Abstract

A kind of controllable multi-wavelength focusing metalenses is proposed. The proposed metalenses consist of identical nanometer holes etched in silver film and the beam focusing at three primary wavelengths is controlled without additional phase compensation. Transmission field of metalens satisfies the in-phase interference condition at different wavelength and the fixed focal effect for three primary wavelengths and the color separation along the transverse or longitudinal direction are realized respectively. Simulation and experimental results verify the controllable focusing performance of the proposed metalenses. Simple design, convenient manufacture and effective color controllable focusing of these proposed metalenses are helpful for the applications of metalenses in lightweight chromatically-corrected displaying and imaging systems.

Export citation and abstract BibTeX RIS

Original content from this work may be used under the terms of the Creative Commons Attribution 4.0 licence. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

1. Introduction

Dispersion is a popular optical phenomenon in the refractive and diffraction of light. For a material with normal dispersion, one refractive lens has larger focal length for the light with larger wavelength than that with smaller wavelength, but one diffraction lens takes on the contrary dispersion [1, 2]. This is because the focusing of refractive lens depends on the refractive law relating to the refractive index of material, which usually decreases with increase of wavelength, and the focusing of diffraction lens is determined by the diffraction equation, where the diffraction angle is proportional to the wavelength. A traditional achromatic system combines many optical components and needs more elaborate design, and it is consequentially more bulky and complex [3, 4].

In recent years, with the development of nanotechnology, metasurfaces based on nanoscatters have gained much attention due to the ultrathin and compact structure and the powerful ability in light field manipulation [5, 6]. With comparison to the conventional optical devices, metasurface modifies the light field through the introduced abrupt change of optical parameters. To date, metasurface devices have been applied in wave front manipulation [7–9], optical spin hall effect [10], optical holography and imaging [11, 12] and so on. Metalenses have been also presented and the dispersion of metalens becomes an inescapable issue. With comparison to multiple-layered or cascaded metasurfaces, single-layered metasurfaces have the advantages of low power loss and convenient manufacture. Therefore, single-layered metasurfaces consisting of complex units have been proposed to eliminate the dispersion of metalenses. Resonant antennas with decades of shapes [13], rotational symmetry pillars with several shapes [14], coupled nanorods [15], double or triple nanofins [16, 17], and solid and reverse nanopillars [18] are utilized to design the metalenses and achieve the achromatic focusing. These excellent works provide the sound basis for promoting the applications of the metalenses.

With comparison to the normal disperse of metalens, the controllable multi-wavelength focusing metalens with easy design and convenient fabrication is more expected and more practical. Multi-wavelength achromatic focusing is realized usually using two or more suits of nanounits [15, 19–21]. In this paper, we aim to use one suit of nanostructure to control the light focusing at three primary wavelengths. The proposed nanostructure consists of the identical rectangular nanoholes, and the phase shift introduced by the rotation of nanoholes enables the lights with different wavelengths focus at the desired positions. The focusing positions may be the same point or different points along transverse and longitudinal directions. Simulation and experimental results verify the fixed-focal effect and color separation performance of the proposed metalenses. Simple design and multi-wavelength controllable focusing of the proposed metalenses are beneficial to extending the applications of metalenses in the color displaying and integrated imaging.

2. Dispersion of metalens

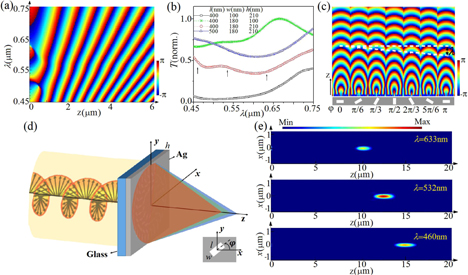

It is known that the transmission of a nanostructure depends on its geometric parameters and the illuminating wavelength. We simulate the transmission of a rectangular hole etched in silver film and figure 1 show the variations of the transmission phase and intensity of a rectangular nanohole at one or more wavelengths with the propagation distance, the size of hole and the rotation of hole. Figure 1(a) gives the transmission phase distribution of one nanohole illuminated by the continuous light with the wavelengths from 0.45 μm to 0.75 μm. Figure 1(b) shows the transmission spectra of the nanohole as the length, the width and the thickness of film take different values and figure 1(c) shows the transmission phase distributions of the rotated nanoholes under the circularly polarized light illumination with the wavelength taking 633 nm. It can be seen that for different illuminating wavelength, the transmission phase difference appears with increase of the propagation distance. The transmission intensity for the same nanohole is different at the different wavelength. Moreover, the wave front is also different for the rotated nanohole, and the phase delay introduced by the rotation of nanohole equals to twice of the rotation angle.

Figure 1. (a) Phase distribution of one rectangular hole for different incident wavelengths changing with the propagation distance, (b) transmission spectra (T) of a rectangular hole with different parameters, (c) transmission phase distributions of a rectangular hole with different rotation angles, (d) schematic diagram for a general focusing metalens and (e) the dispersion focusing effect of a metalens at three primary wavelengths

Download figure:

Standard image High-resolution imageWe arrange the holes along the circle with the radius of r, and the rotation angle of the hole at coordinate of (x, y) with r = (x2+y2)1/2 satisfies the following relation:

The concentric circles satisfying equation (1) form the metalens with the focal length of f. Here, the positive and negative signs are for the right- and left-handed circularly polarized light with the wavelength of λ. In order to compare conveniently, we take the rectangular hole with the close transmissions at three primary wavelengths as the nanounit. Thus, the nanohole with the length of 400 nm, the width of 180 nm and the film thickness of 210 nm is used, and the arrows inserted in figure 1(b) show the transmissions of this nanohole at three wavelengths of 633 nm, 532 nm and 460 nm. For practical metalenses, the transmissions for different wavelengths may change slightly with the arrangement of rectangular holes.

Figure 1(d) shows the schematic diagram for a focusing metalens consisting of the nanoholes etched in silver film and arranged on basis of equation (1), where the illuminating light impinges the nanoholes from the glass substrate. This metalens has the inherent chromatic dispersion because the introduced phase delay depends on the illuminating wavelength. Figure 1(e) gives the simulated focusing effects of one metalens for three primary wavelengths, and the results from top to down are for λ = 633 nm, 532 nm and 460 nm. Obviously, the focal length is smaller for the longer wavelength. This is so-called dispersion of metalens. The intensity difference of three focal spots for different wavelengths results from the interaction of hole arrays.

It needs to be pointed out that these simulated results are obtained by using the finite difference time domain technique [22, 23]. Here, the perfectly matched layers are used to prevent non-physical scattering at the boundaries. The non-uniform mesh type is utilized to satisfy the higher calculation accuracy. The dielectric constant of silver is taken from the value given by Palik [24]. Certainly, since the slight brightness difference results from the unequal transmittance and the size of focal spot depends on the numerical aperture with respect to the focal length, the differences of the brightness and the size among three focal spots are still clear.

3. Multi-wavelength fixed-focal metalens

In order to focus the lights with different wavelengths at the same point on the propagation axis, we let the holes consisting of this metalens rotate the angles satisfying the following relation:

where m and n are integers and three wavelengths satisfy the inequality of λ1 < λ2< λ3.

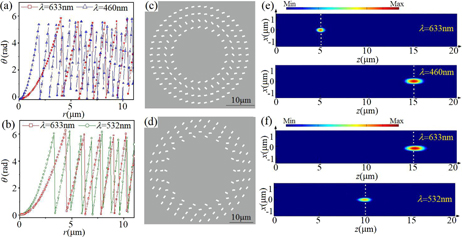

Figure 2(a) shows the phase distributions of three monochrome focusing metalenses for λ1 = 460 nm, λ2 = 532 nm and λ3 = 633 nm. Obviously, their phases at intersecting radii are equal or have phase difference of 2π and these radii can be ascertained by the given wavelengths and the focal length. This means that these phase fronts can construct a fixed-focal metalens. Figure 2(b) gives the structure diagram of the fixed-focal metalens for three primary wavelengths. Here, the focal length of this fixed-focal metalens are set at f = 10 μm, and the radii of four circles for hole arrays take r1 = 8.82 μm, r2 = 13.35 μm, r3 = 17.34 μm and r4 = 21.11 μm, respectively. The numerical aperture of this metalens is about 0.9. Figure 2(c) shows the focusing effect of this fixed-focal metalens illuminated respectively by three monochromatic lights.

Figure 2. (a) Phase distributions of the metalenses for three wavelengths, (b) the top view of the fixed-focal metalens and (c) the focusing effect at different wavelengths.

Download figure:

Standard image High-resolution imageFrom the results of figure 2(c), we can see that the focal spots at three wavelengths appear at the same propagation distance of 10 μm though some secondary bright spots appear among the diffraction patterns. This indicates that this simple metalens can realize the multi-wavelength focusing at the same point.

4. Longitudinal color separation metalens

On basis of the similar design principle, we can obtain the controllable focusing metalens with the focal spot for different wavelength separated along the longitudinal direction, and we call it as longitudinal color separation metalens. As the light with larger wavelength concentrates at the farther distance and the light with smaller wavelength focuses at the nearer distance, we call it as the controllable abnormal or negative dispersion. Reversely, as the light with larger wavelength concentrates at the nearer distance and the light with smaller wavelength focuses at the farther distance, we call it as the controllable normal or positive dispersion. For realizing the longitudinal color separation metalens, the rectangular holes in space rotate in terms of the expression of φ = g(λ1, f1) = g(λ2, f2) + mπ for two wavelengths or g(λ1, f1) = g(λ2, f2) + mπ = g(λ3, f3) + nπ for three wavelengths, where fi denotes the focal length with respect to the light with the wavelength of λi. For the controllable positive dispersion, f1 > f2 > f3 is for λ1 < λ2 < λ3, and for the controllable negative dispersion, f1 < f2 < f3 is for λ1 < λ2 < λ3.

Figure 3 shows the examples for the longitudinal color separation by using the designed metalenses. Figure 3(a) gives the phase distributions of the controllable positive dispersion metalens with the focal length taking 5 μm for λ = 633 nm and 15 μm for λ = 460 nm, and figure 3(b) gives the phase distributions of the controllable negative dispersion metalens with the focal length taking 15 μm for λ = 633 nm and 10 μm for λ = 532 nm. The positions of rectangular holes for these dispersion metalenses can be ascertained by the given wavelengths and the focal length, like the case of figure 2(b), and the radii of four circles for the former metalens take 13.39 μm, 14.4 μm, 15.39 μm and 16.36 μm, and the radii of four circles for the latter metalens take 14.39 μm, 16.24 μm, 18.99 μm and 21.36 μm. Figure 3(c) is the nanostructure for the wavelengths of 633 nm and 460 nm and figure 3(d) is the nanostructure for the wavelengths of 633 nm and 532 nm. Figures 3(e) and (f) show their focusing effect at different wavelengths. We can see that the focal spots for the setting wavelengths appear at their default positions.

Figure 3. (a) Phase distributions of the metalenses for the controllable positive and (b) negative dispersion metalenses, (c, d) structures of two longitudinal color separation metalenses and (e, f) the controllable dispersion effect of two metalenses.

Download figure:

Standard image High-resolution image5. Transverse color separation metalens

Similar to the longitudinal color separation metalens, we can also design the metalens with the focal spot for different wavelength appearing at the position with the different transverse coordinate and the same propagation distance and we call it as the transverse color separation metalens. The rotation angles of nanoholes should satisfy:

where xi denotes the position of the focal spot for the incident wavelength λi. If g(x1, λ1) = g(x2, λ2) + mπ or g(x1, λ1) = g(x2, λ2) + mπ = g(x3, λ3) + nπ, we obtain the color separation metalens for two or three wavelengths along the transverse direction.

Figure 4 gives the examples for the transverse color separation metalenses at two wavelengths. Figure 4(a) gives the phase distributions of the transverse color separation metalenses with the focal length taking f = 10 μm and x1 = 2 μm for λ = 633 nm and f = 10 μm and x2 = 0 for λ = 532 nm, and figure 4(b) gives the phase distributions of the transverse color separation metalenses with the focal length taking f = 10 μm and x1 = −2 μm for λ = 633 nm and f = 10 μm and x2 = 0 for λ = 460 nm. Figure 4(c) is the nanostructure for the wavelengths of 633 nm and 532 nm and figure 4(d) is the nanostructure for the wavelengths of 633 nm and 460 nm. The focal lengths of these two metalenses are set at f = 10 μm, and the transverse positions of the spots appear at x = −2 μm, 0 and 2 μm, respectively. Figures 4(e) and (f) show the corresponding focusing intensity distributions of two metalenses.

Figure 4. (a, b) Phase distributions of the metalenses. (c, d) Structures of two transverse color separation metalenses and (e, f) their focusing effect at different wavelengths.

Download figure:

Standard image High-resolution imageIt is easy to see that the lights with different wavelengths are focused at the designated positions at f = 10 μm and their transverse coordinates of the spots have 2 μm separation distance. Certainly, we can change the transverse positions of the spots for the different wavelengths in different sequence through setting the transverse offsets in equation (3) or choose the different propagation distance. This color controllable longitudinal and transverse focusing is beneficial to the color analyzer.

6. Experiment measurement

In order to verify the controllable focusing performance of the proposed metalenses, we manufacture three samples of metalenses and conduct the practical experiment. The manufacture process of metalens samples is as follow. The silver film with thickness of 210 nm is deposited on the glass substrate by magnetron sputtering. The samples of metalenses are fabricated using the focused ion beam etching technique. Figure 5(b) shows the scanning electron microscopy (SEM) images of three samples, where the inserted white lines in SEM images denote 10 μm. The holes in the centers of three metalens samples are the magnified parts enclosed by the red squares.

Figure 5. (a) Experiment setup, (b) SEM images of three metalens samples and the measured intensity distributions with the illuminating wavelength taking 470 nm, 532 nm and 633 nm. The inserted white lines in SEM images denote 10 μm and the magnified structures are inserted in their centers.

Download figure:

Standard image High-resolution imagePut one sample in the light path of figure 5(a) and measure the transmission intensity distribution of the metalens. Three lasers are chosen as the illuminating sources and their working wavelengths are 470 nm, 532 nm and 633 nm. First, the light field emitted from one laser is converted into the left-handed circularly polarized light by a linear polarizer (P) and a quarter wave plate (QWP), and then impinges onto the metalens sample (S). The intensity distribution of the transmission field is magnified by a microscopy objective (MO), and then received by a charge-coupled device (CCD). Three identical light paths for different wavelengths are utilized. The cover plate (CP) is used to choose the illuminating light and the denser filter (DF) is used to adjust the light intensity. The mirrors Mi and the beam splitter BS are used to change the propagation direction of light. For convenience adjustment, the metalens sample is placed on a moving platform with the precision of 10 nm.

Three samples of S1, S2 and S3 are for the fixed-focal metalens, the longitudinal color separation (negative dispersion) metalens and the transverse color separation metalens. Three patterns below the sample S1 are the measured results for the transverse intensity distributions of the fixed-focal metalens with different incident lights illumination and the working wavelengths are placed at the side of the measured results. These results are measured at the same propagation distance z1. It can be seen that three focal spots appear at the same position though their intensities are different. The results below the sample S2 are the measured results for the longitudinal and transverse intensity distributions of the negative dispersion metalens under the illumination of two lights with λ1 = 532 nm and λ2 = 633 nm. Two long patterns are the longitudinal intensity distributions and two square patterns are the transverse intensity distributions at two longitudinal distances, where the blue lines mark out their positions in longitudinal intensity distributions. The separation distance of two transverse intensity distributions is about 40 μm under the given magnification condition. These results verify the property of the controllable negative dispersion metalens and the longer wavelength is really focused at the farther distance. The results below the sample S3 are with respect to the metalens with the transverse color separation for two wavelengths, where two patterns are obtained at the same propagation distance and the curves are extracted from two intensity patterns along the horizontal direction. It can be seen that two focal spots appear at the positions with a certain transverse distance, and the extracted separation distance is about 180 μm.

These focusing results for the fixed-focal metalens and the color separation metalenses are the same as the theoretical predictions and they show the good dispersion control of the proposed metalenses on the light focusing. Moreover, it needs to be pointed out that the wavelength of blue light used in experiment is 470 nm and it is not the same as the theoretic one of 460 nm. However, the measured result shows the light with this wavelength still focuses at the predicted position though there is a wavelength difference of 10 nm. This result also indicates that the designed metalens has the better performance in manipulating the multi-wavelength focusing. Certainly, the controllable focusing of our proposed metalenses is relative and one metalens with the ascertained structure only fulfill one function.

7. Conclusions

In conclusion, a kind of controllable focusing metalenses for multiple wavelengths is advanced based on the identical nanoholes etched in silver film. This kind of metalenses can realize the focusing for two or three wavelengths at the same or different positions in three-dimensional space. The controllable focusing metalenses enable the wavelength independent focusing and the color separation in space. Simulated and measured results verify the controllable focusing performance of these metalenses with simple nanostructures. This design principle can be also utilized in the controllable focusing for other three lights in visible region such as the set of 488 nm, 532 nm and 650 nm and the set of 488 nm, 551 nm and 633 nm besides the set of 460 nm, 532 nm and 633 nm used in this paper. The lower transmission power of the proposed metalenses may be compensated through increasing the number of nanoholes or substituted by the dielectric nanounits. And its advantages including simple structure consisting of identical nanounits, convenient manipulation and effective color control are prominent. We think our proposed metalenses may expand the applications of metalenses in lightweight chromatically-corrected displaying and imaging systems, color separation and color holography.

Acknowledgments

This work was funded by the National Natural Science Foundation of China (Grant No. 10874105).