Abstract

We report reversible dynamic behavior of a magnetic liquid metal marble by changing magnetic field polarity. We coated iron (Fe) particles on the surface of the oxidized liquid metal by HCl-based chemical reaction to make it to be magnetized and to be non-wettable. We utilized electromagnets and changed current direction on-demand to change the magnetic polarity of the electromagnet. In 1-dimension (1-D), with an applied magnetic field of reverse polarity from the bottom, the conventional wetting shape of the magnetic liquid metal marble was observed, whereas the split was occurred with the applied magnetic field of same polarity due to attractive or repulsive force. With an applied magnetic field of reverse polarity, the split marbles was merged. By removing the magnetic field, the deformed magnetic liquid metal marble was recovered. The applied current dependent deformability and recoverability, and split and merge time were investigated. In addition, in 2-dimension (2-D), we observed various deformations and split behavior of the magnetic liquid metal marble with various magnetic field polarity combinations by utilizing electromagnets, which is reversible.

Export citation and abstract BibTeX RIS

Original content from this work may be used under the terms of the Creative Commons Attribution 4.0 licence. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

The non-toxic liquid metal gets high attention due to its excellent material properties: metallic property such as high thermal and electrical conductivities and liquid property such as infinite deformability. However, it is very challenging to deform the gallium-based liquid metal as its surface is easily oxidized in oxygen-rich environment [1]. Many researches have been focused on the way to deform the liquid metal's shape on-demand for various applications such as tunable antenna [2–4], metamaterial [5, 6], electrical switch [7, 8], energy harvester [9], microvalve [10, 11] and pressure sensor [12, 13]. In order to deform the shape of the liquid metal, a variety of methods such as pneumatic [14, 15], electrochemical [16–19], magnetic [20–22], slip layer insertion [23] and electrowetting [24, 25] were utilized. Among them, the magnetic field method is one of promising methods as it has excellent advantages: the magnetic force can be remotely applied to the target magnetic material; and repulsive and attractive force can be selectively applied by changing the polarity of the magnetic field. Recently, we have investigated magnetic field-based manipulation of the magnetic liquid metal marble by utilizing permanent magnet [26]. We also demonstrated electromagnet-based manipulation in microfluidic channel and three dimensional manipulation which can be applied to the switching application [27, 28]. In this paper, we demonstrated various dynamic behaviors like conventional deformation, recovery, split, and merge of the magnetic liquid metal marble by changing magnetic polarities in 1-D and 2-D configuration of multiple electromagnets. We investigated the current dependent deformability and recoverability, split and merge time of the magnetic liquid metal marble.

In order to make the magnetic liquid metal marble, we measured the mass of a liquid metal droplet and the Fe particles using an analytical balance (AS 110.R1, Radwag) as shown in figure 1. We gently placed the liquid metal droplet (∼10 μL) and Fe particles (45 um diameter, 5 mg) on a glass substrate. Then, we dropped a ∼5 μL HCl droplet (37 wt%) to trigger the chemical reactions between the liquid metal and HCl solution, and between HCl solution and Fe particles [29, 30]. The liquid metal recovered a spherical shape resulting from drastic increase of the surface tension due to chemical reaction [31]. During the chemical reaction, bubble was generated on their interfaces and we found the Fe particle coated area was gradually expanding from the bottom to the top of the liquid metal droplet. The Fe particles surface coated liquid metal, as shown in figure 1(b), is called as a 'magnetic liquid metal marble' [32].

Figure 1. (a) Conceptual schematics and (b) optical images of making a magnetic liquid metal marble using iron particles and HCl solution.

Download figure:

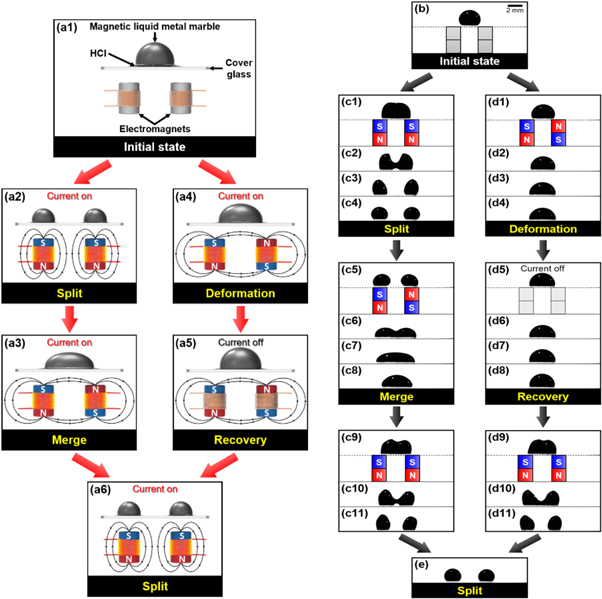

Standard image High-resolution imageThe magnetic liquid metal marble responded to the neighboring magnetic field. We utilized two electromagnets to apply attractive or repulsive force (refer to the supplemental material to see the configuration and characteristics of the electromagnet). Figure 2 shows conceptual schematics and optical images for reversible shape transformation of the magnetic liquid metal marble by changing polarities of two electromagnets. The magnetic polarity of the electromagnet was changed according to the direction of current flow by changing a bias (changing the positive voltage position). The magnetic liquid metal marble (vol. of Galinstan: 10 μL, mass of Fe particles: 10 mg) was placed on the cover glass substrate and the two electromagnets were placed underneath the substrate with 5 mm gap. By changing polarities of the magnetic field generated from the electromagnet, the magnetic liquid metal marble could be reversibly split, merged, deformed, and recovered as shown in figure 2 (refer to the movie #1). When the magnetic field of the same polarity generated from two electromagnets was applied to the magnetic liquid metal marble, the magnetic liquid metal marble was split into two small marbles which have approximately the same volume (figure 2(a2)). Then, by applying the magnetic field of the reverse polarity to two small marbles, they merged into one (figure 2(a3)). In addition, if the same polarity of magnetic field was applied to the merged magnetic liquid metal marble, the marble was reversibly split into two small marble again (figure 2(a6)). On the contrary, one magnetic liquid metal marble was deformed and wetted on the substrate when the magnetic field of the different polarity was applied to the marble because of the repulsive force in-between electromagnets, as shown in figure 2(a4). As the current applied to two electromagnets was turned off, the deformed magnetic liquid metal marble recovered its spherical shape similar to the shape before deformation (figure 2(a5)). When the magnetic field of the same polarity from two electromagnets was applied to the recovered magnetic liquid metal marble, the marble was also reversibly split into two small marbles in the same manner, as shown in figure 2(a6). From these results, we observed that various reversible shape transformation of the magnetic liquid metal marble was selectively achieved by controlling polarity of two electromagnets by simply changing current direction.

Figure 2. (a) Conceptual schematics and (b)–(e) optical images for reversible shape transformations of the magnetic liquid metal marble according to polarities of two electromagnets (refer to movie #1) .

Download figure:

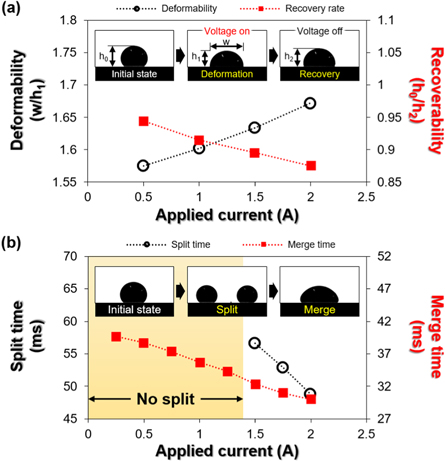

Standard image High-resolution imageBased on these phenomena, we calculated the deformability and recoverability of the magnetic liquid metal marble depending on the applied current (0 ∼ 2 A, 0.5 A step) to two electromagnets, as shown in figure 3(a). When we applied the different polarity of the magnetic field to the magnetic liquid metal marble, the marble was deformed. The experiment was recorded with a high speed camera (Phantom V7.3, USA). With the increasing applied current, the magnetic liquid metal marble was well wetted to the glass resulting in growth of deformability. The deformability (black-colored circle dot) was calculated by measuring a ratio between height (h1) and width (w) of the marble. The deformability increased linearly by increasing the current. The maximum deformability of the marble was ∼1.67 with the applied current of 2 A to two electromagnets. When the applied current was turned off, the deformed magnetic liquid metal marble recovered its spherical shape similar to its initial state. As the applied current increased, the deformed magnetic liquid metal marble gradually did not recover its initial height resulting in decrease of recovery rate. We could calculate the recoverability (red-colored square dot) by dividing h0 (initial height of the marble) by h2 which was height of the marble after turning off the applied current. With increasing the applied current to the electromagnets, the recoverability decreased linearly. The minimum recoverability of the marble was ∼0.88 when the current of 2 A was applied to two electromagnets. In addition, the split and merge time of the magnetic liquid metal marble were measured according to the applied current (0 ∼ 2 A, 0.25 A step) to two electromagnets (figure 3(b)). As the magnetic field of the same polarity was applied to the magnetic liquid metal marble, one magnetic liquid metal marble was split into two smaller marbles. The split time (black-colored circle dot) is the time taken for one magnetic liquid metal marble to be split into two small marbles by magnetic force. The ∼10 μL magnetic liquid metal marble was only split into two small marbles with current greater than 1.5 A. With current less than 1.5 A, the magnetic field intensity was not enough to split the marble. With current greater than 1.5 A, as the applied current was increased, the split time was decreased because of the stronger magnetic flux density generated from two electromagnets. The minimum split time of the marble was measured to be ∼48.8 ms by applying 2 A to each electromagnet. When the magnetic field of the different polarity was applied, the two marbles were merged into one magnetic liquid metal marble. We measured the merge time (red-colored black dot) which is time taken for the two marbles to be combined into one. The merge phenomenon occurred within the range of all currents (0 ∼ 2 A). With the increase of the applied current, the merge time gradually decreased. The minimum merge time of the marble was measured to be ∼30 ms with the applied current of 2 A to two electromagnets. Based on the split and merge time measurements, we concluded that the larger magnetic field generated by applying the larger current occurred the faster deformation (split and merge).

Figure 3. (a) Deformability and recoverability of the magnetic liquid metal marble against applied current, (b) applied current-dependent split and merge time of the magnetic liquid metal marble.

Download figure:

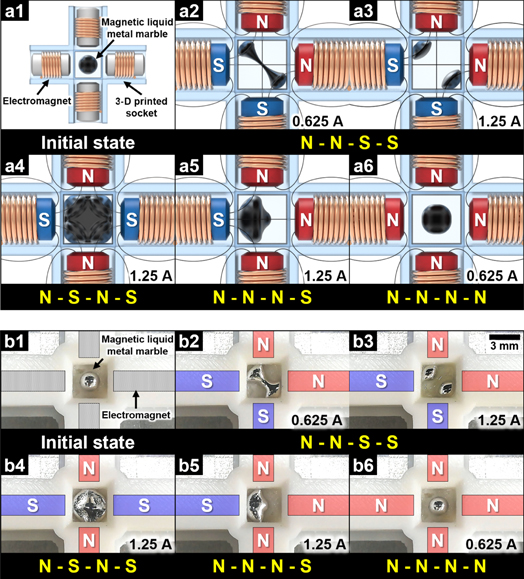

Standard image High-resolution imageWe also demonstrated various deformations of the magnetic liquid metal marble using various polarity combinations of the magnetic field induced by electromagnets in 2-D as shown in figure 4. We fabricated a 3D-printed Poly Lactic Acid (PLA) chamber in which the magnetic liquid metal marble was placed. Electromagnets werde placed symmetrically in four sides. For this demonstration, we used the ∼30 μL magnetic liquid metal marble coated with 30 mg Fe particles. A total of 5 different magnetic polarity combinations with varying currents were tried (polarity of 12–3–6–9 o'clock clockwise direction against the marble): (1) N-N-S-S with 0.625 A, (2) N-N-S-S with 1.25 A, (3) N-S-N-S with 1.25 A, (4) N-N-N-S with 1.25 A, and (5) N-N-N-N with 0.625 A. In the case of (1), the magnetic liquid metal marble was diagonally deformed maintaining a linear shape (Figures 4(a2), (b2)). In the case of (2), as the applied current increased from 0.625 A to 1.25 A, the deformed marble was split into two small marbles as shown in Figures 4(a3) and (b3). In the case of (3), as the polarity of the magnetic field was N-S-N-S, the marble was deformed to be like circular-shape and attached to sides of the chamber where four electromagnets are placed (Figures 4(a4), (b4)). In the case of (4), when three magnets of N pole and one magnet of S pole were used, the marble was deformed into the shape of semicircle with one side protruding (Figures 4(a5), (b5)). In the case of (5), with all four electromagnets maintain the same polarity, the magnetic liquid metal marble was under repulsive forces by electromagnets and formed a smaller circular shape (Figures 4(a6), (b6)).

Figure 4. (a) Conceptual schematics and (b) optical images of various deformations of the magnetic liquid metal marble using various polarity combinations using four electromagnets (refer to movie #2).

Download figure:

Standard image High-resolution imageThe polarity change of the magnetic field can be attributed to the reversible dynamic behavior of the magnetic liquid metal marble. By making the magnetic liquid metal marble whose surface was coated with Fe particles, the magnetic liquid metal marble was non-wettable and reacted to the magnetic field. Using fabricated electromagnets, attractive and repulsive force can be generated on-demand. Under repulsive force, the marble was split while the marble was deformed and merged under attractive force resulting in various reversible shape transformations of the magnetic liquid metal marble. With 4 electromagnets, the magnetic liquid metal marble's shape was variously changed by tuning the polarities of electromagnets. This diverse shape deformation of the magnetic liquid metal marble according to the magnetic polarity change shows the full potential for any tunable application working on the liquid metal active deformation.

Acknowledgments

This work was supported by the 2019 research fund of Leading Research Group of Myongji University in Korea.