Abstract

In this review, we begin by discussing the need for harnessing renewable energy resources in the context of global energy demands. A summary of first- and second-generation solar cells, their efficiency and grid parity is provided, followed by the need to reduce material and installation costs, and achieve higher efficiencies beyond the Shockley–Queisser limit imposed on single junction cells. We also discuss the specific advantages offered by nanomaterials in enhanced energy harvesting, what design platforms comprise nanostructured photovoltaics, and list the prominent categories of nanomaterials used in the design of third generation solar cells. We review the significant nanostructured photovoltaic platforms that have encouraging power conversion efficiencies, have the potential for long term stability (both structural and functional) and have received attention in the field. In addition to their operational principle, we highlight both their advantages and shortcomings, along with insights into possible improvements. We include alternate routes to improving power conversion efficiency, not by tuning material properties to match the solar spectrum but using additives and/or structural modifications to allow more efficient harvesting of sunlight, either by reducing losses or by altering the spectral properties. The properties of nanomaterials that make them well-suited as active materials in photovoltaic devices (broadband absorption, high quantum yield, etc.) also make them ideal candidates for luminescent solar concentrators (LSCs). These devices also harvest solar energy, but instead of directly allowing charge generation, they act as downconverters for other photovoltaic cells. We review dye, thin film, and quantum dot based LSCs that have garnered a lot of attention in recent years as these devices face a resurgence given the advances in materials science and engineering which have led to novel quantum dots and hybrid semiconductors. The review ends with where the future of nanostructured photovoltaics is headed, what device designs and materials development are needed to achieve efficiencies beyond the Shockley–Queisser limits and fulfil the goal of the 3rd and 4th generation photovoltaics.

Export citation and abstract BibTeX RIS

1. Introduction

Global energy consumption has steadily risen since the 1960s, and the last two decades have seen an increase by roughly 53% [1]. A conservative estimate predicts an additional 35% increase in the next two decades, putting our power needs at an overwhelming ∼30 TW by 2050. While there is a strong possibility that fossil fuels will continue to be a mainstay, an optimistic perspective would be to assume that renewable sources will be tapped more substantively in the coming decades, both for resource conservation and climate preservation purposes. Among the various options available on that front, biomass, hydroelectricity, wind and geothermal resources together can account for almost 14 TWy, but solar energy incident at the Earth's surface is a phenomenal 105 TWy [2]. Needless to say, efficient harnessing of solar energy could not only more than satisfy global energy needs, but do so in a clean, carbon-neutral manner. These obvious advantages have spurred extensive research efforts worldwide, and the influence in the commercial sphere has been notable. The sale of photovoltaic (PV) modules has grown from 1 GW to 100 GW between 2004 and the present [3], reflective of market demand and manufacturing growth. Simultaneously, module prices have dropped by a factor of 5 [4], bringing solar energy closer to achieving grid parity. It is estimated that globally, almost 2% of electrical needs are currently provided by PVs [5], and nearly 90% of the PV market consists of crystalline silicon (Si) solar cells [6].

Si PV belongs to the 1st generation of solar cells and is still the most economically viable PV in use. It has some drawbacks, which have contributed to PVs not having more widespread applications. In the simplest terms, these boil down to the net cost of installing and using solar panels to generate electricity rather than conventional sources. This is measured in terms of grid parity, which currently stands at about 0.1$/kWh [7]. Si PVs are close, but the additional inconvenience of switching over to solar energy would be more attractive to the general populace if this price was closer to $0.03/kWh. There are two routes to achieving this: lowering the manufacturing and installation costs of solar panels or producing panels with higher power conversion efficiency (PCE), or both. And this is where the 1st generation Si panels are problematic. Module and installation prices are unlikely to reduce much more than the present value, and PCE has remained unchanged at a peak value of 25% for the last 15 years [8]. And this limitation is rooted in the inherent material properties. Si has an indirect band gap, which results in low absorptivity, which in turn requires the solar cells be thick to have adequate solar absorption. The cell thickness adds to material costs, to panel weight, and to low PCE as this extra path length gives the photogenerated carriers increasing opportunities to recombine, rather than be extracted as photocurrent. Some of these issues were addressed in the 2nd generation solar cells, which are direct band gap semiconductors and can be fabricated as thin films. Gallium arsenide (GaAs), cadmium telluride (CdTe) and copper indium germanium selenide (CIGS) are representative of this generation, and the most successful is GaAs, with a reported record PCE of 29% [9]. These are commercially even less viable though, given their very high price point. But, these can be fashioned into multijunction cells that are not restrained by the Shockley–Queisser limit and have demonstrated PCEs >40% [10]. The theoretical efficiency of a single junction solar cell is limited to ∼33% by the Shockley–Quiesser [11] formulation, and in practice, single junction cells have not achieved this full potential due to spectral limitations. The inherent inability of a semiconductor to absorb photons with energy lower than its band gap, added to the thermalization of photons with energy higher than it, are both unavoidable loss mechanisms and the only way to overcome them is to fabricate multijunction cells. These make them ideally suited for applications where expense is not a limiting factor, but poundage is, such as space exploration. Returning to terrestrial use, research in the newest generation (3rd) of emergent PVs is motivated by the desire to develop solar cells that allow lost cost synthesis while exhibiting high enough efficiency that would allow them to compete with conventional power generation infrastructure. And a large proportion of these emerging solar cells focus on nanostructured components, both organic and inorganic, which is what this review will emphasize. Before we delve into the wide range of nanostructured PV and their successes and limitations, we take a brief look into the broad context as to why nanostructured materials are considered to have such potential as photovoltaics.

'Small is different' is an oft-repeated but very apt phrase to succinctly describe the unique aspect of nanoscale materials. The reduced spatial dimensions lead to quantization of energy and momentum, and this phenomenon, known as quantum confinement [12], is at the origin of their unique optical, electronic, and magnetic properties that are so different from their bulk counterparts. Additionally, these properties are easily tunable by varying the size of the nanomaterials, or by surface modification [13]. In the specific context of photovoltaic devices, the large absorption coefficient of nanoscale materials is particularly advantageous. less material is needed to harness sunlight, which not only makes the device lightweight and less expensive from the raw materials perspective but allows easier extraction of photogenerated carriers by virtue of a shorter effective path length. And while these will key issues of reducing price while improving efficiency, there are additional advantages offered by nanostructured photovoltaic. The nanomaterials are typically chemically synthesized via low temperature, solution-based methods and therefore, suited for deposition on flexible substrates. The devices thus designed can be applied far more broadly than current rigid solar panels, especially for mobile deployment. This also allows the use of organic materials and others like these that have low mobility. Nanostructured surfaces have lower reflectivity, negating the need for AR coatings and subsequently, the added weight and expense. The definition of what constitutes a nanostructured photovoltaic is quite broad, comprising not only devices that use nanoscale semiconductors as the active material, but also those that incorporate nanoscale optoelectronic components to enhance absorption, induce reflective losses and increase light trapping. In our review, we have exhaustively covered both various, focusing on those platforms that have demonstrated encouraging power conversion efficiencies accompanied by the potential for long term structural and functional stability. While discussing the advantages of each type, we will touch upon the shortcomings, along with any insights into arresting the latter and improving the performance. We include a third category of devices as well, luminescent solar concentrators (LSCs), where the active material is not utilized to directly generate photocarriers. Instead, they act as down converters by absorbing solar radiation and re-emitting it in a spectral region more suited for solar cells attached at the edges. LSCs were initially marketed as a less expensive alternative to silicon solar panels, but with the change in pricing all around, this is no longer a valid motivation. However, LSCs do indeed have unique properties, as they can harvest diffuse radiation in addition to direct sunlight. This is a major advantage over solar cells that require tracking to optimize performance. Further, they are better suited for building-integrated photovoltaic installations than solar panels and will round off our review of nanostructured devices for solar energy harvesting.

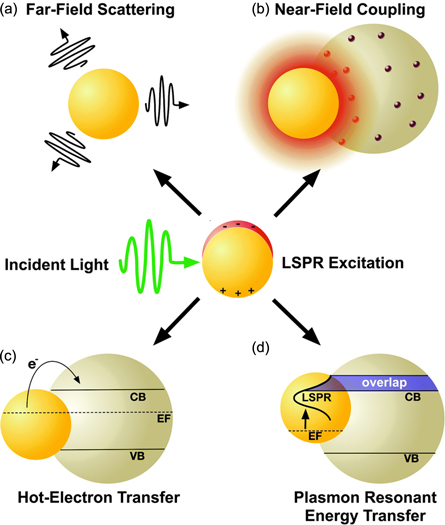

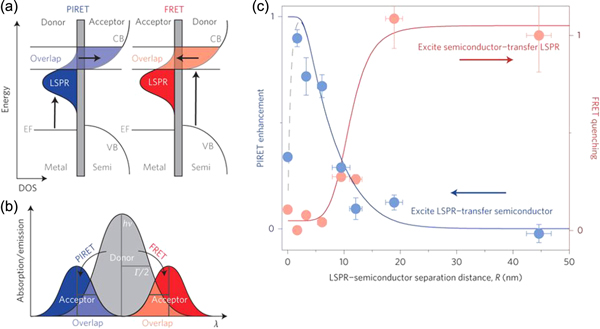

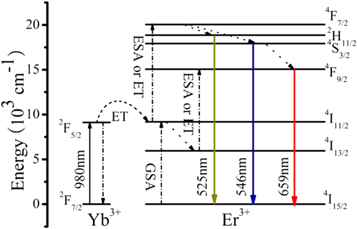

We segregate the nanostructured devices in to two broad categories for the purposes of this review. In the first section we will describe and discuss the significant nanostructured PV platforms where the nanomaterials are the active material. These will include dye-sensitized solar cells, quantum dot-sensitized solar cells, quantum dot solar cells, and solar cells that utilize nanowire arrays. In the next section we focus on an alternate route to improving PCE, not by tuning material properties to match the solar spectrum but using nanoscale additives and/or structural modifications to allow more efficient harvesting of sunlight, either by reducing losses or by altering the spectral properties. We will cover plasmonic inclusions that enhance scattering, and absorption, or offer resonant energy transfer and hot carrier injection into the semiconducting photovoltaic, as well as rare earth ions and compounds that act as up or down converters of the solar spectrum to match the absorption band of the active medium to improve performance. We finish off with a description of alternative nanostructured platforms, devices that also harvest solar energy, but instead of directly allowing charge generation, they act as down converters for other PV cells. We will review dye, thin film, and quantum dot based LSCs that have garnered a lot of attention in recent years as these devices face a resurgence given the advances in materials science and engineering which have led to novel QDs and hybrid semiconductors.

2. Nanostructured PV platforms

Nanostructured PVs offer the possibility of increased surface area due to their nanostructured components without increasing the physical size of the device, whereas tailoring of their individual components is significantly easier than conventional Si-based PV as different processes occurring under illumination are decoupled. In this section we highlight the nanostructured PV platforms that have significant and encouraging power conversion efficiencies, and the potential for long term stability. The various technologies that currently satisfy these criteria, and those we will describe and discuss here include dye-sensitized solar cells, quantum dot-sensitized solar cells (QDSSCs) , colloidal quantum dot solar cells, and nanowire-based solar cells. In addition to their operational principle, we will discuss both their advantages and shortcomings, along with insights into possible improvements.

2.1. Dye sensitized solar cells (DSSCs)

DSSCs were first introduced by O'Regan and Grätzel in 1991 [14]. Their work challenged the conventional solid-state photovoltaic cells, by introducing a device that incorporated nanomaterials and separated the processes of light absorption and charge carrier transport. This new device offered the possibility of low-cost photovoltaic devices, which would provide an alternative to power generation from conventional sources.

The first example of DSSC was prepared using a ruthenium complex as sensitizer, deposited on a TiO2 (titanium dioxide) film, and employed a liquid re-dox electrolyte of tetrapropylammonium iodine mixed with iodine. This device achieved a fill factor of 0.76, and in addition to a PCE of 7.9% [14], it also demonstrated an efficiency of 12% under diffuse sunlight, revealing unexpected benefits of these devices compared to conventional silicon based solar cells. Furthermore, under conditions of low light intensity (<5 W m−2), the fill factor remained above 0.7, which is not observed for conventional devices. This was an initial indication of the absence of recombination processes that normally limit device performance in semiconductor devices. The promise shown by this first DSSC encouraged further research into the processes occurring within the device and potential enhancements of the device design to achieve higher PCE .

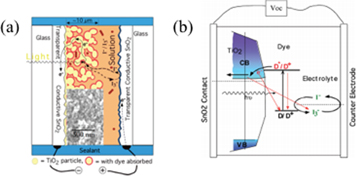

A typical DSSC is shown in figure 1. The device consists of a glass or plastic substrate, which is coated with a transparent conductive oxide (TCO)—common examples include indium tin oxide (ITO) or fluorine-doped tin oxide (FTO). The substrate is coated with a mesoporous oxide layer, which typically serves as the electron transport layer (ETL) that guides electrons to the anode, and TiO2 has been a particularly popular material for this purpose. Dye is deposited onto the ETL and is employed for light absorption followed by electron injection into the conduction band of the ETL. The dye is then regenerated via electron transfer from the redox electrolyte, typically an iodide/triiodide system. Finally, the triiodide formed is reduced to iodide by capture of electron from the cathode, which usually consists of platinum on TCO glass. These processes are shown in figure 1(b). Therefore, at the end of the process the device has returned to its original state [15]. While extensive research has been done on the materials incorporated in these devices, certain dyes have shown great promise. The most impressive PCE from a single sensitizer so far has been achieved by implementing porphyrin sensitizer (SM315) that has been engineered to improve its light harvesting properties, resulting in a PCE of 13.0% [16].

Figure 1. (a) Schematic of a DSSC, and (b) electron transfer processes in a DSSC. Reprinted with permission from [15]. Copyright (2009) American Chemical Society.

Download figure:

Standard image High-resolution image2.1.1. Charge separation, transport, and transfer at dye/ETL interface

Figure 1(b) also shows loss mechanisms that DSSCs are susceptible to. These include direct recombination of the electron and hole pairs in the dye, and recombination of the electrons in the ETL with the oxidized dye or the electrolyte [17, 18]. Hence, optimizing charge injection from the dye to the ETL is crucial for efficient device operation. The dye molecule is responsible for harvesting the incident light energy, resulting in a long-lived excited state, followed by electron injection into the conduction band of the ETL. Two different charge transfer pathways have been identified via femtosecond transient absorption spectroscopy: electron injection from non-relaxed higher-lying excited state, which has been associated with the singlet excited state of the dye, and injection from the fully relaxed excited state, which is associated to the triplet excited state of the dye [18, 19]. These processes compete with back electron transfer from the ETL to the dye, implying that for efficient power conversion, fast electron transfer and slow back electron transfer are needed.

The electron kinetics have been studied extensively in the Ru(dcbpy)2(NCS)2 (RuN3)–TiO2 system, as it is one of the most efficient dye/ETL combinations. Since the lowest excited state of RuN3 is 0.3 eV higher than the conduction band minimum of TiO2, electron injection can occur from the singlet and triplet states of RuN3 [19–22]. By comparing transient absorption signals of the dye deposited on TiO2 and the dye in solution, a shorter time constant was observed for the former case, indicating that a depopulation channel is available. Furthermore, by probing the triplet state absorption, it was concluded that excited state evolution from the singlet to the triplet state is also occurring, with a time constant of approximately 70 fs [19]. The fast component of electron injection from the singlet states has been estimated to occur on a time scale of <100 fs [19, 23–26]. On the other hand, the slow component of electron injection, associated with the transfer from the triplet states of the dye, has been associated with time constants ranging from 1.7 to 100 ps [19, 24–27]. These processes are depicted in figure 2.

Figure 2. Energy level diagram of the RuN3–TiO2 system. Processes: (A) electron injection from the singlet excited state, (B) intersystem crossing, (C) thermalization of triplet state, (D) electron injection from triplet state. Reprinted with permission from [19]. Copyright (2002) American Chemical Society.

Download figure:

Standard image High-resolution imageFigure 2 also shows the energy dependence of the states in the conduction band of TiO2, which has been associated with the variation of the electron injection rate, as it was observed to increase with higher density of states. This has been used to rationalize the presence of a slow component of electron transfer, as the triplet states are close to the energy of the conduction band minimum of TiO2, meaning that there is a reduced density of states available [19, 22, 28]. In addition, while the fast component of electron transfer could occur adiabatically, the slow component could be associated with non-adiabatic processes resulting from the formation of the triplet state [19]. The slow component could also be a consequence of the binding of the dye on the ETL and surface defects [19]. On the other hand, back electron transfer has been observed to happen non-exponentially and is associated with timescales of microseconds to milliseconds, and a negligible picosecond/nanosecond component, therefore reducing competition for the aforementioned electron transfer processes [18, 19]. This difference in timescales justifies the high efficiency of the RuN3–TiO2 system in DSSCs. The slow back electron transfer has been attributed to weak electronic coupling between the oxidized dye and the electron in the ETL, trapping of the electron in the ETL, as well as the inverted Marcus region that slows outer sphere electron transfer [19, 29].

Electron injection studies have been extended to other dyes as well. Work on the Ruthenium bipyridyl sensitizer dye N719 has demonstrated that unlike the RuN3 dye, in which electron injection from the singlet and triplet states is occurring in parallel, electron injection from the triplet state of the N719 dye is the more efficient injection pathway [30]. It was estimated that singlet injection occurs within 1–10 ps, triplet injection occurs within ∼100 ps, whereas intersystem crossing from the singlet to the triplet state occurs within ∼100 fs [19] and decay of the triplet state to ground state requires ∼10 ns. Therefore, Koops et al [30] concluded that electron injection from singlet states occurs only for systems with very favorable interfacial energetics, as is the case in the RuN3–TiO2 system, but for typical devices, due to the presence of the electrolyte which influences the potential, it is unlikely that singlet injection can compete with intersystem crossing. Consequently, electron injection will most likely originate from the triplet state, which results in a ten-fold retardation of injection. This work [30] also investigated the various factors that could influence the electron injection kinetics in a DSSC. While the application of electrical bias or the mere presence of the electrolyte in the device did not affect the injection kinetics, it was found that the composition of the electrolyte had a larger effect. The concentration of tert-butylpyridine (tBP) and lithium cations (Li+) significantly modified kinetics. Incorporation of tBP in the electrolyte is observed to shift the density of states of TiO2 to more negative potentials, whereas Li+ results in less negative potentials. The former changes the conduction band of TiO2 by coordination to the TiO2 surface, or by diminishing the cation concentration on the surface [30–32]. On the other hand, Li+ adsorb or intercalate into the TiO2 layer, eventually modifying the charge and energy levels [28, 30, 33]. However, it was demonstrated that despite the retardation of injection kinetics because of these electrolyte additives, resulting in reduction of the device photocurrent, their presence increases the Fermi level of TiO2 and, consequently, enhances the open circuit voltage of the device, therefore resulting in higher device efficiency. This further establishes the fact that it is not necessary to have the faster injection kinetics for best device performance, but rather a good compromise between driving force that allows competition with dye relaxation and raising the conduction band of TiO2 to reduce recombination losses [30]. Hence, the only requirement is that electron injection from the dye to the ETL happens faster than decay of the excited state.

Although Ruthenium bipyridyl dyes were originally believed to be the best choice for DSSCs, record devices have been prepared with porphyrin sensitizers [16, 34]. Therefore, it is imperative that we discuss the electron injection kinetics of these sensitizers and how they compare with Ruthenium bipyridyl dyes. Ruthenium bipyridyl dyes are characterized by long-lived excited state, good visible absorption, and good photochemical stability [21], as well as a high degree of charge transfer character and mixed singlet/triplet states as discussed previously. On the other hand, other common dyes, including porphyrins, do not show as much mixing of singlet/triplet states and charge transfer, but they also demonstrate long-lived singlet excited states [26, 35–37]. The photophysical characteristics of the two types of dyes are different when in solution; RuN3 exhibits very low emission yield and large red shift of emission, associated with the relaxation of the singlet state to the triplet states, whereas porphyrin dyes (zinc and free base tetracarboxyphenyl porphyrins: ZnTCPP and H2TCPP respectively) show a series of narrow visible absorption bands and small red shift with high emission intensity, characterized by relatively long excited state lifetime [26]. After deposition of all dyes on TiO2, almost indistinguishable, multi-exponential injection kinetics are observed for all, with essentially the same lifetimes and relative amplitudes. This result demonstrates that while for porphyrin dyes electron injection occurs from the singlet state, and for ruthenium bipyridyl dyes charge transfer and relaxation to the triplet state is involved, it does not dominate electron injection kinetics. Furthermore, the recombination kinetics for RuN3 and ZnTCPP are also indistinguishable, whereas H2TCPP demonstrates recombination kinetics that are eight times slower. This result further supports the model that recombination in dyes is mostly controlled by the electron transfer between trap sites in the mesoporous ETL, rather than the electronic structure of the dye [26]. Once the electron is injected into the ETL mesoporous layer, it is transported to the contact, so it can be extracted from the device. Materials such as ZnO and SnO2 have been used in DSSCs, but nanocrystalline porous TiO2 appears to be the best option so far, due to good energy level matching with dyes [38, 39]. The efficient electron transport through the nanocrystalline TiO2 layer is believed to occur by electron hopping from one particle to another [18, 20]. Mesoporous layers are unlike the bulk material as they are characterized by low conductivity, the particles making up the layer are too small to support an electrical field, whereas the mesoporous layer allows for formation of interpenetrating networks that result in a large contact area with the other components of the device [18].

The transport of electrons through the ETL is a complex procedure that has been investigated by multiple research groups. Since the electrons are transported through a trapping and de-trapping mechanism, the traps play a crucial role for both electron transfer and recombination in TiO2 [23, 40, 41]. Traps become important at low illumination intensity, resulting in slow transport and a small diffusion coefficient. At higher light intensity, deep traps are filled, meaning that electron transport is faster and the diffusion coefficient is larger [18, 42]. An additional mechanism regarding the charge transport of TiO2 films has been suggested, indicating that self-doping is occurring under illumination, which results in enhanced conductivity of the originally poorly conductive material [38]. Under illumination, a transient charging process is happening, and when carrier concentration of 1019 cm−3 is reached, the region of the film that is not illuminated undergoes the Mott (insulator-metal) transition, resulting in a significant increase in electrical conductivity [38, 43]. Modification of the TiO2 layer has been attempted by various groups to improve its characteristics, including doping of TiO2 with Zn, Al, Zr, Nb [39, 44, 45], or preparation of 1D nanostructures to enhance electron transport [46].

2.1.2. Liquid electrolytes

For efficient DSSCs, electrolytes must be chosen such that they can transport the charge carriers between anode and cathode successfully, considering the redox potential, regeneration of the dye and the electrolyte. Furthermore, it must ensure good contact with the mesoporous ETL, have minimal leakage and evaporation, as well as long-term stability. In addition, it should not result in dye degradation or desorption, and should not absorb a significant portion of visible light [47–50]. In a DSSC, the electrolyte is acting as a hole-transport medium, and is responsible for regenerating the oxidized dye, with the cycle completed after conversion of the triiodide to iodide at the counter electrode. Therefore, the counter electrode must be chosen to ensure low overpotential and rapid reaction [17, 47, 51]. Platinum (Pt) has been a good candidate for a counter electrode. In liquid electrolytes, ion diffusion occurs via ion hopping or liquid-like diffusion of ionic sub-lattice [47, 52]. However, when there is a high concentration of iodide, polyiodides are formed, resulting in an electron exchange mechanism to be responsible for carrier transportation [47, 53, 54]. In this case, electrons are transported via chemical bond exchanges [53, 55]. Overall, the diffusion process is controlled by the size of the redox species, the solvent viscosity, the redox medium concentration, and the separation between electrodes [47, 56].

In the first example of DSSC, a liquid electrolyte prepared with the iodide/triiodide couple in an organic solvent was used [14]. Liquid electrolytes offer several attractive characteristics: they can be prepared easily, they are highly conductive, they have low viscosity, and can achieve good interfacial contact with the counter electrode [47, 48, 56]. They remain the most common choice for hole transport, and were used in the most efficient DSSCs so far [16, 57]. The liquid electrolyte usually comprises of the solvent, the ionic conductor, and the additives. Good solvents must have melting points below −20 °C, and boiling points above 100 °C to prevent evaporation during cell operation, they must be chemically stable within the operating potential window of the device, have low viscosity to ensure that the redox species has high diffusion coefficient and high conductivity, it should not absorb incident light, it should not react with the sensitizer dye, not dissolve the sealant material, be non-toxic and cheap [47]. While polar organic solvents and ionic liquids are good candidates, a single solvent cannot satisfy all the conditions, therefore solvents are usually mixed. Water was initially used as a solvent in DSSCs, but the oxidation of iodide to iodate, which is not reduced by the counter electrode, prevented long-term operation of the device, whereas many dyes are sensitive to water [17, 47, 56, 58]. Acetonitrile is another good electrolyte as it has low viscosity, good chemical stability and solubility, and was used in the DSSC that achieved record efficiency of 13% [16, 47]. Nevertheless, it suffers from low boiling point and high toxicity, meaning it cannot be implemented in industrial devices. Methoxyacetonitrile and 3-methoxypropionitrile have been used in DSSCs, with the latter demonstrating particularly good stability, retaining 98% of the efficiency after 1000 h of accelerated heat tests under thermal stress [17, 47, 59]. Other common solvents include ethylene carbonate, propylene carbonate, γ-butyrolactone, and N-methyloxazolidinone, which are characterized by high boiling and melting points [47]. A DSSC prepared with γ-butyrolactone solvent has been shown to operate outdoors for almost 2.5 years [60]. It should be noted that basic solvents affect the TiO2 surface, raising its flatband potential, and subsequently not only reducing the driving force for electron injection from the dye to the TiO2, but additionally preventing electron recombination between the TiO2 and the redox species [15, 47, 61]. This results in lower device photocurrent, but higher open circuit voltage.

Ionic liquids have also been incorporated in the electrolytes in DSSCs, as they possess good chemical and thermal stability and high ionic conductivity, while their viscosity can be tailored and they do not evaporate or leak as much [47]. Methyl-hexyl-imidazolium iodide was used in a device that demonstrated impressive stability in 1996 [53]. Later, an electrolyte made with SeCN−/ and without any solvent was implemented, achieving high efficiency at the time (7.5%–8.3%) [62]. The good performance was attributed to the low viscosity, high conductivity, and low light absorption of the ionic liquid, but the stability of the device was not good. Though imidazolium-based ionic liquids are common, other materials that have been used in electrolytes include ionic liquids with sulfonium, guanidinium, ammonium, pyridinium, and phosphonium, but none of these has shown good efficiencies [63–68]. However, implementation of a tetrahydrothiophenium melt demonstrated that ionic liquids can also be used for high efficiency devices [69]. Pure ionic liquids are characterized by high viscosity and low ion mobility, which results in lower diffusion coefficient of the triiodide, in comparison to organic solvents [70]. Hence, in order to improve their performance, ionic liquids are often mixed with organic solvents, which produced devices of high efficiency [71]. Ionic liquids have also been mixed with solid components to improve their conductivity [72]. Mixing with multi-walled carbon nanotubes resulted in significant improvement of device efficiency [73].

and without any solvent was implemented, achieving high efficiency at the time (7.5%–8.3%) [62]. The good performance was attributed to the low viscosity, high conductivity, and low light absorption of the ionic liquid, but the stability of the device was not good. Though imidazolium-based ionic liquids are common, other materials that have been used in electrolytes include ionic liquids with sulfonium, guanidinium, ammonium, pyridinium, and phosphonium, but none of these has shown good efficiencies [63–68]. However, implementation of a tetrahydrothiophenium melt demonstrated that ionic liquids can also be used for high efficiency devices [69]. Pure ionic liquids are characterized by high viscosity and low ion mobility, which results in lower diffusion coefficient of the triiodide, in comparison to organic solvents [70]. Hence, in order to improve their performance, ionic liquids are often mixed with organic solvents, which produced devices of high efficiency [71]. Ionic liquids have also been mixed with solid components to improve their conductivity [72]. Mixing with multi-walled carbon nanotubes resulted in significant improvement of device efficiency [73].

The iodide/triiodide redox couple has traditionally been used in DSSCs for dye regeneration, as it has a redox potential that matches that of the dye, thereby ensuring rapid dye regeneration and slow recombination. Furthermore, this redox couple is soluble, conductive, does not absorb as much visible light, has good stability, and can form good interfaces with the mesoporous ETL [47]. One of the issues of DSSC operation is the recombination of charge carriers at the interface between the ETL and the electrolyte, which can be suppressed by incorporation of a metal oxide blocking layer [74]. It can also be suppressed by introducing additives such as 4-tert-butylpyridine and guanidium thiocynate in the electrolyte [21, 47, 75–77]. Similarly, dyes that have hydrophobic chains also appear to prevent recombination by blocking the contact of the two materials [78], whereas other dyes have the reverse effect of increasing the amount of triiodide near the dye [79, 80]. In order to increase the rate at which the dye is regenerated, the concentration of iodide must be tailored depending on whether organic solvent or ionic liquid is used; higher concentration is needed for the latter due to its lower viscosity [81]. Even though the iodide/triiodide redox species has been used for a large number of DSSCs, it suffers from issues of encapsulation due to the high vapor pressure of iodide and corrosion of the sealant by the iodide, while the polyiodides absorb part of the incident light, limiting the photocurrent [47]. In addition, the mismatch between the redox potential of the dye and that of the redox species causes a reduction of the possible open circuit voltage that can be achieved [47, 82]. As a result, alternative complexes were pursued. These include bromide/tribromide [51], interhalogen redox systems [83], disulfide/thiolate [84], and most notably, cobalt complexes [16, 34, 57]. Cobalt complexes have been used in both devices that currently hold the efficiency record [16, 57] and are considered to be the most efficient redox species for DSSCs, with further improvements expected after tuning the redox potentials of the redox couple [47]. Other metal complexes that have been studied include Ni(III)/Ni(IV), Cu(I)/Cu(II), and ferrocene/ferrocenium [85–89].

Electrical additives are often included in the electrolyte to optimize device performance. As mentioned in sections 2.1.1, 4-tert-butylpyridine (tBP) is a common additive, which improves the open circuit voltage, by shifting the conduction band edge of TiO2 to more negative values [47]. Additives with similar effects include various nitrogen-containing compounds, such as pyridine, alkylaminopyridine, alkylpyridine, benzimidazole, pyrzaole, quinolone, among others [47]. Another type of additive, also mentioned in the previous section, are lithium ions (Li+) or guanidinium ions, which adsorb to the surface of TiO2 and assist in electron injection from the dye and reduce electron recombination by attaching to the surface of the TiO2 layer, thereby improving the device photocurrent. Both types of additives are often combined in devices in order to acquire benefits from each one: raising the conduction band of TiO2 and minimizing recombination losses [90–92].

2.1.3. Solid-state hole transport materials (HTMs)

Liquid electrolytes suffer from instability and leakage issues under exposure to air and prolonged storage. Therefore, research focus shifted to developing solid-state HTMs to avoid such problems. The redox electrolytes discussed in section 2.1.2 can transport charge carriers via ion movement and can be essentially considered a hole-transport layer. Thus, they could be replaced by p-type semiconductors, which are also capable of hole-transport via hole hopping through neighboring molecules [47]. A good HTM must have its valence band maximum above the ground state energy level of the dye to allow for efficient hole transfer and should be characterized by good hole mobility [93–95]. Furthermore, it should not absorb visible light, or cause dye degradation. [96, 97] In addition, as sufficient pore filling of the mesoporous ETL is crucial, the HTM should allow for deposition in an amorphous state to ensure good contact between the various layers of the DSSC [98, 99]. Some of the first types of inorganic solid-state HTMs included copper compounds (CuI, CuBr, CuSCN) [100–103]. These materials allow for solution or vacuum deposition, and are characterized by good hole conductivity [97]. CuI was incorporated in a DSSC for the first time in 1995, with low efficiency, which was attributed to the rapid crystallization of CuI that prevented sufficient filling of the mesoporous ETL and hence, caused insufficient electrical contact [95, 100]. After addition of 1-methyl-3-ethylimidazolium thiocyanate (MEISCN), which acts as a growth inhibitor for CuI, improved pore filling was achieved, leading to increased device efficiency of 3.8% [104]. Nevertheless, devices based on CuI HTM decay rapidly, because of the formation of Cu2O and CuO caused by the iodine molecules on the surface of CuI acting as hole trapping sites [47, 105–107]. Introduction of a MgO blocking layer increased device efficiency by preventing hole transfer from TiO2 to CuI [108]. The low efficiency of these devices could also be attributed to the insufficient contact between the dye and the HTM. However, it was observed that dyes with thiocyanate ligands can be strongly bound to CuI films, improving contact and therefore, device efficiency [109]. Further modification of the Cul HTM and the counter electrode with guanidine thiocyanate enhanced device performance, reaching device efficiency of 7.4% [110, 111].

CuSCN was investigated as an alternative to CuI, as it could offer higher stability [47, 101]. However, CuSCN suffers from low hole conductivity which necessitates material engineering to improve its electrical characteristics. Doping with (SCN)2 led to the formation of acceptor levels below the CuSCN band gap, whereas inclusion of Cu(II) sites in CuSCN increased its hole conductivity, with both modifications resulting in improved device performance [112, 113]. Another promising solid-state HTM is cesium tiniodide (CsSnI3), which demonstrates high hole conductivity and hole mobility, and a band gap of 1.3 eV [47]. Since CsSnI3 can be prepared by solution processing, it allows for good pore filling of the mesoporous ETL, whereas its low band gap improves light absorption at longer wavelengths. Its incorporation in a DSSC resulted in device efficiency of 3.72% and doping of CsSnI3 with SnF2 raised the efficiency to 6.81% [47]. Through additional device engineering, CsSnI3-based DSSCs reached efficiency of 10.2% [114]. Further modifications include use of Cs2SnI6 instead of CsSnI3, which is stable in air and moisture, allowing for device fabrication in air [115].

Organic HTMs offer certain benefits over inorganic materials, such as abundancy, low cost, and facile preparation [47, 116]. and can be broadly classified into polymeric and molecular HTMs [116]. Polymeric HTM polypyrrole was first implemented in a DSSC in 1997, but it performed poorly due to absorption of visible light [117–119]. Polyaniline was also introduced as a potential HTM, but only reached device efficiency of 1.15% [120, 121]. Poly(3-hexylthiophene) (P3HT) and poly(3-octylthiophene) (P3OT) have dominated the polymeric HTM research landscape since then. While initial device efficiencies were low due to insufficient pore filling of the mesoporous TiO2, device engineering boosted efficiency to 1.3% and demonstrated good stability after 3-month storage in air [122–125]. Device efficiencies were further enhanced by addition of bis(trifluoromethanesulfonyl)imide (LiTFSI) and tBP to P3HT reaching 2.7% [126, 127], as well as successful infiltration of P3HT into TiO2 nanotubes [128]. Combination of P3HT with [6,6]-phenyl-C61-butyric acid methyl ester (PCBM) further increased device efficiency to 4.11% [129]. One of the most promising polymeric HTMs is poly(3,4-ethylenedioxythiophene) (PEDOT), which is characterized by minimal absorption in the visible part of the spectrum, good hole conductivity, and good stability at room temperature [47]. DSSCs incorporating PEDOT have reached efficiency of 6.8% [130]. Among molecular HTMs, 2,2',7,7'-tetrakis(N,N-di-p-methoxyphenylamine)-9,9'-spirobifluorene (spiro-OMeTAD) is one that has shown remarkable results [47]. It initially resulted in device efficiency of 0.74% due to charge recombination at the spiro-OMeTAD/ETL interface [93], but through doping of the material with FK102 cobalt(III) complex that increased its hole mobility, and combination with Y123 sensitizer, device efficiency of 7.2% was achieved [131]. Even though solid state HTMs show better long-term stability, they still lag in device efficiency in comparison to their liquid-based counterparts, due to electrical contact issues with the rest of the device layers [47].

2.1.4. Progress on the main limitations of DSSCs

While significant improvements have been made in the materials incorporated in DSSCs, there are still issues to be resolved before the efficiency can be enhanced further. Extensive work has been done on understand and addressing each of these.

2.1.4.1. Absorption in the near-infrared spectral region

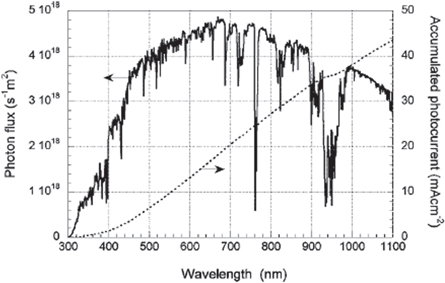

The first record efficiencies in DSSC research were achieved by implementation of the ruthenium N3, N719, and black N749 dyes. These dyes performed well as sensitizers in the visible part of the spectrum, but failed to absorb well in the near-infrared part of the spectrum, which, as shown in figure 3, is a significant portion of the solar spectrum [17, 132]. Therefore, it is imperative to develop dyes with improved response in the region of the spectrum beyond 900 nm to achieve high power conversion efficiencies. To meet this requirement, various types of sensitizers for DSSCs have been developed. Metal complexes, including ruthenium, have been popular due to their broad absorption spectrum. These sensitizers consist of a metal ion and ancillary ligands with an anchoring group, with the absorption in the visible part of the spectrum associated with a metal to ligand charge transfer [17]. The ligands are tuned to modify the properties of the sensitizer to achieve higher device performance.

Figure 3. AM 1.5 G spectrum at 1000 W m−2 and accumulated photocurrent. Reprinted with permission from [17]. Copyright (2010) American Chemical Society.

Download figure:

Standard image High-resolution imageRuthenium N3 dye has been commonly used due to its broad absorption in the visible part of the spectrum, leading to efficiencies of 10% [15]. By modifying the ligands to extend the absorption spectrum to the near-infrared region, the N749 'black dye' was designed, which successfully extended IPCE to 920 nm, and resulted in PCE of 10.4% [133, 134]. Other efforts include preparation of a ruthenium dye with a tetradentate ligand, which extended the absorption spectrum to 900 nm, resulting in efficiency of 5.9% [135]. Due to a modification of the HOMO and LUMO levels of the dye, improved spectral response was achieved, resulting in device efficiency of 8.7% [136]. Introduction of thiophene ligands was observed to alter the energy levels of the dye, red-shifting the absorption spectrum [17]. Therefore, this lead to a 10 nm red shift of the absorption, and a device efficiency of 9.5%, when the modified N719 was implemented [137]. Other metal complexes were also investigated in the efforts to achieve improved near-infrared absorption. By replacing the ruthenium ion with osmium, the IPCE spectrum was extended to 1100 nm, while maintaining good device performance [138].

Porphyrins are also of significant interest in the effort to achieve good absorption in the near-infrared part of the spectrum. They demonstrate strong absorption in the Soret band (400–450 nm) and the Q-band (500–700 nm) [139], indicating that they can operate as panchromatic sensitizers, with efforts made to enhance the Q-band. Porphyrin dyes with a donor-π-acceptor structure, with porphyrin as the donor, and cyanoacrylic acid as the acceptor, can be tuned through various thiophene derivatives which act as the π bridge and can be used to enhance the absorption of the dye [17, 140]. Such a dye was used to achieve record device efficiency of 13% with a single sensitizer, as addition of the proquinoidal benzothiadiazole resulted in broadening of the Soret and Q-band absorption, reaching 800 nm [16]. Phthalocyanines are another type of dye that demonstrate high absorption around 700 nm, and are thus candidates for good absorption in the near-infrared part of the spectrum [17]. Nevertheless, these dyes suffer from poor solubility and aggregation on the ETL surface, necessitating the use of a co-adsorber [17]. A Zn-phthalocyanine dye has demonstrated maximal IPCE in the near-infrared region, but the device efficiency was only 0.57% [141].

Extensive work has also been done on this front on organic dyes, as they also possess a donor-π-acceptor structure, which makes tuning of their absorption spectra easy [17]. Vinylene units were introduced into coumarin sensitizers to extend their absorption spectrum, producing dyes characterized by broad red-shifted absorption, due to a shift of the HOMO level to higher energy, and resulting in device efficiency of 6% [17, 142]. Device performance based on coumarin dyes was enhanced by introduction of thiophene units, as vinylene units proved problematic for dye aggregation, achieving efficiency of up to 8.1% [17, 143]. Furthermore, addition of more cyanate groups to the π bridge of the dye resulted in additional extension of the absorption spectrum [144]. Indoline dyes showed a broader absorption spectrum after incorporation of a rhodamine framework, reaching efficiency of 9.5% after optimization of the dye structure and accompanying ETL [145–147]. One of the highest near-infrared IPCE values for organic dyes of donor-π-acceptor structure was achieved using a tetrahydroquinoline dye, through modification to separate the anchoring and acceptor group, resulting in device efficiency of 3.7% [148]. The broadest IPCE spectrum of organic dye-based DSSCs reached 920 nm and was achieved by incorporation of a phenoxazine dye with a thienyl π bridge and a corhodanine acceptor [149]. Other organic dyes that have been engineered for red-shifted absorption include N,N-dialkylaniline dyes which reached 6.8% efficiency [150, 151], squaraine dyes which show good absorption in the near-infrared region [17, 152], and boradiazaindacene dye, which has a near-infrared absorption spectrum (600–800 nm) and produced a device of 1.7% efficiency [153].

Despite the extensive work that has been done on this aspect of DSSCs, an optimum sensitizer that can cover the entire solar spectrum has not been fabricated yet, although mixing of different sensitizers has been implemented in devices with impressive results [18, 57]. It has been estimated that by extending the absorption spectrum to 920 nm, PCE of 19% can be achieved [154].

2.1.4.2. Leakage in DSSCs

While the most efficient devices yet have been fabricated with liquid electrolytes [16, 57], the use of liquid electrolytes faces issues associated with leakage of the solvent and subsequent instability of the photovoltaic performance of the device, inhibiting commercialization of DSSCs [47]. This encouraged research into alternative materials for hole transport and dye regeneration, which resulted in solid-state DSSCs, but despite demonstrating good stability, they suffer from reduced efficiency due to low conductivity and poor pore filling, and therefore poor electrical contact, of the mesoporous ETL [47]. Work was also done to develop quasi-solid electrolytes, such as polymers [155, 156], and gels [157], but, like solid-state HTMs, they are also plagued by reduced transfer rates of the redox species because of the increased material viscosity and poor contact with the electrodes, meaning that device efficiency of devices incorporating quasi-solid electrolytes remains below (8%–9%) that of DSSCs prepared with liquid electrolytes [47, 158]. This issue has not been resolved yet, but advances are constantly being made towards achieving more stable DSSCs.

2.1.4.3. Photo-bleaching in DSSCs

DSSC stability is not only due to leakage and evaporation of the liquid electrolyte, but also limited by degradation of the electrolyte under long-term irradiation by sunlight, and in particular, ultraviolet (UV) light [51]. The ETL, commonly TiO2, absorbs UV light to form excitons, and the photogenerated holes might react with any other component that is not the iodide, leading to a depletion of triiodide in the device, which hinders the proper operation of the device [159–161]. The lack of redox couples in the device has further implications on the dye stability. As the dye is not reduced, it could react with other elements in the device, producing new species are cannot be used for generation of charges [159]. This has been observed to lead to a significant drop in short-circuit current. Nevertheless, this effect is initially negligible in a full device until the concentration of redox species is significantly quenched, and only a reduction of open-circuit voltage is observed that is associated with reduction of redox species in the electrolyte [159]. Efforts to improve the stability of the electrolyte under UV irradiation include incorporation of UV filters [51, 162], as well as electrolyte additives which can enhance its stability, such as MgI2 and CaI2 [162]. MgI2 appears to perform best for this purpose, and the mechanism behind the improvement is still unclear, although it could be the formation of a MgO surface layer which prevents the reactions between the ETL and the electrolyte, or the reduction of the holes in the ETL by the iodide [162]. Nevertheless, this is another key issue that needs to be addressed before DSSCs can reach the stability level suitable for commercial devices.

2.2. Quantum dot-sensitized solar cells

QDSSCs operate much like DSSCs. In these devices, the sensitizer layer now consists of quantum dots (QDs) instead of a dye, on a mesoporous semiconductor which serves as the ETL, such as TiO2 or ZnO [163, 164]. The solar cell is completed by the electrolyte or HTM, and the counter electrode. As outlined in figure 4, when sunlight is incident on the QDSSC, the QDs will absorb light to generate electron–hole pairs. The electrons are then transferred from the conduction band of the QD to the conduction band of the ETL, and the holes are transferred to the electrolyte/HTM, which is typically made of polysulfides. The oxidized electrolyte is then reduced to its original state by electrons re-entering the cell from the external circuit [163, 165]. The open-circuit voltage is determined by the difference between the fermi level of the QD/ETL system and the redox potential of the electrolyte, whereas the produced current is controlled by the sensitizing ability of the QDs and the efficiency of electron separation and extraction [163, 166]. QDSSCs have become an attractive alternative to DSSCs due to ease of fabrication, tunable spectral properties allowing for tandem architectures, improved stability over DSSCs as they can form better junctions with solid state HTMs, and the potential of multiple exciton generation by impact ionization that could increase the theoretical limit in efficiency to 44% [163–165, 167–169]. The current best efficiency recorded for QDSSCs is 11.61% [170], and while significant enhancements have been achieved in the past few years, the record efficiency is still below the record efficiency of DSSCs [165].

Figure 4. (a) QDs on TiO2 nanoparticles, (b) operating principle of a QDSSC [165]. Common QD sensitizers include CdS, CdSe, CdTe, PbS. Reprinted with permission from [165]. Copyright (2009) American Chemical Society.

Download figure:

Standard image High-resolution image2.2.1. Size tunable properties

Implementation of QDs offers a variety of benefits over dyes as sensitizers in a solar cell. Perhaps their biggest benefit is the ability to tune their spectral properties easily by varying the diameter of the QD, due to quantization effects present. By modifying the energy levels of the QDs, light absorption and electron injection can be tailored to match the needs of the solar cell [171, 172], whereas generation of multiple excitons by a single photon and hot electrons offer new possibilities for enhancement of device performance [171, 173].

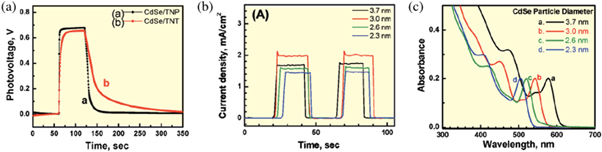

Good QDSSC operation requires that the conduction band of the QD sensitizer be higher than the conduction band of the ETL for efficient electron transfer between the two, as the offset provides the driving force for charge transfer [163, 171]. While the open circuit voltage of the device is independent of the size of the QDs used in the sensitizer, as demonstrated in figure 5(a), the device photocurrent is directly correlated to the properties of the QDs [171]. It has been observed that smaller QDs result in higher photocurrent due to the higher conduction band as shown in figure 5(b), implying that a larger driving force will be available for electron injection to the ETL [171, 174]. However, decreasing QD size is also associated with more limited response in the visible part of the spectrum as shown in figure 5(c) [171].

Figure 5. (a) Open-circuit voltage for TiO2 nanoparticles/3 nm CdSe QDs and TiO2 nanotubes/3 nm CdSe QDs, (b) photocurrent of TiO2 nanoparticles/CdSe QDs of various sizes, (c) absorption spectra of CdSe QDs of various sizes. Reprinted with permission from [171]. Copyright (2008) American Chemical Society.

Download figure:

Standard image High-resolution imageThe emission decay of CdSe/TiO2 electrodes was used to estimate electron transfer constants through measurement of the recombination rate constants [170, 171]. Exponential decay models were implemented to extract emission lifetimes, and it was observed that for smaller nanoparticles, shorter electron transfer constants are obtained [171]. Furthermore, there was no apparent difference between the QDs on TiO2 nanoparticles and TiO2 nanotubes, indicating that the morphology of the ETL does not influence the charge injection process. This further supports the evidence that photocurrent is dominated by QD properties. IPCE was also seen to improve with smaller QDs, establishing that since they possess a more energetic excited state, their electron injection rate is higher. The morphology of the ETL becomes important where open-circuit voltage is concerned. As seen in figure 5(a), the photo-voltage of the solar cell decays more slowly after illumination stops for the TiO2 nanotube substrate, which is direct indication that the electrons injected in the TiO2 have a longer lifetime before recombination, hence the tubular structure can be used to minimize losses at grain boundaries [163, 171]. Therefore, both smaller and larger QDs offer different benefits for the solar cell and its operation. Thus, a tandem structure ('rainbow' configuration) has been proposed for QDSSCs, which would leverage benefits from both small and large QDs [163, 171]. A gradient assembly of QDs of various sizes could be used, in which small QDs would absorb light of higher energy, allowing longer wavelengths to be transmitted and eventually be absorbed by larger QDs below them. This would utilize the fast electron injection of small QDs and high absorption of large QDs at the same time [171].

This concept has also encouraged research into alloyed QDs which would combine the beneficial properties of various materials to fabricate QDs that are most suitable for QDSSCs [163, 175]. This has led to the preparation of the champion device with 11.61% certified efficiency, which used 4 nm Zn-Cu-In-Se QDs as sensitizers and combined absorption onset of 1000 nm and fast electron injection rate of 9.1 × 1010 s−1 [170].

2.2.2. Stability improvement

Another major benefit of QD sensitizers is the potentially higher stability of QDs in oxygen and water, in comparison to molecular dyes [176]. While originally the iodide/triiodide couple was implemented in QDSSCs as well, it was observed to be detrimental to QDs which were unstable in this electrolyte [163, 165]. Instead, the sulfide/polysulfide system was implemented as redox couple, with good results [177]. Nevertheless, this has shown issues with low open-circuit voltage due to the high redox potential of the polysulfide electrode, and various techniques to address this issue have been used, including adjusting the concentration of the redox couple, changing the solvent composition, and incorporating additives [178–181]. However, the inability of the polysulfide electrolyte to scavenge holes from QDs efficiently has been a source of device instability, as the QDs oxidize and subsequently degrade [175]. This has encouraged research into alternative electrode materials, which resulted in improved device fill factor and enhanced stability [165, 175, 182]. Such materials include Cu2S or Au, instead of the typical Pt. Furthermore, QDs with enhanced stability have been engineered to address this issue. Alloyed QDs are observed to demonstrate increased stability in the polysulfide environment in comparison to QDs prepared with the constituent materials [175, 183].

Like DSSCs, QDSSCs also face instability issues due to leakage of the liquid electrolyte [170]. Research efforts to implement quasi-solid and solid-state electrolytes in QDSSCs, such as ionic liquids, gels, hydrogels, spiro-OMeTAD, and P3HT have met with great success [184–188]. QDSSC with a gel electrolyte combined with CdSexTe1−x QDs has demonstrated power efficiency of 9.21% [189], whereas a device with CuS QDs and P3HT has produced PCE of 8.07% [190]. QD-sensitized ETLs appear to form better junctions with solid-state electrolytes as compared to dye-sensitized ETLs, as the thinner layer of sensitizer alleviates the issue of insufficient penetration of the solid-state electrolyte into the sensitizer/ETL structure that is commonly seen in DSSCs [164, 191]. Consequently, more stable solid-state devices are feasible when QDs are used as the light harvesting medium, instead of dyes.

2.2.3. Loading on mesoporous ETLs

Another bottleneck QDSSCs must overcome before the PCE can be enhanced is the poor loading of QDs on the mesoporous or nanostructured ETL. This has been associated with enhanced recombination of photogenerated excitons in QDs at the interface, thereby limiting device efficiency [191, 192]. Different techniques to prepare and deposit QDs on the ETL have been developed, including techniques that QDs are grown in situ and ex situ [193–195]. The former encompasses techniques such as chemical bath deposition, which is a fast and easy process [163, 193], as well as successive ionic layer adsorption and reaction (SILAR), which allows easy tuning of QD sizes [163, 194]. QDs grown ex situ are deposited onto the ETL with the aid of molecular linkers to enable attachment of the QDs to the metal oxide ETL [163, 195]. Other methods include electrodeposition [196], spray pyrolysis deposition [197], and pulsed layer deposition [198].

Work has been done to optimize these techniques and find experimental conditions for optimum loading of QDs on the ETL. In the case of QDs grown ex situ, mercaptopropionic acid (MPA) and cysteine have been identified as good molecular linkers for attachment to metal oxides [199, 200]. It was observed that as coverage of the ETL increased, the IPCE was initially enhanced, before reaching some threshold value after which it started decreasing, which was attributed to enhanced recombination of photogenerated charge carriers brought on by aggregation of QDs as the electrons must now transfer across QD/QD interfaces before reaching the metal oxide [200]. However, the amount of QDs that cause the decline in IPCE is dependent on the molecular linker used, indicating that the choice of linker is influencing the electron transfer process [200, 201]. Similar trends have also been observed in samples with QDs deposited by SILAR or CBD [202–205]. These deposition methods also result in the growth of larger QDs as the quantity of QDs increases. Atomic layer deposition (ALD) has been suggested as an alternative method for in situ growth of QDs that does not suffer from the same problem [192]. This is another aspect in which smaller QDs appear to be superior. The QDSSC with record PCE was obtained with 4 nm QDs, and the authors have attributed the high efficiency partially to the improved coverage of the TiO2 ETL due to the small QD size [170]. The small diameter QDs reduce the blocking effect observed otherwise, allowing the QDs to penetrate through the ETL [175, 206, 207].

2.2.4. Quantum yield of charge injection

Another common issue observed in QDSSCs is poor quantum yield of electron and hole injection into the respective adjacent layers. This has been associated with trap state defects in QDs which result in charge recombination [170, 206, 208, 209]. It has been found that deposition of a 2–3 nm thin ZnS layer on the photoanode improved device performance as it passivated surface traps and prevented electron injection to the HTM [165, 204, 210], whereas alloyed QDs could be engineered to minimize the amount of surface traps [170, 211, 212]. The choice of passivating ligands on QD-sensitized metal oxides has enhanced internal quantum efficiency of photon-to-electron conversion to ∼100%, matching that of DSSCs [213]. Furthermore, use of small QDs increases the difference between excited state of QD and ETL conduction band, providing a larger driving force for electron injection, and leading to higher IPCE [171]. Deposition on nanostructured TiO2 (nanotubes) was also observed to enhance electron injection as it reduced recombination losses observed at grain boundaries of TiO2 nanoparticles [171]. QDSSCs additionally offer the potential of leveraging impact ionization occurring in QDs, which would result in two or more excitons forming with a single photon, as well as hot electron transfer [163, 214, 215]. Work done on this front has resulted in impressive outcomes, with absorbed photon-to-current efficiency of PbS QD-sensitized TiO2 exceeding 100% [214].

2.3. Colloidal QD solar cells

The first example of a solar cell employing colloidal QDs for both light harvesting and charge transport was made in 2005, using a mixture of PbS QDs and a conjugated polymer poly[2-methoxy-5-(2'-ethylhexyloxy-p-phenylenevinylene)] (MEH-PPV), which served as HTM [215]. However, the efficiency of these devices was limited by poor electron transport and after significant enhancements in the conductivity of QD films, the active layer was prepared by PbS QDs only, which was found to enhance charge carrier extraction from the active layer [216]. These devices were built as Schottky cells, as the semiconducting active layer (PbS) formed a rectifying junction with a low work function metal and the operating procedure is outlined in figure 6(a) [217]. Metals used for this purpose included aluminum, calcium, magnesium, silver, and gold. The best device efficiency achieved with such an architecture was 5.2% [218]. Nevertheless, the device performance is limited by the Fermi level at the interface which limits the open-circuit voltage, whereas illumination from the non-rectifying side of the device was required, which meant that internal quantum efficiency was low as this was far from the junction [217, 219].

Figure 6. Device operation of: (a) Schottky colloidal QD solar cell, and (b) depleted heterojunction colloidal QD solar cell. Reprinted with permission from [220]. Copyright (2010) American Chemical Society.

Download figure:

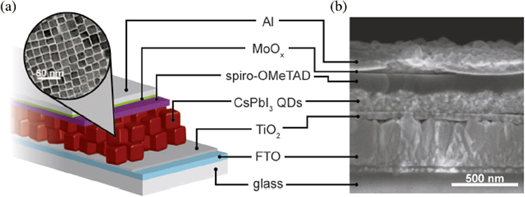

Standard image High-resolution imageThese limitations led to the development of depleted heterojunction colloidal QD solar cells, in which a p-type monolayer of colloidal QDs is deposited on a wide band gap semiconductor, typically n-type, with TiO2 and ZnO being common choices [217, 220]. The device was completed with deposition of a doped metal oxide HTM and a metal contact, and the device operation is shown in figure 6(b). This device architecture allowed illumination close to the interface, and charge carriers in the colloidal QD monolayer are driven by drift currents. This device structure yielded record device efficiency of 13.43% with use of CsPbI3 QDs in the device structure shown in figures 7(a) and (b) [217, 221]. The performance of these devices is limited by short charge carrier transport lengths in the QD film, as enough thickness is necessary for light absorption, with adverse effects on charge carrier transport.

Figure 7. (a) Schematic of the solar cell structure, (b) scanning electron microscopy images of the device. Reprinted/adapted from [221]. © The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. Distributed under a Creative Commons Attribution NonCommercial License 4.0. (CC BYNC).

Download figure:

Standard image High-resolution imageThis limitation encouraged the development of bulk heterojunction colloidal QD solar cells, in which the n-type semiconductor and the colloidal QD film are combined in an interpenetrating layer to ensure that photogenerated excitons are formed close to the interface [217]. Unfortunately, this suffered from increased recombination, reducing the photo-voltage. More work is being done to enhance the performance of colloidal QD solar cells, which ranges from material and ligand modifications, to band engineering and passivation, as will be discussed below.

2.3.1. Pb-based QD solar cells

Pb-based QDs, in particular PbS and PbSe, have been very popular choices as sensitizers in colloidal QD solar cells. PbS QDs were used both in the first case of colloidal QD solar cells, as well as high efficiency colloidal QD solar cells reaching 8.55%, because of their excellent absorption properties, which can be tuned from 800 to 2000 nm [222–224]. Furthermore, PbS QDs demonstrate good air stability, which has been a challenge for colloidal QD solar cells. PbSe QDs have also been implemented in solar cells with impressive results, and both PbS and PbSe have demonstrated multiple exciton generation resulting in internal quantum efficiency that exceeded 100%, proving that QD-based solar cells could reach high efficiencies, beyond that of DSSCs [214, 225]. Hot electron transfer from PbSe QD films to TiO2 has also been observed, which can be additionally leveraged for high efficiency devices [226].

Since one of the major limitations of colloidal QD solar cells is charge transport within the QD layer, the conduction characteristics of materials such as PbSe, PbS, and CdSe QD films were investigated to elucidate the processes occurring during device operation. It was found that after exciton dissociation, charge carrier transport occurs through phonon-assisted hopping between the energy levels in QDs, contrary to earlier claims of band-like conductivity [227, 228]. PbS and PbSe QD films have been shown to possess good electrical properties, with PbSe QD films reaching mobilities of 7 cm2 V−1 s−1 after treatment with passivation and infilling [229], which will be re-visited in the next sections.

2.3.2. Improving drift of carriers

The charge carriers inside the QD film are driven by drift currents generated by the electric field in the device [217]. Since carrier transport is below optimal, improvements are needed to enhance the drift of carriers. Efforts have been focused on band engineering and ligand modification to improve charge transport.

Ligand modification has proven key in controlling the electrical properties of QD films. Use of ethanedithiol (EDT) molecules to assist in film fabrication has demonstrated improvement in carrier mobility, associated with reduced inter-particle spacing [230, 231]. But owing to the vulnerability of organic ligands, inorganic ligands were developed to enhance electronic transport and passivate surface defects [232]. Metal chalcogenide complexes were found to result in electron mobilities of 16 cm2 V−1 s−1 in CdSe QDs [233], whereas atomic ligand passivation produced a PbS QD device with efficiency of 6% in the first attempt to fabricate a photovoltaic device with inorganic ligands [232]. In this device, the PbS QDs were capped with oleic acid ligands when synthesized, with thiol treatments removing the oleic acid and passivating the QDs through a Pb–-S bond [232, 234]. The PbS QDs were then treated in CdCl2, tetradecylphosphonic acid (TDPA), and oleylamine (OLA), which improved sized distribution, stability, and reduced defects. Finally, the film was treated with either cetyltrimethylammonium bromide (CTAB), hexadecyltrimethylammonium chloride (HTAC), or tetrabutylammonium iodide (TBAI) to generate halide-passivated PbS QD films.

Apart from ligand modification, band engineering has also been very useful in improving electrical transport in colloidal QD solar cells, involving tuning of the band alignment between the colloidal QD film and the ETL to favor electron injection into the ETL [217]. This has also led to the concept of quantum funnels, essentially the preparation of graded band gap using five QD layers and leveraging the fact that carriers will end up in the layer with the smallest band gap. This has resulted in improved fill factor, open-circuit voltage, and short-circuit current [217, 235, 236]. In addition, graded doping architectures have been used to improve device efficiency [237]. The dopant can be used to tune the conduction band edge and band bending at interfaces, with ligands such as 3-mercaptobutyric acid and EDT used to dope PbS QD films, showing impressive results and leading to record efficiencies [224, 235]. Other efforts have included doping of the metal oxide used as ETL, incorporating impurities in TiO2 and magnesium doping of ZnO, to achieve optimal band offset [238, 239].

2.3.3. Infilling

Another approach to address the limited mobility and conductivity demonstrated by colloidal QD films is infilling with metal oxides. Deposition of Al2O3 and ZnO via ALD to fill the pores of PbSe QD films was observed to reduce the inter-QD tunnel barriers, enhancing carrier mobility [240, 241]. Enhanced conductivity and carrier mobility was also observed after infilling of CdSe QD films with ZnO [242]. ALD appears to be the optimum technique for deposition of the infilling material as it can uniformly coat structures characterized by high aspect ratio, and in work done on infilling a PbSe QD film with amorphous Al2O3, high charge mobility was achieved (7 cm2 V−1 s−1), due to passivation of the QD surface trap states, as well as strong electronic coupling of the sodium sulfide ligands [229]. Furthermore, infilling of a PbSe QD film with Al2O3 or Al2O3/ZnO was observed to result in multiple exciton generation in the QDs, which was not observed in the non-filled films, providing additional motivation for infilling [243]. This is a consequence of the enhanced charge mobility in the infilled films which reduces the possibility of Auger recombination of charges.

2.3.4. Surface passivation

Since the presence of defects hinders charge carrier transport through the QD film and enhances the possibility of charge recombination before they reach their respective contacts, surface passivation to eliminate these trap states can be a useful tool in improving device performance [227]. This can be achieved through different techniques, with ligand passivation being a common method. It was observed that PbS QD films that were treated with 3-mercaptopropionic acid (MPA) demonstrated improved device performance as compared to oleic acid or EDT, associated with superior passivation of defects, leading to higher mobility and minority carrier transport [244]. Infilling is also used to yield improved device stability which is achieved through surface passivation, as it prevents oxidation and photothermal degradation of QDs exposed to ambient conditions [229, 240, 243].

Surface passivation is achieved by exposure of PbSe QDs to chlorine gas, as it results in a thin PbCl2 layer which passivates the QDs and prevents oxidation [245]. PbCl2 can also be used as a precursor for PbSe QDs to create a passivating thin PbCl2 layer [246, 247], or alternatively, treatment of PbSe QDs with NH4Cl can produce a thin PbCl2 layer [248]. In addition, cation exchange techniques have been used to introduce metal cations post-synthesis and enable implementation of techniques used for Cd structures to be used in Pb structures that can ultimately be used to improve carrier transport and reduction of trap states [249, 250] which has been used to passivate PbSe QD films and eventually produce air-stable devices [250].

While many improvements are needed in terms of device stability, conductivity, and performance, colloidal QD solar cells have demonstrated impressive improvements in efficiency since their inception in 2005, reaching efficiencies close to those of DSSCs [221], showing that they are a very promising photovoltaic technology.

2.4. Nanowires

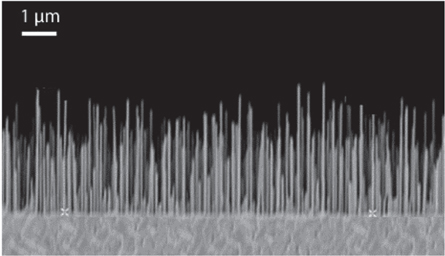

Among nanostructures being actively researched for solar cells, nanowires (NWs) with high aspect ratios and length of 100 nm or more have shown remarkable improvement in PCE compared to their bulk counterparts. Solar cells based on NWs have seen rapid increase in efficiency with PCE values as high as 17% [251, 252], while keeping production costs low. NWs are passive towards impurities present in the bulk, and hence can be fabricated from bulk materials with lower purity, reducing the cost [253]. They help in efficient light management in solar cells through two main methods: (a) by providing spectrally selective improved scattering of light and increased absorption through resonant modes [254–261] and (b) by enhancing charge carrier dynamics through increased efficiency of charge carrier generation and collection [253, 262]. Further, theoretical limit for NW solar cells can reach up to 42% [263], though some have argued that such high performance cannot be attained due to contact and surface recombination [264]. Silicon [258, 265–267] and III–V materials [251, 268–271] are the most commonly studied solar cells possessing NW morphology, although other materials have been studied as well [272]. However, they still have PCE significantly lower than their bulk counterparts and are far from reaching large scale production capabilities. Here, we discuss some key concepts of NW solar cells.

2.4.1. Efficient light management

Scattering of light in NWs is described in terms of wave optics and depends on NW diameter, length, pitch and slant angle [270, 273, 274]. By warrying these parameters it is possible to improve scattering and absorption within a material compared to its bulk counterpart. It is also important to remember that the dependence of these parameters vary with different materials due to differences in their electronic band structure and dielectric properties. Li et al used simulations based on full wave finite element method to show that the hexagonally arranged Si nanopillars with pitch and diameter lying close to 600 nm and 500 nm respectively has increased absorption compared to thin films with the same amount of material [275].

Apart from light scattering, the presence of guided leaky resonant modes are also responsible for increased absorption in nanowires [274, 276]. Multiple studies using analytical waveguide theory have shown that the resonance position of these modes are minimally perturbed from a single NW to sparsely spaced III–V NW array [274, 277], while near field coupling between neighboring NWs is significant in Si NWs [278, 279]. Calculation from Anttu et al showed that these modes had strong diameter dependence and weak dependence on pitch and length in InP NWs with minimal absorption below 100 nm diameter and maximum at 170 and 410 nm respectively [274]. The increase in absorption at these diameters is due to the strong excitation of HE11 (170 nm) and HE22 (410 nm) modes by incident light followed by strong absorption by the NWs. The design of the simulation along with results of which are shown in figure 8. In addition, Dhindsa et al reported that smaller NWs have low absorption at longer wavelengths irrespective of packing density [280], further confirming the dependence of nanowire diameter on performance.

Figure 8. Schematic of the simulation setup used by Anttu et al for InP nanowires. The substrate is of infinite thickness and the space between the wire is filled with air (a) Absorbance spectra for nanowires of pitch 680 nm and length 2000 nm and diameter—100 nm (i), 177 nm (ii), 221 nm (iii), and 441 nm (iv). The light is incident normal to the surface. Reproduced with permission from [274], OSA.

Download figure:

Standard image High-resolution image2.4.2. Charge carrier dynamics

Another important property of NWs is the ability to separate charge carriers near the p–n junction. NWs have significant advantages over bulk materials as the charge carries have to transverse much smaller distances compared to their diffusion lengths, minimizing losses due to scattering and radiative recombination [281, 282]. Some of the important parameters that determine electrical properties of NW solar cells are doping concentration, geometry and surface passivation. In III–V NWs, crystal structure also seem to play an important role in charge separation [264]. Since III–V's can exist in zinc blend and wurzite crystal structure or predominantly as a mixture of the two, such two phase systems can act as scatterers and trap states for radiative recombination [283, 284].