Abstract

A comparative study of Mo/B4C and MoxC1-x/B4C multilayers deposited by DC magnetron sputtering technology was presented in this paper. Using a homemade real-time stress measure instrument, the stress of two kinds of multilayers was investigated. Characterizations of the multilayers before and after annealing were performed by grazing incident and at-wavelength near-normal incident x-ray reflectivity. Experimental results show that after replacing Mo by MoxC1-x, MoxC1-x/B4C multilayers obtain relatively smaller compressive stress compared with Mo/B4C multilayers. The corresponding stress value changes from −0.99 GPa to −0.36 Gpa. MoxC1-x/B4C multilayers have also proven to have better thermal stability up to 600 °C. After repeatedly annealing from 100 °C to 600 °C, Mo/B4C multilayers had a ∼2% decrease in near-normal incident reflectivity, while MoxC1-x/B4C multilayers had a smaller 1.4% loss of reflectivity and a higher stability temperature.

Export citation and abstract BibTeX RIS

Original content from this work may be used under the terms of the Creative Commons Attribution 4.0 licence. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

1. Introduction

Multilayers were successfully used for focusing [1–3], reflecting, and filtering [4, 5] beams from various x-ray sources [6]. Multilayers also allowed the use of normal incidence optics in the soft x-ray regime and substantially enhance the x-ray reflectivity of the optical substrates [7]. Particularly, when multilayers were used under intense x-ray beams, their stability was found even more important than initial high reflectivity [8, 9]. In some experiments, the multilayer-based optics were subject to strong heat loads without cooling system, thermal load may lead to interdiffusion of atoms and subsequent compound formation at the interfaces of multilayers, consequently reducing optical contrast and causing a lower reflectivity [10].

Normal-incidence multilayers operating at 6.6–7 nm wavelength range require a period thickness around 3.5 nm. The interfaces in these short-period multilayers constitute a larger fraction of the multilayer period, thus the interface imperfections, such as interfacial roughness and interdiffusion, play a bigger role in the multilayer performance [11]. High reflectivity was demonstrated with multilayer pairs with B4C used as a spacer layer and La, Ru, Mo or W used as an absorber layer [12, 13]. Theoretically, La/B4C and Ru/B4C give the higher normal incidence reflectivity. However, some disadvantages result in lower experimental value. Previous studies conducted investigations on at-wavelength performances of B4C-based multilayer systems. The La/B4C multilayer structures give the highest reflectivity (40% with 250 bilayers) as compared to other material combinations. However, the active chemical properties of La make it difficult to preserve the high reflectivity of La/B4C multilayers. After annealing at 250 °C, a maximum relative reflectivity loss of 13.4% was found in La/B4C multilayers [13]. After annealing, the serious interdiffusions between Ru and B4C layers make multilayer unsuitable for some applications with high thermal load. For soft x-ray free electron laser. the reflectivity dropped from 20% to 10% after annealing at 500 °C for 1 h [14]. W/B4C multilayers can form smooth interfaces and prove to be thermally stable. Reflectivity of 8% was obtained using W/B4C multilayer consisting of 50 bilayers at the 15° off normal incidence, while the measured reflectivity dropped 1% after 500 °C annealing [15]. We have chosen the Mo/B4C multilayer bilayers in this study because B4C can form relatively smooth interfaces with Mo [16], and Mo/B4C has higher theoretical reflectivity compared to W/B4C multilayers within 6.6–7 nm wavelength range.

Mo/B4C, as a promising material pair of multilayer for the 6.6–7 nm wavelength range, the thermal stabilities of its stress and interface have been extensively studied [17, 18]. Based on the previous results, the main shortcomings of Mo/B4C multilayers are high intrinsic stress and serious interfacial roughness [19], in which the interfacial roughness was the primary cause of low reflectivity. Similarly, a Ru/B4C multilayer with 4 nm period thickness was found to be characterized by a compressive stress of −1.5 GPa [20]. A W/B4C multilayer was reported to have a stress value of −1.51 Gpa, after introduction of reactive sputtering, the stress value is reduced to −0.42 Gpa [21].

It has been observed that serious interdiffusion expansion occurred in Mo/B4C multilayers upon annealing. The phenomenon of both period expansion and compaction were observed during annealing, depending on the thickness of the B4C layers, annealing temperature and annealing time [22]. An increase in multilayer period thickness was observed for annealed La/B4C multilayers. After annealing at 250 °C, a period expansion of 0.6% was found [13]. Similar trend has been found in the W/B4C multilayers. The W/B4C multilayers experience an expansion of 1% after annealing at 500 °C, the period thickness remains the same after annealing at 700 °C and above [15].

Note that while reducing the stress, the introduction of roughness should be avoided especially for multilayers with short period. As a substitute for Mo, Mo2C can effectively optimize the multilayer interface characteristics while reducing the multilayer film stress [23]. In this paper, we fabricated the co-sputtering MoxC1-x/B4C multilayer and compared their stress and thermal performances with the conventional Mo/B4C multilayers.

2. Experiments details

A direct current (DC) magnetron sputtering deposition system was used to fabricate Mo/B4C and MoxC1-x/B4C multilayers on silicon substrates. The machine has 3 targets: Mo target, C target and B4C target. All the Mo/B4C and the MoxC1-x/B4C multilayers used in this study consisted of 100 bilayers. The multilayer period thickness was 3.6 nm and the thickness ratio of Mo (MoxC1-x) layer to the period, Γ = dMo (MoxC1-x)/D, was 0.4. The sputtering was performed with the argon gas pressure of 2 mTorr. While depositing the MoxC1-x layers, Mo and C targets were adjusted at an included angle in order to achieve Mo and C co-sputtering. The power of C target was changed as the period increased in order to control the carbon concentration in Mo and C co-deposited layer. The powers of C were 0 W, 20 W, 40 W, 60 W, 80 W, and 100 W, where 0 W of C power corresponds to a Mo/B4C multilayer structure. For each individual C power, MoxC1-x/B4C multilayers consisting of 6 bilayers were deposited on the substrate.

The curvature of each substrate was measured after each Mo (MoxC1-x) or B4C layer was deposited on the substrate. The measurement was performed using a homemade real-time stress measure instrument. This system mapped the curvature of the substrate related to the stress of the multilayers by a laser matrix with a wavelength of 694.3 nm. The differences in the reflected beam spacing on substrates were used to calculate the stress-induced curvature by Stoney's equation [24]. The real-time stress measure instrument was used to optimize C power corresponding to the lowest stress value.

All samples for thermal annealing and characterization were made with the same C power corresponding to the lowest stress value.

All the samples were divided into three groups for different annealing processes. All the samples were annealed in vacuum chamber of the DC magnetron sputtering machine at the pressure of residual gas atmosphere below 2 × 10−4 Pa. The first group of samples was annealed six times at the constant temperatures of 100, 200, 300, 400, 500 and 600 °C respectively. During each annealing process, the annealing temperature was maintained for 1 h and then cooled. The second and the third group of samples were annealed for only once at 400 °C or 500 °C for 1 h. The samples were determined by grazing incident x-ray reflection (GIXRR) at Cu Kα-line and at-wavelength near-normal incident reflectivity measurements around 6.7 nm before and after each annealing cycle. X-ray reflectivity measurements were performed at the BL08B beamline of the NSRL at 10° off normal incidence. Table 1 shows the group name of prepared multilayer samples and the corresponding annealing methods and test methods, each group included two samples: Mo/B4C and MoxC1-x/B4C multilayers.

Table 1. Parameters, annealing process and measurement of samples.

| Annealing process | Measurement | |

|---|---|---|

| MoxC1-x/B4Cwith different C powers | Non | Real-time stress measurement |

| Group A | Annealed 6 times at temperatures between 100 °C to 600 °C for total 6hs | GIXRR, Reflectivity measurement |

| Group B | Annealed at 400 °C for 1 h | GIXRR, Reflectivity measurement |

| Group C | Annealed at 500 °C for 1 h | GIXRR, Reflectivity measurement |

3. Results and discussion

3.1. Stress measurement

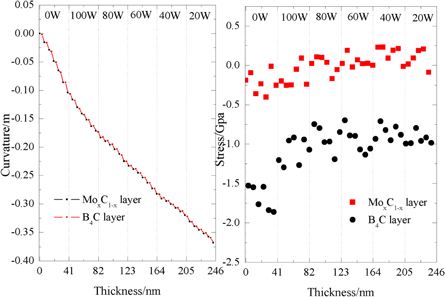

Measurements of the curvature obtained from one sample for 6 different C powers are shown in figure 1(a). Figure 1(b) shows the corresponding stress values of each MoxC1-x and B4C layer in the multilayer. The layer thickness was calculated from the GIXRR measured data. Measured results of the curvatures, the stress value of the entire MoxC1-x/B4C multilayers that correspond with each individual C power, and the standard deviation of the stress values and curvatures are shown in table 2.

Figure 1. Curvature and stress data as a function of multilayer thickness. Compressive stress is negative and tensile stress is positive.

Download figure:

Standard image High-resolution imageTable 2. Measured curvatures and stresses for sputtering under 5 different C powers.

| Power of C (W) | 0 | 20 | 40 | 60 | 80 | 100 |

|---|---|---|---|---|---|---|

| Curvature/m−1 | −0.10 ± 0.010 | −0.05 ± 0.009 | −0.04 ± 0.012 | −0.05 ± 0.008 | −0.05 ± 0.013 | −0.06 ± 0.011 |

| Stress/GPa | −0.99 ± 0.10 | −0.43 ± 0.08 | −0.36 ± 0.11 | −0.46 ± 0.08 | −0.51 ± 0.13 | −0.62 ± 0.11 |

Although the data contained a high level of noise, it was clear that curvature decreased more for Mo/B4C multilayer structure with C power of 0 when compared with other MoxC1-x/B4C multilayer structures. When the C power of co-sputtering was 40 W, the MoxC1-x/B4C multilayers reached the lowest stress value of −0.36 GPa.

Residual stress has proved to be related to microstructure in a multilayer system [25, 26]. In [21], the reduction of stress value is mainly caused by the crystalline-to-amorphous of W layer after the introduction of reactive sputtering. However, multilayers with period thickness of 3.6 nm and Γ = dMo (MoxC1-x)/D of 0.4, contain Mo layers that are much thinner than 2 nm, which is smaller than the critical thickness of the amorphous-to-crystalline transition of molybdenum [27, 28]. This means that the Mo layers in the multilayer are amorphous. The high compressive stress is suggested to mainly come from the stress of the interlayers, not from the polycrystalline structure of Mo layers. It is well known that at low plasma pressures, as used in this study, the material is deposited with a high packing density due to the large energy input by a high number of collisions with energetic Ar ions. This results in high compressive stress which is attributed to the peening-effect [28]. The interfaces are not perfect and the presence of interdiffusion cause the high stress. After the introduction of MoxC1-x layer, the interdiffusion improved significantly, which in turn reduced the stress of the multilayers. Based on above discussions, the thickness changes of the interlayers can effectively modulate the overall stress of the multilayers. Thickness changes of interlayers in the MoxC1-x/B4C multilayers, versus different C sputtering power, can partly explain the observed changes in stress with sputtering power of C in the MoxC1-x/B4C multilayers.

3.2. GIXRR measurement

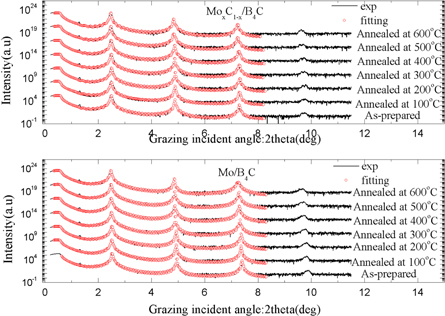

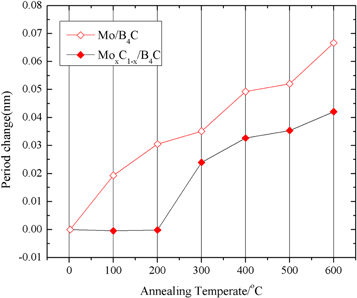

The GIXRR measured data of Mo/B4C and MoxC1-x/B4C multilayers in group A before and after annealing from 100 °C to 600 °C are shown in figure 2. After fitting the GIXRR data [20], the change of the period thickness can be found in figure 3.

Figure 2. GIXRR measured data and fitting data of as-prepared and annealed sample.

Download figure:

Standard image High-resolution imageFigure 3. Normalized multilayer period thickness change for three sets of samples as a function of annealing temperature. The multilayer period was normalized to the as-deposited value.

Download figure:

Standard image High-resolution imageAs depicted in figure 2, peak drift and broadening were observed, especially for Mo/B4C multilayers after annealing, which reveals that the period expansion and interfacial roughness/diffusion of Mo/B4C multilayers were more serious than that of MoxC1-x/B4C multilayers.

The period expansion can be explained by the relaxation of packing density as well as the growth of interlayers. The rich B and C elements in the interfaces results in the formation of relatively low-density compounds and the period expansion [29]. MoxC1-x is already a low-density molybdenum carbides compound which also reduces the growth of interlayers, and therefore reduces the period expansion. Results in the layer expansion can be observed here. A MoxC1-x/B4C multilayers expansion of <1% and Mo/B4C multilayers expansion of <2% were measured for annealing temperatures up to 600 °C.

Based on the GIXRR fitting results, after annealing for 6 h, the Mo-on-B4C interfacial roughness/diffusion of Mo/B4C multilayers increased from 0.3 nm to 0.7 nm, while that of the MoxC1-x-on-B4C interface increased from 0.2 nm to 0.4 nm. The B4C-on-Mo interfacial roughness/diffusion of the Mo/B4C multilayers increased from 0.6 nm to 1.5 while the B4C-on-MoxC1-x interfacial roughness/diffusion increased from 0.3 nm to 0.8 nm. The results in [29, 30] show that after annealing, the increase of interfacial roughness was negligible compared to that of the interdiffusion. So the broadening of Bragg peaks in the kinds of multilayers can be attributed to the fact that the increase of interdiffusion in Mo/B4C multilayers is much more serious than that in MoxC1-x/B4C multilayers.

The fitting results indicated the asymmetry of this multilayer system with a sharper Mo(MoxC1-x)-on-B4C interface and a more diffuse B4C-on-Mo(MoxC1-x) interface. After annealing, the B4C-on-Mo interfaces experience greater expansion than the B4C-on-MoxC1-x interfaces. The expansion of B4C-on-Mo(MoxC1-x) interfaces is more severe than that of the Mo(MoxC1-x)-on-B4C interfaces. After annealing, the difference in roughness/diffusion of the two interlayers changes from 0.3 to 0.8 in Mo/B4C multilayers, from 0.1 to 0.4 in MoxC1-x/B4C multilayers.

The fitting results also indicated that MoxC1-x/B4C multilayers have better thermal stability compared to La/B4C [13] and W/B4C [15] multilayers.

3.3. At-wavelength reflectivity measurement

All three groups of samples were measured by at-wavelength near-normal incident reflectivity at the BL08B beamline of the NSRL. The experimental and fitting results are shown in figures 4 to 6. Table3 compares the changes of the reflectivity, peak wavelength and the corresponding period fitting from the reflectivity measured data for two different multilayer pairs.

Figure 4. Reflectivity measurements (solid line) and fitting results (dotted lines) at 10° off normal incidence of the samples in group A before and after annealing 6 times from 100 °C to 600 °C.

Download figure:

Standard image High-resolution imageTable 3. Changes of reflectivity, peak wavelength and the corresponding period thickness of three groups of samples before and after annealing process.

| Material combination | ΔR | Δλ | ΔD | |

|---|---|---|---|---|

| Group A | MoxC1-x/B4C | −1.4% | 0.070 nm | 0.041 nm |

| Mo/B4C | −2.0% | 0.120 nm | 0.071 nm | |

| Group B | MoxC1-x/B4C | −0.4% | 0.035 nm | 0.021 nm |

| Mo/B4C | −0.9% | 0.055 nm | 0.033 nm | |

| Group C | MoxC1-x/B4C | −0.8% | 0.050 nm | 0.029 nm |

| Mo/B4C | −1.3% | 0.085 nm | 0.048 nm |

Figure 5. Reflectivity measurements (solid line) and fitting results (dotted lines) at 10° off normal incidence of the samples in group B before and after annealing at 400 °C.

Download figure:

Standard image High-resolution imageFigure 6. Reflectivity measurements (solid line) and fitting results (dotted lines) at 10° off normal incidence of samples in group C before and after annealing at 500 °C.

Download figure:

Standard image High-resolution imageThe results presented in table 3 show good agreement with the results calculated from the GIXRR data. Near-normal incident measurements with a synchrotron reflectometer are more sensitive to small changes in the multilayer period and reflectivity than grazing incidence measurements done with the Cu Kα-line. After annealing, the shift in peak wavelength and the decrease in reflectivity were obvious.

It has been reported that the annealing process leads to the broader interlayer and a negligible increase in interfacial roughness in Mo/B4C multilayers [31]. The reduction in peak reflectivity after annealing is due to the increase of interdiffusion, which reduces the optical contrast between two layers. Results of three annealing processes reveal the similar patterns, both Mo/B4C and MoxC1-x/B4C multilayers experienced a peak wavelength shift and a decrease in near-normal incident reflectivity, but the changes were more serious for Mo/B4C multilayers. The difference in the changes of two material combinations indicated that MoxC1-x/B4C multilayers had better thermal stability than Mo/B4C multilayers.

4. Conclusion

Experimental results show that, under 2 mTorr plasma pressures, with C power increased from 0 W to 100 W, MoxC1-x/B4C multilayers stress changes from −0.99 GPa to −0.36 GPa. The data for 40 W C power reveal the lowest stress. After annealing, both MoxC1-x/B4C and Mo/B4C multilayers experience peak shift toward a longer wavelength and a decrease in reflectivity. The shift in the peak wavelength and the decrease in reflectivity were more serious in Mo/B4C multilayers.

All the results show that stress property and thermal stability of MoxC1-x/B4C multilayers are much better than that of the Mo/B4C and other B4C-based multilayers. Therefore, the replacement of Mo layers by co-sputtering MoxC1-x layers can significantly improve the thermal stability and stress property of the multilayers.

Acknowledgments

This work is supported by the National Natural Science Foundation of China (Grant Nos. 11875204, U1932167, 11775295, and 11575127) the Fundamental Funds for Central Universities (No.221201880070) and the Funds from Youth Innovation Promotion Association, CAS (No.2018295).