Abstract

Pre-compression deformation at different strain levels (1.58%, 3.32%, 5.38% and 7.78%) along transverse direction (TD) are conducted to introduce (10–12) tensile twins at room temperature. The static recrystallization process is induced by annealing at 450 °C for 2 h. Then the stretch deformation is conducted at room temperature to investigate the fracture and formability of Mg sheet. The c-axis of grains tiltes from normal direction (ND) to transverse direction (TD) due to the tensile twins; however, the TD-rotated texture is inherited by the new recrystallized grains. The grains grow up and the size increases gradually as the pre-strain levels increasing. Due to the rotated orientation, the basal slips are favored and a larger Schmid factor is obtained on the pre-strained samples. The yield strength reduces, and the ductility increases. Besides, the strain hardening coefficient (n-value) increases and Lankford value (r-value) decreases at the same time. Owing to the TD-rotated orientation, the increased n-value and reduced r-value, the stretch formability is enhanced greatly. The Erichen value (IE-value) increases largestly from 2.83 mm to 5.74 mm which improves by 102.8%.

Export citation and abstract BibTeX RIS

1. Introduction

Recently, as the lightest structure metal, Mg alloys have been given much attention by aerospace, automotive and other industry sectors [1, 2]. However, the poor formability at room temperature limits its applications [3, 4]. As well known, the texture and grain size have significant effect on the improvement of formability of Mg alloy thin sheet. Chino et al [5] indicated that the (0002) pole figure was much random in the large grained AZ31 Mg alloys, leading to an enhancement of the formability. Zhang et al [6] conducted the pre-stretch deformation at a strain degree of 5% on AZ31 Mg alloy sheet. The grain size grew up from 7.2 μm to 35.3 μm after annealing process, however, the basal pole trent to be much more emanative and the Erichen value improved from 3.2 mm to 5.3 mm. Thus, the grain size controlling may be a potential approach to improve the stretch formability of Mg alloy sheet.

As well known, twins can rotate the grains away from basal plane, especially the induced tensile twin which is a soft orientation during the subsequent deformation [7, 8]. Besides, twinning has a significant effect on the recrystallization behaviors. The compressive twins can promote the grain nucleation due to the higher amount of storage energy. However, the recrystallization induced by tensile twins is rarely happened. The recrystallization at the site of tensile twins is mainly related to the strain-induced boundary migration (SIBM). It is reported that SIBM may affect the orientation of the new recrystallized grains as well. {10–12} tensile twins can rotate the grains by 86.3° away from the basal plane which is a soft orientation and does benefit to the sequent deformation. However, this titiled texture may rotate back to ND again after recrystallization. Previous research [9] indicated that the twins induced by the cold shear deformation were consumed and the orientation rotated again to basal plane after the annealing process on AZ31 Mg alloys. Martin et al [10] pointed out that the primary tensile twinning orientation did not help to the annealing texture and the intensity did not decrease on AZ31 Mg alloys. This indicated that some twinning orientations would rotate back to basal plane while some may still keep the parent orientation during annealing. The rotated twinning texture plays a good role to improve the stretch formability of Mg alloys. However, it is very easy to lost stability and bend failure during the deformation on a thin magnesium sheet due to the polarity of twinning.

Thus, the reports about pre-twins on Mg alloy thin sheet as well as the stretch deformation are rarely found so far. In this study, pre-compression strain on AZ31 Mg alloy thin sheet along TD are conducted by a special die. Then the microstructure evolution and the influence of induced basal texture weakening by tensile twins on stretch formability of Mg alloy sheet are investigated.

2. Materials and experiment procedure

The initial material investigated was commercial AZ31 Mg alloy thin sheet with a thickness of 1 mm. The samples with a size of 50 mm × 50 mm along length and width direction are cut from the as-received sheet. Then pre-compression strain was taken out along TD at a strain of 1.69%, 3.32%, 5.38% and 7.76% to introduce {10–12} tensile twins. During pre-compression test, the given punch distance is set, then the actual strain is calculated, respectively. Next all of the pre-twinning specimens are annealed at 450 °C for 2 h. The pre-twinned and annealed samples can be namely as A, B, C, D and E, which are summarized in table 1. In order to prevent bulking during pre-twins, the sheet pre-deformation fixture is designed, as shown in figure 1. The steel sheet is acted as the base plate on the top of Mg alloy thin sheet. During pre-strain, only the deformation on Mg sheet can be considered owing to the higher strength of the pressing plate. Besides, the grease was used as lubricant during pre-twinning.

Table 1. Summarize on various pre-treated Mg alloy samples.

| Sample code | Treatment history |

|---|---|

| Sample A | As received |

| Sample B | pre-compression 1.69% + annealing at 450 °C for 2 h |

| Sample C | pre-compression 3.32% + annealing at 450 °C for 2 h |

| Sample D | pre-compression 5.38% + annealing at 450 °C for 2 h |

| Sample E | pre-compression 7.76% + annealing at 450 °C for 2 h |

Figure 1. The schematic diagram of pre-twinning device on Mg thin sheet (1 and 4. splint; 2. fix plate; 3. connecting plate; 5 and 9. screws; 6. spicimens, 7. steel plate; 8. support pin; 10. steel spring plate.).

Download figure:

Standard image High-resolution imageTensile specimens were machined from various pre-deformed Mg alloy sheet along three directions (RD, 45°, and TD) with gauge length of 24 mm × 3 mm along length × width directions. Then tensile tests were carried out at strain rate of 10−3 s−1 at room temperature. The strain hardening exponent (n) was determined from tensile stress–strain curve. Lankford value (r) was determined by specimen tension to the uniform strain at 12%. During the Erichen test, rectangular specimens with the size of 45 mm × 45 mm from various Mg alloy pre-twined sheet are used at room temperature. The diameter of hemispherical punch is 20 ± 0.05 mm. The punch speed is 10 mm min−1 and the blank-holder force is set to 10 KN. The engine oil is used as a lubricant on the center of the samples.

The microstructure was measured by optical microscopy and SEM equipped EBSD detector. During OM observation, the samples are gridded using sand paper from 400 meshes to 2000 meshes. Then the samples are etched by the solution of 4.2 g picric acid, 10 ml acidic acid, and 10 ml distilled water and 100 ml ethanol. The optical microstructure is observed on a Leica optical microscopy (Leica 2500 M). During EBSD analysis, the samples are electrochemical polished by AC2 solution for 30 s at the temperature of −20 °C. The voltage is 20 V. Then the EBSD microstructures are analyzed on the SEM (GEOL GSM-7800F FEG SEM).

3. Results and discussions

3.1. Microstructure evolution

Optical microstructure evolution of pre-twined AZ31 Mg alloy sheet without annealing are shown in figure 2. From figure 2(a), equiaxed grains with the size of 9.6 μm are distributed in the as-received rolled Mg alloy sheet. However, twinning lamellas are emerged after pre-compression along TD. Besides, the amount of twins increases as the pre-compression strain increasing. As well known, the tensile twinning will start when the compression load is perpendicular to the c-axis of grains [11, 12]. Thus, the twinning lamellas are mainly {10–12} tensile twins.

Figure 2. Optical microstructures of AZ31 magnesium alloy sheet: (a) A, (b) B, (c) C, (d) D, (e) E.

Download figure:

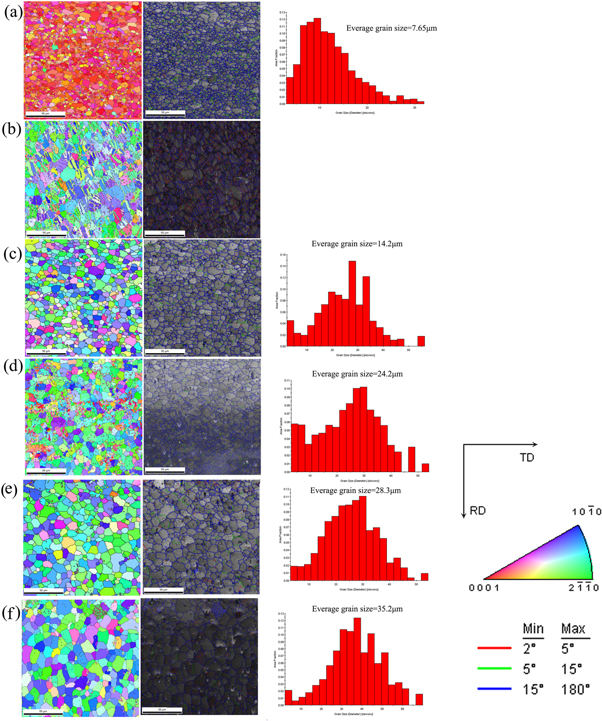

Standard image High-resolution imageFigure 3 shows the EBSD map on various pre-treated Mg alloy sheet. In as-received samples, most of the grains are laid on the basal plane which express a red color. However, the grains rotate away from the basal plane after pre-introducing twins no matter annealing or not. This means that the rotated twinning texture is still kept in new recrystallized grains after annealing process in pre-twined AZ31 Mg alloy sheets. However, the twinning lamellas in the sample D are {10–12} tension twins, as shown in figure 3(b). According to the grains boundary distribution map, the boundaries of various pre-strained and annealed samples are mainly high angle which is typical completed recrystallized boundary. The average grain size of sample A, B, C, D and E is about 9.6, 14.2, 24.2, 28.3 and 35.2 μm, respectively. The grains grow up gradually as the pre-strain increasing after annealing. Previous reports indicated that {10–11} compressive twins and {10–11}–{10–12} double twins can be regarded as the nucleation sites during recrystallization, however, the nucleation cannot take place even at the interaction of {10–12} tensile twins [13]. The recrystallization behavior induced by tensile twins may be mainly owing to the grain boundary migration (SIBM) [14, 15]. The induced strain dislocation increases as the pre-compression deformation increasing, the driving force of grain nucleation and growth increases at the same time. Thus, the grain boundary can move faster to the deformed regions. And the grains grow up more in the higher level pre-strained Mg alloys, as shown in figure 3. However, almost all the new recrystallized grains express the blue color which may be related to the initial twins.

Figure 3. EBSD maps of various AZ31 Mg sheet after annealing: (a) A, (b) pre-compression 5.38% without annealing, (c) B, (d) C, (e) D, (f) E.

Download figure:

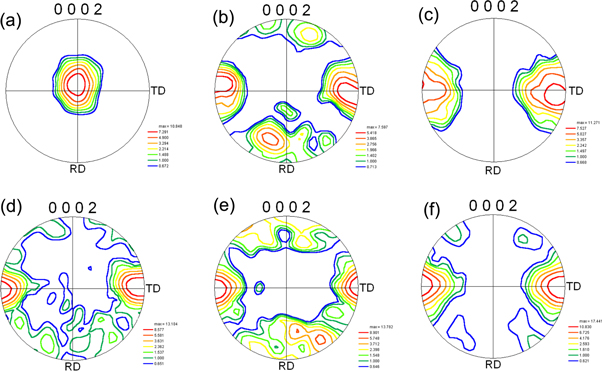

Standard image High-resolution image(0002) pole figures of various pre-treated AZ31 Mg sheet are expressed in figure 4. The rolled AZ31 Mg alloy shows a typical (0002) texture with the intensity of 10.85. After pre-twinning, the TD rotated texture is generated. The intensity of (0002) pole figure of sample B, C, D and E is about 11.27, 13.78, 14.81 and 17.44, respectively. In general, most of grains rotate towards to basal plane again after recrystallization behavior and the basal texture is generated. However, the TD-closed texture is still kept after annealing process at 450 °C for 2 h in this study. This may be owing to the SIBM [16]. After pre-twinning process, the recrystallization during annealing is still strain induced grain boundary migration (SBIM) due to the limited store energy in tension twins. {10–12} tensile twins are almost consumed by neighboring recrystallized grains during annealing. Thus, the orientation of twinning matrix is inherited by the new grains. And the TD-closed texture is still kept after annealing process at 450 °C for 2 h in this study (blue and green gains as shown in figure 3). As the pre-strain increasing, the volume fraction of twinning structures will increase at the same time. Thus, the store energy induced by twins is much larger which promote the recrystallization behaviors. As well know, the store energy induced by tensile twins is much smaller than compressive twins so that the limited store energy cannot meet the requirement for nucleation, while which is enough for growth [17]. The larger amount of tensile twins, the higher rate of grain growth will be. This results to a bigger grain size. Besides, the new grains during nucleation is mainly consuming the {10–12} tensile twins. This might be the main reason why a TD texture component is kept during grain growth. Xin et al [18] traced single parent grain on Mg alloys which was pre-compressed along ND and re-compressed along TD after sequent annealling at 250 °C for 1 h. The results showed that the orientation of new recrystallized grains was same with the adjacent parent matrix grains. It is similar in this study. As the volume fraction of twinning lamellas increasing, more grains rotate to TD and the twinning-inherited texture is enhanced.

Figure 4. (0002) pole figures of various pre-compressed AZ31 Mg sheet after annealing: (a) A, (b) pre-compression 5.38% without annealing, (c) B, (d) C, (e) D, (f) E.

Download figure:

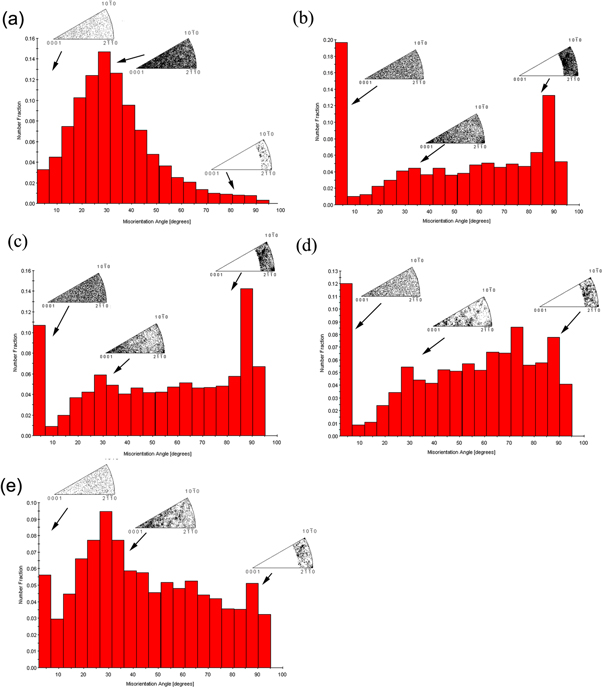

Standard image High-resolution imageThe misorientation distributions of various pre-treated Mg samples are exhibited in figure 5. The peak emerges around 30° in as-received sample A. The volume fraction of low angle grain boundary (LAGB) is much smaller and there is almost no peak emerges around 86°. Samman et al [19] indicated that grains grew up and the c-axis of grains rotated about ∼30° to 〈10–10〉 direction during recrystallization of Mg alloy. However, some grains are still rotated towards TD and the volume fraction of low angle grain boundary (LAGB) is higher though all the twins are disappeared after pre-twinning and annealing. This means that the new recrystallized grains inherites the twins' orientation.

Figure 5. Misorientation distributions of various samples: (a) A, (b) B, (c) C, (d) D, (e) E.

Download figure:

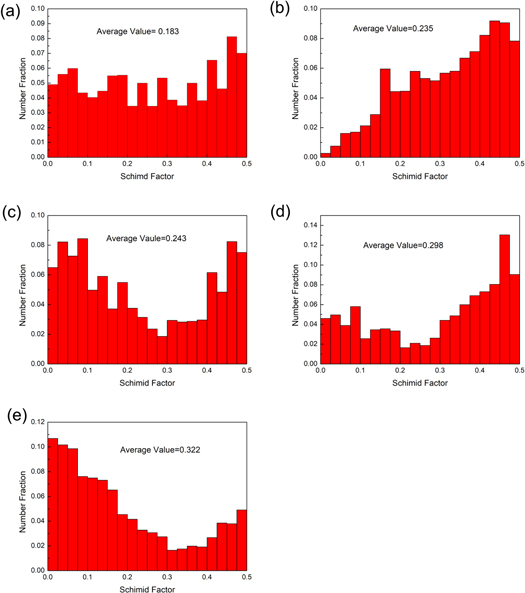

Standard image High-resolution imageFigure 6 exhibits the schmid factor (SF) of the (0002) basal slipping system of various pre-treated Mg specimens. For sample A, the SF of basal slips trends to be smaller and the value is only 0.183 owing to the stronger basal texture. Thus, the basal slips cannot be easily started and the plasticity will be poor at the same time. After pre-twins, the grains rotate away from the basal plane which is a soft orientation during the deformation and a larger SF is obtained [20]. The more grains rotate away from the basal plane, the softer orientation will be. Thus, the SF of various pre-stained samples increases with the pre-strain increasing which is 0.235, 0.243, 0.298 and 0.322 in sample A, B, C, D and E, respectively. The larger of SF for (0002) 〈11–20〉, the easier activity of basal 〈a〉 slips will be. Thus, the subsequent strain can be accommodated by basal slips which does help to improve the stretch formability of a Mg alloy.

Figure 6. Schimid factor distributions of (0002) basal slips on various samples: (a) A, (b) B, (c) C, (d) D, (e) E.

Download figure:

Standard image High-resolution image3.2. The mechanical property and formability

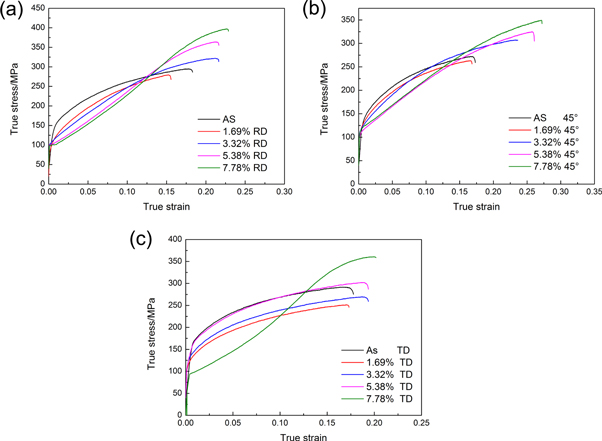

True tensile stress-strain curve of various pre-treated samples along three directions are shown in figure 7. The detail properties as well as strain hardening coefficient are exhibited in table 2. The flow stress decreases after pre-compression and annealing comparing with the as-received sample A. Besides, yield strength (YS) reduces as the increase of pre-strain levels. This is mainly related to the increased grain size. Grains grow up gradually as the increase of pre-strain levels. According to Hall-Petch relationship, lower yield strength should be obtained at a coarse grain structure [21, 22]. Besides, the rotated orientation of the grains is benefit to the activity of basal 〈a〉 slips which introduces a softening effect as well. Thus, yield strength decreases with the pre-deformation levels increases. For the ductility, the orientation softening effect may play a more significant role than grain growth behavior.

Figure 7. True tensile stress-strain curves of various pre-compression and annealed samples along three directions: (a) RD, (b) 45°, (d) TD.

Download figure:

Standard image High-resolution imageTable 2. Mechanical properties of various pre-twinned and annealed AZ31 Mg alloy sheets.

| YS/MPa | UTS/MPa | FE/% | n |

|

r |

|

|||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RD | 45° | TD | RD | 45° | TD | RD | 45° | TD | RD | 45° | TD | RD | 45° | TD | |||

| Sample A | 144.5 | 146.7 | 169.5 | 304.3 | 283.9 | 291.6 | 17.3 | 17.9 | 17.8 | 0.437 | 0.425 | 0.388 | 0.418 | 4.36 | 3.14 | 3.53 | 3.54 |

| Sample B | 135.3 | 125.7 | 129.8 | 259.5 | 223.2 | 211.6 | 15.6 | 16.8 | 17.3 | 0.531 | 0.507 | 0.485 | 0.507 | 0.893 | 0.987 | 0.905 | 0.943 |

| Sample C | 108.8 | 116.3 | 137.5 | 322.1 | 307.4 | 269.7 | 20.5 | 24.1 | 19.4 | 0.609 | 0.506 | 0.478 | 0.525 | 0.576 | 0.929 | 0.721 | 0.789 |

| Sample D | 102.1 | 108.9 | 158.9 | 363.9 | 324.9 | 302.2 | 21.6 | 26.1 | 19.5 | 0.611 | 0.546 | 0.479 | 0.546 | 0.427 | 1.109 | 0.361 | 0.751 |

| Sample E | 100.1 | 117.6 | 140.9 | 347.2 | 311.5 | 412.8 | 24.5 | 27.3 | 20.2 | 0.620 | 0.639 | 0.417 | 0.579 | 0.514 | 1.021 | 0.156 | 0.678 |

For average n-value, it increases from 0.418 on as-received Mg alloy samples A to 0.507, 0.525, 0.546 and 0.579 on samples B, C, D and E, respectively, as exhibited in table 2. This results in the weakening of (0002) basal texture. Due to the weakened basal texture, the orientation softening effects are introduced, and more deformation will be sustained. This lead to the improvement of n-value [23]. As the pre-stain levels increasing, the the TD-rotated texture will be enhanced and more softening effect will be, thus, n-value increases gradually. However, the r-value reduces little by little as the increase of the pre-strain levels. It is reported that the stain along width direction will be accommodated by prismatic slips and the thickness strain will be coordinated by pyramidal slips twinning during the plane deformation on Mg alloys [6, 24]. In sample A, the basal and non-basal slipping systems cannot be easy to start at room temperature with a strong basal texture [25]. Thus, the strain along thickness could not be generated and a larger r-value will be obtained. However, the basal texture is weakened in various pre-twined Mg alloys, and the orientation is favorable by basal 〈a〉 slips. Therefore, the strain along thickness direction could be accommodated by the basal 〈a〉 slips and a smaller r-value would be achieved. More enhanced effect of the TD-rotated orientation, the easier of the activity of basal slips will be and r-value reduces more as the pre-strain degree increasing.

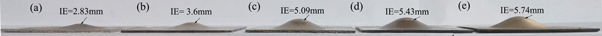

Figure 8 shows the Erishen values (IE) of various pre-twinned Mg alloy samples. For sample A, the IE-value is only 2.83 mm which expresses a poor formability. After pre-strain with levels of 1.69%, 3.32%, 5.38% and 7.76%, IE-value improves to 3.6 mm, 5.09 mm, 5.43 mm and 5.74 mm, which increases by 27.2%, 79.8%, 91.8% and 102.8%, respectively. The stretch formability is enhanced greatly. This is mainly related to the rotated orientation after pre-strain. As previous statement, the TD-rotated twinning texture is kept after annealing on pre-strained Mg alloy samples. The orientation is favored by basal slips and a larger SF is obtained. Thus, the thickness deformation can be coordinated, and a larger stretch formability is achieved. Besides, the larger n and smaller r-value are also benefit to the improvement of formability. Tu et al [26] reported that the material with a larger n-value can sustain more strain hardening and more deformation can be continued. With a smaller r-value, the Mg alloy can prevent the sheet thinning during stretch deformation [27]. Besides, the higer enhancement effect of the TD-rotated texture and the more active of basal slips will be as the pre-strain levels increasing. Thus, a larger IE-value can be expected at the same time. As well know, the twinning may start in a coarse grain structure which can also coordinate the thickness deformation [28]. And the biggest grain size is obtained in pre-strain levels of 7.76%, therefore, the IE-value can be improved largest by 102.8% at sample E.

Figure 8. Erishen values evolution of various pre-compression levels samples: (a) A, (b) B, (c) C, (d) D, (e) E.

Download figure:

Standard image High-resolution image4. Conclusion

To modify the stretch formability of Mg thin sheet, pre-twins are introduced by the pre-compression deformation at various strains (1.69%, 3.32%, 5.38% and 7.76%) at room temperature. Then the annealing process is conducted to induce static recrystallization behavior. The fraction volume of {10–12} tension twins increases as the pre-deformation degree increasing. Besides, the TD-rotated twinning texture is inherited by new recrystallized grains. Due to static recrystallization, the grains grow up. On various pre-strain and annealed Mg alloys, the yield strength reduces sequentially. This is mainly owing to the rotated orientation favors the basal slips and the softening effect is introduced. Besides, n-value increases and r-value decreases as the pre-stain levels increasing. Owing to the rotated orientation, the increased n and decreased r-value, Erichen values (IE) improves from 2.83 mm to 3.6 mm, 5.09 mm, 5.43 mm and 5.74 mm, which increases by 27.2%, 79.8%, 91.8% and 102.8%, respectively.

Acknowledgments

The authors thank the National Natural Science Foundation of China (51704209, 51701033, U1810208, U1810122 ), Advanced Programs of Department of Human Resources and Social Security of Shanxi Province for Returned Scholars Scientific (2017014) and Technological Innovation Programs of Higher Education Institutions in Shanxi (201802034), The Projects of International Cooperation in Shanxi (201803D421086), Outstanding Innovative Teams of Higher Learning Institutions of Shanxi (2018), Chongqing Science and Technology Commission (cstc2017jcyjAX0012) and China Postdoctoral Science Foundation (2018T110948).