Abstract

Nature's light manipulation strategies—in particular those at the origin of bright iridescent colors—have fascinated humans for centuries. In recent decades, insights into the fundamental concepts and physics underlying biological light-matter interactions have enabled a cascade of attempts to copy nature's optical strategies in synthetic structurally colored materials. However, despite rapid advances in bioinspired materials that emulate and exceed nature's light manipulation abilities, we tend to create these materials via methods that have little in common with the processes used by biology. In this review, we compare the processes that enable the formation of biological photonic structures with the procedures employed by scientists and engineers to fabricate biologically inspired photonic materials. This comparison allows us to reflect upon the broader strategies employed in synthetic processes and to identify biological strategies which, if incorporated into the human palette of fabrication approaches, could significantly advance our abilities to control material structure in three dimensions across all relevant length scales.

Export citation and abstract BibTeX RIS

1. Introduction

The control of material morphology and composition from the atomic to the macroscopic scale, with the aim of achieving specific material properties, is a key theme in biology and a major area of focus in science, engineering, and advanced technology development [1]. Biological and biologically inspired photonic materials—in particular when structural coloration is the desired core functionality—are great examples of the efforts of biological organisms and humans to control material structure and composition across length scales [2–4]. In this review, we contrast nature's strategies for creating functional hierarchical structures with human approaches to do the same. Specifically, we focus on material morphologies that enable structural coloration. This permits us to assess the structural outcome simply by visual inspection, allowing us to draw conclusions about the potential of specific processes to ensure correct formation of color-inducing structures.

The science and engineering of structural color have historically intertwined biological phenomena with human-made devices. In 'Opticks: or, a treatise of the reflexions, refractions, inflexions and colors of light', published in 1704, Isaac Newton described how 'the finely color'd Feathers of some Birds ... appear of several Colors ... after the very same manner that thin Plates were found to do ...' [5]. Since then, humans have aimed to understand, replicate, and expand upon a vast variety of biological optical structures [4, 6–14]. While in many instances human-made optical materials exceed natural materials with regards to application-specific performance characteristics—after all, humans did not need nature to build sophisticated lens systems, lasers, imaging devices, and much more—biological optical materials possess some significant advantages.

- (1)Their hierarchical nature, with structure control from atomic to macroscopic levels, enables beneficial synergies between quantum-optical, wave-optical, and ray-optical phenomena, yielding unique macro-scale optical characteristics.

- (2)This same hierarchical nature also confers the ability to integrate optical functions with other properties, such as tailored interfacial interactions, mechanical robustness, or thermo-regulation, to name just a few.

- (3)Biological optical systems often represent highly-evolved synergistic combinations of their intrinsic material properties and structure-imposed emergent behavior. They may therefore offer ideas for how to create a desired optical property in a synthetic system. Although major fundamental light manipulation concepts are well explored, the design of an optical material that satisfies a defined set of performance requirements under specific constraints in the most resource-efficient way is frequently a non-trivial task. Since resource-efficiency, robustness, and optimized performance is often crucial to any organisms' survival, the study of natural optical materials can help the optical designer in bounding challenging optimization scenarios by identifying promising starting points in large parameter spaces.

- (4)Natural optical materials provide insight into design principles that allow for the emergence of dynamic, adaptive, and reconfigurable optical performance.

- (5)Finally, biological optical systems are formed at or close to room temperature, and rely exclusively on bio-compatible materials and sustainable chemical processes; these are factors of increasing importance in the context of energy-efficient, sustainable material design and resource management.

To date, much of the success in the field of biologically inspired optics comes from careful attention to the structures and material composition that enable nature's light manipulation concepts across the animal world, the plant kingdom, and other parts of the tree of life (figure 1) [15–25]. However, little progress has been made toward understanding how these structures form; instead, we still largely rely on conventional synthetic fabrication strategies to form bioinspired optical materials. Alternative processes that bear similarities with biological structure formation strategies are only slowly entering our manufacturing toolbox. This may be due to the lack of detailed knowledge about the processes that organisms harness to achieve the structural control required to form material morphologies that enable a specific optical effect. In this review we argue that bioinspired photonics research can contribute significantly to optical technology advancements, provided we develop a robust understanding of the biological processes that enable structure formation and adopt relevant principles in human fabrication strategies. An in-depth understanding of the differences between human approaches and natural processes in the generation of structurally colored materials could help to pinpoint strategies for overcoming current limitations in our ability to design and manufacture materials with true control over the material structure in all three dimensions, across all relevant length scales. Just as the emulation of natural material morphologies and microstructures have enabled novel optical materials, a stronger focus on understanding and harnessing the processes underlying structure formation will lead to new insights and strategies for the design and fabrication of novel functional materials.

Figure 1. Structural color in the biological world. Structural color has evolved convergently in most major biological groups and is particularly abundant among animals and plants. Terrestrial species, such as birds, insects and fruits, have been studied intensely for several decades; over the last few years, research has increasingly focused on the light manipulation strategies of marine organisms. Groups and clades that contain species which employ structurally colored materials and have been the subject of scientific research efforts and publications are marked in red. Groups that also likely employ structural color are shown in green, although to our knowledge no scientific study has focused on them in this regard. Image credits: Fauchea laciniata—Reproduced with permission from Lovell and Libby Langstroth © California Academy of Sciences. Cellulophaga lytica reproduced from [26]. CC BY 4.0. Selaginella willdenowii republished with permission of The Royal Society, from [22]; permission conveyed through Copyright Clearance Center, Inc. Ophrys speculum—this 'Ophrys speculum subsp. Speculum' image has been obtained by the author(s) from the Wikimedia website where it was made available under a CC BY-SA 2.5 licence. It is included within this article on that basis. It is attributed to Esculapio. Pollia condensata reproduced with permission from [28]. Begonia pavonina reprinted by permission from Springer Nature: Nature, Nature Plants, [29], 2016. Hibiscus trionum [30] John Wiley & Sons.© 2014 The Authors. New Phytologist © 2014 New Phytologist Trust Margaritaria nobilis reproduced from [31]. CC BY 4.0. Comb jelly—reproduced with permission from Kevin Raskoff. Polychaete worm—reproduced with permission from Andrew Parker. Common bleak—this 'Alburnus alburnus photographed in Tiszafüred, river Tisza, Hungary' image has been obtained by the author(s) from the Wikimedia website where it was made available by Etrusko25 under a CC BY 3.0 licence. It is included within this article on that basis. It is attributed to Arkos Harka. Limpet Reproduced from [32]. CC BY 4.0. Sea mouse—reproduced with permission from Dave Harasti. Arctapodema—reproduced with permission from Lawrence P. Madin. Neon tetra—this 'Neon Tetra, Paracheirodon innesi, Family: Characidae' image has been obtained by the author(s) from the Wikimedia website where it was made available under a CC BY 3.0 licence. It is included within this article on that basis. It is attributed to Holger Krisp. Mantis shrimp—this 'A colourful stomatopod, the peacock mantis shrimp (Odontodactylus scyllarus), seen in the Andaman Sea off Thailand' image has been obtained by the author(s) from the Wikimedia website where it was made available by Zaneselvans under a CC BY 2.0 licence. It is included within this article on that basis. It is attributed to Silke Baron. Peacock—this 'A peacock showing off its colours, Sultanpur National Park' image has been obtained by the author(s) from the Wikimedia website where it was made available under a CC BY-SA 4.0 licence. It is included within this article on that basis. It is attributed to Jatin Sindhu. Mandrill—this 'Mandrillus sphinx.' image has been obtained by the author(s) from the Wikimedia website where it was made available under a CC BY 2.0 licence. It is included within this article on that basis. It is attributed to Matt Sabbath. Peacock spider republished with permission of The Royal Society, republished with permission of The Royal Society, from [33]; permission conveyed through Copyright Clearance Center, Inc. Plum-throated cotinga—reproduced with permission from Thomas Valqui. Lepidiota stigma reprinted by permission from Springer Nature: Nature, Scientific Reports, [34], 2014. Eupholus magnificus—this 'Français: Boîte pédagogique sur les insectes de l'indomalais insulaire. Eupholus magnificus.' image has been obtained by the author(s) from the Wikimedia website where it was made available under a CC BY-SA 4.0 licence. It is included within this article on that basis. It is attributed to Édouard Hue. Poecilotheria metallica tarantula—reproduced from https://commons.wikimedia.org/wiki/File:Poecilotheria_metallica.JPG#/media/File:Poecilotheria_metallica.JPG. Image stated to be in the public domain. Sunset moth and Papilio blumei reprinted by permission from Springer Nature: Springer Netherlands, Encyclopedia of Nanotechnology, [35], 2012. Plusiotis boucardi—reproduced with permission from Brett Ratcliffe. Pachyrhynchus beetles—Reproduced with permission from Estan Cabigas.

Download figure:

Standard image High-resolution imageThe next section of this review begins with a few brief comments on the physics of structural color and then continues with a discussion of select examples of biological structural color with a focus on structural diversity, dynamics, and material constituents. Subsequently, we will briefly review an exemplary selection of synthetic structurally colored materials. The third section then forms the review's core. After providing a brief categorization of structure formation processes, we assess what is known about the processes involved in the formation of biological optical materials and then discuss synthetic structure formation strategies. In the final section, we compare and contrast biological and human structure formation concepts, and synthesize a few recommendations for opportunities to advance human manufacturing strategies for advanced optical materials.

2. Biological and synthetic structurally colored materials

2.1. Physics of structural color

Light manipulation is vital for many biological organisms and also critical in a diverse range of human application scenarios including vision and image capture systems, optical detectors, energy conversion, information processing, and communication. The underlying physics is discussed throughout the literature on biological and bioinspired photonic materials, and considered with particular attention to structural colors in [36–38]. In essence, adequate manipulation of light-matter interactions can only be achieved by employing materials that feature the right structural design to exploit a set of specific effects from a wide range of optical phenomena (figure 2).

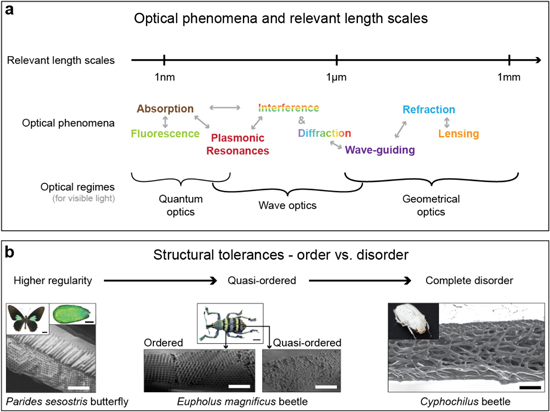

Figure 2. Optical phenomena, relevant length scales, and the role of order in photonic materials. (a) A large diversity of phenomena are involved in the interaction of matter with light on different length scales. Many of these phenomena are exploited in biological photonic materials and certainly also play a role in synthetic optical systems. (b) The brightness and hue of a structural color material depends on a variety of parameters and their variations. One of them is the degree of order. Regular ordered architectures usually provide bright coloration and frequently show some iridescence; the example shown here is the gyroid structure found in the butterfly Parides sesostris. The weevil Eupholus magnificus has differently colored regions on its elytra. The brighter green stripes result from a highly-ordered 3D photonic crystal, while the blue stripes originate from a quasi-ordered 3D photonic structure. Such quasi-ordered structures usually show less angle-dependent color variation. Cyphochilus beetles have a completely disordered fibrillar architecture in their scales, which causes their bright white reflections. ((B) right) Reproduced from [https://www.cam.ac.uk/research/news/the-beetles-white-album] by Lorenzo Cortese and Silvia Vignolini. CC BY 3.0.

Download figure:

Standard image High-resolution imageAbsorption and luminescence (inherently quantum-mechanical effects) necessitate control of structure and composition on the atomic scale, which is far below the characteristic wavelength of visible radiation. Photonic structures on the scale of a few hundred nanometers to several micrometers can exploit diffraction and interference phenomena in the visible optical spectrum and also greatly assist in tailoring absorption and emission originating from light-matter interactions on much smaller scales. Finally, three-dimensional patterns on the scale of tens of micrometers to several centimeters are required to exploit lensing and focusing effects, refraction, and wave-guiding.

The degree of regularity in the color-generating structure has a direct impact on the resulting coloration [42]. The brightest, most iridescent colors usually result from structures with tight geometric tolerances and a high degree of order [28, 43, 44]. Angle-independent hues arise through coherent scattering from quasi-ordered material structures [41, 45, 46]. The most brilliant whites are caused by incoherent scattering of light from completely disordered nano- and microstructures [34, 47–51].

In short, the most stunning visual displays in nature usually rely on sophisticated hierarchical material structures that synergistically exploit several different physical phenomena to create unique coloration effects.

2.2. Biological structural color—structural diversity, dynamics, and materials

In our discussion of select structural color examples in biology, we focus on three specific attributes that we consider as primarily important in the context of this review.

- (1)Structural diversity, signifying the interplay of several different processes and control mechanisms involved in structure formation,

- (2)Color dynamics, enabled by the organism's ability to stimulate controlled structural variations in situ, and

- (3)Material constituents that provide intrinsic optical and mechanical attributes, which are modified by imposing structure and are crucial for dynamic, reversible structure variation.

2.2.1. Structural diversity

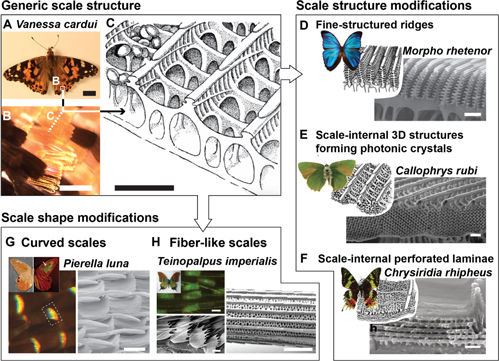

The stunning diversity of hierarchical photonic architectures in butterfly scales exemplifies the ability of biological systems to evolve and reliably produce structural elements with fine-tuned optical functionality (figure 3). A generic morphology of ridges, cross-ribs, and lamellae forms the basic blueprint for scales across lepidopteran species [52]. However, a rich variety of modifications to this generic building plan results in a range of strategies to display colors of tailored intensity and spectral composition, satisfying the organisms' requirements for conspecific and cross-species communication, camouflage, thermal management, air flow modification, or wetting control [53–59].

Figure 3. Structural diversity in butterfly wing scales. (A) The 'Painted Lady' butterfly Vanessa cardui (scale bar 1 mm) and (B) its orange and black wing scales (scale bar 100 μm), which (C) display a generic scale architecture (scale bar ∼1 μm). (D)–(F) This generic design is modified by many butterfly species to enable unique color displays. (D) Fine-structured ridges on the wing scales of many Morpho species (scale bar 1 μm). (E) Three-dimensional photonic crystal structures in the wing scales of the 'Green Hairstreak' butterfly Callophrys rubi (scale bar 1 μm). (F) Perforated lamella forming a Bragg reflector in the scales of the sunset moth Chrysiridia rhipheus (scale bar 500 nm). (G) and (H) Other butterfly species harness changes in the overall scale shape to produce structural colors. (G) The 'Moon Satyr' Pierella luna produces varying coloration effects by curving its scales to orient the fine-scale cross-rib architecture such that it forms a vertical diffraction grating (scale bar 50 μm). (H) The "Kaiser-i-Hind' butterfly Teinopalpus imperialis displays scales and long fibers with very similar micro- and nanoscale architecture on its wings (scale bar 2 μm). (C) Republished with permission of The Royal Society, from [52]; permission conveyed through Copyright Clearance Center, Inc. (D) This 'blue morpho butterfly' image has been obtained by the author(s) from the Wikimedia website where it was made available by Lycaon under a CC BY-SA 3.0 licence. It is included within this article on that basis. It is attributed to Gregory Phillips. (D), (E) and (F) [60] John Wiley & Sons. © 1998 Wiley-Liss. ((D) SEM) Republished with permission of The Royal Society, from [61]; permission conveyed through Copyright Clearance Center, Inc. (E) This 'Callophrys rubi insect collections SLU, Uppsala' image has been obtained by the author(s) from the Wikimedia website where it was made available under a CC BY-SA 3.0 licence. It is included within this article on that basis. It is attributed to Vítězslav Maňák. ((E) SEM) Republished with permission of The Royal Society of Chemistry, from [62]; permission conveyed through Copyright Clearance Center, Inc. (F) Reprinted by permission from Springer Nature: Springer Netherlands, Encyclopedia of Nanotechnology, [23], 2012. ((F) SEM) Reprinted by permission from Springer Nature: Springer Netherlands, Encyclopedia of Nanotechnology, [24], 2012. (G) Reproduced with permission from [64]. (H) This 'Teinopalpus imperialis (male) verso' image has been obtained by the author(s) from the Wikimedia website where it was made available under a CC BY-SA 3.0 licence. It is included within this article on that basis. It is attributed to Anaxibia.

Download figure:

Standard image High-resolution imageButterflies of the Morpho family utilize specialized ridge designs [43, 61, 65, 66]; the sunset moth Chrysiridia rhipheus relies on perforated lamellae located in the scales between the ridges [67, 68]; Papilio palinurus, Papilio ulysses and others, impose microscopic curvature on such multilayers to create specific optical effects [69, 70]; and Parides sesostris, Callophrys rubi, and Teinopalpus imperialis form continuous three-dimensional periodic networks that act as photonic crystals [71–74]. While the optical working principles of such structures are well characterized and some research has been devoted to the processes underlying their formation [72, 75], a clear understanding of the formation mechanisms remains elusive.

Birds appear to have perfected the art of forming quasi-ordered, and amorphous photonic materials with a short-range periodicity but no long-range order [46, 76–79], an approach to create non-iridescent structural color. Quasi-order has also been found to be employed in some scarab beetles [41].

2.2.2. Dynamic coloration

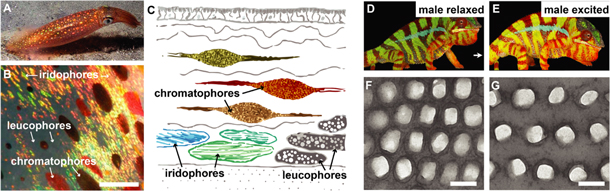

Even more intriguing examples of the ingenuity of biological organisms in harnessing micro- and nanoscale structures for light manipulation can be found in the dynamic coloration of cephalopods and chameleons. Exploiting intracellular pigmentation- and structural coloration-based architectures, cephalopods are capable of changing their skin coloration using a sophisticated combination of chromatophores, iridophores, and leucophores [80–82] (figures 4(A)–(C)). One exciting aspect that we are slowly beginning to understand is the neural control of this dynamic coloration [83]. In contrast to cephalopods, which employ proteins to form their dynamic iridophores [84, 85], chameleons embed regularly organized guanine crystals in expandable skin structures, allowing the animal to vary the resulting structural color by expanding or contracting the tissue [86] (figures 4(D)–(G)).

Figure 4. Dynamic coloration. (A) The squid Loligo pealeii is capable of changing its coloration using three different types of optical elements within its skin. Reproduced with permission from Laptew Productions. (B) and (C) Chromatophores are cells filled with brown, red, and yellow pigments that can expand and contract to cover more or less skin area. Iridophores contain regular layered protein structures that reflect blue, green, yellow, and red colors. Leucophores are cells that are filled with randomly arranged, poly-disperse, highly scattering spheres. They provide a white canvas for the colors of iridophores and chromatophores (scale ∼1 mm). (D) and (E) The panther chameleon (Furcifer pardalis) native to Madagascar is capable of dynamically changing color to facilitate courtship and male rivalry. (F) and (G) The color change is enabled by controlling the lattice period of a regular arrangement of guanine crystals within the chameleon's skin tissue (scale 200 nm). (A) Reproduced with permission from Mike Laptew. (B) and (C) Adapted with permission of The Royal Society, from [82]; permission conveyed through Copyright Clearance Center, Inc. (D), (E), (F) and (G) Reprinted by permission from Springer Nature: Nature, Nature Communications, [86], 2015.

Download figure:

Standard image High-resolution image2.2.3. Material constituents for biological structural color systems

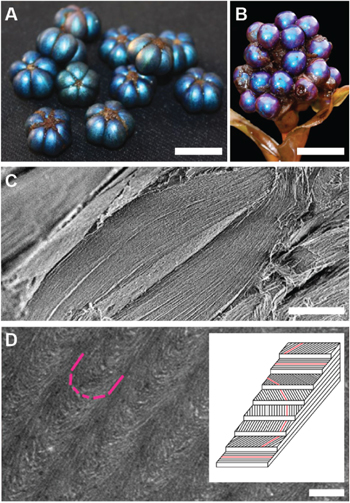

The photonic architectures found in tropical fruits, such as Pollia condensata and Margaritaria nobilis [28, 31], represent inspiring examples of the use of cellulose (figure 5), earth's most abundant biopolymer [87]. These structures intrigue by their nano-scale arrangement of cellulose nano-crystals in a regular helicoidal chiral architecture, which strongly reflects circularly polarized light of the same handedness as the cellulose structure.

Figure 5. Cellulose photonics. (A) Fruits of the plant Margaritaria nobilis native to tropical Central and South America (scale ∼ 1 cm). (B) Fruits of the plant Pollia condensata an African forest species (scale ∼ 1 cm). (C) Scanning electron micrograph of a section through a single pericarp cell of M. nobilis showing a multilayered architecture (scale 10 μm). (D) A transmission electron micrograph of a section of this multilayer architecture reveals the Bouligand arch pattern, which is a clear signature of a helicoidal cell-wall architecture (scale 250 nm). This micrograph was taken from P. condensata, which like M. nobilis creates color with a regular helicoidal arrangement of cellulose microfibrils in its cells. The inset shows a schematic of the arrangement of the cellulose microfibrils to form a chiral structure with a well-defined pitch. (A) and (C) Reproduced from [31]. CC BY 4.0. (B) and (D) Reproduced with permission from [28].

Download figure:

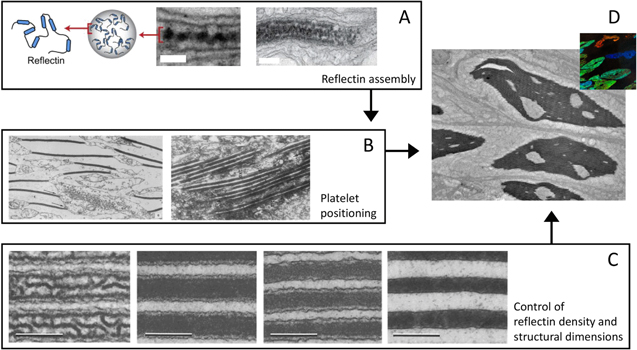

Standard image High-resolution imageIn insects, functional biophotonic architectures are mainly composed of chitin, guanine, pterins and melanins [77, 88]. Fish and copepods use regular guanine arrangements [89–91]. Birds have evolved strategies to pattern keratins, melanins, and carotenoids in their feathers [77, 92] and in addition use collagen structures in their skin [45], similar to some of the color-generating structures in mammals [93]. Mollusks have found ways to extracellularly structure calcium carbonate, and intracellular proteins, such as reflectin [32, 85, 94]. Finally, plants and insects apply a variety of waxes (in addition to the cellulose and chitin discussed above) to create photonic architectures [27, 95].

2.3. Synthetic structural color—exemplary man-made materials and devices

In this section, we complement the previous discussion of representative examples of biological structural color with a perspective on exemplary man-made materials and devices that involve structural color. As in the previous section, we emphasize the color-generating structures, dynamics, and material constituents.

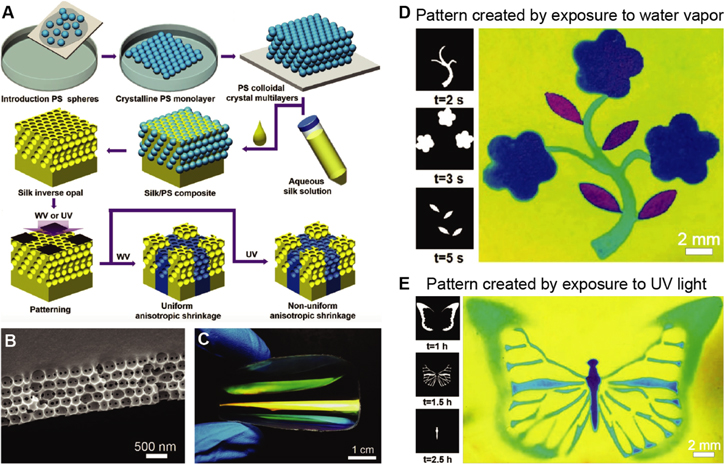

2.3.1. Silk inverse opals—modulation of photonic lattices with water and light

Opals and inverse opals consist of close-packed, nano-scale, high refractive index colloids within a low-index matrix, or low refractive index pores within a high-index matrix, respectively. Opal- and inverse opal-like photonic architectures can be found in nature [21, 96–98], and have also been synthetically fabricated using a wide variety of strategies [98–107]. One common strategy for fabricating inverse opals is to create a colloidal crystal of polymer spheres, casting a matrix material onto the crystal, and subsequently removing the spheres [108].

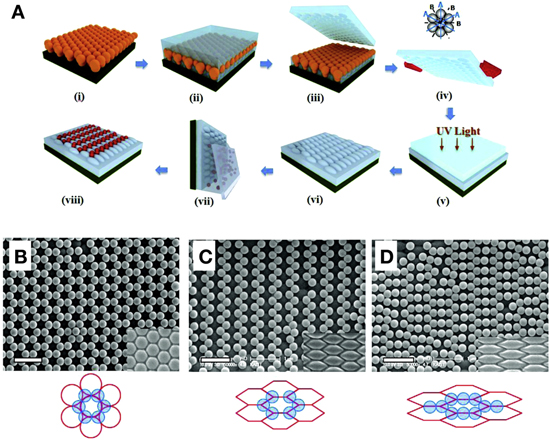

This method has recently been applied to creating large-area, highly ordered silk inverse opals [109] (figure 6). Silk, a biopolymer sourced in industrial quantities from domesticated silkworms, is an excellent optical material due to its transparency, low surface roughness, nanoscale processability, and mechanical durability [110, 111]. It has been used to form many useful optical components, including photonic crystals, microlens arrays, color-tunable diffraction gratings, and even random lasers [112–114]. Silk is usually processed in aqueous solutions. Control over the solution chemistry and water evaporation kinetics allows for tuning the material's nanoscale morphology to tailor its macro-scale properties. The silk inverse opals are iridescent and highly flexible. After formation of the inverse opal, the structural properties of the silk can be modified through exposure to water vapor or ultraviolet light [115, 116]. This allows for controlled modulation of the photonic crystal's lattice parameters to inscribe structural color variations and patterns into the inverse opal films. This represents a promising new strategy for facile creation of stimuli-responsive photonic materials with tunable structural color, which could be beneficial in biosensors, including direct antigen-detection in colorimetric immunosensors [117].

Figure 6. Painting patterns in silk inverse opals. (A) The fabrication process consists of the deposition of a direct opal by repeatedly scooping up polystyrene colloid monolayers from an air-water interface (top row), before infiltrating the opal with aqueous silk solution, followed by drying and removal of the of the colloids with solvent to obtain the inverse opal (middle row). The inverse opal is then patterned by local exposure to water vapor or ultraviolet light. (B) Scanning electron micrograph of a silk inverse opal. (C) Photograph of film as it is bent, showing its excellent flexibility. (D) Exposure of a silk inverse opal to water vapor through different porous stencil masks is used to enable a multicolor pattern. (E) Similar effects can be achieved by exposing the silk to UV light through patterned photomasks. [109] John Wiley & Sons. © 2017 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim.

Download figure:

Standard image High-resolution image2.3.2. Full-color reflective MEMS displays

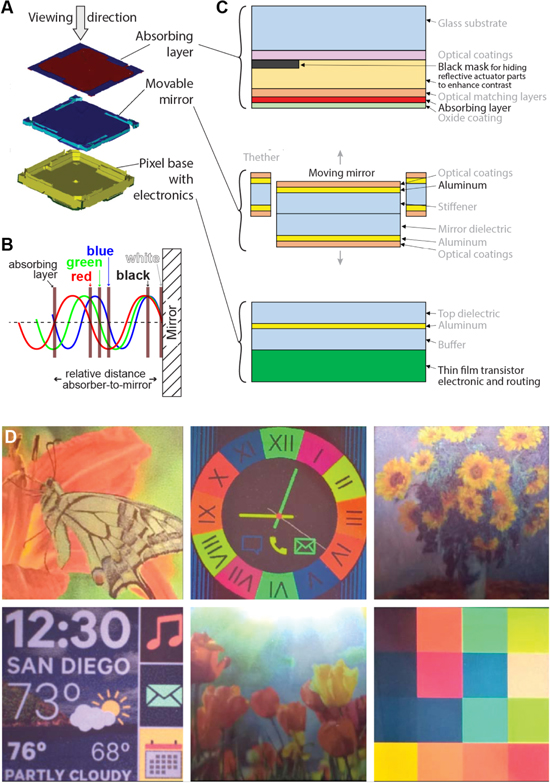

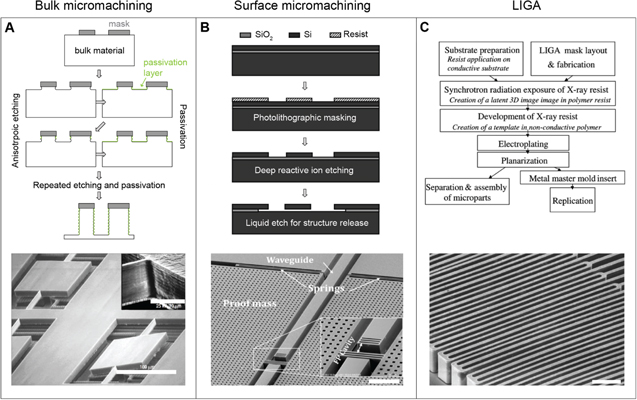

Microelectromechanical systems (MEMS) are microscale devices that contain both electrical and mechanical functionality. Advanced MEMS micromachining approaches have unique advantages for the creation of miniaturized optical devices (called micro-opto-electro-mechanical systems, short optical MEMS or MOEMS). The precision mechanics of MEMS combined with industrial surface micromaching processes that are compatible with optically relevant materials have enabled a diverse range of rapidly reconfigurable, tunable, micro-optical elements, including lenses, mirrors, and filters. These components have made significant impact in a wide variety of commercial applications [118–120]. Digital micro-mirror devices—invented at Texas Instruments over 35 years ago—are an example of MEMS based optical systems [121], which have tremendous technological and commercial value in digital projection displays and other applications [122].

Newer MEMS display technologies specifically make use of structural color to enable energy-efficient, large-area reflective displays that eliminate the need for device-internal light sources, thereby drastically reducing energy demand. One of the more recent examples of this type of technology is the single mirror interferometric display by Qualcomm [123, 124]. Each of the display's pixels consists of a thin layer of a light-absorbing molybdenum chromium alloy suspended over an aluminum mirror (figure 7(A)). In this geometry, incident light interferes with light that reflects off the mirror, which results in standing wave patterns. The position of extrema and zeros in the light field varies with the light wavelength, which can be exploited to induce spectrally selective absorption via controlled positioning of the absorbing layer (figure 7(B)). If the absorber is placed at a location of maximally varying amplitude in a specific wavelength's standing wave pattern, light of that particular wavelength is absorbed, while light in different spectral ranges can pass. In the actual device, positioning of the absorbing layer within the standing wave field is achieved through moving the pixel's mirror using the integrated high-precision MEMS actuator infrastructure that is controlled by a thin-film transistor circuit within each pixel. The elaborate pixel infrastructure, shown schematically in more detail in figure 7(C), is produced in a series of surface micromachining steps. Prototype devices can switch their pixels at 120 frames per second, display 16 primary color states, and have a display density of 346 points per inch (figure 7(D)). Since these devices do not require internal illumination, they only consume energy to switch and hold the displayed information, promising significantly higher energy efficiency then current displays. In principle, the fabrication process is amenable to flexible substrates, which in the future could provide avenues for flexible reflective display designs that could be used in optically adaptive, color- and information-changing wearables.

Figure 7. A reflective MEMS-based single mirror interferometric display. (A) Overview of the device layout showing the fixed absorbing layer, the moving mirror, and the pixel base. (B) Schematic depicting the display's working principle. Precise positioning of the absorber in the standing wave field enables controlled spectrally-selective absorption. (C) Detailed schematic of the pixel architecture, fabricated in an elaborate surface micromachining process. (D) Full color images displayed by a 483 × 483 pixel array. (A), (C) and (D) © [2017] IEEE. Reprinted, with permission, from [124]. (B) Reprinted with permission from ref [123], OSA.

Download figure:

Standard image High-resolution image2.3.3. 3D-printing with block copolymer-based structurally colored filaments

3D printing, in particular fused deposition modeling, has significantly gained in popularity in recent years, both in a professional manufacturing context and as a hobbyist tool. Commonly, colored parts are created by mixing a pigment dispersed within the polymer of interest. More recently, that coloration has instead been achieved by making use of structural color [125]. As shown in figure 8, the polymer of interest is a block copolymer, which self-assembles during the filament heating and extrusion process to create an ordered nanostructure that exhibits structural color. This filament can then be used for 3D printing. Adjusting the molecular weight of the BCP alters the dimensions of the nanostructure, which in turn alters the wavelength of reflected light.

Figure 8. 3D-printing with structural color. (A) Colorless block copolymer granules are loaded in the filament extruder. (B) Emergence of structural color during filament extrusion, caused by molecular-scale self-assembly of the polymer (inset diagrams suggest molecular structure). (C) The same filament 3D printed via fused deposition modeling in the shape of a butterfly wing. Reprinted with permission from [125]. Copyright (2017) American Chemical Society.

Download figure:

Standard image High-resolution image3. Processes that drive the formation of structurally colored materials

3.1. Processes—preliminary comments

In the preceding sections, a few representative examples for biological photonic systems and man-made materials that rely on structural color were chosen to emphasize three important process attributes that are the focus of this review.

- (1)Control over the material structure to allow for a wide variety of architectures,

- (2)Control over the local material composition, and

- (3)Control over the materials' dynamic properties.

These examples show that biological and synthetic processes have unique characteristics that determine 'what goes where' during the structure formation. In this review, we chose to specifically focus on processes that create materials with structural color for several reasons.

- (1)The structural outcome is immediately apparent.

- (2)The structures at the origin of structural color have a varying but controlled degree of order on distinct length scales.

- (3)The underlying formation processes must be robust, as can be seen in the impressive degree of reliability with which biological microstructures are realized.

- (4)Many of the prominent biological structurally colored materials are based on easily handled, abundant biomaterials, including cellulose, chitin, and calcium carbonate, which readily lend themselves to the full spectrum of materials analysis techniques.

- (5)Hierarchical designs are prevalent, and often each component of the hierarchy adds to the material's functionality.

- (6)The perceived color is a proxy for the structures' optical qualities; visual / spectral assessment of their optical characteristics on the macro- and microscale provides a convenient pathway to assessing changes that might be imparted by modifying the formation processes.

- (7)Understanding processes that lead to the formation of structurally colored materials could help to identify avenues for realizing synthetic analogs for a wide range of optical applications.

3.2. Process classification

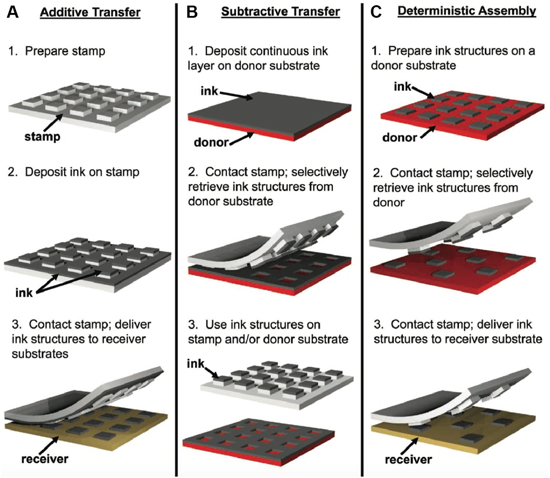

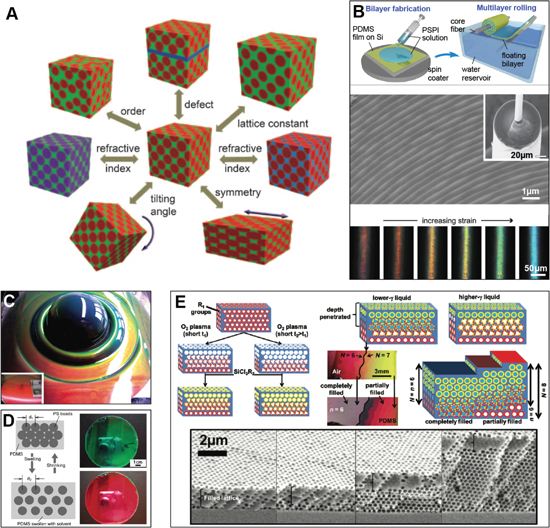

The controlled formation of morphologies that induce structural color in biological and in synthetic material systems usually depends on the interplay of several processes. In this review, we broadly classify structure formation processes into the following categories (figure 9).

- Additive processes: material is added sequentially to an existing structure. In biology, this includes the secretion of chitin in insect cuticles and the deposition of calcium carbonate in mollusk shells. Examples of synthetic additive processes are the formation of thin metal oxide layers on an optical filter by atomic layer deposition or chemical vapor deposition, as well as the 3D-printing of complex micromorphologies.

- Subtractive processes: an initial material volume is modified by spatially selective removal of material. In biology, this includes the degradation of insect cuticles (for instance occurring during ecdysis, or the digestion of actin scaffolding structures during the formation of butterfly wing scales). A plethora of subtractive processes are used in synthetic manufacturing, ranging from metal machining on larger scales to a variety of micromachining approaches that employ physical and chemical etching procedures for structure formation on smaller length scales.

- Continuous processes: material with the desired shape and structure is continuously extruded or drawn. We consider the biological growth of hairs, bristles, and scales broadly as such a continuous process. A synthetic analog might be found in the extrusion of layered polymer architectures with controlled internal morphology or the drawing of photonic crystal fibers.

- Net-shape processes: an initial mass of material is deformed until it gains the final desired shape, without a significant change in the material's initial mass. A biological example for such processes are anisotropic cell deformations occurring in flower petal formation. Molding of nano-scale surface structures by nano-imprinting, or casting and curing onto a template, are examples of shaping processes in synthetic manufacture.

- Assembly processes: building blocks with desired base characteristics are assembled into complex functional material architectures. If this happens autonomously, just driven by the interactions of the unit elements and their surrounding medium, the process is termed 'self-assembly'. The formation of regular three-dimensional photonic structures in butterfly and beetle scales is likely driven in-part by self-assembly. Synthetic opaline and inverse opal photonic crystals are usually formed through self-assembly.

We note that it is not necessarily easy or straightforward to fit natural processes into these specific categories. This is primarily due to the fact that in nature many of these processes occur in parallel and are difficult to separate neatly, while in synthetic manufacture processes occur primarily in sequence. Additionally, the classification of a process depends on where the system boundaries are defined; when viewed in different contexts, a single physical phenomena may be best described by different categories. However, the classification that we employ here provides benefits for the comparison between biological and synthetic structure formation processes and enables us to propose potential strategies for advancing human manufacturing concepts by gaining inspiration from biological processes.

Figure 9. Process categories.

Download figure:

Standard image High-resolution image3.3. Biological processes

In broad terms, processes that enable the formation of biological structures have one of three purposes.

- They contribute to the generation of constituent materials;

- They are involved in organizing these materials into structures;

- They facilitate clean-up and/or continuous maintenance of the final structure to ensure persistent functionality.

These processes may occur sequentially, but often they are integrated with some degree of overlap.

The generation of material constituents is prescribed by the organism's genetic code: information encoded in DNA is transcribed into RNA, which then is translated into a protein by assembling amino acids at a ribosome [126–128]. The protein must then move via some method of cellular transport to a new location inside or outside the cell [129–131]. At its new location, the protein may interact with other molecules in its environment, pulling, pushing, and bending the aggregate structure into shape [132]. However, non-protein materials (carbohydrates, lipids, minerals, purines, and pterins) are not produced directly via gene expression [128]. Instead, these materials are gathered, modified, and assembled by a collection of enzymes. Since enzymes are proteins, the organism's genes still control this palette of constituent materials, albeit more indirectly. In some cases, the material is produced at the site of its final destination [133, 134]; otherwise, it is transported to that destination, where it integrates with the aggregate structure [132]. Thus a unique aspect of biological growth as a fabrication process for micro- and nanostructured materials is that, in general, the structure-forming cell synthesizes the materials and shapes the forming structures all within itself or in a region closely surrounding the cell.

Processes contributing to biological structure formation can be broadly classified within the categories outlined in section 3.2. Because cells typically produce their own raw material needed for structure formation, all biological processes have at least some stages that can be described as 'additive': on-site synthesis, secretion, and various methods of intracellular transport are all indicative of additive processes. Reciprocally, subtractive processes are rarer in biological structure formation; when they do occur, their main function tends to be removal of a mold that has supported structure formation. Subtraction of temporary material is generally achieved by degradation, such as enzymatic digestion [135–137]. In various cases, materials can be formed in a continuous fashion, by linearly propagating a given shape: examples are lipid extrusion through a pore or linear growth of cytoskeletal elements; examples of larger macro-structures are bristles and feathers [138–143]. We also find that an abundance of processes in nature shape a given net volume of material using other elements, such as membranes or biological scaffolds, as a template or mold [144]. Lastly, a wide variety of intermolecular forces contribute to the assembly of various materials.

While we generally know how to identify the material constituents and structural components that impart function, we know little about how these materials are formed by living organisms. Control and regulation of multiple processes across various length scales are required to form the material morphologies that enable specific structural color effects. Structure formation has to be controlled from the nano- to the macro-scale to enable the harnessing of different light–matter interaction principles, such as absorption and fluorescence (quantum-optical regime), diffraction and interference (wave-optical regime), and refraction or lensing (ray-optical regime); yet, our understanding of biological structure control and regulation is still in its infancy. In fact, many of the biological structure formation processes that we discuss below are, at best, incompletely understood.

In the following section, we describe the phenomena that have been observed during the formation of structurally colored materials in different organisms. In addition—where possible—we outline hypotheses that have been formulated regarding the underlying physical phenomena. We hope to capture the 'status quo' of the current scientific understanding of the formation of material structures used in nature to manipulate light, and specifically focus on structures in butterfly wing scales, cephalopod iridophores, bird feathers, and flower petal surfaces as representative examples.

3.3.1. Diversity of processes

Example, scale formation in lepidopterans: the formation of scales on the wings of Lepidoptera (butterflies and moths) is a complex process that has interested scientists for well over a century [145, 146]. Although the wing scales of butterflies and moths develop during metamorphosis, the tissue for the wing already starts forming as an 'imaginal disc' in the larval stages [147, 148]. As the larva initiates pupation, the disc initiates a dramatic pace of growth. The wing tissue begins to grow and thicken, after which differentiated scale precursor cells become readily identifiable by their larger size (figure 10(A)).

Figure 10. Timeline of scale structure formation in two butterfly species. Percent duration of pupation in Vanessa cardui denoted by *; Junonia coenia denoted by †. Magenta shows plasma membrane, and yellow shows actin. (A) After the caterpillar pupates, specific cells on the wing tissue differentiate into scale precursor cells (large cells as denoted by arrow) (scale 30 μm). (B) The precursor cells align in distinct rows that lead to the tissue-wide organization of the wing scales (scale 30 μm). (C) Top, Scale cells begin to grow actin and extend away from the wing surface (scale 15 μm); bottom left, close up of actin growth (scale 5 μm); bottom right, cross section of yellow scale cell actin and blue scale cell nucleus (pink arrows), as well as the supporting socket cell structures (green arrows) (scale 5 μm). (D) As the scale cell is extended, actin begins to take on a more regular order, and supports the growing membrane (scale 15 μm). (E) Actin bundles further organize into regularly spaced bundles (which will later support membrane undulations) (scale 15 μm). (F) The cell membrane flattens and maintains the actin in their bundles (scale 15 μm). (G) The cell membrane then begins to 'wrinkle' in a controlled fashion consistent with the actin bundles; around the same time, chitin secretion accelerates (scale 15 μm). (H) Chitin expression continues; the actin disintegrates (scale 15 μm). (I) Toward the last third of the pupa stage, the scale cell begins to appear in its final structure; the cuticle hardens, pigment appears, and the cell dies leaving behind the cuticular scale (scale 15 μm). (Fluorescence) Reprinted from [148], with permission from Elsevier. (Wings) Reproduced with permission from [149].

Download figure:

Standard image High-resolution imageA number of historical and recent seminal studies have provided phenomenological insights into scale formation once the final stage of morphogenesis—the pupation—has started [15, 40, 148, 150–154]. This provides the basis for identifying the scale components relevant to structure formation and for forming hypotheses about their interactions and the mechanisms leading to the formation of the final chitin-based scale architectures. Based on these studies, we know that each scale is formed by a single scale cell that extrudes a scale protrusion, which is seated in a socket formed by an adjacent socket cell. Furthermore, we can establish the following (rough) timeline for scale development. In this phenomenological overview of scale formation, we state the developmental stages in percentages relative to the overall pupation duration; this duration changes from species to species and depends significantly on exterior conditions such as temperature [155].

At around 15% of pupal development, the epithelial cells have aligned on the wing membrane. Socket and scale cells have formed from a common mother cell (figure 10(B)). At this point the scale cell begins to build a protrusion that is to become the scale (figure 10(C)). The membrane of the scale cell is extended by actin filaments, pushing through the middle of the toroid-shaped socket cell in the fashion of a continuous process. As the scale cell reaches about a third of its final length at around 25% of pupal development, the actin filaments begin to assemble in regularly spaced bundles running the length of the scale; these bundles are essential in the following 'netshape' stages of molding the membrane [148]. The scale protrusion is still circular (figure 10(D)). At around 30% of pupal development, regular F-actin filament structures are apparent in the scale protrusion, which is in the process of flattening (figure 10(E)). Soon after, stationary undulations appear across the top surface of the scale, lining up with the actin bundles (figure 10(F)). Although the actin has been demonstrated to be crucial to the formation of the membrane mold [148], the precise physical phenomena behind the actin-membrane interactions are unknown. While buckling phenomena have been hypothesized to be responsible for the formation of undulations on the scale cell surface [15], the mode and control of this buckling have not been elucidated.

With the mold in place, the cuticle (chitin fibrils in a matrix of supporting proteins) begins to appear to form a single-cell exoskeleton (figure 10(G)). The polymerization of chitin is enabled by an enzyme, chitin synthase, which is reported to operate at the apices of a membrane [156–158]; which, in the case of the wing scales, are located along the tops of the ridges. The cuticle is thus secreted in an additive fashion; in addition to the molded configuration, the surface takes different morphologies, likely due to internal forces within the cuticle aggregate [15, 159], which may be thought of as self-assembly. During the production of chitin, the membrane template does not remain fixed, but rather retracts from its original position. The chitin is then sclerotized and the cuticle is hardened. At around 60% of pupal development, the scale ridges show pronounced features and the cell cytoplasm appears to retract and degrade (a subtractive process) (figure 10(H)). At this point, substantial amounts of chitin have been secreted at the apices of pleats in the top surface of the scale cell membrane (figure 10(I)). It is likely that the membrane and cell cytoplasm retraction contribute to the final shaping of the end product: a non-living scale.

This growth of butterfly scales exemplifies how the cell's plasma membrane can function as a template mold, while the internal actin skeleton in turn appears to structure this mold; yet it also illustrates how the other modes of production such as the secretion of chitin (additive processing), and the retraction of the cell cytoplasm and membrane (subtractive processing) are utilized in biological structure formation.

As the result of this complex structure formation process, all scales have an undulating upper surface of ridges connected by cross-ribs (figure 11); these cover a lower lamina, with intermittent trabeculae connecting the upper and lower portions. Lepidopterans follow this basic blueprint but variations on this theme reveal a wide range of geometries that achieve structural color (figure 3). For instance, a variety of butterflies and moths forms regular perforated laminae in the scale interior, which act as multilayer reflectors. Layered photonic architectures are prevalent in nature and besides their just mentioned presence in the scales of many lepidopteran species, are found in the cuticles of beetles and spiders, the scales of fish, the skin of cephalopods and the waxes of plants [20, 35].

Figure 11. Cross sections of scales of Colias eurytheme at different stages of development. (A) Developing scale of C. eurytheme with ridges clearly defined, with cuticle being expressed at the lower lamina and the ridges, but not at the windows (arrows) (scale 0.5 μm). (B) Developing scale of C. eurytheme with multiple lamellae developing on the ridge cuticle (scale 0.5 μm). (C) Mature scale cell of C. eurytheme, with lower lamina (**), ridges, and multiple lamellae formed on the ridges (scale 1 μm). (A) [40] John Wiley & Sons. © 1994 Wiley-Liss, Inc. (B) and (C) Reprinted with permission from ref [15], OSA.

Download figure:

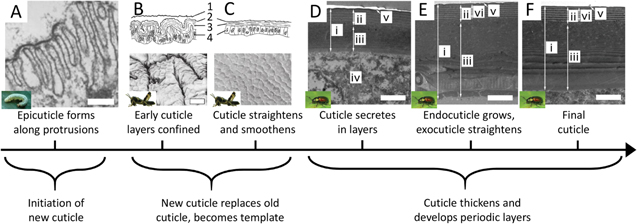

Standard image High-resolution imageMultilayer secretion: in general, layered biological morphologies that cause structural coloration appear to conform to a support structure, which operates as a template or a mold to help define the final material conformation. This approach commonly occurs in carbohydrate structures (such as chitin and cellulose) which tend to be secreted along a surface that defines its shape. Although the information available on cuticle formation is spread over diverse organisms, we can build an approximate, representative framework of the processes involved [160–166]. For instance, the leaf beetle Gastrophysa viridula secretes a chitin surface like its fellow arthropods, the butterflies; unlike them however, it forms the cuticle above tissue rather than on individual cells, and yet it also deposits in layers, each surface supporting the last [160] (figure 12). Cellulose too is secreted, forming the iridescent, pixelated reflectors found on the fruits of Pollia condensata and Margaritaria nobilis [28, 31]; in these plants the deposited cellulose nanocrystals form helicoidal structures, which give the material its unique abilities to strongly reflect circularly polarized light. This secretion likely involves additional physical processes that result in regular chirality. Curiously, similar physics might be at play in the formation processes of the helical circularly-polarized light reflecting cuticle nanoarchitectures found in some beetles, which have been compared to cholesteric liquid crystal structures [95, 167].

Figure 12. Secretion of cuticle multilayer. Although the research on cuticle growth is spread among various arthropods and life cycle stages, we can gather an overall sense of cuticle formation. (A) To begin growing a new cuticle, microvilli of epidermal cells secrete the outermost epicuticle (scale 0.5 μm). (B) The young, unhardened cuticle grows to a surface area larger than the older cuticle, causing many folds to develop (shown here in larval Schistocerca gregaria); (1) old molting cuticle, (2) epicuticle, (3) procuticle, (4) epidermis (scale 3 μm). (C) After molting, the new cuticle is allowed to straighten and smooth as it takes the place of the older cuticle, becoming in effect a template for future layers (S. gregaria). (D) As the procuticle (exocuticle and endocuticle) begin to grow, cyclic growth patterns result in alternating bands of distinct chitin arrangements (shown here in imago of Gastrophysa viridula after ecdysis; (i) dorsal elytral cuticle; (ii) exocuticle; (iii) endocuticle; (iv) hemolymph space under the cuticle; (v) epicuticle; (vi) reference length (scale 1 μm). (E) With time, the cuticle grows, and the layers may undergo slight changes in uniformity and electron density (G. viridula) (scale 1 μm). (F) The fully developed cuticle of G. viridula (scale 1 μm). (A) Reprinted from [161], Copyright (1979), with permission from Elsevier. ((A) inset) Reproduced with permission from [68]. ©2000 University of Florida IFAS. (B) and (C) Reproduced with permission from [162], Cambridge University Press. ((B) and (C) insets) Reprinted by permission from Springer Nature: Springer, Applied Entomology and Zoology, [169], 2008. ((D) to (F)) Reprinted by permission from Springer Nature: Nature, Scientific Reports, [160], 2017. ((D) to (F) insets) Adapted with permission of The Royal Society, from [170]; permission conveyed through Copyright Clearance Center, Inc.

Download figure:

Standard image High-resolution imageMinerals, which are often deposited alongside with organic materials [171, 172], can also be formed into a layered photonic structure as found in the case of blue-rayed limpets [32]. In general, mollusk shells are formed by calcification underneath the periostracum, a thin elastic membrane at the growth edge that is secreted by the mantle and links it to the forming shell. The stiffness differences between the calcified material and the mantle can lead to various shell configurations [173, 174], but the impact on the microstructure is still not well understood.

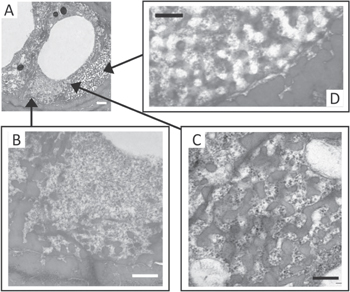

Other layered photonic structures, notably iridophores, are made by filling a mold rather than coating a template-like surface. In cephalopods, the protein reflectin fills a multilamellar membrane (discussed further below). Guanine crystal structures are likewise formed by filling intracellular membranes, in some cases with further support from fibrous structures [89, 175]. Two recent studies on copepods and scallop eyes have demonstrated that these small marine organisms can generate either highly regular hexagonal or square crystal elements that are then assembled into more complex architectures in their soft tissues to create specific optical effects [91, 176]. The extremely regular shape and size of guanine crystals are a clear sign of the exquisite control that the two organisms can exert on the underlying formation processes.

Mechanical stress deformation: mechanical stresses can modify the morphologies of secreted flat layers, leading to microscale undulations and patterns that cause light diffraction thereby producing color. In many situations, these mechanical stresses occur in response to material growth, in turn affecting the growing structures. In some butterfly species, pronounced chitin structures develop on the ridges, such as the Christmas tree-like cross-sectional pattern in Morpho species. Ghiradella proposed that lamellae formation in butterfly scales occurs by buckling [15]. The notion of buckling poses an interesting question for mechanical stresses in biological materials, because of the various approaches taken to understand buckling [177]. Some of these different frameworks include: quantifying residual stresses due to the growth of a material [178], prestrain of a substrate layer that supports a thinner layer [179, 180], and comparisons between stretching energies and substrate stiffness [181].

On the macroscale, mollusk shell growth provides an interesting case study for how stresses between soft mantle tissue and hard secreted shell determine the forming shell morphology. The mollusk's growing mantle, which deposits new shell at the growth edge, is constrained in its expansion by the already deposited shell. This leads to characteristic mantle deformations, the shape of which is then 'frozen' into the forming shell morphology as the mantle secretes the shell mineral [173, 174]. However, it is not yet known exactly if and how mechanical stresses and strains occurring between soft secreting cells and tissues and the harder secreted materials manifest themselves at the micro- and nanometer scale of the lamellar morphologies in structurally colored mollusks and other animals.

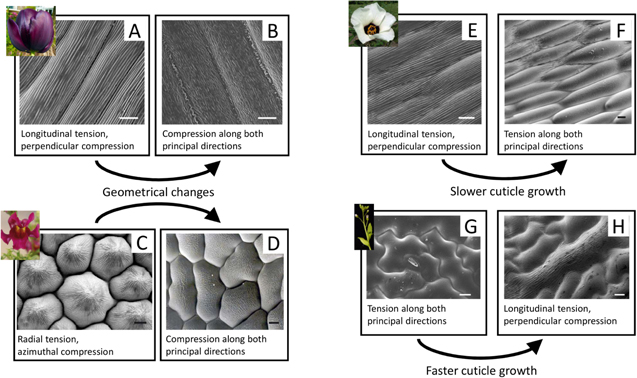

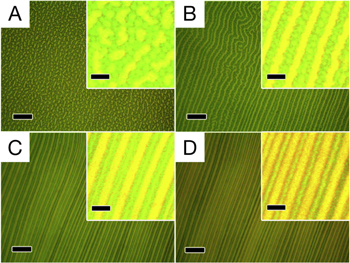

Recent models suggest that striated flower petal architectures, which are implicated in structural color generation, may result from mechanical deformation phenomena during petal development (figure 13). The petal's growth and associated mechanical boundary conditions have been characterized according to cuticle growth rate and developing principal stretches along two axes [182]. Various combinations can lead to tension in both directions (promoting smooth cells), compression in both directions (promoting disordered wrinkles), or compression in one direction and tension in another (promoting organized wrinkles). By regulating the initial geometry of the cell and the ensuing cuticle growth rate, flower petals may produce ridge patterns that cause diffraction as the origin of their structural coloration [183, 184].

Figure 13. Proposed models of cuticle pattern formation in petals and leaves. Geometrical changes can regulate ridge morphology: (A) in the 'Queen of the Night' tulip, parallel ridges are consistent with wrinkles that form under longitudinal tension and compression in the perpendicular direction. (B) In the non-iridescent petals of the tulip, minimal geometrical changes are capable of changing the stress conditions causing disorder in ridge orientation. (C) Similarly, the radial ridges in the snapdragon (Antirrhinum majus) are consistent with radial tension and azimuthal compression. (D) Mutations that lower the cone protrusion of these cells decrease the radial tension and introduce disorder in ridge material. Cuticle growth rates affect ridge formation: (E) in the dark iridescent center of Hibiscus trionum, parallel ridges also form due to the particular anisotropic conditions. (F) In the transition to non-iridescent white, the cellular cuticles are smooth, consistent with models that demonstrate slower cuticle growth, despite similar geometries. (G) The opposite is proposed to occur in the leaves of Arabidopsis thaliana, whose wild type is smooth. (H) When the organism is modified to increase cuticle growth, ridges appear. (Scale for all, 10 μm.) Adapted with permission of The Royal Society, from [182]; permission conveyed through Copyright Clearance Center, Inc.

Download figure:

Standard image High-resolution imageMechanical stresses and buckling thus may be instrumental in creating some of the morphologies found in structurally colored materials. However, to our knowledge, the role of mechanical stresses have not yet been verified in situ during the actual development of any structurally colored biological material. Nevertheless, careful assessment of material morphology and boundary conditions during the formation of specific photonic structures (such as striations on flowers), combined with mechanical modeling, could provide deeper insights into the role of mechanical effects during their growth.

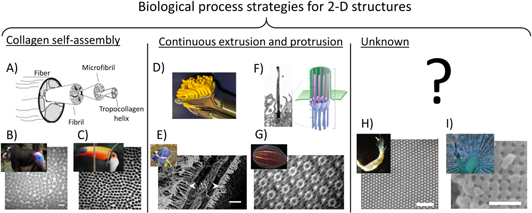

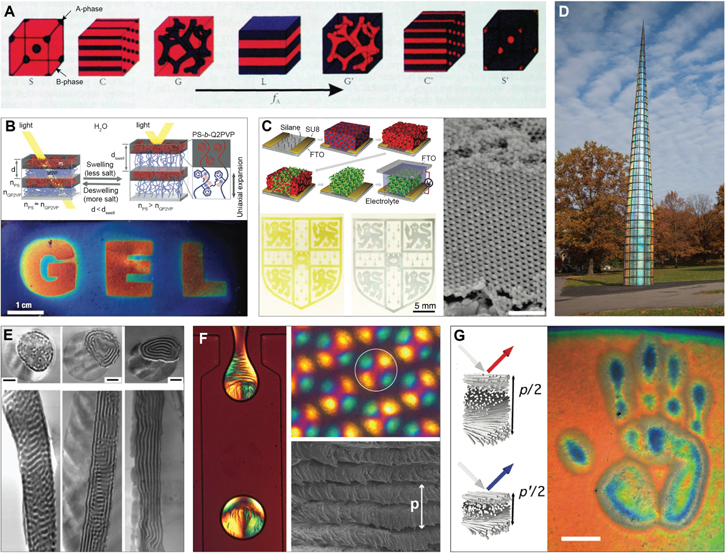

Variety in two-dimensional structures: in order to achieve material structures with two-dimensional periodicity, nature draws from a wide variety of processes (figure 14). Regularly packed collagen fibers in the coloration structures of various birds and mammals are hypothesized to form by self-assembly, which in the case of collagen is driven by inter-fiber physics [45, 93, 185–187] (figures 14(A)–(C)). Other biological 2D periodic material structures are highly suggestive of continuous processes. For example, the repeated axial symmetry in the cilia of the comb-jellyfish are composed of a central axoneme surrounded by microtubules, which are frequently involved in cilia structures and other cell protrusions [188] (figures 14(F), (G)). Other examples of continuous processes are found among members of the Odonata, who produce a wax pillar forest (with a low degree of order, yet two dimensional) via continuous extrusion through cuticle pores [138, 189, 190] (figures 14(D), (E)).

Figure 14. Biological process strategies for 2D structures. (A) Collagen fiber assembly begins with the self-assembly of the tropocollagen helix that is organized into microfibrils and fibrils, which then form a fiber. The direction, size, and spacing of these fibers are critical to the structural coloration. Collagen fibers yield 2D quasi-order in (B) the blue skin of Mandrillus sphinx (scale 250 nm) and (C) the blue skin around the eye of Ramphastos toco (scale 200 nm). (D) In extrusion, material is forced through a specified shape (as when clay is forced through a press). (E) Wax pillar forests extrude through pores in the cuticle of the dragonfly Zenithoptera lanei (scale 2 μm). (F) Cilia grow from cells due to the growth of nine microtubules protruding from the cell surface (cilia exist in a wide variety of cells; shown here is a cilia in the canary brain together with a microtubule schematic) (scale 1 μm). (G) In the comb-jellyfish B. cucumis, cilia are grown immediately next to one another, resulting in bright rainbow colors as they beat (scale 200 nm). (H) The mechanism driving the 2D order of the cylindrical voids in the chitinous setae of Pherusa is unknown (scale 2 μm). (I) Likewise, we do not yet know the physics that regulates melanin granule size and organization in avian feathers, such as those on Pavo muticus (scale 500 nm). (A) Reprinted from [192], Copyright (2003), with permission from Elsevier. (B) This 'Mandrill at Singapore Zoo' image has been obtained by the author(s) from the Wikimedia website where it was made available by Avala under a CC BY 2.0 licence. It is included within this article on that basis. It is attributed to Robert Young. ((B) SEM) Reproduced with permission from [93], The Journal of Experimental Biology. (C) This 'Toco toucan (Ramphastos toco) adult' image has been obtained by the author(s) from the Wikimedia website where it was made available by Charlesjsharp under a CC BY 4.0 licence. It is included within this article on that basis. It is attributed to Charles J Sharp. ((C) SEM) Reproduced with permission from [45], The Journal of Experimental Biology. (E) Reprinted from [189], Copyright (2015), with permission from Elsevier. ((F) Singla) From [193]. Reprinted with permission from AAAS. ((F) Alvarez-Buylla) Republished with permission of Society for Neuroscience, from [Primary Neural Precursors and Intermitotic Nuclear Migration in the Ventricular Zone of Adult Canaries, Arturo Alvarez-Buylla, 18, 3, 1998]; permission conveyed through Copyright Clearance Center, Inc. ((F) Anderson) Republished with permission of Rockefeller University Press, from [The three-dimensional structure of the basal body from the Rhesus monkey oviduct, Richard G. W. Anderson, 54, 2, 1969]; permission conveyed through Copyright Clearance Center, Inc. ((F) Preble) Republished with permission of Genetics Society of America, from [Extragenic Bypass Suppressors of Mutations in the Essential Gene BLD2 Promote Assembly of Basal Bodies With Abnormal Microtubules in Chlamydomonas reinhardtii], Andrea M. Preble, 157, 1, 2001]; permission conveyed through Copyright Clearance Center, Inc. (G) Reproduced with permission from Kevin Raskoff. ((G) TEM) Reprinted figure with permission from [188], Copyright (2007) by the American Physical Society. (H) Reproduced with permission from Andrew Parker. ((H) SEM) Reprinted figure with permission from [139], Copyright (2009) by the American Physical Society. (I) This 'Pavo muticus - Hai Hong Karni' image has been obtained by the author(s) from the Wikimedia website where it was made available by JJ Harrison under aCC BY-SA 3.0 licence. It is included within this article on that basis. It is attributed to JJ Harrison. ((I) SEM) Reproduced with permission from [191]. Copyright (2003) National Academy of Sciences, U.S.A.

Download figure:

Standard image High-resolution imageMelanin structures in some avian feathers result in two-dimensional structurally colored morphologies (figure 14(I)). During their formation, regular melanin granule structures must be generated and assembled in an orderly fashion [191, 197]. Although some older studies provide hints about the internal timeline of granule location [198], the underlying processes and related physics are generally unknown.

Polychaete worms offer another puzzle related to the formation of 2D periodic structures (figure 14(H)): the setae of the genera Aphrodita and Pherusa have well-ordered cylindrical voids in a chitin matrix [139, 199]. The authors of one study propose that chitin fibril defects may force the regular positioning of the chitin structure [139], but we do not know the time line nor the physics of the development of this structure.

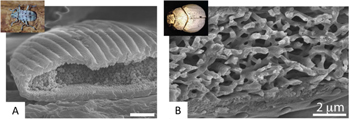

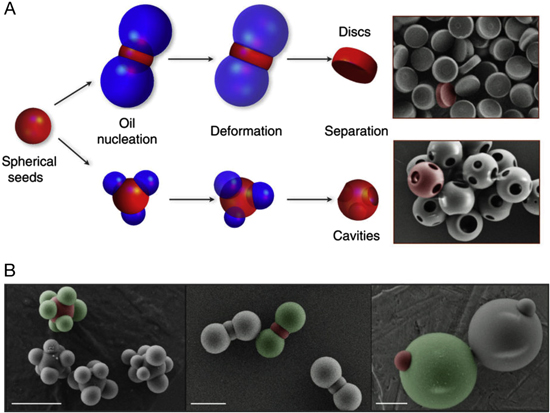

Three-dimensional structures and self-assembly: three-dimensional photonic structures appear to rely heavily on self-assembly processes [144, 200]. In some butterflies, gyroid structures—regular three-dimensional continuous network architectures—are found between the upper and lower surfaces of the scale. Gyroid morphologies are believed to be formed with the assistance of internal membranes (just as we saw in the case of multilayer formation) [71, 72, 75, 144]. Three-dimensional photonic structures observed in bird feathers offer strong indications for phase separation to be involved in the structure formation process (discussed in further detail below). Beetles also exhibit a variety of three-dimensional geometries, the formation of which is not fully understood (figure 15). Various beetles, including Pachyrhynchus argus and Pseudomyagrus waterhousei, use chitin to create 3D morphologies of ordered or quasi-ordered spheres [19, 201], which could be reminiscent of either phase separation or colloidal packing. The Cyphochilus beetle produces a different 3D geometry, employing bulk disorder to achieve brilliant white; this geometry is particularly intriguing since this particle size and distribution have not been manufacturable [202]. Disordered colloidal morphologies also form the basis for the whites produced by leucophores in cephalopod skin, although disordered multilayers have also been found to be the source of bright whites in squids [203, 204]. Little to nothing is known about the formation of these leucophore structures.

Figure 15. 3D photonic structures in beetles. (A) Although the actual processes leading to quasi-ordered 3D organization as found in the longhorn beetle P. waterhousei are unknown, both phase separation and colloidal packing can lead to similar configurations. (B) Unknown processes enable disorder of thinner structures among larger voids to achieve highly scattering white in Cyphochilus beetles. (Scale for both: 2 μm.) (A) Reprinted figure with permission from [201], Copyright (2001) by the American Physical Society. (B) Reprinted by permission from Springer Nature: Nature, Scientific Reports, [34], 2014.

Download figure:

Standard image High-resolution imageHierarchical elements: the various features of the butterfly scale also typify the hierarchical nature of biological materials. Biological shapes are frequently appreciated for being hierarchical [205–207]. One useful definition for hierarchy is pattern or order at various length scales [107]. Hierarchical design of material structures might be essential to ensure a particular function, as well as enabling multifunctional behavior [42, 208].

For example, the hierarchical silica frustules of diatoms are of interest not only for their optical behavior [209–211], but also for a wide range of applications, from drug delivery to fluid filtering [212]. In diatoms, organization of actin and microtubules appear to be closely related to their silica structure patterns [213], perhaps hinting at a templating-like process similar to those in butterfly scales. Yet a broad range of components seem to impact the structures at various orders of magnitude, from silica deposition to the overall valve structure [214–216]. However, the physical processes driven by these components and, moreover, their combined effects is still an open question.

Although biology is particularly adept at integrating diverse structural motifs across many length scales, little is known about the biological processes that define and control hierarchy throughout the 100 nm–10 μm range.

3.3.2. Self-assembly

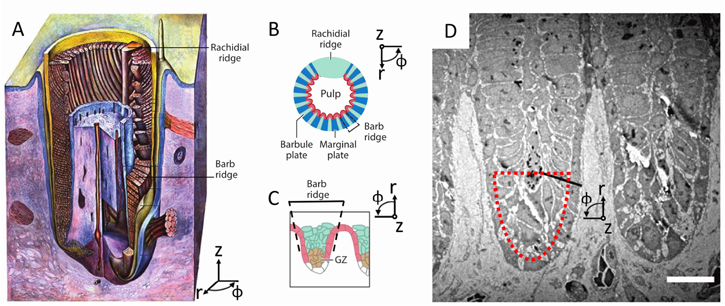

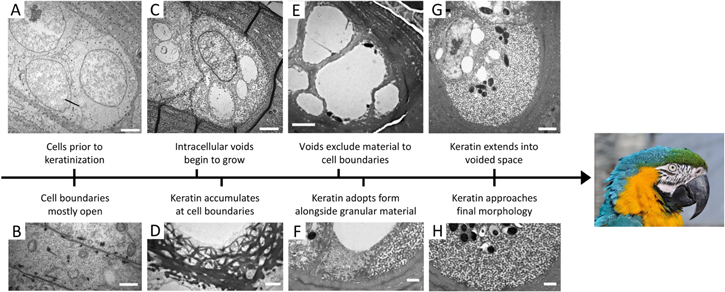

Example, keratin self-assembly in avian feathers: self-assembly processes appear to occur in the formation of biological photonic materials and they carry significant potential for technical understanding and synthetic material design. Keratin development in bird feathers offers an exemplary case study of the self-assembly of three-dimensional structurally colored biological materials. In addition to the nanostructuring that imparts coloration, the development of feathers is of interest for their varied hierarchical morphologies, which has implications for the function of feathers [140, 197, 217–221]. A bird's feather grows from a follicle on the birds' skin (figure 16). The follicle begins as a proliferation of epidermal cells, which form into a budding papila, dipping below the surface of the epidermis to form the cavity and rising to form the initial protrusion. Inside the bulk of the papila is the dermal pulp, which is surrounded by exterior cells called the collar. The cells in the collar then differentiate and begin to form into barbs (some of which merge into the main vain, the rachis); later cells further differentiate into barbules. As the papila grows upward, the barbs marvelously grow 'backward,' their tips extending back to eventually merge with the rachis. During this progression in cellular arrangement, keratin is produced via normal protein production within the cells [133] (figure 17). The keratin aggregates, with keratin fibrils elongating as the feather grows. Later, the cells dehydrate, altering the relative composition and arrangement of the cell, before finally leaving behind the keratinous structure of the feather [133, 222].

Figure 16. The growing feather. (A) Feather growing from feather follicle in the dermis (purple): the epidermis (blue cross section and yellow-blue surface) invaginates the dermis (purple), leaving a central core, the dermal pulp (also purple); the rachis, barbs, and barbules grow in the cavity. (B) A representative cross-sectional schematic of the growing feather; the barb ridges wrap around the pulp, meeting at the rachis. The feather grows out and away from the surface out of the follicle collar; unlike typical plant growth, where tips grow at the leading edge, the feather first grows the distal tips and then proceeds to grow the proximal regions of the feather. (C) A close-up cross-sectional schematic of the developing barb ridge, showing the region that will form the marginal plate (red) and the growth zone (GZ, brown); the pulp is toward the bottom of the image. (D) Along a cross-section of the growing feather, multiple barb ridges are shown, with the center of the follicle toward the bottom of the image; outlined in red is the general region shown in figure 17 (scale 10 μm). (A) Reproduced from [223]. (B) Reprinted from [224], Copyright (2007), with permission from Elsevier. (C) Republished with permission of Annual Reviews, from [220]; permission conveyed through Copyright Clearance Center, Inc. (D) 'Republished with permission of The Royal Society, from [222]; permission conveyed through Copyright Clearance Center, Inc.

Download figure:

Standard image High-resolution imageFigure 17. Development of keratin structures in feathers of the macaw Ara ararauna. (A) Prior to keratinization, medullary cells have enlarged nuclei (scale 2 μm). (B) Unknown structures are found along cell boundaries, which are otherwise mostly free (scale 1 μm). (C) The cells then develop voids in the cytoplasm (scale 2 μm). (D) At the same time, keratin begins to accumulate at cell boundaries (scale 1 μm). (E) Later in development, the cytoplasmic voids have filled almost the entire cell (scale 3 μm). (F) Keratin begins to develop its tortuous channel, spinodal form alongside other 'granular' material (scale 1 μm). (G) The keratin structures spread and the voids shrink (scale 2 μm). (H) The keratin network is nearly fully developed (scale 1 μm). Republished with permission of The Royal Society, from [222]; permission conveyed through Copyright Clearance Center, Inc. (Parrot) This 'Portrait of a Blue-and-yellow Macaw (Ara ararauna) in the Vogelburg (bird park) Hochtaunus, Weilrod, Germany' image has been obtained by the author(s) from the Wikimedia website where it was made available under a CC BY-SA 3.0 licence. It is included within this article on that basis. It is attributed to Quartl.

Download figure:

Standard image High-resolution imageThe resulting microstructure of the feather is remarkably similar to the structures that self-assemble during polymer phase separation [46, 79, 222] (figure 18). The study of polymer blend systems has shown that phase separation can proceed in two different ways: spinodal decomposition (which leads to winding or tortuous channels), or nucleation and growth (which leads to spherical or inverse sphere structures) [225, 226]. Transmission electron microscopy studies of feathers from various species illustrate that the spatial distribution of keratin closely matches the structures from one of either of these two phase-separation processes [79]. Additionally, another study of feathers at mid-development reveals no sign of template or mold features like those observed in the butterfly, but rather show a progression of aggregation and voids in the cellular space [222]. However, the authors of that study point out that the structural growth is not identical to 'simple' phase separation, but rather is likely modified by spatially varying composition changes within the cell. Moreover, some targeting must be involved in the initial keratin production, since keratin growth begins at the periphery of the cell [133, 222]. Thus, when considering self-assembly in biology we must be careful to account for other guiding processes that contribute to structure formation.

Figure 18. Various stages of keratin structure formation. (A) Various stages of structure development are present in medullary cells (scale 1 μm). (B) Granular material interspersed with 'unformed' keratin (scale 600 nm). (C) Keratin structure undergoing formation (scale 300 nm). (D) Keratin begins to take final form (scale 300 nm). Republished with permission of The Royal Society, from [222]; permission conveyed through Copyright Clearance Center, Inc.

Download figure:

Standard image High-resolution imageTolerance control: tolerances in the formation of particular features are worth considering when studying biological growth of structurally colored materials, since the materials' interaction with light is closely determined by optical path lengths and structural order. For feathers, timing is key to halt spinodal decomposition, when the channels are the exact right size [222]. Many feathers demonstrate short-range order but less long-range order [79]; additionally, feathers can achieve a smooth color gradient by having cells create one of only two structural colors [222]. In beetles of the genus Eupholus, different degrees of long-range order in three-dimensional photonic structures leads to differences of brightness and color in the beetle's scales, resulting in a characteristic stripe pattern [41].

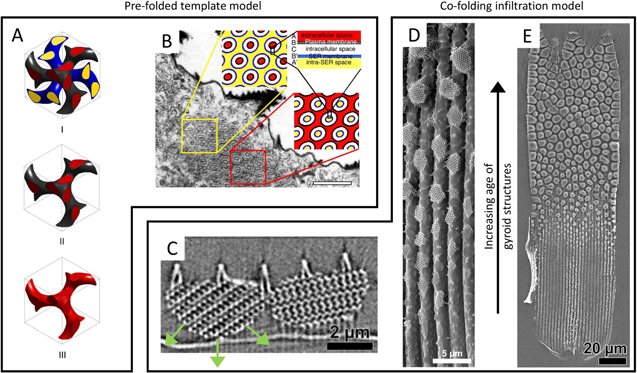

Gyroids, a debate in self-assembly: self-assembly is also believed to drive the structural formation of gyroid morphologies in butterfly wings. Lipid membranes have a variety of stunning phases that are compatible as scaffolds for chitin growth [144]; in the butterfly scales, the plasma membrane and the smooth endoplasmic reticulum membrane are thought to define a double-gyroid phase, allowing chitin to fill the space excluded by the plasma membrane [72] (figures 19(A), (B)). Yet, an alternative model recently proposed that, instead of any phase separation process, the chitin and the plasma membrane co-fold [75] (figures 19(C)–(E)). Under this model, the chitin and plasma membrane gradually self-assemble a gyroid and grow into the cell interior; this process initiates at different sites: it appears to be first occurring at the scale tip and progressing backwards from there.