal micro-calorimetry section. This should be enough time to include the diminishing heat generation resulting from the time delay of the calorimeter and the equilibration processes within the cell, yet not too long to erroneously include too much heat from parasitic processes, such as electrolyte decomposition. However, if the heat signal of the complete rest phase had been taken instead, the resulting total IMC heat would correspond to 97% of the electrical work lost. Overall, we conclude that within the accuracy of the IMC measurement quasi all of the electrical energy lost during the third cycle is converted into waste heat. Table II shows that ≈33% of the overall measured heat of 87.7 mWh g−1 is dissipated during charge (28.7 mWh g−1) and ≈67% during discharge (59.0 mWhg−1). The irreversible heat determined from intermittent cycling thereby covers ≈57% of the heat generated during charge and ≈47% of the heat observed during discharge. The residual part of the heat is caused by the OCV hysteresis, which is discussed in detail in our previous IMC study.

20

The analysis of the first cycle shown in Table II illustrates that of the total heat ≈55% is generated during charge (78.8 mWh g−1) and ≈45% during discharge (64.2 mWh g−1). The irreversible heat determined by intermittent cycling accounts for ≈19% of the heat during charge and ≈43% of the heat during discharge. The fact that only a small share of the heat generated during the first charge is due to polarization effects means that a considerable amount is caused by another heat source. This will be discussed in more detail in Heat resulting from activation and hysteresis section. A comparison of the absolute numbers of

). With 93%, the accuracy of this measurement is comparable to our previous study,

20

where we discuss possible error sources that might have led to the deviation observed. These include the cables connecting the coin cell holder, which might remove heat from the cell and hence the detector. Another issue is the choice of the integration limit for the calculation of the IMC heat. From the 6 h OCV phase at the end of each half-cycle, only the first 1.5 h were considered for the calculation, as explained in Isothermal micro-calorimetry section. This should be enough time to include the diminishing heat generation resulting from the time delay of the calorimeter and the equilibration processes within the cell, yet not too long to erroneously include too much heat from parasitic processes, such as electrolyte decomposition. However, if the heat signal of the complete rest phase had been taken instead, the resulting total IMC heat would correspond to 97% of the electrical work lost. Overall, we conclude that within the accuracy of the IMC measurement quasi all of the electrical energy lost during the third cycle is converted into waste heat. Table II shows that ≈33% of the overall measured heat of 87.7 mWh g−1 is dissipated during charge (28.7 mWh g−1) and ≈67% during discharge (59.0 mWhg−1). The irreversible heat determined from intermittent cycling thereby covers ≈57% of the heat generated during charge and ≈47% of the heat observed during discharge. The residual part of the heat is caused by the OCV hysteresis, which is discussed in detail in our previous IMC study.

20

The analysis of the first cycle shown in Table II illustrates that of the total heat ≈55% is generated during charge (78.8 mWh g−1) and ≈45% during discharge (64.2 mWh g−1). The irreversible heat determined by intermittent cycling accounts for ≈19% of the heat during charge and ≈43% of the heat during discharge. The fact that only a small share of the heat generated during the first charge is due to polarization effects means that a considerable amount is caused by another heat source. This will be discussed in more detail in Heat resulting from activation and hysteresis section. A comparison of the absolute numbers of  in Table II indicates that the heat generated during discharge is similar for the first and the third cycle and that a comparable proportion of the heat observed is due to polarization effects. In contrast, with

in Table II indicates that the heat generated during discharge is similar for the first and the third cycle and that a comparable proportion of the heat observed is due to polarization effects. In contrast, with  78.8 mWh g−1, the total heat released during the first charge is almost three-fold of that released during the third charge (28.7 mWh g−1). The most striking observation is that for the first cycle, the lost electrical energy (333.6 mWh g−1) far exceeds the waste heat observed by IMC (143.0 mWh g−1), as Table II shows. In fact, only ≈43% of the energy lost is converted into heat. From the analysis of the third cycle, we know that this cannot be caused by instrumental errors. The question thus arises as to why the electrical energy lost cannot be observed as waste heat. In order to clarify this, we need to revisit the cyclic voltage curve in Fig. 2a, which shows that the charge/discharge process is not a closed loop for the first cycle. The large irreversible loss of capacity (≈40 mAh g−1) together with the fact that the first charge profile is unique and includes irreversible processes mean that the first cycle is not a thermodynamically reversible process. Simply speaking, the LMR-NCM material at the end of the first cycle differs from the pristine material at the beginning. The difference in the charge and discharge energy therefore includes not only waste heat but also a considerable amount of electrical energy that is consumed by irreversible processes in the active material or that cannot be extracted anymore during discharge because of the restructuring of the LMR-NCM and the loss of chemically available Li sites. From the voltage curve alone, it is therefore not possible to assess how much waste heat will be released during the first cycle. IMC measurements enable us to quantify the heat generated during the activation cycle of LMR-NCM as a function of SOC and separate it into its share in charge and discharge direction, which, to our knowledge, is reported here for the first time.

78.8 mWh g−1, the total heat released during the first charge is almost three-fold of that released during the third charge (28.7 mWh g−1). The most striking observation is that for the first cycle, the lost electrical energy (333.6 mWh g−1) far exceeds the waste heat observed by IMC (143.0 mWh g−1), as Table II shows. In fact, only ≈43% of the energy lost is converted into heat. From the analysis of the third cycle, we know that this cannot be caused by instrumental errors. The question thus arises as to why the electrical energy lost cannot be observed as waste heat. In order to clarify this, we need to revisit the cyclic voltage curve in Fig. 2a, which shows that the charge/discharge process is not a closed loop for the first cycle. The large irreversible loss of capacity (≈40 mAh g−1) together with the fact that the first charge profile is unique and includes irreversible processes mean that the first cycle is not a thermodynamically reversible process. Simply speaking, the LMR-NCM material at the end of the first cycle differs from the pristine material at the beginning. The difference in the charge and discharge energy therefore includes not only waste heat but also a considerable amount of electrical energy that is consumed by irreversible processes in the active material or that cannot be extracted anymore during discharge because of the restructuring of the LMR-NCM and the loss of chemically available Li sites. From the voltage curve alone, it is therefore not possible to assess how much waste heat will be released during the first cycle. IMC measurements enable us to quantify the heat generated during the activation cycle of LMR-NCM as a function of SOC and separate it into its share in charge and discharge direction, which, to our knowledge, is reported here for the first time.

Table II. Measured and calculated energy losses for a 0.33 LMR-NCM/Li cell at C/10 and 25 °C for the first and third cycle separated by charge and discharge direction. The heat measured by IMC during charge (QIMC,cha) and discharge (QIMC,dis) and the respective irreversible heat (Qirrev,cha and Qirrev,dis) are shown together with the ratio of the irreversible/measured heat during charge and discharge. Energy terms are given in mWh g−1 and ratios in %.

| Cycle |

[mWh g−1] [mWh g−1] |

[mWh g−1] [mWh g−1] |

[%] [%] |

[mWh g−1] [mWh g−1] |

[mWh g−1] [mWh g−1] |

[%] [%] |

|---|---|---|---|---|---|---|

| 1 | 78.8 | 15.2 | 19 | 64.2 | 27.5 | 43 |

| 3 | 28.7 | 16.2 | 57 | 59.0 | 27.6 | 47 |

In addition to the overall heat generation, the heat flow profiles provide valuable information resolved as a function of SOC. The heat flow curves of the first and the third cycle of an LMR-NCM/Li cell measured by IMC at C/10 are shown in Fig. 2b for the charge direction and in Fig. 2c for the discharge direction. In both plots, the heat flow measured by IMC,  (solid lines), is contrasted with the irreversible heat generation,

(solid lines), is contrasted with the irreversible heat generation,  (filled symbols), determined from identical cells by intermittent cycling. As explained in Isothermal micro-calorimetry section, a 6 h rest phase was applied between charge and discharge of the IMC cells in order to enable separation of the heat flow of the two respective half-cycles. The heat flow was measured as a function of time and with the applied constant current this time axis was converted into an SOC scale. However, we wish to emphasize that with this approach, the time delay of the calorimeter is neglected. As was already discussed in our previous IMC study,

20

the resulting error is small for slow C-rates. With the C/10 current applied here, it is in the order of ≈2% when the time delay of ≈11 min, until 99% of the signal is observed, is compared to the duration of the first charge (≈12 h).

(filled symbols), determined from identical cells by intermittent cycling. As explained in Isothermal micro-calorimetry section, a 6 h rest phase was applied between charge and discharge of the IMC cells in order to enable separation of the heat flow of the two respective half-cycles. The heat flow was measured as a function of time and with the applied constant current this time axis was converted into an SOC scale. However, we wish to emphasize that with this approach, the time delay of the calorimeter is neglected. As was already discussed in our previous IMC study,

20

the resulting error is small for slow C-rates. With the C/10 current applied here, it is in the order of ≈2% when the time delay of ≈11 min, until 99% of the signal is observed, is compared to the duration of the first charge (≈12 h).

Figure 2c shows that the heat generated during the first discharge agrees well with that during the third cycle—similar to what is expected from the voltage curve. In the first part of the discharge process (300 mAh g−1 > SOC > 175 mAh g−1), heat generation is relatively constant (≈3 mW g−1). When the cell is discharged below ≈175 mAh g−1, the heat signal increases to ≈10 mW g−1 and at the end of discharge, another sharp increase in the heat generation is observed. The irreversible heat is rather constant (≈1 mW g−1) over a wide SOC range and increases exponentially when the cell is discharged below ≈125 mAh g−1. Irreversible heat is caused by polarization effects in the cell. These include the ionic resistance of the separator, the electric resistance of the external cell contacts, the resistance of the Li anode, the charge transfer resistance of the cathode, the contact resistance between the cathode coating and the current collector, and the ionic resistance of the electron and ion conduction across the cathode. For reversible cycles such as the third cycle shown in Fig. 2, a detailed discussion on the underlying resistances causing  can be found in our previous publication

20

in which we conducted impedance measurements and concluded that the charge transfer resistance of the cathode dominates the polarization effects. Its increasing values at low and high SOC give rise to the observed curve shape as a function of SOC, which is in agreement with the results of Teufl et al.

5

The data in Fig. 2c suggest that the polarization effects in the first discharge agree with those of the third cycle. The difference observed between

can be found in our previous publication

20

in which we conducted impedance measurements and concluded that the charge transfer resistance of the cathode dominates the polarization effects. Its increasing values at low and high SOC give rise to the observed curve shape as a function of SOC, which is in agreement with the results of Teufl et al.

5

The data in Fig. 2c suggest that the polarization effects in the first discharge agree with those of the third cycle. The difference observed between  and

and  will be discussed in more detail in the next chapter.

will be discussed in more detail in the next chapter.

In contrast to the discharge direction, the heat generation observed by IMC during the first charge differs significantly from the profile during the third charge as can be seen in Fig. 2b. During activation,  has a constant region with values between 1 and 2 mW g−1 at the beginning of charge until the cell reaches an SOC of ≈100 mAh g−1, where the heat signal starts to increase. At SOC > 125 mAh g−1, the heat flow profile then shows a saturation behavior, where

has a constant region with values between 1 and 2 mW g−1 at the beginning of charge until the cell reaches an SOC of ≈100 mAh g−1, where the heat signal starts to increase. At SOC > 125 mAh g−1, the heat flow profile then shows a saturation behavior, where  is between ≈7 mW g−1 and ≈12 mW g−1. At the end of charge, another steep increase is observed. In contrast, during the third charge, the heat flow profile exhibits a U-shape starting at ≈4.5 mW g−1 at low SOC. This is followed by a plateau around ≈1.5 mW g−1 in the mid-SOC region and an increase up to ≈10 mW g−1 at the end of the charge. The heat flow curves during activation and the following cycles thus differ significantly in case of the charge direction. With the results from intermittent cycling, we can analyze whether the observed mismatch is caused by differences in the irreversible heat profile. For the low SOC region, both heat flow profiles are dominated by the irreversible heat. In the third charge, which starts at ≈40 mAh g−1 because of the irreversible capacity loss in the first cycle (see voltage profile in Fig. 2a), the irreversible heat and IMC signal agree well below ≈200 mAh g−1, which means that the measured heat is mainly caused by polarization effects. In the first charge,

is between ≈7 mW g−1 and ≈12 mW g−1. At the end of charge, another steep increase is observed. In contrast, during the third charge, the heat flow profile exhibits a U-shape starting at ≈4.5 mW g−1 at low SOC. This is followed by a plateau around ≈1.5 mW g−1 in the mid-SOC region and an increase up to ≈10 mW g−1 at the end of the charge. The heat flow curves during activation and the following cycles thus differ significantly in case of the charge direction. With the results from intermittent cycling, we can analyze whether the observed mismatch is caused by differences in the irreversible heat profile. For the low SOC region, both heat flow profiles are dominated by the irreversible heat. In the third charge, which starts at ≈40 mAh g−1 because of the irreversible capacity loss in the first cycle (see voltage profile in Fig. 2a), the irreversible heat and IMC signal agree well below ≈200 mAh g−1, which means that the measured heat is mainly caused by polarization effects. In the first charge,  is close to

is close to  in the SOC region <100 mAh g−1. The observed mismatch between the first and the third charge in the low SOC region is thus caused by the irreversible heat flow. For the third charge, the results for

in the SOC region <100 mAh g−1. The observed mismatch between the first and the third charge in the low SOC region is thus caused by the irreversible heat flow. For the third charge, the results for  agree with those previously reported,

20

thereby indicating that the charge transfer resistance of the cathode dominates the underlying polarization effects. Based on the impedance measurements by Teufl et al.,

5

it is known that for a cell with an LMR-NCM cathode that has not yet been charged beyond 100 mAh g−1, the polarization effects are significantly lower and have a different profile as a function of SOC compared to a cell that underwent a full activation cycle. The observed mismatch in the

agree with those previously reported,

20

thereby indicating that the charge transfer resistance of the cathode dominates the underlying polarization effects. Based on the impedance measurements by Teufl et al.,

5

it is known that for a cell with an LMR-NCM cathode that has not yet been charged beyond 100 mAh g−1, the polarization effects are significantly lower and have a different profile as a function of SOC compared to a cell that underwent a full activation cycle. The observed mismatch in the  curves of the first and the third charge in the SOC region below ≈100 mAh g−1 are thus caused by differences in the underlying cathode resistance, which dominate the irreversible heat. However, for the SOC range in which the mismatch between the

curves of the first and the third charge in the SOC region below ≈100 mAh g−1 are thus caused by differences in the underlying cathode resistance, which dominate the irreversible heat. However, for the SOC range in which the mismatch between the  curves of the first and the third charge is most striking (>100 mAh g−1), the results from intermittent cycling prove that this is not caused by the irreversible heat. When comparing the curves for

curves of the first and the third charge is most striking (>100 mAh g−1), the results from intermittent cycling prove that this is not caused by the irreversible heat. When comparing the curves for  in the first (blue symbols) and the third charge (black symbols) in Fig. 2b, we observe that in this SOC range, the curves for

in the first (blue symbols) and the third charge (black symbols) in Fig. 2b, we observe that in this SOC range, the curves for  agree well for both cycles. For the first charge, there must therefore be an additional source of heat, which can no longer be observed in the following cycles. This additional heat generation will be discussed in detail in the following.

agree well for both cycles. For the first charge, there must therefore be an additional source of heat, which can no longer be observed in the following cycles. This additional heat generation will be discussed in detail in the following.

Heat resulting from activation and hysteresis

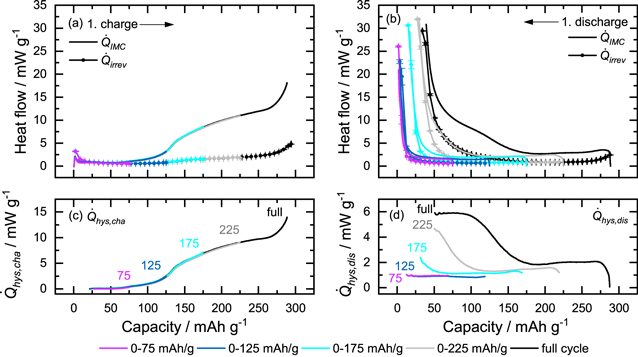

Figure 3a and Fig. 3b show a detailed analysis of the heat flow that is observed during the first activation charge and discharge. There, heat generation measured by IMC (solid lines) is compared with the irreversible heat flow determined by intermittent cycling (black circles and shaded gray area). As mentioned in the Experimental section, the intermittent cycling was conducted with identical cells as used for the IMC experiments. The apparent charge and discharge capacity of the cells from intermittent cycling is slightly higher than that of the IMC cells because of the different cycling procedures (see Determination of irreversible heat by intermittent cycling section).

Figure 3. Heat flow of a 0.33 LMR-NCM/Li cell during activation at C/10: (a) and (b) show the heat flow measured by IMC,  (solid black lines) together with the irreversible heat flow determined by intermittent cycling,

(solid black lines) together with the irreversible heat flow determined by intermittent cycling,  (black circles) during charge and discharge. The colored areas in (a) and (b) correspond to the irreversible heat (gray) and the heat resulting from OCV hysteresis (red for charge, blue for discharge). The error bars for

(black circles) during charge and discharge. The colored areas in (a) and (b) correspond to the irreversible heat (gray) and the heat resulting from OCV hysteresis (red for charge, blue for discharge). The error bars for  are calculated from the measurement of two identical cells. The generation of

are calculated from the measurement of two identical cells. The generation of  for charge and discharge is plotted in (c) and (d); the solid lines correspond to the

for charge and discharge is plotted in (c) and (d); the solid lines correspond to the  generation during the first cycle, and the dashed lines represent the third cycle.

generation during the first cycle, and the dashed lines represent the third cycle.

Download figure:

Standard image High-resolution imageFor the charge half-cycle, the IMC signal agrees with the calculated value of  until SOC ≈100 mAh g−1, i.e., up to the point where the gradual transition to the upper voltage plateau initiates (see Fig. 2a). During the transition to the upper voltage plateau that is reached at ≈125 mAh g−1,

until SOC ≈100 mAh g−1, i.e., up to the point where the gradual transition to the upper voltage plateau initiates (see Fig. 2a). During the transition to the upper voltage plateau that is reached at ≈125 mAh g−1,  increases significantly, while

increases significantly, while  remains constant, indicating that an additional source of heat is present for LMR-NCM. When comparing the heat generation profiles in Fig. 3a to the voltage curve in Fig. 2a, it becomes clear that the onset of this large heat generation coincides with the beginning of the upper voltage plateau during which irreversible structural rearrangements lead to the activation of the LMR-NCM. We thus ascribe this large generation of heat to these activation processes, as suggested by Assat et al.

21

for the first cycle of Li2Ru0.75Sn0.25O3. The additional heat source shall here be termed

remains constant, indicating that an additional source of heat is present for LMR-NCM. When comparing the heat generation profiles in Fig. 3a to the voltage curve in Fig. 2a, it becomes clear that the onset of this large heat generation coincides with the beginning of the upper voltage plateau during which irreversible structural rearrangements lead to the activation of the LMR-NCM. We thus ascribe this large generation of heat to these activation processes, as suggested by Assat et al.

21

for the first cycle of Li2Ru0.75Sn0.25O3. The additional heat source shall here be termed  and is illustrated by the red shaded area in Fig. 3a for the first charge. Above ≈125 mAh g−1,

and is illustrated by the red shaded area in Fig. 3a for the first charge. Above ≈125 mAh g−1,  is the main source of heat. For the discharge direction, the IMC signal deviates from the irreversible heat over the whole SOC range. This means that there is a continuous

is the main source of heat. For the discharge direction, the IMC signal deviates from the irreversible heat over the whole SOC range. This means that there is a continuous  generation corresponding to the blue shaded area in Fig. 3b. To better analyze the profile of the

generation corresponding to the blue shaded area in Fig. 3b. To better analyze the profile of the  generation, Fig. 3c and Fig. 3d show the difference curve, which is obtained by subtracting

generation, Fig. 3c and Fig. 3d show the difference curve, which is obtained by subtracting  from

from  in the respective upper panels (solid lines for the first cycle). For the charge direction, the generation of

in the respective upper panels (solid lines for the first cycle). For the charge direction, the generation of  starts at ≈100 mAh g−1 with a steep increase until ≈140 mAh g−1, where the curvature changes into an approximately linear slope. In the SOC range between ≈140 mAh g−1 and ≈260 mAh g−1, the

starts at ≈100 mAh g−1 with a steep increase until ≈140 mAh g−1, where the curvature changes into an approximately linear slope. In the SOC range between ≈140 mAh g−1 and ≈260 mAh g−1, the  generation continuously rises from ≈4.5 mW g−1 to ≈10 mW g−1. At the end of charge, another steep increase to ≈14 mW g−1 is observed. Figure 3d shows that, during the discharge half-cycle,

generation continuously rises from ≈4.5 mW g−1 to ≈10 mW g−1. At the end of charge, another steep increase to ≈14 mW g−1 is observed. Figure 3d shows that, during the discharge half-cycle,  is generated over the entire SOC range. The heat flow profile of

is generated over the entire SOC range. The heat flow profile of  can be described with two plateaus at high and low SOC that are connected by a step-like feature: at the beginning of discharge, a constant value of ≈2 mW g−1 is observed, which increases when the cell is discharged below ≈170 mAh g−1. The second plateau is reached at SOCs < 100 mAh g−1, where

can be described with two plateaus at high and low SOC that are connected by a step-like feature: at the beginning of discharge, a constant value of ≈2 mW g−1 is observed, which increases when the cell is discharged below ≈170 mAh g−1. The second plateau is reached at SOCs < 100 mAh g−1, where  is ≈5 mW g−1. The

is ≈5 mW g−1. The  generation thus shows a clear asymmetry between the first charge and discharge.

generation thus shows a clear asymmetry between the first charge and discharge.

When we compare the generation of  during the first cycle with that during the third cycle (solid vs dashed lines in Fig. 3c and Fig. 3d, we see a clear difference for the charge direction. For the discharge cycles, on the other hand, both

during the first cycle with that during the third cycle (solid vs dashed lines in Fig. 3c and Fig. 3d, we see a clear difference for the charge direction. For the discharge cycles, on the other hand, both  curves overlap, as do the total heat flow and the irreversible heat generation,

curves overlap, as do the total heat flow and the irreversible heat generation,  (see Fig. 2c). The fact that the heat evolution during discharge in the first and the consecutive cycles agrees resembles the behavior of the lattice parameters

8

and the entropy curve

9

of the same LMR-NCM material reported in the literature. In contrast, while the irreversible heat during charge at SOCs above ≈100 mAh g−1 is fairly comparable for the first and the third cycle, the overall heat signal differs significantly (see Fig. 2b). This, in turn, leads to a considerably different

(see Fig. 2c). The fact that the heat evolution during discharge in the first and the consecutive cycles agrees resembles the behavior of the lattice parameters

8

and the entropy curve

9

of the same LMR-NCM material reported in the literature. In contrast, while the irreversible heat during charge at SOCs above ≈100 mAh g−1 is fairly comparable for the first and the third cycle, the overall heat signal differs significantly (see Fig. 2b). This, in turn, leads to a considerably different  generation profile. In the third cycle,

generation profile. In the third cycle,  is observed only at high SOCs (>200 mAh g−1), where it increases steadily and reaches a maximum of ≈7 mW g−1 at the end of charge, as reported in our previous study.

20

On the other hand, in the first charge, the onset of

is observed only at high SOCs (>200 mAh g−1), where it increases steadily and reaches a maximum of ≈7 mW g−1 at the end of charge, as reported in our previous study.

20

On the other hand, in the first charge, the onset of  is earlier (≈100 mAh g−1), and the overall heat generation observed is substantially higher (

is earlier (≈100 mAh g−1), and the overall heat generation observed is substantially higher ( ≈12.3 mWh g−1 for the third vs

≈12.3 mWh g−1 for the third vs  ≈63.8 mWh g−1 for the first charge). Thus, what we label here as

≈63.8 mWh g−1 for the first charge). Thus, what we label here as  is not the same for the first and any consecutive cycle, because

is not the same for the first and any consecutive cycle, because  during the first charge includes the heat generation from irreversible activation processes, which occur only during the upper voltage plateau of the first charge half-cycle.

during the first charge includes the heat generation from irreversible activation processes, which occur only during the upper voltage plateau of the first charge half-cycle.

Interestingly, for the charge direction, the onset of  in the first cycle occurs in the same SOC region where the transition to the upper voltage plateau initiates (at ≈100 mAh g−1). Thus, in the SOC window between ≈100-125 mAh g−1, both the voltage curve and the

in the first cycle occurs in the same SOC region where the transition to the upper voltage plateau initiates (at ≈100 mAh g−1). Thus, in the SOC window between ≈100-125 mAh g−1, both the voltage curve and the  curve show a steep increase. At SOCs above ≈150 mAh g−1, the upper voltage plateau is reached, and the voltage curve flattens out. In this SOC range, the

curve show a steep increase. At SOCs above ≈150 mAh g−1, the upper voltage plateau is reached, and the voltage curve flattens out. In this SOC range, the  profile increases in an approximately linear manner. The major proportion of

profile increases in an approximately linear manner. The major proportion of  is generated in this high SOC region, which coincides with the upper voltage plateau of the cell. As explained above, irreversible processes

10,13

occur during the upper voltage plateau. Our results clearly indicate that this activation process generates a significant amount of heat release.

is generated in this high SOC region, which coincides with the upper voltage plateau of the cell. As explained above, irreversible processes

10,13

occur during the upper voltage plateau. Our results clearly indicate that this activation process generates a significant amount of heat release.

There are also some similarities between the  generation during activation and the gas release measured by on-line electrochemical mass spectrometry (OEMS). For a similar LMR-NCM material as used in the present study, Strehle et al.

12

and Teufl et al.

3

report that the CO2 generation during the first charge starts between ≈100-125 mAh g−1. This coincides with the sloping region at the beginning of the upper voltage plateau and the onset of the

generation during activation and the gas release measured by on-line electrochemical mass spectrometry (OEMS). For a similar LMR-NCM material as used in the present study, Strehle et al.

12

and Teufl et al.

3

report that the CO2 generation during the first charge starts between ≈100-125 mAh g−1. This coincides with the sloping region at the beginning of the upper voltage plateau and the onset of the  generation observed here. The increase of the CO2 concentration as a function of SOC resembles the shape of the

generation observed here. The increase of the CO2 concentration as a function of SOC resembles the shape of the  signal up to ≈270 mAh g−1. When the cell is charged even higher, both

signal up to ≈270 mAh g−1. When the cell is charged even higher, both  and the CO2 generation show a steep increase. In this high SOC range, O2 generation is observed by OEMS.

3,12

The CO2 evolution below 4.6 V (≈270 mAh g−1) is attributed to the chemical decomposition of Li2CO3, which reacts with protons formed by either the anionic oxidation of the electrolyte or trace impurities.

3,12,24

The CO2 and O2 evolution at high SOC are ascribed to the release of lattice oxygen from the surface of the LMR-NCM particles, which either reacts with the electrolyte to form CO2 or is evolved as O2.

4

An O-depleted spinel/rock salt surface layer is thereby formed around the LMR-NCM particles.

3,12,13

and the CO2 generation show a steep increase. In this high SOC range, O2 generation is observed by OEMS.

3,12

The CO2 evolution below 4.6 V (≈270 mAh g−1) is attributed to the chemical decomposition of Li2CO3, which reacts with protons formed by either the anionic oxidation of the electrolyte or trace impurities.

3,12,24

The CO2 and O2 evolution at high SOC are ascribed to the release of lattice oxygen from the surface of the LMR-NCM particles, which either reacts with the electrolyte to form CO2 or is evolved as O2.

4

An O-depleted spinel/rock salt surface layer is thereby formed around the LMR-NCM particles.

3,12,13

Let us first discuss the decomposition of Li2CO3. According to the enthalpies of formation listed in the NIST database,

25

the enthalpy of reaction for Li2CO3 + 2 HF  2 liF + H2O + CO2 is ≈−155.6 kJ/

2 liF + H2O + CO2 is ≈−155.6 kJ/ and thus exothermic. The decomposition of Li2CO3 as a surface impurity is reported to be on the order of ≈0.6 wt%,

12

which means that per gram of LMR-NCM active material, only ≈80 μmol of Li2CO3 are decomposed. The enthalpy of the decomposition thus translates to a heat generation per gram of LMR-NCM of ≈3.5 mWh g−1. When we calculate absolute numbers for

and thus exothermic. The decomposition of Li2CO3 as a surface impurity is reported to be on the order of ≈0.6 wt%,

12

which means that per gram of LMR-NCM active material, only ≈80 μmol of Li2CO3 are decomposed. The enthalpy of the decomposition thus translates to a heat generation per gram of LMR-NCM of ≈3.5 mWh g−1. When we calculate absolute numbers for  based on the difference between the total heat measured by IMC and the irreversible heat determined by intermittent cycling shown in Table i and Table II, we observe that

based on the difference between the total heat measured by IMC and the irreversible heat determined by intermittent cycling shown in Table i and Table II, we observe that  amounts to ≈63.8 mWh g−1 (≈20 kJ mol−1, based on a molecular mass of the 0.33 LMR-NCM of 88.5 g/mol) for the first charge of LMR-NCM. Compared to this value, the decomposition reaction can explain only a small fraction of the observed heat generation. We can therefore exclude that it is the predominant source of the

amounts to ≈63.8 mWh g−1 (≈20 kJ mol−1, based on a molecular mass of the 0.33 LMR-NCM of 88.5 g/mol) for the first charge of LMR-NCM. Compared to this value, the decomposition reaction can explain only a small fraction of the observed heat generation. We can therefore exclude that it is the predominant source of the  generation. However, as mentioned in Calculation approach section, other sources of heat, such as reversible and parasitic heat, contribute to the overall heat signal, but as will be shown in Estimate of the magnitude of other sources of heat during the first cycle activation section, both of these terms are negligible compared to the magnitude of the heat generation observed. The second process that causes gas evolution at high SOCs is the transformation of the surface-near region of the LMR-NCM particles from a layered to a spinel/rock salt structure.

3,12,13

At high degrees of delithiation, this process is reported to be exothermic.

26,27

According to DFT calculations by Wang et al.,

26

layered Li0.25NiO2 can be transformed to rock salt NiO and/or spinel LiNi2O4 with reaction enthalpies of ≈−10 kJ mol−1 to ≈−15 kJ mol−1. However, in the presence of electrolyte, which reacts with the evolved O2, the heat is reported to be approximately 10 times higher, with numbers between ≈−75 kJ/mol for Li0.45Ni0.33Co0.33Mn0.33O2 and ≈−130 kJ/mol for Li0.45Ni0.8Co0.15Al0.05O2 in 1.2 m LiPF6/EC:EMC (3:7 wt%).

27

It needs to be stressed that these literature values refer to a complete material decomposition, while in the present study only a few mol% of the LMR-NCM at the particle surface are expected to be reconstructed.

3,12

For the first charge, we observe that

generation. However, as mentioned in Calculation approach section, other sources of heat, such as reversible and parasitic heat, contribute to the overall heat signal, but as will be shown in Estimate of the magnitude of other sources of heat during the first cycle activation section, both of these terms are negligible compared to the magnitude of the heat generation observed. The second process that causes gas evolution at high SOCs is the transformation of the surface-near region of the LMR-NCM particles from a layered to a spinel/rock salt structure.

3,12,13

At high degrees of delithiation, this process is reported to be exothermic.

26,27

According to DFT calculations by Wang et al.,

26

layered Li0.25NiO2 can be transformed to rock salt NiO and/or spinel LiNi2O4 with reaction enthalpies of ≈−10 kJ mol−1 to ≈−15 kJ mol−1. However, in the presence of electrolyte, which reacts with the evolved O2, the heat is reported to be approximately 10 times higher, with numbers between ≈−75 kJ/mol for Li0.45Ni0.33Co0.33Mn0.33O2 and ≈−130 kJ/mol for Li0.45Ni0.8Co0.15Al0.05O2 in 1.2 m LiPF6/EC:EMC (3:7 wt%).

27

It needs to be stressed that these literature values refer to a complete material decomposition, while in the present study only a few mol% of the LMR-NCM at the particle surface are expected to be reconstructed.

3,12

For the first charge, we observe that  amounts to ≈63.8 mWh g−1 (≈20 kJ mol−1). However, these calculated numbers refer to the whole SOC range, whereas O2 evolution from the CAM reconstruction is observed only at high SOC. By fitting a baseline through the

amounts to ≈63.8 mWh g−1 (≈20 kJ mol−1). However, these calculated numbers refer to the whole SOC range, whereas O2 evolution from the CAM reconstruction is observed only at high SOC. By fitting a baseline through the  profile between 100 mAh g−1 and 250 mAh g−1, the heat generation that is observed on top of this baseline at higher SOCs (i.e., between ≈250-280 mAh g−1) can be integrated. We thus estimate the additional heat generated above 250 mAh g−1 to be ≈1.1 mWh g−1 (≈0.36 kJ mol−1). Assuming that ≈3 mol% of the LMR-NCM at the surface are transformed to a spinel/rock salt structure,

3,12

the expected energy values are between 0.3 kJ mol−1 and 0.45 kJ mol−1, assuming no reaction of the evolving O2 with the electrolyte

26

and between 2.25 kJ mol−1 and 3.9 kJ mol−1 with electrolyte decomposition.

27

Because the OEMS studies indicate that the CO2 signal increases once O2 is detected,

3,12

a combination of both reactions is observed. We therefore conclude that the increase in the

profile between 100 mAh g−1 and 250 mAh g−1, the heat generation that is observed on top of this baseline at higher SOCs (i.e., between ≈250-280 mAh g−1) can be integrated. We thus estimate the additional heat generated above 250 mAh g−1 to be ≈1.1 mWh g−1 (≈0.36 kJ mol−1). Assuming that ≈3 mol% of the LMR-NCM at the surface are transformed to a spinel/rock salt structure,

3,12

the expected energy values are between 0.3 kJ mol−1 and 0.45 kJ mol−1, assuming no reaction of the evolving O2 with the electrolyte

26

and between 2.25 kJ mol−1 and 3.9 kJ mol−1 with electrolyte decomposition.

27

Because the OEMS studies indicate that the CO2 signal increases once O2 is detected,

3,12

a combination of both reactions is observed. We therefore conclude that the increase in the  profile above ≈250 mAh g−1 might be correlated to the reconstruction of the CAM particle surface from a layered to an O-depleted spinel/rock salt structure. The heat of this reaction together with the heat generated when the evolved O2 reacts with the electrolyte might be the cause of the sharp increase in the IMC signal towards the end of charge (see Fig. 3c). However, a more thorough analysis is required to prove this hypothesis. Moreover, it is important to stress that the O2 evolution of the LMR-NCM can explain only this rather small part of the overall

profile above ≈250 mAh g−1 might be correlated to the reconstruction of the CAM particle surface from a layered to an O-depleted spinel/rock salt structure. The heat of this reaction together with the heat generated when the evolved O2 reacts with the electrolyte might be the cause of the sharp increase in the IMC signal towards the end of charge (see Fig. 3c). However, a more thorough analysis is required to prove this hypothesis. Moreover, it is important to stress that the O2 evolution of the LMR-NCM can explain only this rather small part of the overall  heat above ≈250 mAh g−1. Most of the heat generation observed is thus caused by bulk phenomena and not by the gas evolution from the LMR-NCM particle surface.

heat above ≈250 mAh g−1. Most of the heat generation observed is thus caused by bulk phenomena and not by the gas evolution from the LMR-NCM particle surface.

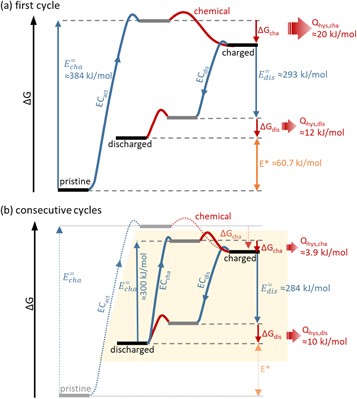

The findings discussed above feed into a scheme for the reaction energy landscape of LMR-NCM shown in Fig. 4. It is similar to previously reported hysteresis loops for molecular hysteresis

28,29

and follows the scheme drawn for the Li-rich layered model material Li[Li0.33Ru0.5Sn0.17]O2.

21

The first cycle (Fig. 4a) starts from the pristine material, which is electrochemically oxidized on charge requiring the electrical charge energy  The difference between

The difference between  in Fig. 4 and

in Fig. 4 and  as used above, e.g. in Table I, is that the latter is the measured electrical charge energy (1240.1 mWh g−1) including the overpotential (and thus

as used above, e.g. in Table I, is that the latter is the measured electrical charge energy (1240.1 mWh g−1) including the overpotential (and thus  ) while

) while  is the charge energy describing the thermodynamics of the system in equilibrium without any polarization effects (

is the charge energy describing the thermodynamics of the system in equilibrium without any polarization effects ( =1224.9 mWh g−1 or ≈384 kJ/mol). The electrochemical charge reaction (termed as "ECact" and marked in blue in Fig. 4) is followed by a chemical process (red), in which the LMR-NCM bulk structure is rearranged. In the scheme in Fig. 4a, this is visualized by the transition from the intermediate (gray) to the stable charged state (black). The structural modification happens during the upper voltage plateau and is most likely caused by a combination of irreversible processes (e.g., anionic redox, TM migration, and/or the loss of the honeycomb ordering), whereby the definitive mechanism is still under debate.

8,13,30

While we cannot make any statement on the mechanistic processes during activation, we are able to measure the heat release associated with these activation processes. The material conversion to the stable charged state thus explains the considerable heat generation observed during the upper voltage plateau in the first charge,