Abstract

The overall aim of the PROMETHEUS project is to develop high power ultra-short pulse lasers and the associated optics to enable the precise periodic texturing of surfaces to impart a range of surface functionalities at unprecedented processing speeds. The project focusses upon the industrial application of ultra-short pulse lasers for manufacturing and on the development of high power ultra-short pulse laser technologies in the range of 700 ps – 10 ns. In summary, new textures will be manufactured to achieve functional surfaces utilising fewer raw materials, less energy and less waste; improve accuracy, power and control over existing technologies; increase achievable precision and minimize heat impact on sensitive materials. This article will provide the outcomes of the first results achieved from the monitoring solutions being used to assess surface textures with micrometer resolution.

Export citation and abstract BibTeX RIS

Original content from this work may be used under the terms of the Creative Commons Attribution 4.0 license. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

1. Introduction

Among the different approaches that can be used to fabricate biomimetic structures on surfaces, short/ultra-short (S/US) laser pulses gained in the last years a high relevance [1–3]. The material removal takes place locally at the zone where the laser beam is interacting with the substrate surface which also causes limited chemical surface modification [4]. From an industrial point of view, S/US pulsed laser technologies are very flexible and allow to treat a wide range of materials, as long as the substrate absorbs the used laser wavelength (i.e. IR and VIS for metals [5, 6] and UV for polymers [7]). In addition, the scale-up of such technologies for industrial applications has been already demonstrated in several cases [8].

Although the fabrication of functional surfaces has been demonstrated on different materials, the main drawback of the traditional direct laser writing (DLW) technology is the long processing time with machining speeds in the range of minutes per square centimetre [9–11]. Multiple solutions are available for scaling-up the fabrication speed of DLW including the use of polygonal scanners and multi-beam approaches. However, the achievable feature sizes of DLW are typically limited to 5–15 µm [12, 13].

Considering the fabrication of periodic patterns with different length scales (larger or even smaller than the laser wavelength) other well-established laser technologies can be considered such as Direct Laser Interference Patterning (DLIP) [14, 15]. This method relies on the overlap of two or more coherent laser beams which results in the formation of well-defined interference patterns.

For a given laser wavelength and number of beams, the spatial period can be easily adjusted by modifying the angle of the interfering beams [15]. By changing the polarization and the geometrical configuration of the interfering beams, very different pattern geometries can be created. For instance, in a two-beam arrangement a line-like pattern is generated whereas a three-beam configuration lead to dot-like patterns.

Although the fabrication of periodic structures using DLIP has been demonstrated on different materials and employing different laser sources, the assessment of the structuring quality during the manufacturing process remains an open topic of great interest for its exploitation under industrial conditions. The aim of the present work is therefore to demonstrate a promising method to characterize microstructured surfaces employing scatterometry and diffractometry techniques and their possible implementation in an inline process monitoring system.

1.1. Hydrophobicity and oleophobicity

Achieving super-hydrophobicity is specific to achieve water repellent surfaces. However, super-oleophobicity requires surfaces that are not wetted by organic liquids that typically have lower surface tensions compared to that of water. It has been demonstrated that the synergistic effects of re-entrant topographic features, combined with tailored surface chemistry properties, helps to promote super-oleophobicity which inherently provides super-hydrophobic properties. However, it is possible in some cases that oleophobic properties can occur alongside hydrophilic properties instead. This phenomenon is not fully understood. The PROMETHEUS project will investigate both hydrophobic properties and oleophobic properties for different materials.

In order to achieve hydrophobic/oleophobic properties, a robust Cassie wetting state must be met [16, 17]; the re-entrant feature must promote the net traction to drive the liquid/air interface to recede to the top edge of the microstructures, resulting in a three-phase (solid/air/liquid) interface. To simplify, the microstructures of the material surface can be overall be divided into two types that represent either a trapezoid (figure 1(a)) or an inverted trapezoid (figure 1(b)).

Figure 1. Schematic of two possible robust Cassie states: (a) trapezoid and (b) inverted trapezoid.

Download figure:

Standard image High-resolution imageIn the case of water, the trapezoid microstructures can promote a robust Cassie state for having hydrophobic surfaces.

However, according to the design constraint, oils which commonly have very low surface tension and almost all of their Young's CAs smaller than 90°, are unable to be form a robust Cassie state. In this case, this can be realised on inverted-trapezoid textures. Thus, inverted-trapezoid surface microstructures are usually termed re-entrant textures [18].

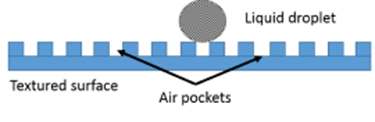

In the PROMETHEUS laser station prototype, laser texturing processes will be based on Direct Laser Interference Patterning (DLIP) by two laser beams. In this case, the pattern generated by the two-beams interference is a line-like pattern. If a metallic or polymeric surface is patterned with the proper line-like structures, then this becomes hydrophobic or oleophobic. Figure 2 depicts the wetting behaviour of a water droplet on a patterned surface.

Figure 2. Schematic sketch about the wetting of a water droplet on a microgroove patterned surface.

Download figure:

Standard image High-resolution imageThe water droplet sits on the top of the patterns with air trapped in between the patterns, thereby giving rise to hydrophobicity due to composite wetting as described by the Cassie-Baxter model [16, 17]. Based on previous experimental works performed [34], a line by line laser scanning process will be investigated for the generation of micro-conical structures and trapezoids on metallic and polymeric samples.

2. Materials and methods

In the scope of the PROMETHEUS project, several European partners have shown interest in the DLIP surface texturization technology, leading to a large range of materials been studied. Several metals such as steels and aluminium are currently under investigation and are showing promising results in both the texturization process and in the physical property obtained.

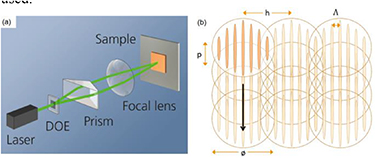

For the laser experiments, a compact diode-pumped Nd:YLF laser (Tech 1053 basic, Laser Export, Russia) emitting 15 ns pulses with TEM00 mode (Gaussian beam) at 1053 nm was used to irradiate the materials. The main laser beam was then directed through a compact DLIP optical module (developed at Fraunhofer IWS, Dresden) capable to fabricate line-like interference patterns with varying spatial periods (software-controlled). The main laser beam is divided into two sub-beams by a diffractive beam-splitting element. The two sub-beams are collimated by a prism and then overlapped by a lens onto the sample surface resulting in a line-like interference pattern in a well-defined interference area (denoted as DLIP pixel), as depicted in figure 3(a). By changing the distance between the beam-splitting element and the prism, the interference period Λ can be selectively changed in a range of 1.5–8.5 µm. The size of the DLIP-pixels Ø in the working position is ∼100 µm.

Figure 3. Schematic representation of the DLIP setup (a) and of the pixel-based structuring mechanism (b).

Download figure:

Standard image High-resolution imageHigh precision positioning stages (AEROTECH PRO115) were used for displacing the sample and distributing the interference pattern over a larger area both in the direction parallel and perpendicular (hatch distance h) to the interference pattern, as highlighted in figure 3(b). The quantity p defines also the pulse-to-pulse overlap and can be expressed as number of pulses per pixel (P/px) which also denotes the cumulative fluence dose.

It is worth mentioning that the h value have been adjusted for the employed spatial period, in order to match a distance equal to an entire multiple of the period. In the present work, a period of 8.5 µm and a hatch distance of 25.5 µm have been used.

2.1. Characterization and selection of textures

Once a matrix of sample is manufactured, their properties are studied, in order to select the best process parameters for a successfull texturization. Two aspects are mostly looked at in this phase: on one hand, the reproducibility of the pattern, and on the other hand the physical properties of the newly texturized material.

Regarding the reproducibility of the pattern, a valley detection algorithm was developed at AIMEN, in order to identify each individual period and easily extract the associated geometrical parameters. An illustration of this algorithm applied to a reproducable texture can be found in figure 4. By using this algorithm on all samples, it become obvious that some strategies for texturing are not optimal. The main parameters of the texturing process been the number of laser pulses and the energy of each laser pulse, we can observe that if a low energy is used on the laser, the desired patterns tend not to appears correctly on the surface. Using more pulses with lower energy does not always compensate for this issue, even with the same total energy. To the contrary, using too much energy in the pulses leads to a degraded material, and a non-reproducible pattern, even with less pulses.

Figure 4. Extraction of the geometrical parameters and typical profile from the confocal images.

Download figure:

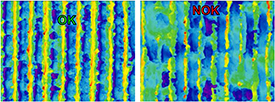

Standard image High-resolution imageFor each texture, an optimal texturing strategy is then obtained. An illustration of this selection can be found in figure 5 where both a 'good' and a 'bad' cases are shown side by side for comparison. Table 6 gives the actual values found by the detection algorithm with both mean value and standard deviation for different fabrication receipes.

Table 1. Results for different process recipe for the aluminium sample.

| pitch | pitch std (%) | height (µm) | height std (%) | width (µm) | width std (%) | slope | Slope std (%) | Valid flag (%) | |

|---|---|---|---|---|---|---|---|---|---|

| Aluminium—target pitch 8.5 µm—03 P/px—low laser power | 8.49 | 7.31 | 2.51 | 21.37 | 4.20 | 11.63 | 0.38 | 29.30 | 100 |

| Aluminium—target pitch 8.5 µm—03 P/px—medium power | 8.53 | 6.71 | 4.00 | 17.40 | 4.50 | 12.84 | 0.67 | 29.58 | 99 |

| Aluminium—target pitch 8.5 µm—03 P/px—high laser power | 8.53 | 9.58 | 5.29 | 19.12 | 4.42 | 14.54 | 0.92 | 30.77 | 99 |

| Aluminium—target pitch 8.5 µm—10 P/px—low laser power | 8.47 | 5.92 | 6.45 | 13.20 | 5.08 | 8.44 | 1.30 | 18.86 | 100 |

| Aluminium—target pitch 8.5 µm—10 P/px—medium laser power | 8.51 | 7.06 | 9.40 | 22.69 | 5.15 | 13.59 | 1.66 | 37.39 | 100 |

| Aluminium—target pitch 8.5 µm—10 P/px—high laser power | 8.54 | 9.94 | 9.61 | 30.72 | 5.62 | 16.08 | 2.03 | 60.43 | 93 |

| Aluminium—target pitch 8.5 µm—17 P/px—low laser power | 8.47 | 6.42 | 8.08 | 17.05 | 5.42 | 8.40 | 1.67 | 21.50 | 100 |

| Aluminium—target pitch 8.5 µm—17 P/px—medium power | 8.47 | 10.92 | 8.25 | 31.50 | 5.94 | 14.79 | 1.82 | 60.01 | 90 |

| Aluminium—target pitch 8.5 µm—17 P/px—high laser power | 8.70 | 15.41 | 7.35 | 42.22 | 6.47 | 14.74 | 1.78 | 63.27 | 75 |

Figure 5. Example of OK and NOK texture definition: The texture on the left show a 6% standard variation in the 8.5 um optimal pitch, a 8% variation in width and a 13% variation in height, therefore its considered OK. The texture on the right show a 22% standard variation in the 8.5um optimal pitch, a 24% variation in width and a 31% variation in height, therefore it is considered NOK.

Download figure:

Standard image High-resolution imageThe other aspect of the qualification of the textures concern the physical properties. Indeed, the PROMETHEUS project been designed to create hydrophilic or hydrophobic materials, a contact angle measurement is performed on the fabricated DLIP textures [19, 20]. An example of the contact angle measurement can be found in figure 6. Note that this method is limited to the reaction with water and is therefore not always directly linked to the requested property of the final product: for instance, if the final product will be in contact with oil (like for the case of a car's engine component) or oily products (like cosmetics product), the relation between the contact angle and the behaviour with the final product will not necessary be linear [21].

Figure 6. Contact angle measurement of a hydrophobic structure.

Download figure:

Standard image High-resolution imageHowever, as a first approach, a set of potential strategies for texturing the end-materials are selected and will be tested by the different customers in order to assess a first corelation between theoretical models and the real application. Eventually, a range of geometrical properties (such as pitch, gap width, structure height and slope) will be selected, as those properties are the ones that are responsible for the physical property of the material [19]. An ideal DLIP laser strategy will be later developed to create the line-like structures with the highest reproducibility.

(Θc > 160°)

2.2. Process qualification: scatterometry

During the process of characterization of the line-like structures described earlier, the geometrical characteristics of the lines are studied, and a good reproducibility of those geometrical characteristics is expected. Those values have been extensively studied with the help of a confocal microscope and a scanning laser microscope, among others. However, such technics are very time consuming and cannot be implemented in-line during the manufacturing process.

Therefore, in order to monitor the quality of the process, a different approach is being adapted: the scatterometry technology [22], in which we compare the measured reflected light on the texturized sample, with an optical model of RCWA.

For the measure of the reflected light, a preliminary setup has been mounted at AIMEN. In this setup, a white polarized and collimated light is shined into the texturized sample, as illustrated in figure 7. The sample which contains a line-like structure that acts as a diffraction grating will diffract light in a well-defined way. Each diffraction order will have a certain intensity which will depend on several parameters such as the angle of incidence, the polarization, the wavelength, the optical index of the material, the order itself (1st order, 2nd order...), and finally the geometrical parameters of the lines. This means that, since we are shining a white light onto the sample, each wavelength will reflect a different quantity of energy in 0th order, that is strongly dependent of the geometrical parameters. A spectrum of intensity of reflected light is therefore obtained experimentally for the 0th order of diffraction for different wavelengths.

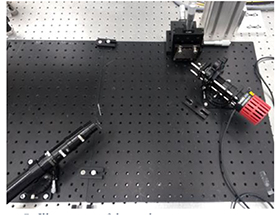

Figure 7. Illustration of the preliminary scatterometry setup.

Download figure:

Standard image High-resolution imageThis behavior of a predictable reflection/diffraction has been extensivally explained and study by the scientific literature [23–25] and is only adapted in the PROMETHEUS project with the expected geometrical dimension required by hydrophobic/hydrophylic textures.

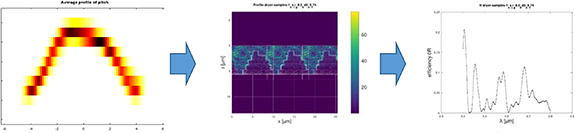

The measured reflected spectrum is directly compared with a commecial RCWA simulator. The geometrical parameters are injected directly into the simulator, along with the optical index of the material, the polarization and the angle of incidence. By changing the value for the wavelength in the simulator, the full spectrum of intensity of the reflected light for the 0th of diffraction is also obtained. Figure 8 illustrated this spectrum generation principal, where for a given experimental typical profile, we can obtain the spectrum reflected by the sample, by simulating the electromagnetic propagation of the 0th order with a RCWA simulator.

Figure 8. Illustration of the RCWA method. From the standard profile, a simulation is run to obtain the reflection spectrum of the 0th order of diffraction.

Download figure:

Standard image High-resolution imageIf the sample is correctly fabricated and present a good enough reproducibility, both spectrums from the measurement and from the simulator should match. This has been proven to work succesfully for at least one sample in such a way that we can successfully correlate the measured spectrum with the RCWA simulation as illustrated in figure 9.

Figure 9. Comparison between measurement and simulations.

Download figure:

Standard image High-resolution imageSuch a scatterometry technology offers the advantage of been easily scalable in term of speed. Implementing a scatterometry technique has been proven very efficient in other industries such as semi-conductor [26], nanoimprint [27], grating structure [28, 29] and hologram fabrication [30], and it has been proven to be a very effective and time efficient qualification method for line-like structures.

One difficulty that is already forseen with the proposed technic reside in the retrieval algorithm. In the literature, different technics are proposed to match the measured sample with the simulated sample. The most commonly used is the direct libery search [22]. This implies that a large number of samples are simulated, and an algorythm is developed in order to find a match within this library.

In the PROMETHEUS project, a sligthly different approach is anticipated, and a neural network will be trained to find and match the measured spectrum, and therefore validate the parameters defining the texture (height, pitch, gap, slope...). The idea is to simulate thousands of spectrum corresponding to structures within the observed standard variation of the geometrical parameters (for example, 5% height fluctuation), and to fed the neural network with those 'good' spectrum. The same is done with 'bad' sample. If the neural network is successful, it should be able to identify which structures are from a 'good' sample, and therefore be able to validate the fabrication process in-line with the scatterometry technics, eliminating the need for time-consuming measurement. Such methodology has already been proven to be working by different studies [31, 32].

2.3. Process qualification: diffractometry

Complementary to scatterometry characterization, diffractometry is being established as optical monitoring technique in a dedicated setup at IRIS in order to obtain the necessary information on surface geometry and thus assess structure quality.

Diffractometry is an optical technique, similar to scatterometry, that analyzes the diffraction pattern produced by a microstructured surface when light interacts with it [25]. The main requirements for the illumination in the case of a diffractometry measurement are the high directionality of the light and its monochromaticity (because scattering angles depends both on the size of the scatterers and the wavelength of incident light). Those two conditions are easily fulfilled by using a laser source.

In case of periodic structures, experimental parameters such as diffraction angle separation between the orders and orientation of the diffraction orders are measured in order to deduce sample features like the period and orientation of the lines. The depth of the lines may be determined by measuring the intensity of the diffracted spots, the degree of order/disorder by measuring the relative intensity of peaks compared to background etc This technique provides average information of all the lines illuminated. The optical analysis can be enhanced by optimizing the polarization state and direction of the light as well as its wavelength.

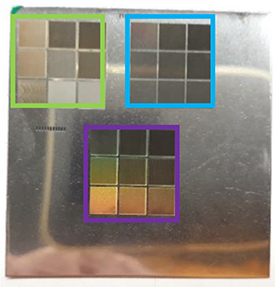

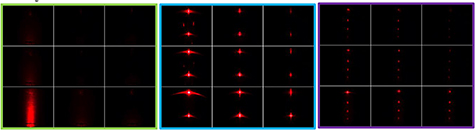

Preliminary measurements of the diffraction behavior from textures with line-like structures are shown in figure 11. The photograph (figure 10) displays the sample matrix with three panels (framed in green, blue and purple) of textures, all fabricated with varying process parameters. The corresponding diffractometry measurements for each texture in the respective panel were obtained by a prototype lab rig (excitation wavelength 638 nm, 30° incidence angle) and exhibit characteristic diffraction patterns. A clear dependence on the process parameters is observable. While most of the textures in the green panel do not reveal a clear diffraction pattern due to a potentially strong extinction of the incident visible light, the situation is different in the blue and purple panels. Here, the individual diffraction orders are more pronounced and related to the different texture dimensions. Structural information will be deduced in the future from the distances between the diffraction orders and also from their shapes. Especially in the blue panel, additional features are visible, indicating a deviation from perfectly straight and regular lines on the texture. Moreover, sample structures with more complex diffraction patterns will be analyzed in forthcoming studies in order to establish a correlation to the process parameters, supported by the aid of RCWA model simulations [33].

Figure 10. Photograph of the studied sample containing the matrix of textures.

Download figure:

Standard image High-resolution imageFigure 11. Diffraction patterns of a textured sample, obtained by the diffractometry prototype.

Download figure:

Standard image High-resolution image3. Risks and challenges

In order to successfully implement the scatterometry or diffractometry technique within the PROMETHEUS project, several aspects need to be considered and accounted for. Although they have already been successfully implemented in other industries where the reproducibility of the structures is very high its implementation within the PROMETHEUS project presents some challenges.

One risk is due to the 'low' reproducibility of the line-like pattern. Indeed, even with the best initial texturing strategies, a 5% to 10% error margin can be found on the geometrical parameters of the lines (width, height, slope...). This is widely bigger than the error found in the semi-conductor or in the nanoimprint industries. Those fluctuations will yield different spectrum, which still needs to be fully identified and quantify, for the validation algorithm to successfully recognize if the patterns have properly been engraved.

Another risk comes from the fact that some structures present a strong extinction for visible and infrared wavelengths. Therefore, a very large spectrum needs to be analysed in order to successfully identify the structures. Apart from being a challenge for integration due to a more complex setup, strategies have to be developed to prevent potential limitations in case diffraction orders are hardly detectable.

The final challenge to overcome is the scalability of the spectrum/angular measurement and matching with a database in order to deduce the geometrical parameters, or at least an OK/NOK. Indeed, if it is easy to compare a given simulated spectrum with a measured spectrum offline, this is not sufficient for in-line measurement during process. A full invert model needs to be built with a large spectrum database, capable of retro-finding the geometrical parameters from a measured spectrum. Not only this model needs to accurately predict the geometrical parameters, but it also needs to do it with enough speed that it does not slow down the process, a challenge which will be approched in the near future in order to facilitate the successful implementation of an in-line monitoring technique.

4. Conclusions

Within the PROMETHEUS project, we successfully created a first surface textured using the Direct Laser Interference Patterning (DLIP) technology, which resulted in hydrophobic and hydrophilic surfaces. The used DLIP setup will be further developed with the goal of implementing it on an industry compatible and scalable prototype.

Two inline characterization approaches are currently being developed to validate the DLIP texturization process, in particular scatterometry and diffractometry. Those techniques need to be able to determine the quality of the textures with high speed and high accuracy in order to be successfully implemented inline into the DLIP prototype machine.

Both complementary techniques are currently being studied, and measured spectrum are manually compared with optical model and RCWA simulation. The preliminary results are promising, and both techniques give useful information on the texture's characteristics and quality of the texturing process.

The next steps are to match the measured spectrum with the simulated spectrum, to built-up an invert model in order to retrofit the geometrical parameters from the measured spectrum.

Eventually, the PROMETHEUS project supported by the EU Horizon 2020 project aims to create a scalable prototype that can generate and validate hydrophobic/oleophobic and hydrophilic/oleophilic structures in a way that is relevant for the industry. Such prototype would lead to a large diffusion of new products within the consumer market.

Acknowledgments

This project has received funding from the European Union's Horizon 2020 research and innovation programme under grant agreement No 825503—PROMETHEUS and from the "Photonics Public Private Partnership" www.photonics21.org.