Abstract

The Taklamakan Desert in China's Xinjiang region faces severe heat conditions that cause rutting in asphalt pavements. In order to combat this issue, local construction management has been advocating for the utilization of low-grade asphalt with penetration levels between 20 and 50, to enhance the pavement's resistance to rutting. However, there is limited research on the durability of low-grade asphalt under intense UV irradiation in the region. To this end, a multiscale investigation was conducted, examining three different types of asphalt (30#, 50#, and 70#), under various conditions such as virgin, UV aging, and Pressure Aging Vessel aging. Analytical techniques such as Atomic Force Microscope, Gel Permeation Chromatography, Fourier Transform Infrared Spectroscopy, Dynamic Shear Rheology, and Bending Beam Rheometer were employed. The results revealed that the surface roughness of the three types of asphalt increased by 15.50% (30#), 5.99% (50#), and 2.70% (70#) after UV aging, compared to the virgin samples. Furthermore, the adhesion properties of lower-grade asphalt were less affected by UV aging. Weight-average molecular weight of the three types of asphalt increased significantly after UV aging, with a 26.96% increase in 30#, 51.92% increase in 50#, and 43.76% increase in 70# compared to the samples prior to UV aging. The 30# asphalt with higher large molecule content exhibited slower UV aging. The 30# asphalt also exhibited the smallest increase of C=O and S=O after UV aging among the three types of asphalt. The study also found that UV aging had a lesser effect on the high- and low-temperature performance of asphalt, compared to PAV aging. Overall, the effects of UV irradiation on various properties of 30# asphalt were less pronounced than those of 50# and 70# asphalt. These findings offer valuable insights into aging resistance in the Taklamakan Desert, benefiting road contractors and the academic community.

Export citation and abstract BibTeX RIS

Original content from this work may be used under the terms of the Creative Commons Attribution 4.0 licence. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

1. Introduction

The Taklamakan Desert, situated in the heart of the Tarim Basin in southern Xinjiang, is China's largest desert and the world's tenth largest, covering an area of 330,000 square kilometers. The region is endowed with abundant solar radiation, with an average annual total radiation of 6000 MJ·mm−1, and extended sunshine duration (3000–3500 h per year), prolonged periods of high temperatures, low precipitation levels (averaging less than 100 mm annually), a substantial annual evaporation of 2000–3400 mm, and a considerable temperature differential between day and night [1]. These conditions pose significant challenges in constructing asphalt pavement in this area. Asphalt mixtures are highly susceptible to temperature, leading to rutting, which becomes the primary issue in southern Xinjiang. Rutting deforms the road surface and impairs the road's flatness, posing a serious threat to driving safety and comfort [2–6]. Many regions worldwide utilize anti-rutting agents and modified asphalt to improve the high-temperature rutting resistance of asphalt mixtures [7–11]. However, this method substantially raises production costs, and economically underdeveloped regions, such as the southern border area, cannot bear the additional expenses. To overcome this challenge, the local construction department conducted experiments with low-grade asphalt paving in the region around 2010. Due to the higher softening point and lower penetration of low-grade asphalt, it is less susceptible to softening and flow at high temperatures. Consequently, it enhances the stability of asphalt mixtures under high-temperature conditions. This implies that asphalt pavements are less likely to deform or suffer damage in hot seasons or high-temperature regions. This endeavor has yielded favorable technical outcomes in the past. Recently, with the expansion of the petrochemical industry in Xinjiang (including Karamay oil field, Tuha oil field, Tarim oil field, Tahe oil field, etc), which has made low-grade asphalt more readily available in South Xinjiang, the use of low-grade asphalt in this region has gained more widespread attention [12–15].

Low-grade asphalt is typically defined as asphalt with a penetration grade of 50# or lower, equivalent to hard or hard-grade asphalt, with a penetration grade of 40/60 (0.1 mm) or lower at 25 °C. France and other European countries have conducted extensive research on and application of low-grade asphalt (known as hard-grade asphalt in France), and China has also made some progress in this area [13, 16]. France produces three types of low-grade asphalt: penetration grade 15/25, 10/20, and 5/10, with the former two being the most commonly used, while the latter is still in the experimental stage [17]. In China, 30# asphalt with a penetration grade of 20/40 is commonly used as low-grade asphalt.

Scholars have conducted research on low-grade asphalt and asphalt mixtures. Tong et al investigated the properties of 30# asphalt and found that it exhibited superior high-temperature performance and favorable water stability compared to high-grade asphalts [18]. However, the unique composition of 30# asphalt hindered its crack resistance at low temperatures, while contributing to improved resistance to thermal oxygen aging [19–22]. Zou et al explored the effects of three types of crude oil on low-grade asphalt and the corresponding asphalt mixtures, revealing significant variations in performance according to the type of crude oil used [23]. Similarly, Zhang et al evaluated various preparation and compaction methods for low-grade asphalt mixtures and found that they demonstrated excellent fatigue resistance, although their low-temperature performance could be further enhanced [24, 25]. The long-term service performance of low-grade asphalt in practical engineering applications has also received considerable attention. For example, the 30# asphalt mixture was shown to exhibit superior high-temperature rutting resistance and fatigue performance compared to AH-70 asphalt mixture and Styrene-Butadiene-Styrene (SBS) polymer-modified asphalt mixture, while also demonstrating good water stability and long-term service performance during 5–10 year tracking observations [26, 27].

Low-grade asphalt typically has a low penetration grade, yet it boasts a high dynamic modulus and exceptional resistance to high-temperature rutting, comparable water stability, and fatigue performance. However, its low-temperature performance is less favorable compared to high-grade asphalt. Despite the well-established properties of low-grade asphalt and its asphalt mixtures, systematic research on their aging resistance under intense UV irradiation in the Taklamakan Desert region of Xinjiang has been lacking, impeding the determination of asphalt pavement durability in the area. Therefore, it is imperative to further investigate the aging resistance of low-grade asphalt, particularly the effects of UV aging in this region.

2. Objectives and scopes

In 2020, the Ruoqiang-Minfeng Expressway project proposed employing 50# matrix asphalt as the binding material for the AC-20 asphalt mixture in the subgrade layer of the asphalt pavement (refer to figure 1). Despite the guidance provided in the 'Xinjiang Highway Asphalt Pavement Design Guideline' regarding the use of low-grade asphalt, and previous experience with similar projects in the region, the technical staff harbored reservations regarding the UV aging resistance of 50# asphalt. Consequently, the project's investor spearheaded a research initiative, entitled 'Key Technology Research on the Road Performance of Low-Grade Asphalt in Rutting Resistant Areas at High Temperatures and Drought.' As a significant component of this endeavor, the present study aims to compare the durability of low-grade asphalt (30# and 50#) with that of the standard 70# asphalt under intense UV irradiation in the Taklamakan Desert.

Figure 1. The construction project of Ruoqiang to Minfeng highway in the south of the Taklamakan Desert in Xinjiang, the used map was supported by Baidu Map No. GS (2021) 6026.

Download figure:

Standard image High-resolution imageThe present study examines the properties of three different types of asphalt, namely 30# and 50# low-grade asphalt and 70# asphalt, across three aging conditions: virgin, UV-aged, and Pressure Aging Vessel (PAV)-aged, at the nanoscale, microscale, and macroscale. The analytical flowchart for this study is illustrated in figure 2. The objective is to provide practical guidance for the application and recycling of low-grade asphalt in regions with elevated levels of ultraviolet radiation. The findings of this study may contribute to the development of sustainable infrastructure in such regions.

Figure 2. The flow chart of this study.

Download figure:

Standard image High-resolution image3. Materials and methods

3.1. Raw materials

The selected materials for testing are virgin asphalts named Kelian 30#, Kunlun 50#, and Kunlun 70#. These asphalts were produced by the China National Petroleum Corporation in Karamay and sourced locally from Xinjiang. A table of fundamental parameters for the aforementioned asphalts is presented in table 1. Moving forward, we shall refer to Kelian 30# as 30#, Kunlun 50# as 50#, and Kunlun 70# as 70#.

Table 1. The basic parameters of the three asphalts.

| Items | 30# | 50# | 70# | Test methods |

|---|---|---|---|---|

| Penetration at 25 °C (0.1 mm) | 26.0 | 43.9 | 60.8 | ASTM D5 |

| Softening point (°C) | 57.5 | 53.5 | 50.5 | ASTM D36 |

| Ductility at 15 °C (cm) | 22.5 | >100 | >100 | ASTM D113 |

| Dynamic viscosity at 60 °C (Pa·s) | 1064.32 | 353.6 | 268.8 | ASTM D2171 |

3.2. Test methods

3.2.1. UV radiation accelerated aging test

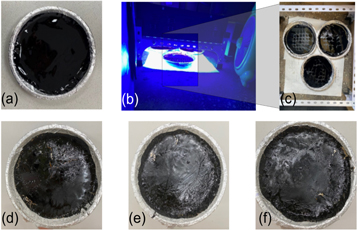

In figure 3(a), the virgin asphalts were liquefied and subsequently poured into petri dish with a layer of aluminum foil wrapping. An accelerated aging test was performed on the cooled samples using UV radiation, as demonstrated in figure 3(b), with a UV aging device [28]. The device featured a high-pressure mercury lamp as the UV light source, rated at 1 kW, which generated a significant amount of heat and high radiation intensity. To effectively regulate the surface temperature of the samples, the asphalt samples were placed 20 cm away from the lamp.

Figure 3. Preparation of UV aged samples. (a) Virgin asphalt sample (unaged); (b) UV aging device; (c) Sample position; (d) 30# asphalt sample after ultraviolet aged; (e) 50# asphalt sample after ultraviolet aged; (f) 70# asphalt sample after ultraviolet aged.

Download figure:

Standard image High-resolution imageAs referenced, the mean annual aggregate solar radiation in the southern region of the Taklamakan Desert is 1700 kWh m−2, with ultraviolet radiation accounting for approximately 5% of this value [29]. At the project site, the total mean annual UV radiation is 85 kWh m−2. The central asphalt sample's UV radiation intensity was measured using a UV intensity meter and found to be 400 W m−2 during indoor testing. Based on the principle of UV radiation energy equivalence [30, 31], the duration of indoor exposure is determined as:

The duration of indoor exposure,  is determined by the intensity of ultraviolet radiation,

is determined by the intensity of ultraviolet radiation,  and is influenced by the duration of outdoor exposure,

and is influenced by the duration of outdoor exposure,  and the intensity of outdoor ultraviolet radiation,

and the intensity of outdoor ultraviolet radiation,  By applying the principle of equivalence of UV radiation energy, the duration of exposure required for one year of equivalent UV radiation energy was calculated to be 212.5 h. The asphalt samples underwent a 14-day UV aging test, which is equivalent to 1.58 years of aging in the southern region of the Taklamakan Desert. The images of 30#, 50#, and 70# asphalt after UV aging are shown in figures 3(d)–(f), respectively. A comparative analysis was conducted on the PAV-aged samples, which were prepared in accordance with ASTM D6521.

By applying the principle of equivalence of UV radiation energy, the duration of exposure required for one year of equivalent UV radiation energy was calculated to be 212.5 h. The asphalt samples underwent a 14-day UV aging test, which is equivalent to 1.58 years of aging in the southern region of the Taklamakan Desert. The images of 30#, 50#, and 70# asphalt after UV aging are shown in figures 3(d)–(f), respectively. A comparative analysis was conducted on the PAV-aged samples, which were prepared in accordance with ASTM D6521.

3.2.2. Atomic force microscopy (AFM)

To investigate the micro-morphology changes of low-grade asphalt resulting from UV aging, atomic force microscopy (AFM) observations were conducted on three different asphalt samples before and after exposure to UV radiation. For observation purposes, asphalt film samples with a diameter of approximately 10 mm were prepared by hot casting. The Bruker Dimension Icon AFM with the RTESPA-150 probe, featuring an elastic coefficient of 5 n m−1, resonance frequency of 150 kHz, and a radius of curvature of 8 nm, was selected for this test. The scanning images were obtained using tapping mode, with a scanning range of 20 μm × 20 μm at a temperature of 25 ± 1 °C and a pre-pressure of 10 nN. Furthermore, adhesion force was obtained by calculating the difference between the lowest point of the curve and the horizontal line. Offline analysis software NanoScope Analysis was utilized to analyze the images and perform calculations.

3.2.3. Gel permeation chromatography (GPC) test

Gel permeation chromatography (GPC) was employed in this study to evaluate the effects of UV aging on low-grade asphalt by determining the changes in molecular weight and distribution. The GPC analysis was performed using the PL-GPC-50 chromatograph manufactured by Polymer Laboratories, with tetrahydrofuran (THF) serving as the solvent at a mobile phase rate of 1 ml min−1 and a temperature of 40 °C. An injection volume of 100 μl was utilized, and the testing was conducted using three chromatographic columns, each 300 mm in length. The asphalt samples, both pre- and post-UV aging, were dissolved in THF prior to undergoing GPC testing. Through this analytical method, the differential distribution curve of molecular weight was derived, providing insights into the asphalt's structural changes upon exposure to UV radiation.

3.2.4. Fourier transform infrared (FT-IR) spectroscopy test

To investigate the impact of UV aging on the various functional groups of low-grade asphalt, EQUINX55 Fourier transform infrared spectrometer in attenuated total reflection infrared mode was employed to analyze the virgin, UV aged, and PAV aged asphalt samples. Infrared spectroscopy is a versatile technique that can be utilized to determine the molecular structure of compounds, identify unknown substances, and analyze mixture components. The FT-IR test was performed in the wavenumber range of 400 cm−1 to 4000 cm−1. The position and shape of the absorption peaks in the spectrum can provide valuable information about the chemical structure of an unknown compound, while the intensity comparison of the characteristic absorption peaks can aid in determining identifying functional groups present in the samples [32, 33].

3.2.5. Dynamic shear rheology (DSR) test

Dynamic shear rheological (DSR) tests were conducted to evaluate the high-temperature rheological properties of asphalt, which undergo changes upon aging, particularly when exposed to UV radiation. To investigate the influence of UV aging on the high-temperature rheological properties of low-grade asphalt, dynamic shear rheological tests were carried out on the virgin, UV aged, and PAV aged samples of three kinds of asphalt. The tests were conducted using a dynamic rheometer (TA Instruments) in the mode of temperature sweep, with a test temperature range of 46 °C to 82 °C and an interval of 6 °C. The frequency was set at 10 rad s−1, and the diameter of the parallel plates was 25 mm with a spacing of 1 mm. The tests recorded the complex modulus (G*) and phase angle (δ), from which the rutting factor (G*/sinδ) can be calculated.

3.2.6. Bending beam rheometer (BBR) test

Bending Beam Rheometer (BBR) tests were conducted to characterize the low-temperature performance of asphalt samples. The BBR equipment was provided by Cannon Instrument Company and the tests were conducted in accordance with the ASTM D6648 standard. The samples included virgin, UV-aged, and PAV-aged asphalt of three types. The testing temperatures were set at −6 °C, −12 °C, −18 °C, and −24 °C. The low-temperature performance of the asphalt samples was evaluated by measuring the stiffness modulus (S) and creep rate (m) at low temperature, both before and after UV aging. Stiffness modulus reflects the resistance to a constant testing load, while creep rate represents the slope of the stiffness versus time curve. A low stiffness modulus and high creep rate are favorable for resisting low-temperature cracking at a given low temperature.

4. Results

4.1. AFM analysis

4.1.1. AFM surface morphology of asphalt before and after UV aging

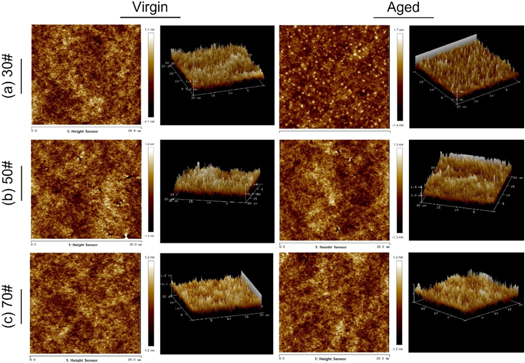

Figure 4 displays the atomic force microscopy (AFM) images of the surface morphology of 30#, 50#, and 70# asphalt, before and after UV aging, in both two-dimensional (2D) and three-dimensional (3D) microscale. As can be seen from the images, there are no distinct bee-like structures on the surface of the three types of asphalt before or after UV aging, which can be attributed to the origin, composition, and structural makeup of the asphalt.

Figure 4. 2D and 3D AFM morphology images of different asphalt before and after UV aging.

Download figure:

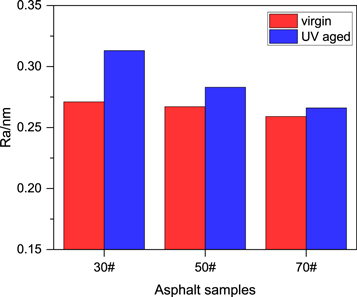

Standard image High-resolution imageIn this study, we aim to investigate the correlation between surface morphology parameters and UV aging in asphalt. To quantify the AFM images, surface roughness was utilized as a characteristic index. The formula (2) was employed to calculate the surface roughness (Ra) of asphalt, where A represents the scanning area of 20 μm × 20 μm, h(x,y) denotes the equation of the topography height parameter, and h0 is the reference height. The surface roughness values of the three asphalt samples under virgin and UV aged conditions were computed and depicted in figure 5.

Figure 5. Surface roughness of the three asphalts before and after UV aging.

Download figure:

Standard image High-resolution imageBased on figure 5, it is evident that the surface roughness of the 30#, 50#, and 70# asphalt samples has increased by 15.50%, 5.99%, and 2.70%, respectively, after UV aging compared to their values prior to testing. Moreover, the trend of increasing surface roughness for the 30#, 50#, and 70# asphalt samples appears to be slowing down. This indicates that the surface roughness of the asphalt increases after UV aging. As the asphalt grade increases (i.e., 30#, 50#, 70#), the penetration gradually increases, and correspondingly, the content of light components also increases. Thus, the increase in surface roughness decreases with the rise in asphalt grade after UV aging.

4.1.2. Adhesion properties

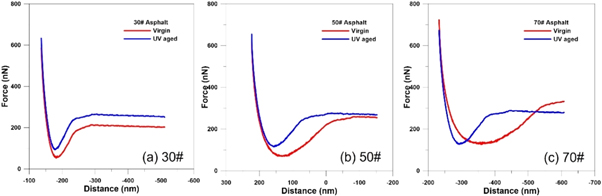

Furthermore, figure 6 presents the force-distance curves obtained from the AFM tests, which reflect the bending state of the free end of the AFM microcantilever probe during contact with and detachment from the sample surface, as the fixed end approaches vertically. By applying Hooke's law, the equation for calculating the adhesion force can be derived, as follows:

Figure 6. Force-distance curve of three asphalt samples.

Download figure:

Standard image High-resolution imageThe displacement of the probe microcantilever from its non-bending state to completely leaving the sample surface is represented by ΔX, while the bending elastic coefficient of the probe microcantilever is represented by Kc . The adhesion force between the asphalt and the probe is represented by Fad , and θ is the correction factor that accounts for the difference between the actual situation and the theoretical analysis. Therefore, the adhesion force between the probe and asphalt can be calculated by analyzing the force-distance curve. The calculations of the adhesion force can be observed in figure 7.

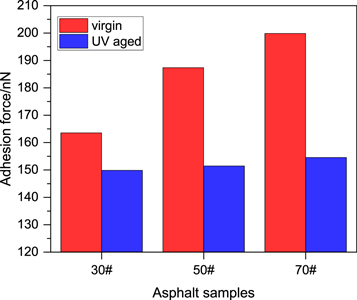

Figure 7. Adhesion force of different asphalts before and after UV aging.

Download figure:

Standard image High-resolution imageThe data presented in figure 7 reveal that the adhesive force of 30#, 50#, and 70# asphalt decreased by 8.35%, 19.16%, and 22.66%, respectively, after undergoing UV aging compared to their original states. It is important to note that the decrease in adhesive force gradually increased for 30#, 50#, and 70# asphalt.

In accordance with the surface physicochemical theory of materials, adhesion work is defined as the energy required to separate a unit adhesion interface between two adhering materials. Among the numerous theories that exist, the well-established John-son-Kendal-Roberts (JKR) contact theory is particularly well-suited for high adhesion systems and imposes minimal restrictions on object rigidity [34, 35]. Consistent with the JKR theory, the conversion relationship between adhesion force and adhesion work can be expressed as follows:

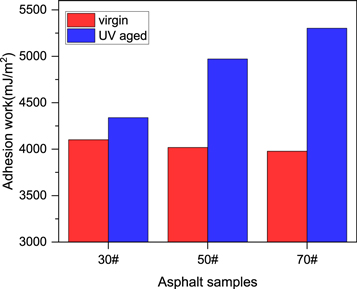

Fad represents the adhesion force, while W represents the adhesion work. Referring to the tip of the probe utilized in this study, the contact radius is 8 nm. Employing equation (4) to calculate the adhesion work between the asphalt and the tip, the results are presented in figure 8.

Figure 8. Adhesion work of the three asphalts before and after UV aging.

Download figure:

Standard image High-resolution imageTo accurately calculate the change in free energy of the asphalt surface energy, it is imperative to understand the adhesion work between the asphalt and the tip of the probe. In order to do so, the Fowkes model has been selected as the preferred methodology for calculating the surface energy of the asphalt. The calculation methodology is described as follows [36]:

The dispersion component of surface energy is represented by γd

, Wab

refers to the adhesion work between interfaces, and γab

is the surface energy between materials. As for asphalt materials, it can be approximated that γa

is nearly equal to  . The parameter Wab refers to the adhesion work between the asphalt and the tip of the probe as:

. The parameter Wab refers to the adhesion work between the asphalt and the tip of the probe as:

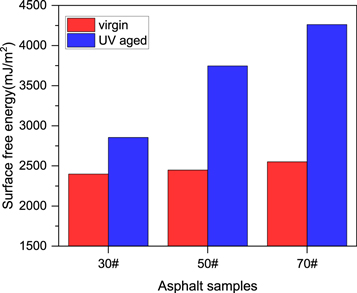

After utilizing AFM equipment, it was determined that the surface energy γb for the tip of the probe is 1649.07 mJ m−2. Therefore, utilizing equation (7), the corresponding surface free energy γa can be calculated. The obtained results are presented in figure 9, which demonstrates the surface free energy values for the three asphalt materials, both before and after undergoing UV aging.

Figure 9. Surface free energy of the three asphalts before and after UV aging.

Download figure:

Standard image High-resolution imageAs shown in figures 6–8, it was observed that the adhesion force, adhesion work, and surface free energy of the three asphalt types (30#, 50#, and 70#) followed the trend of 30# < 50# < 70# under virgin conditions. After undergoing UV aging, it was found that the adhesion force, adhesion work, and surface free energy of the three asphalt types decreased correspondingly. Moreover, the degree of decrease increased progressively with the grade of the asphalt. In other words, it was observed that the impact of UV aging on the adhesion properties of asphalt was less significant in lower-grade asphalt compared to the conventional asphalt samples.

4.2. GPC analysis

Figures 10(a)–(c) depict the differential distribution curve of molecular weight for the asphalt samples of 30#, 50#, and 70#, both prior to and post UV aging. The horizontal axis displays the logarithm of weight-average molecular weight, whereas the vertical axis exhibits the relative content of the asphalt. Figure 10(d) showcases the calculated weight-average molecular weight (Mw) of 30#, 50#, and 70# asphalt before and after UV aging to quantitatively evaluate the overall impact of UV aging on the molecular weight of the asphalt samples.

Figure 10. Molecular weight distribution curve and weight-average molecular weight of different asphalts before and after UV aging. (a), (b), (c) Molecular weight distribution curve for 30#, 50#, 70# asphalt, (d) Weight-average molecular weight.

Download figure:

Standard image High-resolution imageAs evident from figure 10, substantial variations exist in the molecular weights of the three asphalts. Notably, the molecular weight curve of the 30# asphalt differs from that of the other two asphalts. Before UV aging, the weight-average molecular weight order of the three asphalts, namely 30#, 50#, and 70#, is as follows: 30# > 50# > 70#. This observation suggests that the large molecule content declines with an increase in the grade of asphalt before UV aging. After ultraviolet aging, the weight-average molecular weights of the three types of asphalt increased by 26.96%, 51.92%, and 43.76%, respectively. In general, an increase in the content of large molecules within the same type of asphalt implies a certain degree of aging has occurred. Therefore, the higher the increase in large molecule content, the greater the degree of asphalt aging. Of the three asphalts, the increase in the weight-average molecular weight of 30# asphalt is the least pronounced. The higher large molecule content in the virgin 30# asphalt is advantageous in decelerating the UV aging reaction.

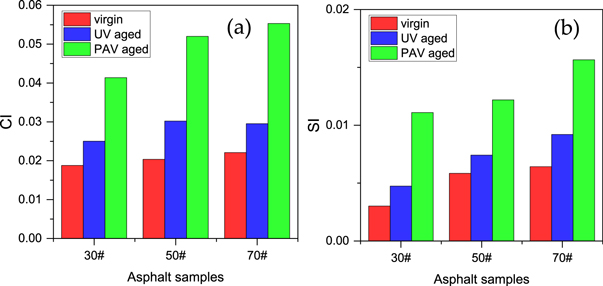

4.3. FI-IR spectroscopy analysis

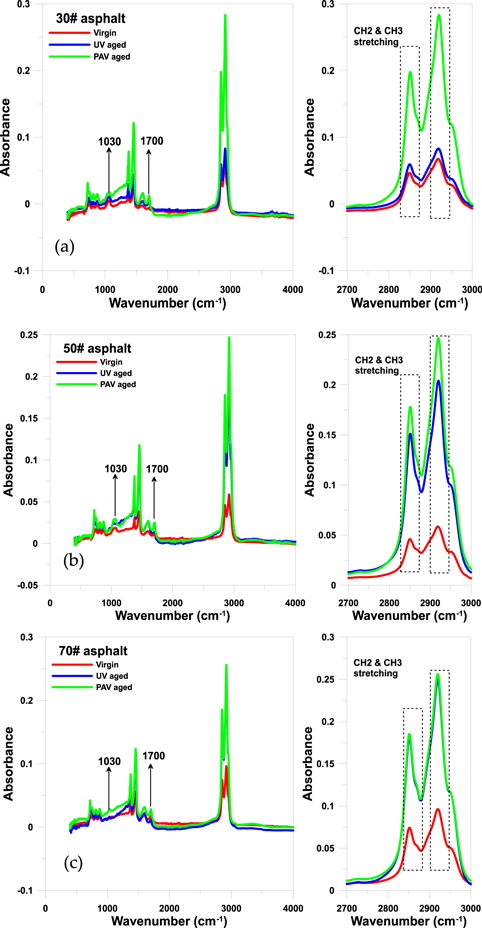

The infrared spectra of the three asphalt samples, namely before aging, after UV aging, and after PAV aging, are depicted in figure 11, which presents the wave number range of 400–4000 cm−1. It is noteworthy that the stretching vibration of the carbonyl compound (C=O) occurs at 1700 cm−1, whereas the stretching vibration of the sulfoxide compound (S=O) is observed at 1030 cm−1. The degree of asphalt aging can be accurately assessed by measuring the area of the characteristic peaks, which increases as the asphalt ages. In order to evaluate the changes in functional groups of asphalt following various aging methods, we have selected the carbonyl index (CI) and sulfoxide index (SI) for analysis. The equations (8) and (9) [37, 38] provide a clear calculation of the carbonyl index and sulfoxide index.

Where, A1700 and A1030 are the peak areas corresponding to wavenumbers 1700 cm−1 and 1030 cm−1, respectively. ∑Ai is the sum of the peak areas under the ith reference (i = 1, 2, 3, ..., n).

Figure 11. FT-IR spectroscopy of the three asphalts with different aging conditions.

Download figure:

Standard image High-resolution imageBased on the findings presented in figure 11, it is observed that the positions of the characteristic peaks of the three asphalt samples remain nearly constant under varying aging conditions. However, there is a significant variation in the absorbance of these peaks. Specifically, the absorbance of the characteristic peaks after PAV aging is markedly higher, whereas that of UV-aged asphalt is moderate, and that of virgin asphalt is the lowest. This observation suggests that PAV aging has resulted in a more substantial degree of asphalt aging compared to UV aging, as concluded by this study.

Based on figure 12, the trend of both CI and SI increases with the increase in asphalt grade (30#, 50#, 70#). Within the same asphalt grade, PAV aged > UV aged > Virgin in terms of the orders of CI and SI. The larger the CI and SI values, the higher the number of C=O and S=O groups present in the asphalt, which indicates a greater level of asphalt aging. C=O and S=O possess a stronger polarity than -CH2- and -CH3, leading to stress concentration in asphalt during the loading process, which eventually causes asphalt embrittlement. After UV aging and PAV aging, the increase in the number of C=O and S=O of 30# asphalt is the smallest among the three asphalt grades. This difference could be related to the composition of asphalt, as indicated in figure 11, where the absorption of 30# asphalt characteristic peaks for CH2 and CH3 stretching is relatively higher. The significantly distinct chemical structures and compositions in the 30# asphalt are beneficial for enhancing UV aging resistance.

Figure 12. Functional group index of the three asphalts with different aging conditions.

Download figure:

Standard image High-resolution imageAccording to figure 12, there is an upward trend in both CI and SI with an increase in asphalt grade (30#, 50#, 70#). Within the same asphalt grade, the order of CI and SI is as follows: PAV aged > UV aged > Virgin. As the values of CI and SI increase, the number of C=O and S=O groups present in the asphalt also increases, resulting in a higher degree of asphalt aging. Since C=O and S=O exhibit stronger polarity than -CH2- and -CH3, the loading process is more likely to cause stress concentration in asphalt, leading to asphalt embrittlement. The increase in the number of C=O and S=O of 30# asphalt after UV aging and PAV aging is the smallest among the three asphalt types. This difference may be attributed to the composition of asphalt, as demonstrated in figure 11, where the absorption of 30# asphalt characteristic peaks for CH2 and CH3 stretching is relatively higher, indicating significant differences in chemical structures and compositions that are conducive to enhancing the UV aging resistance.

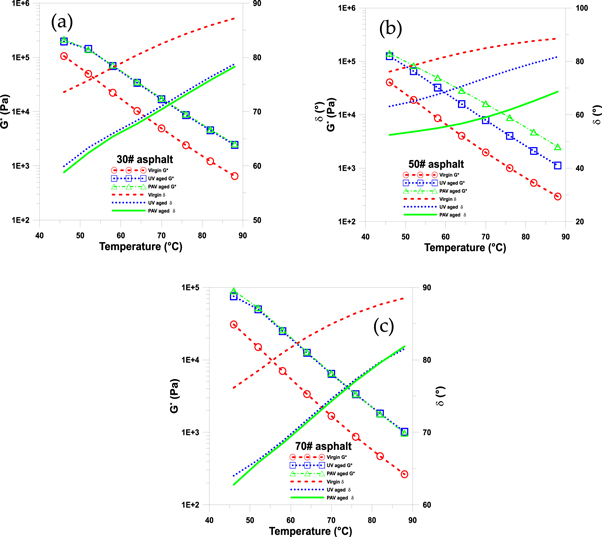

4.4. High temperature rheology evaluation

Figure 13 showcases the complex modulus (G*) and phase angle (δ) of three different types of asphalt, namely virgin, UV-aged, and PAV-aged. The complex modulus determines the asphalt's capacity to resist deformation at elevated temperatures, with higher values indicating superior resistance. Conversely, the phase angle indicates the ratio of an asphalt's viscosity to its elasticity, with lower values indicating greater elasticity. As depicted in figure 13, the complex modulus of 30# asphalt decreases, while the phase angle increases, as temperature increases across all three aging conditions. However, after undergoing UV aging and PAV aging, the complex modulus increases, and the phase angle decreases, compared to the virgin asphalt. This indicates that under UV and PAV aging conditions, the asphalt's viscosity decreases, thereby enhancing its ability to resist deformation, ultimately resulting in improved deformation resistance and reduced rutting in high-temperature environments. Additionally, both UV aging and PAV aging have a similar effect on asphalt regarding complex modulus and phase angle. Furthermore, figures 13(b) and (c) exhibit similar changes in complex modulus and phase angle for 50# and 70# asphalt compared to figure 13(a).

Figure 13. Complex modulus and phase angle of the three asphalts under different aging conditions.

Download figure:

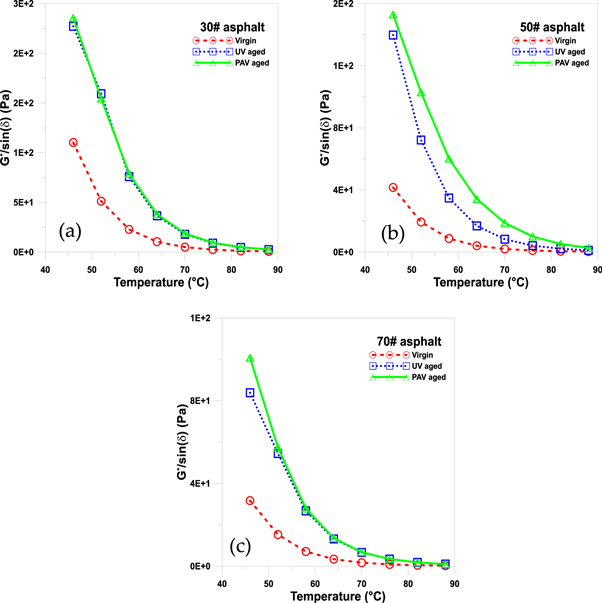

Standard image High-resolution imageFigure 14 displays the rutting factors of asphalt under varying aging conditions, indicating the asphalt's capacity to resist deformation under high temperature. Notably, higher rutting factor values correspond to greater rutting resistance. Based on the findings of figure 14, the rutting factor of 30# asphalt decreases significantly with an increase in temperature, while the differences in rutting factors under diverse aging conditions gradually diminish. At a given temperature, the rutting factor follows the sequence of PAV aged > UV aged > Virgin, implying that the effect of UV aging on asphalt's rutting factor is less pronounced than that of PAV aging under the current experimental conditions. For 50# and 70# asphalt, the rutting factor exhibits a similar pattern of variation to that of 30# asphalt, but the values are lower under identical testing conditions.

Figure 14. Rutting factor of the three asphalts under different aging conditions.

Download figure:

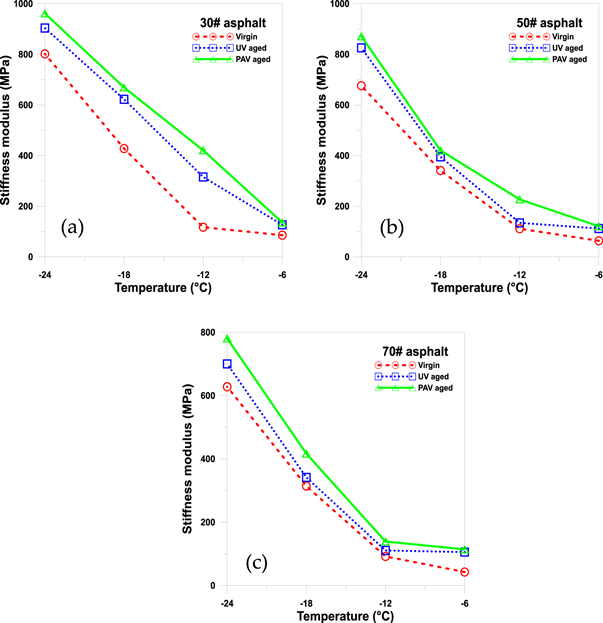

Standard image High-resolution image4.5. Low temperature property evaluation

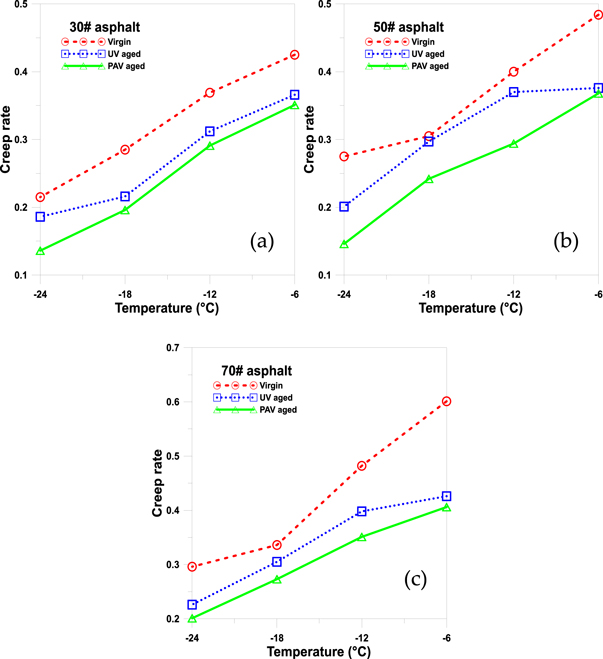

The stiffness modulus and the creep rate of the three asphalts before aging, after UV aging, and after PAV aging are shown in figures 15 and 16.

Figure 15. Stiffness modulus of the three asphalts under different aging conditions.

Download figure:

Standard image High-resolution imageFigure 16. Creep rate of the three asphalts under different aging conditions.

Download figure:

Standard image High-resolution imageThe stiffness modulus (S) is a critical parameter that characterizes the ability of asphalt to withstand low-temperature deformations, which is a fundamental requirement for asphalt pavement design and construction. A lower S value signifies a decreased risk of asphalt binder cracking when exposed to low temperatures. Conversely, the creep rate (m) refers to the rate of change of stiffness modulus with respect to time and reflects the asphalt binder's stress relaxation ability. A higher m-value corresponds to a more significant stress relaxation capacity, which reduces the likelihood of asphalt cracking. Hence, at a given temperature, a low S-value and a high m-value are desirable to enhance the resistance against low-temperature cracking of asphalt binder.

Based on figures 15 and 16, it is evident that the stiffness modulus of asphalt increases as the temperature decreases, while the creep rate decreases. Specifically, at a certain temperature, the stiffness modulus of the PAV-aged asphalt exhibits the highest value, followed by the UV-aged asphalt, whereas the virgin asphalt exhibits the lowest stiffness modulus. In contrast, for the creep rate, the PAV-aged asphalt exhibits the lowest value, followed by the UV-aged asphalt, whereas the virgin asphalt exhibits the highest creep rate. These findings suggest that the impact of UV aging on the low-temperature performance of asphalt is less significant than that of PAV aging.

After analyzing 30#, 50#, and 70# asphalt under identical aging conditions and testing temperature, a comparative analysis was performed, revealing that the stiffness modulus follows an order of 30# > 50# > 70#, and the creep rate follows an order of 70# > 50# > 30#. These findings suggest that the low-temperature performance of asphalt decreases with a decrease in asphalt grade (penetration). Additionally, PAV aging is shown to have a more negative impact on the low-temperature performance of asphalt when compared to UV aging. This observation highlights the importance of the material composition and molecular weight distribution of low-grade asphalt in its low-temperature cracking resistance. Specifically, the decrease of lighter molecules and increase of heavier molecules after UV aging are critical factors that impact the low-temperature performance of low-grade asphalt.

5. Conclusions

A multiscale study was conducted on low-grade asphalt under different aging conditions, including virginity, ultraviolet (UV) aging, and pressure aging vessel (PAV) aging. The investigation was carried out in the context of the Ruoqiang to Minfeng highway construction project in the southern region of the Taklamakan Desert, Xinjiang. The results are as follows:

- (1)The surface roughness of three asphalt grades (30#, 50#, and 70#) increased after UV aging by 15.50%, 5.99%, and 2.70%, respectively, compared to their virgin state. Consequently, the adhesion force, adhesion work, and surface free energy of the asphalt decreased. The impact of UV aging on the adhesion properties was more pronounced for higher-grade asphalt.

- (2)After UV aging, the weight-average molecular weight of the asphalt grades significantly increased. Notably, the 30# asphalt showed the highest percentage increase (26.96%), while the 50# and 70# asphalts experienced increases of 51.92% and 43.76%, respectively. This increase in molecular weight was attributed to the higher proportion of large molecules in the virgin 30# asphalt, which slowed down the rate of the UV aging reaction.

- (3)As the asphalt grade increased, both the carbonyl index (CI) and sulfone index (SI) increased accordingly. Among the various aging conditions, PAV aging had the greatest impact on CI and SI, followed by UV aging and virgin asphalt. The 30# asphalt exhibited a relatively lower increase in C=O and S=O after UV aging compared to the other two asphalt grades.

- (4)The study revealed that under the applied testing conditions, UV aging had a lesser impact on the high- and low-temperature performance of asphalt compared to PAV aging. Moreover, the material composition and molecular weight distribution of low-grade asphalt significantly influenced its low-temperature cracking resistance.

Data availability statement

The data cannot be made publicly available upon publication because they are not available in a format that is sufficiently accessible or reusable by other researchers. The data that support the findings of this study are available upon reasonable request from the authors.

Author contributions

L S: Conceptualization, funding acquisition, writing—original draft preparation; L H: methodology, software, investigation, visualization; P T: investigation, data curation; P F: formal analysis, visualization; Y L: investigation; J G: writing—review and editing, resources, funding acquisition.

Funding

This study is jointly found by the Tianshan leading talents in scientific and technological innovation (2022TSYCLJ0045), Natural Science Foundation of Xinjiang Uygur Autonomous Region, China (2020D01A92), Science and Technology Projects of Xinjiang Communications Investment Group Co., Ltd (ZKXFWCG-202211-010).