Abstract

We have demonstrated an industrial 6 kW single-stage end-pumped all-fiber laser oscillator based on a conventional large mode area ytterbium-doped fiber (YDF) with 30 μm core diameter and 600 μm inner-cladding diameter. As a result, the fiber oscillator achieved a maximum output power of 6.07 kW at a central wavelength of ∼1080 nm with a slope efficiency of ∼65.8%. The power of Raman Stoke light was 21.6 dB smaller than the signal light at the output power of 6.07 kW. For industrial application, the stimulated Raman scattering effect was further suppressed by employing a 50 μm-core delivery fiber, and no sign of dynamic transverse mode instability comes into view during the whole experiment. The power stability measurement at ∼6 kW operation was carried out for continuous 2 h, and the power fluctuation was within 0.31%. To the best of our knowledge, this is the first detailed demonstration of industrial 6 kW high-stability single-stage all-fiber laser oscillator based on conventional YDF. The results provide a significant guidance for the construction of more than 6 kW output power single-stage end-pumped all-fiber laser systems.

Export citation and abstract BibTeX RIS

1. Introduction

Benefiting from the excellent beam quality, convenient thermal management, simple structure and high robustness, the fiber lasers are becoming one of the most promising laser sources in various fields, ranging from industrial processing, national security, medical sciences and so on [1, 2]. During the past two decades, owing to the rapid development of high-brightness laser diodes (LDs) and the large mode area (LMA) double-cladding fiber fabrication technology, the average output power of fiber lasers has experienced a dramatic boost with near diffraction-limited beam quality [3–5]. At present, a number of high-power continuous-wave (CW) fiber lasers with output power beyond 5 kW are realized through a master oscillator power amplifier (MOPA) architecture [6–10]. However, the MOPA system is susceptible to reflection from materials during processing, which makes it restricted in industrial applications. In comparison with the MOPA system, the single-stage monolithic fiber laser oscillator has the advantages of a fewer components, robust operation, strong anti-reflection ability. For the industrial application, the fiber oscillator with all-fiber-integrated structure enables more compact size as well as maintenance-free and convenient operation, compared to the free-space optics setup [11]. Due to the improvements of key components including LMA fiber Bragg gratings (FBGs), the single-stage all-fiber laser oscillators have earned an increasing output power and become more favored in industry [12–17]. In 2012, the researches in Alfalight Inc. reported a 1 kW CW all-fiber laser oscillator, of which the active fiber was ytterbium-doped fiber (YDF) with a core/inner-cladding diameters of 20/400 μm [12]. In 2016, Yang et al demonstrated a 2.5 kW single-mode monolithic all-fiber laser oscillator based on 20/400 μm YDF as well as the bidirectional 976 nm pump scheme [14]. Later in 2018, the researchers in Fujikura Inc. presented a 5 kW single-mode single-stage all-fiber laser oscillator based on a specially designed active fiber with a mode area of 600 μm2 [16]. Recently, the output power of the single-stage all-fiber laser oscillator has further scaled to 8 kW by researchers from Fujikura Inc. [17].

Yet, despite the aforementioned fiber oscillators with a relatively high power, most of these were realized by utilizing specially designed active fiber, which did not provide more information about detail and are not commercially available [16, 17]. In order to develop the industrial-grade high-power fiber lasers, employing the commercial fiber optic devices, especially commercial active fiber, is the most convenient and costless solution. However, the maximum output power of the single-stage all-fiber laser oscillator based on a conventional commercial YDF is only 5 kW level [18, 19], which is still menaced by the stimulated Raman scattering (SRS) and transverse mode instability (TMI) [20–24]. In 2018, Yang et al reported a 5.2 kW monolithic all-fiber laser oscillator based on an active fiber with core/inner-cladding diameters of 25/400 μm [18]. But the Raman intensity was only ∼22 dB below the signal laser and further power scaling was severely restricted by the SRS effect. Also in 2018, a single-mode 5 kW monolithic fiber laser oscillator was achieved by researchers from Jena based on a commercial active fiber with core/inner-cladding diameters of 20/400 μm [19]. However, because of the active fibers with smaller core areas, the SRS effect became the striking limitation for the monolithic all-fiber laser oscillator to obtain higher output power. In terms of the industrial fiber laser, adopting a larger mode area fiber to inhibit the SRS effect is the most effective and simplest strategy to achieve high-power stable output.

In this manuscript, an industrial 6 kW single-stage end-pumped all-fiber laser oscillator was demonstrated by employing a conventional YDF with a core/inner-cladding diameters of 30/600 μm and corresponding FBGs operating at the center wavelength of ∼1080 nm. When the pump power reaches ∼9.3 kW, the maximum output power of 6.07 kW was achieved with a slope efficiency of ∼65.8%. The intensity of Raman stoke light was 21.6 dB smaller than the signal light at the maximum output power, and no sign of the TMI effect has been observed during the whole experiment. Finally, an industrial prototype of 6 kW CW all-fiber laser oscillator was developed by further suppressing the SRS.

2. Experimental setup and design

The experimental setup of the single-stage all-fiber laser oscillator is illustrated in figure 1. The fiber oscillator is constructed as a bidirectional pumping scheme, which can not only increase the injected pump power, but also disperse the heat load, thereby mitigating the TMI effect [15, 25]. High brightness 915 nm LDs are used as the pump source and each LD module can provide a maximum pump power of ∼900 W. The pump lights inject into the laser cavity through two (6 + 1) × 1 pump/signal combiners which act as the forward combiner and backward combiner, respectively. Both combiners incorporate the pump light into the inner-cladding of the output fiber which has a diameter of 600 μm and a numerical aperture (NA) of 0.46. The pump ports of the two combiners are multimode fiber with a core/cladding diameters of 220/242 μm, which are identical to the pigtail fiber of the LD module. The occupied pump ports have a coupling efficiency of more than 98% and the unoccupied ports are angle cleaved to avoid facet reflection. The signal ports of the combiners have a core/inner-cladding diameters of 30/250 μm. The laser oscillator cavity consists of an active fiber and a pair of FBGs which are utilized as the resonant cavity mirror. The active fiber in the cavity is a conventional double-cladding YDF with 30 μm/0.061 NA core and 600 μm/0.46 NA inner-cladding. The pumping absorption coefficient of the YDF is 0.47 dB m−1 at 915 nm. The length of the YDF is adopted as ∼40 m in the experiment to guarantee sufficient pump absorption. Considering the impact of fiber bending on TMI and optical efficiency [26, 27], the YDF is coiled in a circle groove of water-cooled plate with a minimum bending diameter of ∼18 cm. Both the FBGs are engraved on the double-cladding fiber which are the same parameters as the active fiber. The reflectivity of high-reflectivity FBG (HR-FBG) and output-coupler FBG (OC-FBG) is ∼99.9% and ∼10.8% at ∼1080 nm, respectively. The full width at half maximum (FWHM) of the HR-FBG and OC-FBG is respective ∼1.90 nm and ∼1.01 nm. To deliver the signal laser, a ∼3 m passive fiber with a core/inner-cladding diameters of 30/400 μm is spliced to the signal fiber of the backward combiner. On the passive fiber, a homemade cladding light stripper (CLS) is conducted to remove the unwanted cladding light. At the end, a ∼4 m commercial quartz block head (QBH) with the same size as the passive fiber is utilized to output the signal laser and eliminate the end facet reflection. In the experiment, all of components, except of the endcap and the measuring system (as shown in the inset of figure 1), are fixed on a water-cooled plate for efficient thermal management.

Figure 1. Experimental setup of the single-stage all-fiber laser oscillator system (the inset is the measuring system, including CO: collimator, HR: high reflector, PM: power meter, OSA: optical spectrum analyzer, PD: photodetector, DM: dichroic mirror).

Download figure:

Standard image High-resolution imageAlthough the active fiber with a larger core diameter (∼30 μm) can help to alleviate the SRS effect, the TMI effect could appear during high-power operation because the more high-order modes (HOMs) are supported in the fiber core, thus requires more attention. In order to detect the occurrence of the TMI, the temporal signals are measured by using two photodetectors (PD1, PD2) (150 MHz, 700–1800 nm), which are put in the center of the collimated light and near the CLS, respectively [27–29]. The SRS in the spectrum is monitored by an optical spectrum analyzer. The beam quality and beam profile of the output laser is measured with a beam quality analyzer (M2-200).

3. Results and discussion

3.1. Power scalability in the co-pump scheme

To estimate the power scalability, the output performance of the fiber oscillator with only co-pumping is firstly investigated. The output performances including output power, optical spectrum, temporal signals are measured and recorded. The measured output power and the corresponding optical-to-optical efficiency are shown in figure 2(a). It can be seen that the output power exhibits linear increase with the injected pump power with a slope efficiency of ∼66.3%. The output laser gets a maximum power of 3.08 kW with an optical-to-optical efficiency of ∼65.5%. It is worth noting that no saturation is observed in the curve near 3.08 kW, which shows an ability to further scale the power. The output spectrum of the fiber oscillator at different output powers are exhibited in figure 2(b). With the increasing of output power, the spectral bandwidth of signal laser broadens slightly, which is mainly attributed to the fiber nonlinear effects, such as self-phase modulation and four-wave mixing effect [30]. In the spectrum, no Raman Stokes component is observed in the range of ∼1120 nm–1145 nm, which indicates no obvious SRS effect appears at this power level.

Figure 2. (a) The output power and corresponding optical efficiency in co-pump scheme and (b) the optical spectrum at different output powers.

Download figure:

Standard image High-resolution imageFurthermore, the temporal signals of output laser and stripped cladding light are record with two PDs to confirm the appearance of TMI, which is typical characteristics of the TMI resulting from the dynamic coupling between the fundamental mode and the HOMs [28]. The standard deviations (STDs) of the temporal signals of the output laser are calculated and shown in figure 3(a), which can be employed to quantify the temporal stability and verify the occurrence of TMI in the power scaling [4, 27, 29]. During the power scaling process, all of the STD of temporal signals are at a very low level (STD < 0.01), and no remarkable increase of the STD is observed. Figure 3(b) presents the both normalized temporal signals of both output laser and the stripped cladding light at the output power of 3.08 kW. The corresponding Fourier spectra by conducting Fourier transform on the temporal signals are shown in figure 3(c). As we can see, both temporal signals are quite stable and there are no coupling frequency peaks emerged in the corresponding Fourier spectra, which implies that the fiber oscillator system does not suffer from TMI effect at this power. Compared with our previous work pumped by 976 nm LDs [31], this fiber oscillator under 915 nm pump holds a higher TMI threshold. This is mainly due to the fact that the 915 nm pump corresponds a lower pump absorption compared with 976 nm, which leads to lower upper state populations and results in stronger transversal hole burning, thus, contributes to increase the TMI threshold [24]. Besides, for an enough pump absorption, under 915 nm pump condition, the active fiber has a longer fiber length. In long fibers, the inversion levels are relatively lower and more prone to transversal hole burning, thus enhances the TMI threshold [24].

Figure 3. (a) The STD of the temporal signals of the output laser; (b) the temporal signals at 3.08 kW; and (c) the corresponding Fourier spectra at 3.08 kW.

Download figure:

Standard image High-resolution imageAccording to the above analysis, it can be concluded that the fiber oscillator has no obvious evidence of SRS and TMI observed when the output power reaches to 3.08 kW in co-pump scheme. In previous works, it is well-known that the counter-pump scheme and the bidirectional-pump scheme provide a relatively higher TMI threshold than the co-pump scheme in fiber oscillators [15, 22]. Accordingly, the laser performance of the output laser with counter-pump scheme is not given in this work for brevity.

3.2. Power scalability in the bidirectional pump scheme

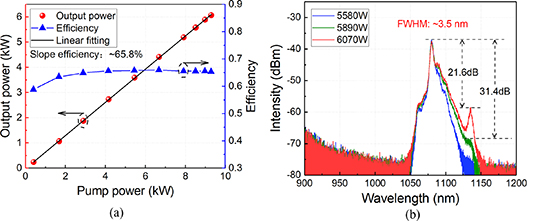

After completing the co-pumping experiment, the laser performances of the monolithic all-fiber laser oscillator with bidirectional pumping are carefully studied. The output power and the corresponding optical-to-optical efficiency as a function of the pump power are shown in figure 4(a). One can see that the output power maintains linear increment with the pump power with a slope efficiency of ∼65.8% and no evidence of roll-over power is observed. When the total pump power reaches ∼9.3 kW, the maximum output power of 6.07 kW is achieved with the corresponding optical-to-optical efficiency of ∼65.3%, which is relatively higher than the optical efficiency reported in [18]. This is mainly because that the bending diameter (∼18 cm) in this fiber oscillator is larger than that of ∼12 cm in [18], thus more guide modes propagate in the fiber core with larger bending diameter. The optical spectra dependence on the output powers are also measured, as depicted in figure 4(b). At the maximum output power, the FWHM bandwidth of the signal laser is ∼3.5 nm. Thanks to enough pump absorption and the CLS performing on the passive fiber, no residual pump light can be found in the spectrum. In addition, a spectral peak in the central wavelength of ∼1132 nm is emerged because of the SRS effect. With the output power increasing to 5.89 kW, the intensity of Raman Stokes light is 31.4 dB smaller than the signal light. When the output power is further extended to 6.07 kW, the Raman intensity is only 21.6 dB below the signal laser, but it still shows that the contribution of signal laser to the output power is more than 99%.

Figure 4. (a) The output power and the corresponding optical efficiency in bidirectional pump scheme; and (b) optical spectra at different power levels.

Download figure:

Standard image High-resolution imageThe STD of the temporal signals of the output laser and stripped cladding light at different power levels are shown in figure 5(a). It is clear that the STD of both output laser and stripped cladding light did not increase remarkably during the power scaling process. The time domain signals of the output laser at different output power levels are recorded and shown in figure 5(b). As the output power raises to 6.07 kW, the STD of the normalized temporal signal is only 0.006 and there is no characteristic periodic fluctuation observed in the time trace, which means the absence of dynamic mode coupling in the output laser. The corresponding Fourier spectrum are calculated and given in figure 5(c). It can be seen that the Fourier frequency spectrum are all clean at the output power of 5.58 kW, 5.89 kW and 6.07 kW, which further confirms that no TMI effect has occurred during the power scaling.

Figure 5. (a) The STD of the temporal signals at different power levels; (b) temporal signals at different output powers; and (c) the corresponding Fourier spectra.

Download figure:

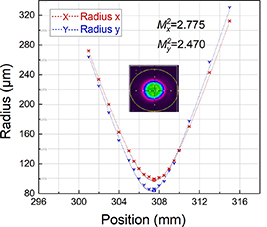

Standard image High-resolution imageThe beam quality of the output laser is also measured with a beam quality analyzer (M2-200). The measured M2 factors and beam profile at the beam waist are shown in figure 6. The M2 factor is measured to ∼2.6 (M2 x =2.775, M2 y =2.470) at the output power of 6.07 kW. Compared with the fiber oscillator reported by Fujikura Inc. [17], the beam quality of this fiber oscillator is relatively worse, because the adopted gain fiber does not have mode selection capability. The gain fiber in the experiment has a large core diameter of 30 μm (NA = 0.061), which corresponds to a V parameter of ∼5.36 at the operation of ∼1080 nm and thus several core modes (LP01, LP11, LP21, LP02, LP31) are supported in this fiber. According to the classical theory by Marcuse [32], while the minimum fiber bend diameter with ∼18 cm, the bend loss of LP01 and LP11 mode are much less than 0.1 dB m−1 and the bend loss of LP21 mode is ∼1.77 dB m−1, which implies this fiber oscillator is all the time in the few-mode operation. Therefore, it comes very naturally that the output laser contains some HOM contents and a relatively poor beam quality is observed during high-power operation. Although the beam quality in the experiment is not very good, it is acceptable for industrial high-power fiber lasers with output power exceeding 6 kW.

Figure 6. Beam profile at an output power of 6.07 kW.

Download figure:

Standard image High-resolution image3.3. SRS suppression and power stability

In order to realize an industrial 6 kW high-power all-fiber laser oscillator with long-term stable output performance, the limitation of SRS has to be effectively mitigated. For the industrial fiber laser, it is common and effective approach to adopt a delivery fiber with a larger mode field area to further suppress the SRS effect [2]. In the experiment, a homemade QBH with a fiber core diameter of 50 μm and the length of ∼4 m is used to instead of the 30/400 μm QBH at the output end. During the power scaling process, the output spectrum versus different output powers are measured and plotted in figure 7(a). One can see that the nonlinear effects, especially SRS effect, are greatly suppressed and the intensity of Raman Stokes light is more than 40 dB below the signal light at the output power of 6.06 kW. At last, to better characterize the performance stability and engineering capability of this 6 kW single-stage end-pumped all-fiber laser oscillator, a continuous 2 h test at an output power of ∼6 kW is conducted. During the test process, the power, spectrum, temporal signal and thermal distribution are measured and exhibit a considerably stability. The evolution of the output powers dependence on the test time is illustrated in figure 7(b). The average output power during the test is ∼6.04 kW and the power fluctuation is less than 0.31% with no sign of photo-darkening observed. The experimental results show that this 6 kW single-stage end-pumped all-fiber oscillator based on conventional active fiber has high stability in the long-term operation.

Figure 7. (a) Output spectrum with 50 μm-core endcap; and (b) the evolution of the output powers during the test process.

Download figure:

Standard image High-resolution image4. Conclusion

In conclusion, an industrial 6 kW high-stability single-stage monolithic all-fiber laser oscillator was demonstrated based on a conventional YDF with a core/inner-cladding diameters of 30/600 μm. In the experiment, we have achieved a maximum output power of 6.07 kW with an optical-to-optical efficiency of ∼65.3%. With the 30/400 μm fiber output, the intensity of the Raman Stokes light was 21.6 dB below the signal laser at the output power of 6.07 kW and no sign of the TMI has been observed during the whole experiment. The FWHM bandwidth of ∼1080 nm signal laser is ∼3.5 nm and the beam quality (M2 factor) is measured to ∼2.6 at the maximum output power. For the industrial application, the SRS effect was further suppressed by using a 50 μm-core delivery fiber. An industrial prototype of a 6 kW CW end-pumped all-fiber laser oscillator was developed and tested for continuous 2 h. The average output power was ∼6.04 kW with a long-term power stability within 0.31% during the test process. To the best of our knowledge, this is the first detailed demonstration of industrial prototype of 6 kW single-stage all-fiber laser oscillator based on conventional YDF. These results provide a reliable engineering solution for constructing the single-stage end-pumped all-fiber laser systems with output power exceeding 6 kW or above.

Acknowledgments

This work is partly supported by the National Natural Science Foundation of China under Grant No. 61735007. The authors wish to thank Mr Kun Zhang, Mr Xiaoyong Xu, Mr Tao Song, Mr Chuanchuan Zhang and Mrs Siliu Liu for their helpful assistance in the experiment.