Abstract

In this paper, molecular dynamics (MD) simulation software LAMMPS is used to simulate the elastic properties and stability of Ti-V single-crystal alloys. The relationship between the elastic constant and the mechanical stability of Ti-V alloy with a body-centered cubic (BCC) structure is studied. The energy relationship between TiV alloys with hexagonal close-packed (HCP) structure and BCC structure are compared, respectively. The effects of temperature, crystal orientations, and V content on the mechanical properties of TiV alloys are calculated under uniaxial tensile test. The results show that both ultimate tensile strength and plasticity of the Ti-V alloy with BCC structure decrease with the increase of temperature and V content, due to the phase transition from the BCC structure to the face-centered cubic (FCC) structure. Finally, it is identified that the modes of the transformation from BCC structure to FCC structure during the tensile process are BCC(100)//FCC(110), BCC(010)//FCC(10).

Original content from this work may be used under the terms of the Creative Commons Attribution 4.0 licence. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

1. Introduction

Titanium and its alloys are widely used in high-temperature heating building materials. The Ti-V alloy with a BCC structure has been widely used in the development of high-temperature structural components in nuclear reactors and automotive industries and aerospace [1]. In principle, pure BCC titanium may be a good choice for high temperature applications, but it only exists at high temperatures above 1155 K, and it is dynamically unstable at low temperatures. Alloying with vanadium, molybdenum, iron, manganese, niobium and other elements can stabilize the high-temperature BCC phase of titanium at a temperature below 1155 K. As a model system, the BCC titanium-vanadium alloy is dynamic and thermodynamically stable over the entire concentration range at high temperatures, but cannot exist stably at low temperatures [2]. Therefore, the research on BCC Ti-V alloy, especially the analysis of its thermodynamic and mechanical properties has aroused great interest.

The reported experimental Ti-V phase diagrams can be divided into two groups: with and without the isostructural phase separation line for the BCC solid solutions, respectively. Murray et al and Nakano et al pointed out that there is a reaction at 948 K: β-Ti,V = α-Ti + V [1]. However, Wei and Fowler [3] believed that this reaction was caused by oxygen impurities and pointed out that there is no stable monotectoid reaction was likely to exist in this system. Nowadays, the Ti-V phase diagram without monotectic reaction is the widely accepted diagram [4].

At present, most of the development of new materials is based on labor-intensive scientific research and expensive experimental research. In recent years, the most important and difficult task of condensed matter physics is to reduce labor intensity and reduce experimental expenses. First-principles methods serve as a powerful tool for generation of reliable data on thermodynamic properties [1, 5–7]. However, quantum mechanics cannot be used in isolation because it needs to consider the effect of electrons' behavior [8]. For this the reason, multi-scale simulation calculation based on the calculation parameters of quantum mechanics is a very promising large-scale material calculation method such as the Deep MD potential function (Deep learning package for many-body potential energy representation and molecular dynamics )developed by machine learning and the semi-empirical (Second Nearest-Neighbor Modified Embedded-Atom Method Potential)2NN MEAM potential function [9, 10]. The molecular dynamics software LAMMPS (Large-scale Atomic/Molecular Massively Parallel Simulator ) adopts the relevant parameters of quantum mechanics calculations and then combines Newton's second law to obtain large-scale calculation software, which has broad application space in materials, biomedicine, and chemical engineering [11].

Many scholars have studied the dynamic instability of titanium and the performance of the Ti-V system using first principle calculation methods. However, it is extremely difficult to calculate the instability of the BCC-Ti phase using the first principle calculation methods like density functional theory [12]. It is more accurate to determine the mechanical stability of the Ti-V system based on the elastic constant calculated using the first principle calculation method [13]. It is shown that the instability is relatively strong and C' (tetragonal shear modulus) is quite negative for BCC-Ti metal, However, alloying with vanadium rapidly increases C' and reduces the strength of the instability, it is in accordance with the behavior of the bcc phase line in the Ti-V alloy.

In this paper, the elastic properties, mechanical instability, and phase transformation of the Ti-V system under tensile loading are calculated based on the molecular dynamics software LAMMPS. First, the lattice constant and elastic constant of the BCC-TiV system are calculated. Then the relationship between the 3D representation surface of Young's modulus and phase stability is investigated in detail. Finally, the uniaxial tensile test simulation on the BCC-TiV single crystal was conducted for exploring the influence of the tensile deformation process on its mechanical properties under the effect of crystal orientation and temperature.

2. MD simulation process

MD simulation is performed using LAMMPS [11]. The simulations employ the modified embedded atom method (MEAM) potential developed by Maisel SB [14].

Since the different solid solution ratio of V in Ti directly affects the lattice constant in BCC- TiV, it is necessary to calculate the lattice constants for different BCC-TiV systems, and then calculate the elastic constants and perform tensile tests. The calculation process is shown in figure 1.

Figure 1. Calculation process.

Download figure:

Standard image High-resolution image2.1. Calculation of cohesive energy of Ti-V alloy

Owing to vanadium is a β-titanium (BCC structure) alloy stabilizing element, and the content of vanadium has a great influence on the stability of the Ti-V system, it is necessary to establish a HCP structure and a BCC structure respectively when calculating the cohesive energy of the Ti-V system. In the calculation of the HCP structure, the LAMMPS is applied to set a circulant matrix with a-axis and c/a-axis as parameters with consideration of the different substitution ratios of V to obtain the lattice constant a from 2.9 to 3.0, c/a from 1.5 to 1.7. The atomic ratio of vanadium is 1%, 10%, 30%, 50%, 70%, which correspond to the average cohesive energy of each atom.

The same method is also used to calculate the corresponding relationship between the lattice and the cohesive energy of the BCC Ti-V system.

2.2. Elastic constant and representation surface of Young's modulus

The elastic constant is a value calculated based on Hooke's law. Ordinary crystals need to calculate 21 independent elastic tensors [15]. For cubic crystal, there are three independent parameters: C11, C12, and C44. Therefore, the general form of Hooke's law can be reduced to formula (1):

They are connected to the tetragonal shear modulus

The elastic relations (Hooke's law) between the strain (ε) and stress (σ)matrices are mediated by the elastic compliance ( S ) or the elastic stiffness ( C ) matrices:

or

From the elastic equations, the relations between the compliance matrix and the stiffness matrix are

The elastic matrix for body-centered cubic has the form:

The relations between the elastic stiffness constants Cij and the elements of the compliance matrix Sij are found from equation (5) [16]:

The elastic properties of single crystals are completely determined by the elastic stiffness matrices and the elastic compliance matrices. In reality, polycrystalline materials are considered more often than single-crystal. The elastic properties of polycrystalline materials are determined by two independent elastic moduli: the shear modulus (G) and the bulk modulus (B).

The mechanical properties of polycrystalline materials are approximated in the Voigt-Reuß-Hill approach [17], where the bulk and shear moduli are given by arithmetic averages:

The bulk modulus B of a material characterizes its resistance to compressibility, whereas the shear modulus G characterizes its resistance to plastic deformations [18]. Young's modulus E also relates the bulk and shear moduli:

Unless all the elastic modulus Cij must be positive, otherwise the mechanical stability is still open [16]. Born et al developed a theory on the stability of crystal lattices [19]. For Body-centered cubic crystals, the five elastic stability criteria are given by:

The representation surface of Young's modulus for Body-centered cubic system is given by [20]:

where l1, l2, l3 are the three physical dimensions of space—length, width, and height in the 3D Cartesian coordinate system, respectively.

Studies have shown that the mechanical stability of β-Ti alloys with low elastic modulus can be determined based on the size of criterion E001 [21]. E001 is the Young's modulus of elasticity of the BCC crystal in the 〈001〉 crystal direction and its relationship with the elastic constant is shown in formula (11). When E001 is positive, its structure can exist stably. The anisotropy of single crystal BCC-TiV Young's modulus is so prominent that it is necessary to study the anisotropy of Young's modulus of single-crystal.

2.3. Modeling and analysis method of tensile deformation process

The BCC-TiV supercell is constructed to model the BCC structure, and part of Ti atoms are replaced using V atoms for the modeling (60 Å × 60 Å × 120 Å), and then the NPT (isothermal-isobaric) is performed for relaxation of the structure until the system stabilizes at a specific temperature. After the relaxation, both the uppermost atom (thickness of 10 Å) and the lowermost atom (thickness of 10 Å) of the structure are fixed. Periodic boundary conditions in the x and y directions and non-periodic boundary conditions in the z direction are applied, respectively. The temperature of the system is controlled under the NVT canonical ensemble and the stretching command is executed. And then the atomic stretching process is visualized through OVITO [22]. The V atom substitution model in Ti-V system is shown in figure 2.

Figure 2. BCC-TiV model with different V content: (a) V content is 20% in tensile direction 〈110〉, (b) V content is 20% in tensile direction 〈111〉, V content is 20% (c), 30% (e), 40% (g), 50% (i), 60% (k) in tensile direction 〈001〉, the V atomic position of BCC-TiV with a V content of 20% (d), 30% (f), 40% (h), 50% (j), 60% (k).

Download figure:

Standard image High-resolution image3. Results and discussion

During the MD simulation process, the relationship between the solid solution ratios of V and lattice constant, mechanical strength, phase stability of α-Ti of HCP structure and β-Ti of BCC structure were calculated.

3.1. Cohesive energy

The calculation result of the cohesive energy with the lattice constant is shown in figure 3(a), from which the lattice constant value corresponding to the lowest cohesive energy can be obtained. The correlation of the solid solution ratios of V in β-Ti with the change of the lattice constant can be obtained from figure 3(b). It can be seen from the figure that the lattice constant decreases from 3.23 Å to 2.99 Å (V) as the content of V in β- Ti increases. As can be seen the difference in the cohesive energy of the TiV alloy system of the HCP structure and the BCC structure in figure 3(c), the average atomic energy of the BCC structure is lower than that of the HCP structure after the V content exceeds 1%, therefore the TiV system with BCC structure is more stable than that with HCP structure as the V content increases. It is known that BCC-TiV cannot exist stably when the V content is 1% [23].

Figure 3. The effect of V content on the lattice constant in β-Ti: Hexagonal close-packed structure (a), Body-centered cubic structure (b), Comparison of minimum energy of two structures with different V content (c).

Download figure:

Standard image High-resolution imageIt can also be seen from figure 3(b) that the lattice constant corresponding to the lowest cohesive energy of BCC-TiV has a linear relationship with the V contents and gradually approaches the lattice constant of pure vanadium.

3.2. Elastic constant and structural stability of BCC-TiV alloy

Figure 4(a) shows the dependence of elastic constants C11, C12, C44 on V concentration in BCC-TiV alloy. It can be seen from figure 4(a) that C11 increases monotonously, C12 fluctuates from 100 GPa to 120 GPa, and C44 has a trend of increase firstly and then decrease, which is consistent with [14]. The V content increased from 10% to 90%, and C11 increased from 80.9 GPa to 227.49 GPa, which is consistent with the [21, 24]. The obtained elastic results for C11 show good quantitative agreement with the experimental data [21]. The fluctuation of the elastic constant of C12 within a certain range is due to the instability of BCC-TiV as previously report shown [14]. In the calculated result, C44 increases firstly and then decreases, which is slightly larger than the experimental value, but overall, it is within a reasonable range. The stability of the BCC structure can be judged using its elastic constant C'(or E001 ). When the elastic constant C' is greater than zero, its structure is relatively stable, otherwise its structure is not stable. The dependence of the elastic constant C' on V concentration is shown in figure 4(b). It can be seen from the figure that the calculated elastic constant C' gradually increases with the increase of V content, and it exceeds zero by about 15%–20%, which is consistent with the PAW-SQS of [5]. From the previous experimental and calculational results, it is known that when the V content in β-Ti is less than 20%, the elastic constant C' is less than zero, and this result is consistent with other papers [13, 24, 25]. This also shows that the calculation model is more suitable for predicting the phase stability of the Ti-V system.

Figure 4. Dependence of elastic constants C11, C12, C44 (a), elastic constant C' (b), Young's modulus E (c), bulk modulus B and shear modulus G (d) in the bcc Ti-V alloy. ([24]- Exp. T = 300 K, [21]-Cal., [5]-Cal.).

Download figure:

Standard image High-resolution imageIn addition, C12 and C11 do not have any exclusive physical basis; in other words, no phonon mode directly corresponds to these constants [16]. When vanadium is added, the number of valence electrons increases and the Fermi level shifts toward the higher energy practically without changing the shape of the band and provides atomic bonds. This effect leads to an increase in the elastic constant C11 and, as a result, to the mechanical stabilization of the alloy [5]. C12 is fairly constant over a large concentration region, which is related to the elastic instability of pure BCC titanium [14]. As can be seen from figure 4(c), the number of Young's modulus of elasticity is increased when vanadium is added. These parameters are of great significance for the development of titanium alloys with low elastic modulus. The bulk modulus B of a material characterizes its resistance to fracture, whereas the shear modulus G characterizes its resistance to plastic deformations as shown in figure 4(d).

Figure 5 shows the spatial distribution of Young's moduli E(r) of BCC-TiV single crystal with a V content of 50%, from which it can be seen that it has a relationship with the crystal orientation. Young's modulus of elasticity is the smallest in the 〈001〉 direction and the largest in the 〈111〉 crystal direction. Figure 6 shows the spatial distribution of Young's moduli E(r) with V content ranging from 20% to 70% in BCC-TiV alloy. It is easy to obtain that Young's modulus of elasticity increases in all crystal directions with the increase of V content. However, the increment of Young's modulus of elasticity in each crystal direction is different. With the increase of V content, both strength and mechanical stability of the BCC-TiV alloy system are enhanced, and the three-dimensional Young's elastic constant of the single crystal tends to be smooth. It can be seen from figure 6 that Young's modulus of β-TiV in each crystal orientation increases with the increase of V content, and the 〈110〉 crystal orientation in the (010) plane increases compared to the 〈001〉 crystal orientation. The content of V in β-TiV increases from 20% to 70%, and Young's modulus in the 〈001〉 direction increases from 4.1 GPa to 111 GPa. Since the elastic constant in the Ti-V system is highly dependent on the crystal orientation and V content, it will affect the strength and plasticity.

Figure 5. Calculated spatial distribution of Young's moduli E(r) of Ti0.5V0.5 compounds.

Download figure:

Standard image High-resolution imageFigure 6. Sections of BCC-TiV alloy with different V content in the 2nd and 3rd quadrants. (a) 20% V, (b) 30% V, (c) 40% V, (d) 50% V, (e) 60% V, (f) 70% V.

Download figure:

Standard image High-resolution image3.3. Uniaxial tensile test simulation

The metal with conventional BCC structure exhibits low temperature brittleness, that is, it exhibits better plasticity at high temperature while brittle fracture at low temperature. This is related to the screw dislocation movement activation of BCC metal. Screw dislocations are affected by interstitial elements, metal bond types and exhibit brittleness at low temperatures [26]. It can be seen from figure 7 that as the temperature increases, the strength and elongation of BCC-TiV decrease. Figure 8(a) displays a diagram of the atomic evolution process of BCC-TiV with 20% V content stretched along the 〈001〉 direction at 1 K and 300 K. The tensile yield strength of 25 GPa is obtained with stretching system temperature of 1 K (the stretching process avoids the influence of thermal activation energy). When the number of stretching steps reached 400,000 steps, that is, the deformation was about 40%, the system also showed yielding, and no crack source was found. In the stretching process, Moreover, there is a phase transformation process that the BCC structure transforms into FCC structure. When the tensile temperature is 300 K, Ti-20%V shows yield at about 200,000 steps, and only part of the BCC structure is transformed into a face-centered cubic structure before yielding. Comparing the atomic cloud diagram of Ti-20%V tensile deformation with different crystal orientations as shown in figure 8(b), 〈111〉 crystal orientation shows the largest Young's elastic modulus. The stretching of the 〈111〉 crystal orientation and the 〈110〉 crystal orientation does not show the phase transformation process, i.e., the change process of BCC structure to FCC structure.

Figure 7. Tensile curves of BCC-TiV alloy with 20% V content at different crystal orientations and different temperatures.

Download figure:

Standard image High-resolution imageFigure 8. Atomic evolution diagram of BCC-TiV alloy with 20% V content at different temperatures (a) and (b) different orientations.

Download figure:

Standard image High-resolution imageFigure 9(a) shows the stress-step curves of BCC-TiV single crystal alloy with different solid solution ratios V ranging from 20% to 60% in the [001] crystal direction.

Figure 9. BCC-TiV alloy stress-step curves (a) and atomic evolution diagrams (b) of different V content.

Download figure:

Standard image High-resolution imageAs the V content increases, Young's modulus of single crystal increases due to the solid solution strengthening, while the strength decreases and the plasticity deteriorates. In order to explain it, the atomic evolution process of the tensile process of 30% and 40% vanadium content of BCC-TiV alloy are calculated, as shown in figure 9(b). When the vanadium content in BCC-TiV alloy is 30%, the phase changes from BCC structure to FCC structure before 200,000 steps, and a HCP structure appears after 200,000 steps. The appearance of HCP structure may be related to the formation of crack source. The transformation from BCC structure to FCC structure is the result of a combination of elastic and plastic deformation during the stretching process. When the vanadium content in BCC-TiV alloy reaches 40%, the transition rate of the material from the BCC structure to the FCC structure is lower due to the increased phase transition stability. The tensile curve shows that the structural transformation is relatively stable, and the ratio of the FCC structure determines the decrease in plasticity and strength of the material.

A unit cell stretch diagram (figure 10) is adopted for analyzing the mechanism of conversion of BCC structure to FCC structure. The coordination number of BCC is 8, and the closest distance to the central atom is r = √3/2a (a is the lattice constant). Because the BCC structure is transformed into the FCC structure during the stretching process, it is a process of elastic or plastic deformation. According to the stretching deformation process, when stretching in the Z direction, the other two dimensions remain unchanged. Therefore the formula:

Figure 10. Crystal deformation during stretching (before (a) and after (b)).

Download figure:

Standard image High-resolution imageVBCC is the volume of BCC-TiV before stretching, and VFCC is the volume of the system after the BCC structure is converted to the FCC structure. The coordination number of the atom of the FCC structure is 12 and its coordination distance is r'.

Combining the above formula, it can be obtained that the z-direction stretches by 1.414 times. This also means that without temperature influence the material can realize the conversion of BCC to FCC in about 375,000 steps. When the vanadium content is 20% and the temperature is 1 K, 67.8% of the BCC structure transforms to FCC structure at 260000 steps. This is due to vanadium being a stable element of β-Ti.

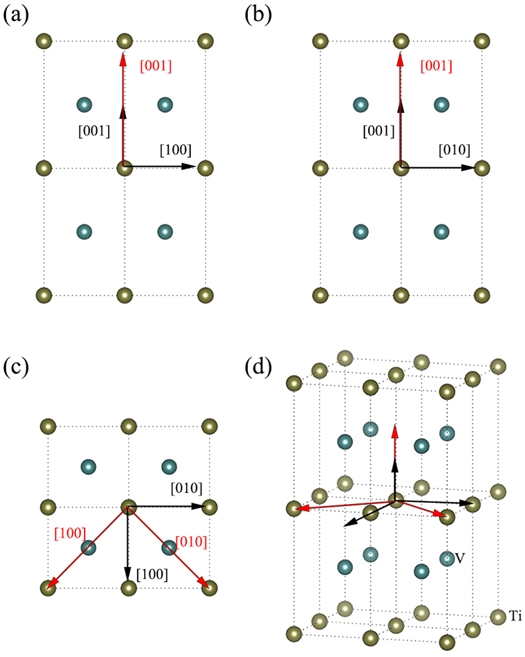

As shown in figure 11, the z-axis direction does not change, and the x-axis and y-axis directions are rotated 45° clockwise, which is the crystal orientation of the FCC crystal convert by BCC, and the crystal plane changes to BCC(100)//FCC(110), BCC(010)//FCC(-110). The lattice constant is 1.414 times the original lattice constant. This phenomenon has also been confirmed in single crystal stretched BCC-Ta materials [22].

Figure 11. BCC (Black)) crystal to FCC(Red) crystal conversion diagram: (a) front view, (b) R side view, (c) top view, (d) overall view.

Download figure:

Standard image High-resolution imageThe above analysis shows that the BCC-TiV alloy system will undergo a BCC vertical direction FCC phase transformation process in the stretching process along the 〈001〉 direction. This phenomenon is caused by lattice deformation. Increasing the the whole system temperature and the β-Ti (BCC) stabile element V will hinder the phase transformation from BCC structure to the FCC structure. After tensile fracture occurs, the FCC structure will return to BCC structure, which indicates that the transformation of the BCC structure into a FCC structure is an elastic deformation process. Since the BCC-Ti stabile element V will hinder this phase transformation, the calculation process without the elastic deformation process may cause a misjudgment of the short-range order of the Ti-V system.

4. Conclusion

In this paper, the molecular dynamics simulation software LAMMPS is used to calculate the cohesive energy of the HCP structure and the BCC structure of the TiV alloy system. The conclusions for the tensile fracture deformation calculation of the TiV system at different crystal orientations and temperatures as below:

- (1)The Young's elastic constant C11 of BCC-TiV single crystal alloy shows an increasing trend with the increase of V content, C44 fluctuates within a certain range, and the solid solution ratio of V in BCC-TiV alloy exceeds 15%, BCC-TiV can exist stably.

- (2)BCC-TiV single crystal alloy will show the phase transformation deformation from BCC structure to FCC structure during the tensile deformation along the 〈001〉 crystal orientation. With the increase of V content, the tensile strength and the elongation decrease. Both tensile strength and plasticity are decreased with increase of temperature. This phenomenon is mainly caused by the increase of V content, which hinders the transformation from BCC to FCC structure.

- (3)The deformation process from the BCC to the FCC structure during the stretching process of the BCC-TiV single crystal alloy is mainly caused by the elastic deformation of the crystal lattice. Phase transformation occurs throughout the entire tensile deformation process from the BCC structure to the FCC structure. The transition mode is BCC(100)//FCC(110), BCC(010)//FCC(10).

Data availability statement

The data that support the findings of this study are available upon reasonable request from the authors.