Abstract

In this work, we review recent progress achieved in the use of chemical solution deposition (CSD) based on fluorinated metalorganic precursors to grow superconducting REBa2Cu3O7 (REBCO) films and coated conductors (CCs). We examine, first of all, the advances in optimizing the steps related to the solutions preparation, deposition and pyrolysis based on novel low-fluorine metalorganic solutions. We show that a new type of multifunctional colloidal solutions including preformed nanoparticles (NPs), can be used to introduce artificial pinning centers (APCs). We analyze how to disentangle the complex physico-chemical transformations occurring during the pyrolysis with the purpose of maximizing the film thicknesses. Understanding the nucleation and growth mechanisms is shown to be critical to achieve a fine tuning of the final microstructure, either using the spontaneous segregation or the colloidal solution approaches, and make industrially scalable this process. Advanced nanostructural studies have deeply modified our understanding of the defect structure and its genealogy. It is remarkable the key role played by the high concentration of randomly distributed and oriented BaMO3 (M = Zr, Hf) NPs which enhance the concentration of APCs, such as stacking faults and the associated partial dislocations. Correlating the defect structure with the critical current density Jc(H,T,θ) allows to reach a tight control of the vortex pinning properties and to devise a general scheme of the vortex pinning landscape in the whole H–T phase diagram. We also refer to the outstanding recent achievements in enhancing the vortex pinning strength by shifting the carrier concentration in REBCO films towards the overdoped state, where the pinning energy is maximum and so, record values of critical current densities are achieved. This confirms the performance competitiveness of nanocomposite CCs prepared through the CSD route. We conclude with a short summary of the progress in scaling the CC manufacturing using fluorinated solutions.

Export citation and abstract BibTeX RIS

Original content from this work may be used under the terms of the Creative Commons Attribution 4.0 license. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

Acronyms as they appear in the article

| HTS | High temperature superconductor |

| REBCO | REBa2Cu3O7 |

| RE | Rare earth or yttrium |

| CC | Coated conductor |

| APC | Artificial pinning center |

| PLD | Pulsed laser deposition |

| MOVCD | Metalorganic chemical vapor deposition |

| RCE-DR | Reactive co-evaporation-deposition and reaction |

| CSD | Chemical solution deposition |

| CAPEX | Capital expenses |

| TLAG | Transient liquid assisted growth |

| SS | Spontaneous segregation |

| STEM | Scanning transmission electron microscopy |

| EELS | Electron energy loss spectroscopy |

| XMCD | X-ray magnetic circular dichroism |

| TFA | Trifluoroacetate |

| BYF | (Ba1−x Yx )F2 + x |

| TEA | Triethanolamine |

| PEG | Polyethylene glycol |

| acac | 2,4-pentanedione |

| BYTO | Ba2YTaO6 |

| BZO | BaZrO3 |

| BHO | BaHfO3 |

| BCO | BaCeO3 |

| BTO | BaTiO3 |

| BSO | BaSnO3 |

| SZO | SrZrO3 |

| BNO | BaNbO3 |

| UTOC | Ultra-thin once-coating |

| PVP | Polyvinylpyrrolidone |

| CTAB | Hexadecyltrimethylammonium bromide |

| Ps-DVB | Poly(styrene-co-divinylbenzene) |

| TREG | Triethylene glycol |

| MW | Microwave |

| SEM | Scanning electron microscopy |

| FIB | Focused ion beam |

| IJP | Ink jet printing |

| OM | Optical microscopy |

| TGA | Thermogravimetric analysis |

| EGA | Evolved gas analysis |

| MS | Mass spectroscopy |

| DTA | Differential thermal analysis |

| DSC | Differential scanning calorimetry |

| OI | Optical interferometry |

| FT-IR | Fourier transformation infra-red |

| TMA | Thermomechanical analysis |

| CTA | Conventional thermal annealing |

| OF | Ba(Fx Oy )2 |

| FH | Flash heating |

| Y225 | Y2Cu2O5 |

| LAO | LaAlO3 |

| CZO | Ce1−x Zrx O2−y |

| YSZ | (Zr,Y)O2−x |

| IBAD | Ion assisted beam deposition |

| ABAD | Alternating beam assisted deposition |

| RABiT | Rolling assisted biaxial texturing |

| HAADF | High angle annular dark field |

| LAADF | Low angle annular dark field |

| EDX | Energy dispersive spectroscopy |

| SQUID | Superconducting quantum interference device |

| SF | Stacking fault |

| TB | Twin boundary |

| APB | Antiphase boundary |

| FFT | Fast Fourier transformation |

| Y123 | YBa2Cu3O7 |

| Y124 (Y248) | YBa2Cu4O8 |

| GPA | Geometric phase analysis |

| MTG | Melt textured growth |

| DFT | Density functional theory |

| NP | Nanoparticle |

| Bi2212 | Bi2Sr2CaCu2O8 |

| OD | Overdoped |

| UD | Underdoped |

1. Introduction and scope

Since the discovery of HTSs there has been an overwhelming interest in developing suitable conductors for the many potential applications where HTS can bring unique or improved functionalities, particularly in power and magnet applications [1]. Several generations of conductors have been examined in the last 30 years which have diverse performances when they work under different conditions of temperature and magnetic field [2, 3]. As a general rule, it has been demonstrated that the HTS conductors achieve excellent performance, and in many cases, such as in magnet applications, they are unique, i.e. there is no other conductor capable of generating the high or ultra-high magnetic fields that HTS conductors can (B > 30 T) [4]. In other cases, HTS conductors lead to very appealing performances but they must compete with other non-superconducting materials to generate competitive devices (cables, motors, etc) [5, 6]. In both cases a figure of merit determines how fast will be the penetration degree of HTS conductors into the market, i.e. the cost/performance ratio which can be measured in terms of €/kA m, where € considers the capital and manufacturing cost for 1 m of conductor when it carries 1 kA of transport current without losses at given conditions of temperature and magnetic field. Of course, the acceptable figure of merit will differ for each application and also the selected working conditions and also other performances will also influence the acceptability of the conductors. Overall, it is clear that the R&D effort must be directed towards reducing this figure of merit as much as possible by reducing the production costs and enhancing the performance (figure 1) [7, 8].

Figure 1. General schema of the combined objectives required to increase the market penetration of coated conductors in power applications and magnets. Reducing the figure of merit cost/performance requires combining two paths: increasing the performance and decreasing the cost. A non-exhaustive list of the most relevant issues to be considered are included which apply for coated conductors processed by chemical solution deposition (CSD), although not all of them are tackled in the review.

Download figure:

Standard image High-resolution imageSince the discovery of suitable methods to grow the REBa2Cu3O7 (RE = rare earth or yttrium; REBCO) HTS phase as epitaxial film on metallic substrates, i.e. the creation of CCs [9], a new avenue for the fabrication of practical conductors based on the HTS materials and having the highest superconducting performance in a very extended range of temperature and magnetic fields was opened. The challenges in terms of materials science were tantalizing, it was never even imagined that kilometric epitaxial films could be produced. However, the progress achieved in the development of high performance CCs has been extraordinary in the last 20 years and now CCs can be considered a reliable industrial product, even if the figure of merit mentioned before still requires further reduction to become widely commercial. In addition, throughput, yield homogeneity and reproducibility require further improvement. Many different CC architectures (metallic substrates, texturing source, buffer layers) and deposition and growth methods of REBCO films have been devised, all of them with some advantages and disadvantages. Overall, impressive efforts have been made to further advance the knowledge to enhance their competitiveness [2, 10, 11].

The second big boost in the enhancement of the CCs performance was the creation of methodologies to prepare nanocomposite films where nanometric secondary phases could be introduced in high concentration. The increase of CC performance at high magnetic fields requires that vortices pin in APCs with dimensions in the range of few nm (∼5–10 nm) with separation in the range of few tens of nm. Additionally, these secondary phases (NPs, nanorods, etc) usually interact with the preexisting defects and so the very challenging objective of controlling the nanostructure of REBCO nanocomposite films was extensively revised.

Among the different successful film growth approaches for nanocomposite CC fabrication we particularly mention PLD [3, 12–14], MOVCD [15, 16], e-beam metal evaporation [17] as procedures where deposition and growth are simultaneous processes, or in short, simultaneous methods. On the other hand, RCE-DR [18] and CSD are growth methodologies where the precursors are first deposited and then reacted to grow the REBCO pristine and nanocomposite films (i.e. sequential deposition and growth approaches, or in short, sequential methods) [10, 19–27] which have also reached very attractive performances. Many reviews have addressed the peculiarities of the various available growth techniques. Most relevant discussed issues were in connection with the demands on materials characteristics, cost and performance requirements, specially from the device developer's side.

In the case of the CSD approach to CCs, although more than 34 years have spanned since the first demonstration of epitaxial YBCO thin films growth on single crystal substrates [19], it was clear from the beginning that the CSD route was very promising but was still in its infancy. Therefore, a huge amount of new knowledge was needed in many areas, such as solution chemistry, materials science, physics and engineering, as well as to disentangle the correlation to the final performances [20, 22, 23, 28–32]. Many different academic and industrial groups have contributed to progress in the knowledge generation about the CSD approach to CCs. Nowadays, this technique has achieved the required degree of maturity for its industrialization. A very significant appeal of CSD, is the low CAPEX required to build a manufacturing unit, owing to the fact that it does not require the use of vacuum systems or complex furnaces. It is also based on relatively common chemicals and so the running expenses are expected to be rather low, however, as it will discussed later, there remains some drawbacks related to the production throughput which limits an extensive commercial penetration. Therefore, the CSD approach to CCs is being considered as a potential competitive manufacturing technique provided that performance, throughput and yield can be enhanced at industrial scale [8].

Owing to the fact that the knowledge about CSD epitaxial film growth was at the lowest level [25, 26, 32–39], as compared to the other more classical thin film growth approaches used to grow CCs, it was required to deeply investigate many aspects of this technique. During the last 11 years an extraordinary progress has been made in the generation of knowledge about different steps of the CSD approach to thin films and CCs (figure 2). This review intends to be a timely overview of the recent progress of this technique [20, 28, 40].

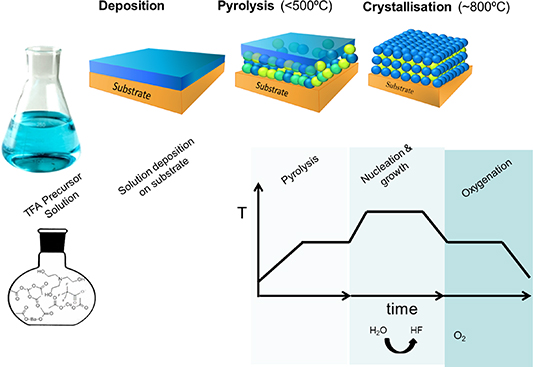

Figure 2. General schema of the different processing steps involved in the chemical solution deposition route to YBa2Cu3O7 films: metalorganic solution preparation, solution deposition, pyrolysis, nucleation and growth of the epitaxial films and oxygenation.

Download figure:

Standard image High-resolution imageThe review is organized in a sequential manner. All the aspects being relevant in the achievement of pristine and nanocomposite REBCO films and CCs are tackled following the steps of the CSD route based on fluorinated precursors. Emphasis is made on the low fluorine metalorganic solutions leading to intermediate oxides and the fluoride precursor BaF2. This route was initiated 34 years ago and it was considered very relevant because the formation of BaCO3 could be avoided as an intermediate phase. At that time, the general belief was that it would become impossible to grow REBCO CCs at a reasonable temperature because BaCO3 was stable at to very high temperatures. Recently, this assumption has been reconsidered and fluorine-free metalorganic precursors have shown to be suitable for CSD routes to CCs, even if BaCO3 is formed as an intermediate compound [41–49]. The fluorine-free approach encompasses completely different growth routes with mechanisms which still require further research to be elucidated [43, 46]. Particularly, it has been recently shown that the so called CSD-TLAG technique benefits from the developments previously made in the conventional fluorinated CSD route to CCs but goes well beyond its practical limitations. The REBCO growth route fully differs because intermediate transient liquids are used to grow the films and so the growth rate can be enhanced by three orders of magnitude [8, 50]. The fluorine-free metalorganic precursors have also been used to fabricate superconducting joints between REBCO CCs [51, 52]. Owing to the fact that the CSD fluorine-free approach is still an emerging field of research we will consider this topic out of the scope of the content of this review.

In section 2, the review concentrates on the new developments related to the preparation of low fluorine metalorganic solutions which are the starting point for any CSD REBCO thin film growth, as well as in the synthesis of oxide NPs through high throughput chemical methods and their stabilization into colloidal multifunctional solutions. In this section we review as well the advances on the complex preparation of thick films by a single deposition, mainly using in-situ analysis of the pyrolysis stage. The issue of the nanoscale film homogeneity is envisaged in relationship with the intermediate phases evolution during the heating process.

Section 3 is mainly devoted to the analysis of the nucleation and growth mechanisms of the epitaxial REBCO films, either pristine or nanocomposite. First, the in-situ study of the film growth rate of pristine films at different temperatures is presented and then the mechanisms to control the supersaturation degree in thick film are described.

The most significant part of section 3, however, focuses on the progress in understanding the growth mechanisms of nanocomposite REBCO films. We first review the case of the SS route where the NPs and the REBCO films grow from the same solutions. A second, more innovative approach, is to use the multifunctional inks described in section 2 to grow films. This approach is novel in the broad field of oxide nanocomposite processing by means of CSD and so extensive analyses are presented of the different phases and complex phenomena. Overall, we show that this new type of multifunctional colloidal inks is a very attractive tool for a very competitive industrial route to CSD CCs.

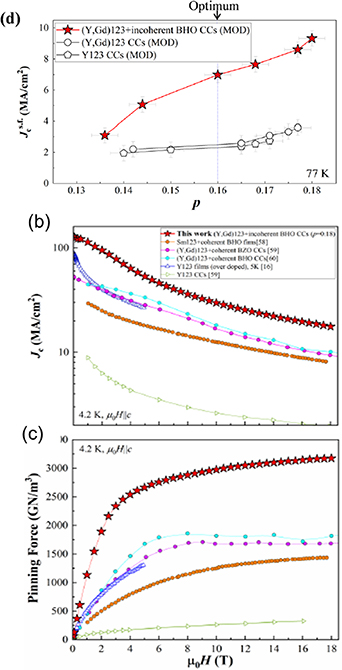

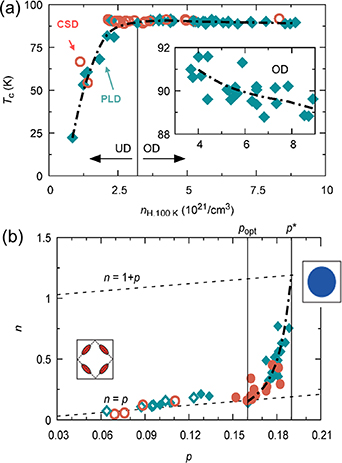

In section 4 we report on the advances in the control of the nanostructure of the nanocomposite films and its correlation with the superconducting critical currents. First, we include an overview of how the self-field percolating currents can be reduced due to existing defects or secondary phases and how this effect can be minimized. Additional important content of this section is a summary of the advances in understanding the nanoscale structure of pristine and nanocomposite REBCO films grown by CSD. A wide spectrum of defects is described, based on studies made with advanced transition electron microscopy (mainly STEM-EELS) and complemented with the insights of other complementary techniques available in synchrotron radiation facilities, such as XMCD, to detect tiny magnetic moments in specific atomic positions. A great deal of effort has been made during years to clarify how the vortex pinning landscape can be described and controlled to optimize critical currents in different regions of the magnetic phase diagram. In this section an overview of the most relevant advances in this topic is made. Finally, we close section 4 with a summary of the recent advances in enhancing vortex pinning strength following the strategy of increasing the charge carrier concentration by positioning REBCO CCs in the OD state, where the condensation energy is enhanced and consequently the vortex pinning energy is increased. We also include a short summary of the progress on the use of fluorinated solutions to prepare CCs at the industrial scale to produce long length conductors.

We conclude with section 5 where several general remarks are made, including an outlook on the future of CSD routes towards fabrication of CCs.

2. Chemical solutions, NP preparation and colloidal solutions synthesis

2.1. Low fluorine solution synthesis

Preparation of adequate metalorganic precursor solutions is the first step in the route to grow high quality CSD REBCO films. The main requirements are high purity, long term stability and having adequate rheological properties for the specific deposition process to be used. Also good control of the metals stoichiometry is desired to tune the growth properties and/or the superconducting performance. Since the late 80s it was shown that TFA metal salts were promising precursors specially because they led to BaF2 as an intermediate precursor [19]. In recent years, however, it was noticed that the fluorine content of the metalorganic solutions could be strongly reduced without essential modifications of the YBCO film growth mechanism. The reduction of fluorine in the precursor salts has been the most relevant progress in the design of solutions using the BaF2 process and, as it will be shown here and in next sections, several practical advantages have been demonstrated, besides the more obvious environmental interest of reducing the potential hazardous nature of fluorine derivative exhaust gases.

Systematic analyses of low fluorine solutions were presented by several authors [53–57]. For instance, in [54] the influence of starting salts, solvents and additives were tested. Early investigation of the intermediate phases formed after the TFA precursor pyrolysis showed that, when full TFA salts are used, the intermediate precursor containing fluorine after pyrolysis was (Ba1−x Yx )F2 + x (x ⩽ 0.3) (BYF), which means that the total initial F content can be strongly reduced. In [54] it was concluded that the F content could be reduced down to 10% versus the all fluorine content, i.e. a ratio F:Ba of 2:1 could be used which implies that only BaF2 is formed after pyrolysis. The low fluorine solutions have been investigated by several authors demonstrating that excellent superconducting properties can be achieved [53–55, 58–62]. The introduction of fluorine in the solutions could be performed through several salts. For instance, using YTFA salts as the only source of fluorine, and fluorine-free metalorganic precursors for Ba and Cu which are then dissolved in methanol-propionic acid containing a specific amount of TFAH to generate BaF2 after pyrolysis [54]. Another approach uses the minimum amount of BaTFA required to generate BaF2 after pyrolysis mixed with acetates as salts of all the remaining metals [54, 55, 58, 59]. In some cases, the initial acetate metal salts were then converted to propionates. Other used precursors are Cu-2 ethylhexanoate, octyllic acid or Cu–naphtanate salts [53, 57, 63]. Several solute mixtures and additives were investigated to enhance the metal solubility and tune the rheological properties of the solutions with the purpose of generating homogeneous and thick films after pyrolysis. TEA was one of the best choices as additive owing to the well-known stabilization effect as a ligand of Cu complexes [54, 64], however, its content in the solution should be strictly limited to avoid an excessive increase of the solution viscosity which then would increase the film thickness to values where crack formation during the pyrolysis would be unavoidable. Other additives which have been tested are acetylacetone [64–66] and PEG [67] or also AgTFA salts which are known to decrease the nucleation temperature of YBCO films [68–71]. An additional advantage of using low fluorine precursor solutions is that water absorption is strongly reduced during deposition or manipulation of the solution [54, 72, 73] if acac additives are included in the initial solution [64]. This is believed to be due to the existence of coordination compounds (TEA, propionic acid, acac) with the metal salts which consequently prevents their coordination with water molecules. The detrimental effects of high water content in REBCO solutions is widely known, because they lead to inhomogeneous pyrolyzed films. Therefore, to keep a tight control of water content is a critical issue to achieve high reproducibility and high superconducting performance [54, 64, 70].

Concerning the initial metal composition of the pristine YBCO solutions, we should note that several modifications of the stoichiometric Y:Ba:Cu ratios have been reported to tune the growth properties and superconducting performance. We should particularly mention the case of a reduced Y:Ba ratio down to 1:1.5, instead of the stoichiometric 1:2 value in both thin films and CCs. The main consequence of this reduced ratio is that the YBCO growth temperature is decreased and the superconducting properties improved due to the modified microstructure [31, 53, 57, 74–77]. Microstructural studies have shown that these non-stoichiometric compounds display a reduced porosity and a lower concentration of a/b nucleated crystals while the expected secondary phases (mainly Y2Cu2O5 and CuO) do not perturb in a relevant way the epitaxial microstructure and so this modified metal stoichiometry has been widely used by many authors to grow CCs displaying very good superconducting performance [57, 74, 76, 78–81]. It is also worth to mention that the validity of the TFA approach has been widely proved for most of the Rare Earth compounds in REBCO films where high superconducting performances have been demonstrated [40, 73, 82]. In addition, evidence of a systematic evolution of properties and epitaxy development with the RE size was reported [82–84].

Besides the progress in the preparation of pristine solutions for CSD growth of REBCO films, a great deal of work has also been performed in recent years to prepare more complex solutions envisioned for the generation of REBCO nanocomposite films. The first demonstration of nanocomposite CSD films was made using excess of RE2O3 oxides in the solution which then remained in the grown film as NPs [85]. A more successful approach was made by adding Zr or Hf salts (acetylacetonates, naphtenates) and Ba salts excess to form BaMO3 (M = Zr, Hf) NPs through a SS process of NPs displaying a homogeneous nucleation occurring at lower temperatures than the REBCO epitaxial nucleation and growth [20, 22, 23, 40, 73, 86–88]. The solution preparation in these cases was quite straightforward and most of the rules applying to pristine solutions were also valid in these more complex compositions. Other NP compositions were also demonstrated, such as the double perovskites Ba2YTaO6 (BYTO) [89, 90]. In this case, the metal precursors for Ta were tantalum (V) ethoxide while Ba, Y and Cu precursors were TFA salts. NPs concentrations in the final YBCO layer up to ∼15% (mol) were demonstrated, similar to other BaMO3 perovskites. This evidenced that similar compositions, widely investigated in PLD and MOCVD YBCO nanocomposite films, could be prepared and analyzed with the particular microstructure of CSD nanocomposite films [22, 23, 40, 73].

In conclusion, a thorough knowledge advancement related to define the routes to prepare chemical solutions suitable for the preparation of high quality and high performance pristine and nanocomposite REBCO films through the BaF2 route was achieved. The improved robustness, reproducibility and control of the solutions using cost-effective salt precursors, solvents and additives is a definitive boost of the competitiveness of the CSD route to CCs.

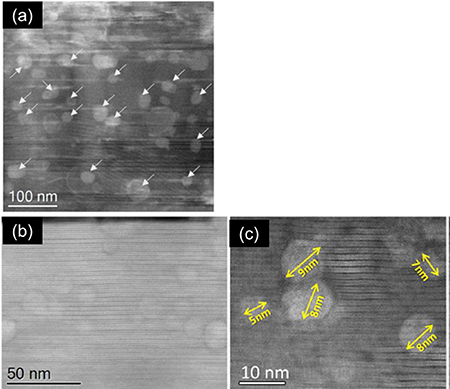

2.2. NP preparation and colloidal solution stabilization

Nanocomposite film growth by CSD based on SS of the secondary phases was the first demonstration that nanomaterials could be prepared by this route with very appealing superconducting performances. However, it was shown by several authors that the approach presents several intrinsic limitations related to the control of the size, distribution and homogeneity of the NPs. It was shown that above a concentration of 10%–12% mol in the final YBCO layer there was a tendency towards NP aggregation and the size control of the NPs was compromised [90, 91]. An alternative deposition approach was devised which hindered the NP diffusion and coarsening by taking advantage of the CuO interlayer formed at the intersurfaces of multideposited pyrolyzed films, called UTOC [40, 79–81]. This novel process selects ultrathin (∼30 nm) YBCO layers and a solution multideposition approach to reach competitive total film thickness and critical currents, for instance, 35 repetitions of the spin-coating/pyrolysis cycle were required to get a final film thickness of ∼0.6–0.7 μm [40, 92]. As we will see, the results obtained with this approach are very attractive to achieve very small embedded NPs at the end of the growth process and so high superconducting performances. On the other hand, although the multideposition approach may seem cumbersome, it can be efficiently overcome at industrial scale using automated multilane furnaces and so thick REBCO layers can be easily prepared [93].

Taking into account the practical limitations of the SS approach, a new route to CSD nanocomposites has been explored, never devised before in any type of functional oxides: the multifunctional colloidal solution approach. The main innovation of this route was to prepare separately the selected NPs with a well-defined size, composition and structure through a chemical approach allowing to stabilize them as a colloidal solution. This new colloidal solution has a multifunctional character because it leads to a superconducting YBCO matrix where NPs having other functionalities (insulating, metallic, magnetic) are embedded. Needless to say, many practical difficulties were encountered to reach the desired functional properties, as it will be described in more detail in next sections. Here we will summarize the different approaches which were followed to prepare NP solutions with the desired characteristics of NP size, concentration, distribution and with a long term stability. We should remind that in nanocomposite superconductors the secondary phases should behave as APC, therefore the optimal size of the NPs should be in the range of 2–3 times the superconducting coherence length of the HTSs (d = 5–10 nm). It is also very relevant that the colloidal solution is based on highly polar solvents, mainly alcohols and carboxylic acids, that the NP concentration in the colloidal solution is in the range of ∼12%–25% mol, that the solution remains stable for months, that the NPs keep their composition stable, i.e. they do not react with the YBCO salts, and, finally, that they keep their size (no coarsening) during the following thermal treatments to grow the epitaxial YBCO thin films.

Several oxide NPs were investigated using the multifunctional colloidal solution strategy to prepare YBCO nanocomposites by CSD using the fluorinated solutions [94–96]. After a first trial using metallic NPs, such as Au, the first oxide NPs investigated were the ferrimagnetic spinel ferrites MFe2O4 (M = Mn, Co) which were already available close to the required size [97, 98]. Unfortunately, it was found that these NPs have a strong chemical reactivity with the YBCO precursors and so other simple oxides were investigated, such as CeO2, ZrO2 and HfO2 with the fluorite structure where an accurate choice of ligands was necessary to avoid the formation of supraparticles [94, 99–102]. Since these latter oxides were found to display some reactivity with the Ba salt, forming BaMO3 (M = Ce, Zr, Hf), it was already demonstrated that they enhance the superconducting properties, hence opening a new route to generate attractive YBCO nanocomposite films grown by CSD [95, 103–107]. However, owing to the difficulties to control the NPs size and their distribution when some chemical reactivity exists, the route of using non-reactive ternary oxides, such as the BaMO3 (M = Zr, Hf, Ti) perovskites, was explored by several authors [91, 103–106]. This approach was finally successful, thus very competitive multifunctional colloidal solutions to prepare YBCO superconducting nanocomposites are now available fulfilling all the practical requirements mentioned above.

The most outstanding methodologies which have been used up to now to synthesize oxide NPs through chemical methods are: sol–gel precipitation, hydrothermal, solvothermal and micro-emulsions [107–109].

Although sol–gel precipitation [109] and microemulsion technologies [106], are well established synthetic methods to prepare NPs, they were not useful in the discussed case, since they did not allow to prepare high NP concentrations keeping well dispersed solutions.

Hydrothermal and solvothermal approaches are mild temperature, and sometimes high pressure, growth methods which have been widely used to prepare several binary and ternary oxides and they are considered as high throughput methods, therefore, they were the most used methods for the purpose of preparing CSD superconducting nanocomposites at large scale [103, 110, 111]. Hydrothermal growth uses water as solvent at high pressure, usually adding oleic acid as surfactant to keep control of size and dispersibility. Solvothermal method is a non-hydrolytic pathway where alcohols are used as solvents, either under normal pressure conditions or under pressure using an autoclave. The polyol route allows in this case to control the ligand formation and so achieving stable solutions with fairly high concentrations. The control of homogeneous nucleation and growth of the NPs is usually analyzed following the LaMer model [103, 109, 112]. Solvothermal methodologies have been, therefore, the most successful routes to prepare preformed NPs for CSD nanocomposite growth.

When Au metallic NPs were prepared, reduction of Au salts, such as HAuCl4, were used where the NPs were stabilized with citrate ligands. These solutions are then transformed into colloidal solutions using several polymers (PVP; CTAB; Ps-DVB) which can be redispersed in alcohols (methanol, ethanol). The achieved NPs have an adequate size (∼5 nm), however, only low concentrations could be achieved (few mM) and during the YBCO growth process the NPs displayed a strong tendency to migrate to the film surface [113].

Spinel ferrites MFe2O4 (M = Fe, Co, Mn, Ni, Zn) is a class of oxides which have been widely investigated due to their magnetic properties and NPs have been produced through several chemical methods. The use of the polyol route, i.e. a solvothermal method including metal acetylacetonates and TREG or oleylamine as solvents, was found to be a one pot facile synthesis approach leading to stable and well dispersed colloidal solutions in polar media [97, 98]. The NP sizes were in the range of 3–5 nm and they could be transferred to more polar solvents such as alcohols. These colloidal solutions were dispersed and stabilized in the TFA solutions, however, the strong chemical reactivity occurring at high temperatures strongly limited the suitability of these NPs [114].

An additional advance in preparing oxide NPs for CSD nanocomposites was the growth of fluorite NPs, such as ZrO2, HfO2 and CeO2 [94, 99–101, 115, 116]. These compositions had already been used in YBCO nanocomposites grown through PLD, MOCVD and CSD-SS deposition methods [12, 14, 22, 23, 117, 118]. In addition, the synthesis of the ZrO2 NPs was already reported before and so there were guidelines to synthesize them in the desired size through the solvothermal method using different inorganic precursors (ZrCl4), solvents (benzyl alcohol, dibenzyl ether) and heating methods (conventional furnace heating or MW heating) [94, 100]. Individual, aggregate-free colloidal solutions were achieved with sizes in the range 3–8 nm using alcoholic solvents and keeping ligands in apolar solvents. An interesting result was that using MW heating the growth time could be decreased by a factor ∼40, as compared to conventional heating, conserving a high crystallinity [94, 100, 104]. In all cases, however, ligand exchange was necessary to stabilize the solution in alcoholic media through steric or charge effects [94, 95, 102, 103, 115, 116, 119]. A similar route was followed to demonstrate the suitability of CeO2 NPs to achieve colloidal solutions. The synthesis of NPs with sizes in the range of 5–6 nm could be completed by MW heating during ∼10 min and starting from Ce(III) acetylacetonates and TREG, which was later exchanged with decanoic acid, and so leading to stable solutions in alcohols [94]. The mutifunctional colloidal solutions prepared with TFA or low fluorine YBCO solutions including ZrO2 or CeO2 NPs were stable during months and so they were adequate to grow nanocomposite YBCO films by CSD, as it will be described in later sections, even if they were reactive with Ba precursors.

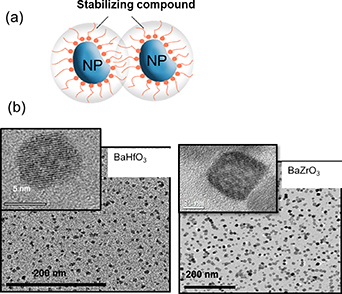

The most successful approach, up to now, to prepare YBCO nanocomposites by CSD using preformed NPs with controlled size, shape and distribution has been the use of the non-reactive compositions of BaMO3 (M = Zr, Hf) perovskites [103, 105, 120]. These ternary oxides led to self-assembled nanostructures in the case of vacuum deposition approaches (PLD, MOCVD), where simultaneous nucleation and growth of both phases occur and strain is the driving force for self-organization in nanorods structures [121–123]. They were also the best compositions demonstrated so far to prepare CSD YBCO nanocomposites using the SS processes, as we have described in previous sections. Therefore, it was very appealing to develop a robust and reliable method to prepare perovskite NP colloidal solutions. Previous works on perovskite oxide NP growth were mainly focused on the ferroelectric BaTiO3 phase, which is unsuitable for YBCO nanocomposites due to the chemical interdiffusion of Ti and Cu in YBCO that reeduces the superconducting transition temperature [124]. Therefore, the main efforts were centered in preparing Zr and Hf perovskite compositions. Initial attempts were made using microemulsion or sol–gel approaches which led to either non-homogeneous dispersions, low solution concentrations or very long reaction times [100, 105, 106]. To go beyond, a hybrid approach was proposed combining sol–gel and solvothermal respective advantages [103] or also a single solvothermal process performed in a MW reactor [105]. In the novel hybrid approach a suspension is first prepared by sol–gel at room temperature during a short time (∼5 min) using metal alkoxyde precursors and Ba(OH)2 and then a milky solution is obtained by adding TEG and NH3. This solution is then transferred either into a steel autoclave during 1 h or into a MW reactor during a much shorter time (∼5 min) and heated at 180 °C in both cases. The resulting colloidal solutions were finally cleaned through a very specific procedure and dispersed into absolute ethanol, thus being suitable for the preparation of the multifunctional colloidal solution [103]. The use of a single solvothermal step also allows to prepare well crystallized NPs, although with a reduced control of the nucleation step [105] (figure 3).

Figure 3. (a) Schema of stabilized oxide nanoparticles prepared for being used to prepare colloidal solutions; (b) TEM images of BMO (M = Zr, Hf) nanoparticles prepared through a solvothermal methodology. Reproduced with permission from [103].

Download figure:

Standard image High-resolution imageIn summary, the knowledge generated on the reaction paths, nucleation and growth mechanisms of the NPs synthesis methods enabled to tune accurately the size and size distribution of NPs [103]. Consequently, a large scale production process for the most successful perovskite cases was devised and can be widely used in long length production of CCs based on CSD [91, 105]. The use of adequate ligands enables long term stability and high concentrations (∼20% mol) of the desired NPs in the REBCO layers.

2.3. Solution deposition and pyrolysis analysis

A key step in the development of high quality CSD thin films and CCs is the solution deposition and the corresponding pyrolysis step. At this stage the metalorganic precursors are decomposed generating a porous nanocrystalline layer where the solid precursors to grow YBCO films should keep the maximum nanoscale homogeneity, and a strict control of the residual porosity is critical to enable a fast gas diffusion afterwards. Thorough analytical studies of the correlation between the characteristics of the chemical solutions, the selected deposition methodology (spin coating, dip coating, slot die coating, IJP) and the pyrolysis process have been undertaken for many years. The most suitable inks for each of these deposition methods may differ owing to the modified rheological properties required in each case. Therefore, fine tuning of the final inks is needed to adapt to the selected solution deposition method. Additionally, many unknowns still remained concerning the physico-chemical transformations of the inks before being transformed into stiff films behaving as inorganic precursors of the YBCO films and, therefore, the pyrolysis process deserved further scrutiny [20].

Most of the first analyses of the pyrolysis process were performed in TFA solutions [20, 32], while more recently, a thorough analysis of the physico-chemical transformations of low fluorine precursors for YBCO films were performed which helped to disentangle the most critical steps. The novel knowledge generated was then successfully used to optimize the thermal treatments to increase the film thickness in a single deposition [125, 126]. Other authors also investigated the pyrolysis process in low fluorine precursors for SmBCO thin films (<300 nm thick) with the aim of accelerating the pyrolysis step [127].

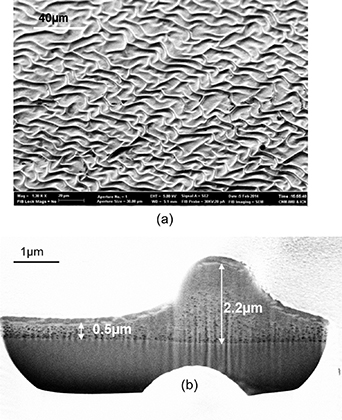

The most troubling sources of film inhomogeneities are the morphological defects generated during the pyrolysis step, i.e. film wrinkling and cracking, both being related to the in-plane stress generated during the metalorganic decomposition process due to the film shrinkage (figure 4). These morphological defects have a strong perturbing effect on the current percolation in superconducting films, therefore, it is absolutely critical to ascertain how to avoid them. Actually, the stress control is a very challenging objective widely investigated in many CSD functional oxides [20, 125, 128–130]. The first goal in this analysis is to determine the temperature windows where each physico-chemical phenomenon appears in order to correlate the multiple aspects being involved: thermal, chemical and mechanical.

Figure 4. (a) SEM image of a film surface displaying wrinkles after pyrolysis when the film was heated at 15 °C min−1; (b) cross section FIB-SEM micrograph of a wrinkled film. Reproduced from [125]. CC BY 3.0.

Download figure:

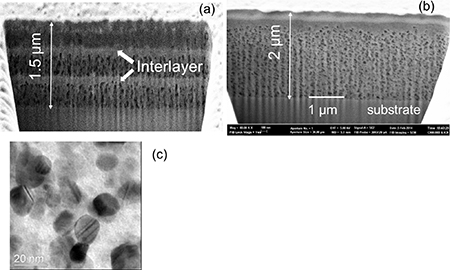

Standard image High-resolution imagePrevious analyses of films during the pyrolysis were mainly performed using ex-situ measurements and mainly on thin films (∼200–300 nm) [20, 59, 131–133], however, these ex-situ approaches limit the information about the kinetic aspects of the complex pyrolysis. To go beyond this restrained picture, an investigation combining different experimental tools, most of them working under in-situ conditions, was performed using annealing conditions close to those used in the pyrolysis process. The final film thickness used to perform these in-situ analyses was in the range of 800–1000 nm with low fluorine films deposited by mutideposition spin coating or by IJP in a single deposition. Typical SEM-FIB cross section images of these pyrolyzed films are displayed in figure 5. A fairly homogeneous microstructure is observed in the single deposition films, while those prepared through multideposition display segregated CuO interlayers created during the pyrolysis (figure 5) [20, 36, 40]. The coupled experimental tools used in this study were: in-situ OM including a video recorder, TGA, EGA, MS, DTA, DSC, in-situ OI to determine the film thickness, FT-IR spectra of volatile species and in-situ determination of the viscosity of the films through TMAs [42, 50, 134–137].

Figure 5. (a) and (b): Scanning electron microscopy (SEM) micrographs of YBCO pyrolyzed films' cross section obtained by focused ion beam (FIB). In (a) 3 coatings with a thickness after pyrolysis of 500 nm were performed by spin coating, showing CuO segregated interlayers. The final film thickness would be around 700–800 nm. (b) Micrograph of a pyrolyzed film with a single coating made by IJP, presenting a fairly homogeneous cross section, except for the formation of a CuO nanolayer at the surface. The final film thickness would be around 1000 nm. (c) TEM image of a pyrolyzed film showing the nanoparticles formed. Reproduced from [125]. CC BY 3.0.

Download figure:

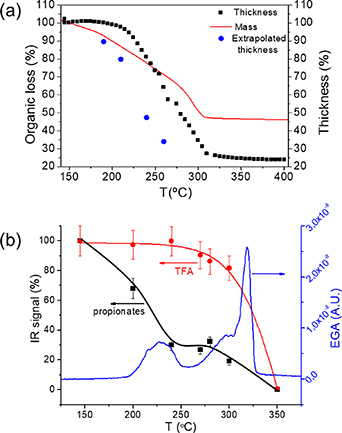

Standard image High-resolution imageThis integrated analysis showed that the pyrolysis process in the low fluorine films differs from that of TFA precursors although it still displays three temperature zones characterized by similar transformations (figure 6): Zone I corresponds to the solution drying region where the solvents are eliminated; Zone II covers the temperature window where wrinkling occurs as a reversible or irreversible phenomenon and the organic precursors start to decompose; Zone III is the region where film cracking occurs and where the transformation of the organic precursors is completed.

Figure 6. Summary of the three different identified temperature regions correlated with the corresponding phenomena. The required temperature ramps are also indicated. (I) Solution drying; (II) reversible or irreversible wrinkling formation; (III) crack formation. The final film thickness would be around 1000 nm. Reproduced from [125]. CC BY 3.0.

Download figure:

Standard image High-resolution imageIn the first zone (T < 150 °C) it was clearly discerned that kinetic effects are not very relevant and so the heating process can be fast (∼20 °C min−1) without any degradation of the film homogeneity. After this stage the film thickness is still in the range of 7 μm for a final film thickness of 700–800 nm. Zone II (150 °C–240 °C) is the scenario, instead, of very relevant transformations. In-situ OM recording shows that depending on film heating rate some wrinkled regions are generated in the film and also that depending on the film composition the wrinkled structure can become reversible. Typically, heating rates in the range of ∼5 °C min−1 are necessary in thick films to avoid permanent wrinkling. TGA and EGA evidenced that in this zone some mass loss already occurs and the composition of the decomposed compounds were identified by FT-IR of the exhaust gases while FT-IR of the remaining films allowed to discern which salts were remaining after decomposing at each temperature [50, 136–138]. It was concluded that the propionate salts decompose in this region while the TFA salts still remain stable in the bonding skeleton of the film (figures 7(a) and (b)). Parallel in-situ determination of the film thickness evolution clarified that the films have a viscoelastic behavior (time dependent thickness evolution) in this temperature range with a limited shrinkage (∼20%–30% film thickness reduction). It was concluded that an in-plane compressive stress develops which lies at the origin of the observed wrinkling phenomena. The film viscosity measurements, additionally, evidenced that the films display a liquid-like behavior in this region and this feature should be at the origin of the observed reversible behavior of the wrinkled structure in some films.

Figure 7. (a) Comparison among mass and thickness evolution during pyrolysis measured by TGA and interferometry, respectively. Film thickness is measured for a film with a final thickness of 700 nm prepared by IJP; (b) comparison of the data obtained from IR spectroscopy and EGA during the pyrolysis of a film deposited with a solution including Y(TFA), Ba and Cu acetates and propionic acid +5% vol DEA as solvent. The blue curve corresponds to the EGA-MS analysis, m/z = 28 (propionates, CO), while the dots, with their guidelines, are the values obtained from the integration of IR bands, black for the integration between 2800–3050 cm−1 (propionates) and red for the bands between 1100–1200 cm−1 (TFA). Reproduced from [125]. CC BY 3.0.

Download figure:

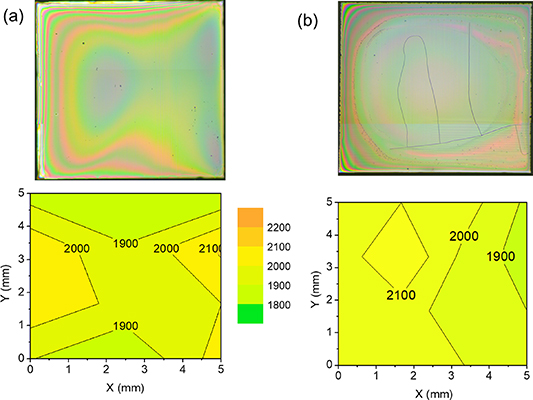

Standard image High-resolution imageThe final temperature zone of the pyrolysis process (zone III) extends from 240 °C to the temperature where the metalorganic decomposition has been completed (T ∼ 320 °C). Within this temperature window, crack formation is occasionally observed by in-situ OM video recording, while FT-IR and TGA show that the remaining metal–TFA bonds are destroyed. Accordingly, significant film shrinkage occurs (∼75% film thickness reduction) generating a strong in-plane tensile stress that can potentially lead to the irreversible formation of macrocracks (figure 8). The previously observed viscous behavior in zone II is progressively lost here when the remaining molecular bonds of the film skeleton are transformed to a stiff nanocrystalline and porous film composed of metal oxides (CuO) and mixed fluorides. It is worth to noting that the prevalence of the remaining TFA bonds in this region plays a crucial role in minimizing the adverse effect of crack formation. Therefore, the kinetics of the process is relevant here and it is advisable to use low heating rates (∼5 °C min−1). It is also worth to remark that heterogeneous nucleation of cracks may be promoted at film impurities and so it is concluded that to achieve homogeneous films is very important (high precursor purity and clean room environment are needed). Also keeping a good film thickness homogeneity during the film deposition and drying is clearly an important issue because, otherwise, the sites of enhanced film thickness may become a crack nucleation center which then propagates along the whole film, as it could be discerned when in-situ OM video recording of the crack formation was made [125] (figure 8).

Figure 8. Typical OM images of IJP films (5 × 5 mm) after pyrolysis and the corresponding thickness maps, as determined by optical interpherometry. (a) Homogeneous film with a final nominal thickness of ∼1100 nm not displaying any crack; (b) corresponding thickness map of the film shown in (a); (c) and (d) pyrolyzed films with a final film thickness of ∼1050 nm showing a few cracks nucleated at the edges of the film. Reproduced from [125]. CC BY 3.0.

Download figure:

Standard image High-resolution imageThe thorough knowledge generated about the physico-chemical transformations occurring during the pyrolysis process has become very useful to maximize the film thickness [139], as well as to accelerate the pyrolysis step [59, 133]. This was demonstrated in an effort to define the best parameters for thick (∼1 μm) film deposition of YBCO films by single deposition IJP to approach the thickest CSD films reached by slot die coating or spin coating by multideposition [29, 126, 140].

IJP has indeed a strong potential as compared to slot die coating for being used as a digital approach of complex material structures, including stripes for low ac losses superconductors, combinatorial screening as a high throughput experimentation technique and so on [127, 141–146]. However, after the first attempts of preparing thick films, it was immediately clear that the composition of the low fluorine solutions and the IJP deposition parameters should be properly optimized to reach a very homogeneous liquid thickness before the pyrolysis process. Concerning the pyrolysis step, similar difficulties appear in IJP as compared to slot die coating or spin coating respect the above mentioned morphological inhomogeneities (wrinkling, cracking) [125, 128, 129, 132, 139]. It is not a trivial goal then to control all the relevant parameters involved in solution deposition by IJP because it is needed to adapt the solutions to the sort of nozzles to be used. For instance, a recent use of machine learning analysis of fluorine-free IJP solution deposition has shown that high throughput experimentation may help to predict the most relevant processing parameters (drop volume, drop pitch, wettability, solvent evaporation rate, etc) [143, 147].

Keeping the liquid layer homogeneous after IJP deposition requires first to redesign the low fluorine YBCO inks in order to avoid the so-called coffee ring effect, i.e. a liquid sucking effect from dried regions of the film. To avoid this effect, the selected strategy was to use solvents with high boiling points (propionic acid and butanol) to avoid evaporation during deposition and preserve the liquid state of the film during the whole deposition process. It was also very beneficial to use small amounts of a photocurable polyacrylic varnish as an ink additive. Then the use of a UV lamp curing process contributed to pin the liquid after deposition and optimize the film thickness homogeneity [126] (figure 9).

Figure 9. (a) and (b) OM images of IJP films (5 × 5 mm) after pyrolysis and the corresponding thickness maps (in nm), as determined by OI. (a) Homogeneous film with a final nominal thickness of ∼1100 nm not displaying any crack; (b) film with a final thickness of ∼1050 nm showing a few cracks in the central part of the film. Reprinted with permission from [126]. Copyright (2021) American Chemical Society (see also videos S2 and S3 in supporting information).

Download figure:

Standard image High-resolution imageOnce being successful in the goal of keeping a wet high film thickness homogeneity after solution deposition, the optimal heating conditions previously defined in the physico-chemical analysis of the pyrolysis were used. In this way films prepared with a single deposition and a final thickness of ∼1.2 μm could be achieved. These films had typical thicknesses after drying of ∼9 μm and they shrink down to ∼2 μm after the pyrolysis without any film inhomogeneity (figure 9). The performance in terms of film quality of these pristine films could be extended then to the multifunctional colloidal solutions described in the previous section and so thick YBCO nanocomposite CSD films could also be prepared [126, 139]. It is also worth to mention that films thickness in CSD films can be always further increased through multideposition of solutions after an intermediate pyrolysis processes. This multideposition strategy to prepare thick films has been demonstrated by several authors by IJP with thicknesses in the range of ∼1–1.6 μm [126, 127] and by slot die coating with thicknesses in the range of ∼2.5–3.0 μm [29, 31]. In all cases the REBCO growth process of the thick films needed to be reformulated to reach high superconducting performances. Slot die coating has been demonstrated to be a suitable industrial approach to prepare CSD CCs in long lengths when a multideposition approach is used because it can be adapted to a multilane automatized manufacturing system [30, 31, 63, 79, 148–150].

In conclusion, reaching a deep understanding of the chemistry of metalorganic solutions and of colloidal inks to optimize the deposition process is a very relevant goal, whatever deposition technique is used. Afterwards, the use of the detailed knowledge about the physico-chemical transformations occurring during the pyrolysis process for the corresponding chemical precursors is a key issue to optimize the processing conditions.

Needless to say, the deposition and pyrolysis steps can be performed separately from the growth process and so the growth process does not need to be synchronized with the pyrolysis facility. For that reason, minimization of the duration of the deposition–pyrolysis process, though relevant, is not mandatory, contrary to the demand of keeping a high pyrolyzed film quality which is a real requirement to assure high performance after growth.

2.4. Intermediate phase evolution

After the pyrolysis step, an additional relevant process is the nanoscale control of the intermediate solid phases during the heating stage towards the growth temperature. The final reaction leading to the formation of REBCO films in the case of the BaF2 derived processes is a solid–solid reaction controlled by gas diffusion phenomena [20, 21, 28]. Therefore, it is clear that any parameter which may modify the kinetics of this reaction will influence the formation and, very likely, the microstructure of the epitaxial films, including the particular case of the nanocomposite films. Several investigations have been reported in the past concerning the evolution of the intermediate phases during this heating stage. In most of the cases this process is performed under a humid atmosphere and with a fairly low heating rate (∼25 °C min−1) [20, 21, 151, 152]. During this CTA process it has been shown that a deep transformation of the chemical and nanoscale structure occurs. It was shown that the solid solution BYF is transformed to a mixture of an oxyfluoride phase Ba(Fx Oy )2 (OF) and Y2O3 in the early stage of the heating ramp. Sometimes, the existing CuO partially reacts at higher temperatures with the Y2O3 phase forming the intermediate phase Y2Cu2O5 which, actually, competes with the main reaction leading to the direct formation of YBCO (see equations (1)–(3)) [20, 56, 153, 154].

The main reaction leading to the formation of YBCO is:

with 0 < y < 1. The intermediate competing reactions with the main reaction (1) are:

Additionally, all the intermediate solid phases display particle coarsening which could even reach, in some cases, particle sizes as big as ∼100 nm (Y2Cu2O5 for instance), thus losing the nanoscale film homogeneity preserved after the pyrolysis process. Needless to say, the nucleation and growth of epitaxial YBCO are influenced by the size evolution of the intermediate phases which then modifies the kinetics of reactions (1)–(3) and the final microstructure.

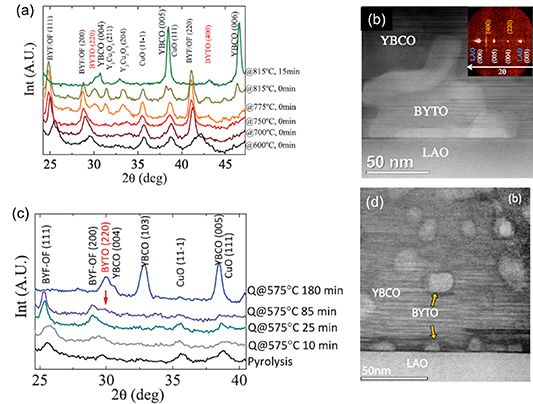

To minimize the adverse effects of CTA a new heating process was recently devised called FH, where the heating rate is strongly increased to values in the range of hundreds to thousands of °C min−1 (inconstant heating ramp), and so the final heating time is reduced by a factor ∼30 as compared to CTA [152, 155]. The first consequence of using FH is that the initial reactions previously mentioned (BYF transformation, yttria formation) were hindered up to the nucleation and growth temperature of YBCO (∼750 °C–800 °C) and so reactions (1)–(3) occur at a single temperature.

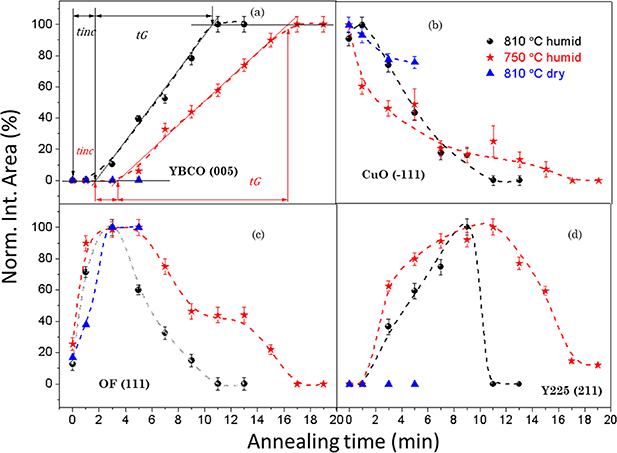

By examining x-ray diffraction patterns of FH films quenched to room temperature after annealing during different times at 810 °C, the evolution of the different crystalline phases could be determined and a kinetic phase diagram could be devised and compared with that obtained with a similar process using the CTA as a heating profile (figures 10 and 11). The first observed modification is that Y3+ ions are expelled from the BYF fluorite phase at higher temperature forming Y2O3 and OF. Immediately after Y3+ ions are expelled from the fluorite structure the competitive reaction (2) leading to Y2Cu2O5 is initiated. However, owing to the short diffusion lengths required to form the new solid phases, the incubation time to nucleate the epitaxial YBCO nuclei was also very short (∼3 min) and so the advancement of the undesirable intermediate reaction forming Y2Cu2O5 is strongly minimized.

Figure 10. Normalized integrated area dependences with annealing time of x-ray diffraction peaks in a FH process. (a) YBCO(005), where tinc is the incubation time and tG

is the growth time; (b) CuO(−111); (c) OF(111); (d) Y225 (211), respectively, while the samples were quenched at 810 °C in a dry gas atmosphere (blue  ) at 810 °C in a humid gas atmosphere (black

) at 810 °C in a humid gas atmosphere (black  ) and at 750 °C in a humid gas atmosphere (red

) and at 750 °C in a humid gas atmosphere (red  ) after annealing for selected time periods. Reproduced from [155]. CC BY 3.0.

) after annealing for selected time periods. Reproduced from [155]. CC BY 3.0.

Download figure:

Standard image High-resolution imageFigure 11. (a) Experimental phase diagram of the intermediate phase evolution in the FH route towards YBCO film formation. The films were heated in a humid atmosphere using the FH process at given temperatures, and quenched after being annealed for different time periods at these specific temperatures. The x-ray diffraction patterns were used to identify the different crystalline phases; (b) corresponding phase diagram of films heated following the conventional thermal annealing approach. Reproduced from [154]. © IOP Publishing Ltd. All rights reserved. Reproduced from [155]. CC BY 3.0.

Download figure:

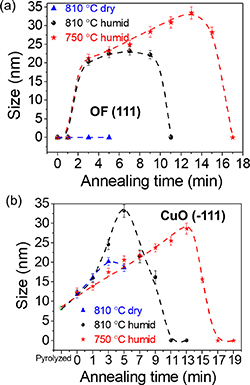

Standard image High-resolution imageThe second very relevant consequence of FH is that the coarsening of the intermediate NPs is severely restricted and so the nanoscale homogeneity of the precursor films leading to YBCO is strongly enhanced. The increase of the kinetics of reaction (1) leading to YBCO involves the use of the precursor phases (CuO, OF), as it is seen in the fast decrease of the intensity of the corresponding Bragg peaks (figure 10). The main consequence is that the time available to induce some NP coarsening is strongly reduced to less than ∼10 min, i.e. at least one order of magnitude shorter than in CTA films. The estimated coarsening rates of the intermediate phase NPs (CuO, OF, Y2Cu2O5) were in the range 1–4 nm min−1 for the diameter and so their size remains in the range of 5–20 nm, thus strongly enhancing the film homogeneity (figure 12). The observed decrease of the precursors NP size follows the decrease in the Bragg peak intensities (figures 10 and 12) thus indicating that they are consumed to form YBCO. Overall, therefore, the accelerated growth of the YBCO films is facilitated by the enhanced nanoscale homogeneity of the precursor films which reduces the incubation time, even if the growth rate of the YBCO films (⩽0.5 nm s−1) remains similar to those prepared by CTA because the growth mechanism is not modified [152, 153, 156–162].

Figure 12. Size evolution of nanocrystalline precursors under different annealing conditions following the FH process: (a) OF, (b) CuO. YBCO thin films are either quenched from 810 °C after heating in a dry gas atmosphere (blue triangle), from 810 °C after heating in a humid gas atmosphere (black sphere) and from 750 °C heating in a humid gas atmosphere (red star). In all cases the nanoparticle size evolution in the FH process can be followed. The nanoparticle size was calculated from the Debye–Scherrer formula using CuO(−111) and OF(111) Bragg peaks. Reproduced from [155]. CC BY 3.0.

Download figure:

Standard image High-resolution imageThe kinetic advantages of the FH process were also found very useful in optimizing the growth of YBCO nanocomposite films through the multifunctional colloidal process described in previous sections. The preformed NPs included in the multifunctional colloidal solutions are always designed to have the optimal sizes for their functionality as APC, therefore, it is desirable that their composition and size are preserved during the processes previous to growth (pyrolysis and heating).

The evolution of the preformed NPs during the whole thermal annealing processes to grow the YBCO nanocomposites was precisely investigated in some particular cases, such as the ferrimagnetic CoFe2O4 NPs, selected as a typical example of oxide system where the magnetic properties are key indicators of their evolution [163]. It was concluded that during the pyrolysis process (T < 310 °C) there is no appreciable NP coarsening.

Summarizing, only the heating process following pyrolysis can influence the NP's size and so special care should be taken to ascertain their stability during the growth in nanocomposite films. Fortunately, as it will be demonstrated in next sections, the ternary perovskite BaMO3 (M = Zr, Hf) NPs displayed a stable behavior (chemical composition and coarsening) when a FH process is used.

In conclusion, a thorough analysis of the intermediate phase evolution during the heating step of the CSD REBCO films from the pyrolysis to the growth temperature has demonstrated that the chemical and microstructural evolution is significant enough to select attractive heating processes, such as FH, which minimize the effects of particle coarsening. Preserving the nanoscale homogeneity facilitates and accelerates the epitaxial growth of the REBCO films.

3. Nucleation and growth of REBCO pristine, nanocomposite films and CCs

3.1. Nucleation, growth and oxygenation of pristine REBCO films and CCs

Understanding the nucleation and growth mechanisms of YBCO epitaxial films prepared through the BaF2 process has been a key objective since the initial efforts to use it as a route to practical applications of films and CCs. It was soon realized that the reaction is based on a solid–solid reaction–diffusion process controlled by gas diffusion which is initiated by a Volmer–Weber type island epitaxial nucleation [20, 28, 35, 164, 165]. Several parameters have been shown to influence the supersaturation degree (total pressure PT , water pressure P(H2O), film thickness, gas flow, ...) and the heterogeneous nucleation (c-axis or ab-axis orientation, nuclei density, strain, RE ion, metal stoichiometry, Ag additives), the growth rate (temperature, PT, P(H2O), PO2), the film strain state (lattice misfit, interfacial defect structure) and the reactivity with the substrate or buffer layer [20, 28, 69, 142, 163, 166–168].

Owing to the complexity of the whole process of epitaxial growth of REBCO films, a steady effort was made in recent years to further advance our understanding of the growth mechanisms and its influence on superconducting performance.

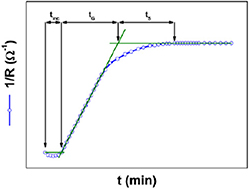

A particularly appealing experimental technique to analyze nucleation and growth is the in-situ electrical resistivity measurements performed during the YBCO growth process [153, 156–158]. This technique allows not only to determine equilibrium thermodynamic parameters but it also reveals very useful kinetic aspects. The typical time dependence of isothermal electrical resistance R during growth shown in figure 13 follows the law:

Figure 13. Typical time evolution of the electrical conductance 1/R of YBCO films during the isothermal growth stage. The identification of the different characteristics times is indicated: tinc is the incubation time, tG is the growth time and ts is the sintering time of YBCO grains. Reproduced from [156]. © IOP Publishing Ltd. All rights reserved.

Download figure:

Standard image High-resolution imagewhere R is the electrical resistance, G is the growth rate, tG the growth time and the rest are proportionality constants. Previous to this linear time dependence, an incubation time is also evidenced, which is related to the nucleation barrier to form stable YBCO islands and to the diffusion time required to reach percolation among them [156].

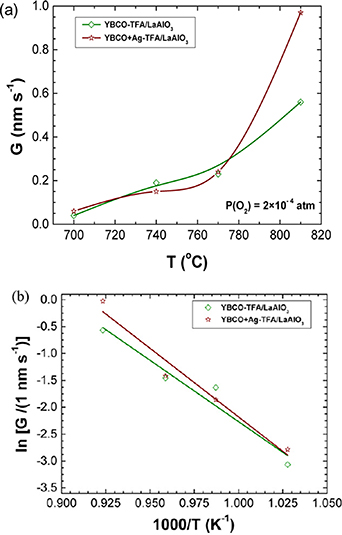

Through an analysis of the temperature dependence of G(T) for YBCO films it was possible to ascertain that the exponential dependence (van't Hoof equation) of the equilibrium constant Ke (Ke = Keo exp–(ΔHθ /RT), where ΔHθ is the reaction enthalpy) governing the reaction of equation (1) is the main parameter determining the observed strong temperature dependence of G (from 0.04 nm s−1 at 700 °C to 0.60 nm s−1 at 810 °C, i.e. a factor 15) (figure 14) and from this analysis the formation enthalpy ΔHθ of YBCO could be determined [156]. From this study it was also evidenced that the incubation time strongly depends on temperature, which reflects that because the in-plane growth rate is reduced it takes longer to achieve nuclei percolation. The typical nuclei separation distance was estimated to be ∼1 μm which is in agreement with previous estimated values [28, 164].

Figure 14. (a) Temperature dependence of the growth rate G measured for YBCO films grown from TFA and TFA-Ag solutions on an LAO substrate. (b) Analysis of the temperature dependence of the growth rate G measured for YBCO and YBCO-Ag films according to the law established from thermodynamic principles and chemical kinetics. The equilibrium constant of the reaction is assumed to follow the van't Hoof equation and so the standard enthalpies of the reaction, ΔHθ , can be deduced. Reproduced from [156]. © IOP Publishing Ltd. All rights reserved.

Download figure:

Standard image High-resolution imageAn additional complex problem associated to the BaF2 process that needs to be considered is the control of the supersaturation degree when thick films are being grown [28, 63, 139]. It was previously established that the gas controlled solid–solid reaction leading to YBCO should be analyzed differently in thin (up to ∼300 nm) and thick (beyond ∼600 nm) film limits [28, 139, 164]. While in the thin limit the classical nucleation energy barrier of a single nuclei is controlling the nucleation rate, in the thick limit the model needs to be extended to include the interaction among nuclei. As a consequence, the H2O gas flow and the diffusion permeability of the HF exhaust gas (equation (1)) across the films are also modifying the supersaturation degree and so the nucleation and growth rates [28, 139]. These two limits need to be taken into consideration when YBCO films with thicknesses in the range of ⩾1 μm are prepared.

While the general trends described up to now concerning nucleation and growth of YBCO films are valid with whatever REBCO film is considered, the precise optimal conditions for the different RE compositions and also in YBCO films with modified metal stoichiometry (Ba deficiency for instance) will be different because their corresponding equilibrium phase diagrams are slightly modified, i.e. the stability lines and optimal growth regions are shifted [57, 75, 169]. For instance, systematic analysis of different REBCO films grown under the same conditions showed a systematic shift of the superconducting properties (Tc, Jc ) [82, 83] while when larger RE ions are used (GdBCO for instance) the optimal growth conditions are shifted to lower PO2 values and higher temperatures [73], as compared to YBCO. We should note that (Y,Gd)BCO CCs with thicknesses in the range of ∼2.5 μm obtained through 15–20 depositions have been demonstrated with very high superconducting performance [63]. In the case of Ba deficient YBCO films, a decrease of the optimal growth temperatures was also demonstrated, very likely due to the shift of the stability line of YBCO in these Ba-poor compositions [74, 75]. The appealing consequence of this shift in the YBCO stability line is that the temperature dependence of supersaturation is also modified and so the crossover of the c-axis nucleation versus that of a/b grains is also shifted to lower temperatures. The main advantage of this shift is that high quality epitaxy (c-axis orientation) is achieved at lower temperatures with an improved microstructure (less porosity and a reduced concentration of a/b grains) [53, 74, 76, 80].

Understanding the main trends of REBCO nucleation and growth has strongly facilitated to prepare CCs using different metallic substrates (RABiT, IBAD) leading to fairly good superconducting performances, including the reel-to-reel continuous process used at industrial scale [30, 58, 140, 142, 169–172]. It is also worth to remark that owing to the global complexity of the CSD BaF2 growth process, several attempts of using experimental fast screening and big data approaches have been made to accelerate the optimization of CCs and to correlate processing, nanostructure and superconducting properties [143, 147, 173].

A special case of multilayer architecture requiring additional analysis of the growth conditions due to the relevance of the lattice misfit with the substrates or buffer layers is the case of YBCO films grown on sapphire. This architecture needs to handle the complex problem of the influence of strain in functional oxides. In the case of REBCO films grown through the BaF2 process it is even more complex because a partial relaxation of the interfacial strain occurs [174]. YBCO films grown on sapphire have appealing properties, both for MW and fault current limiter applications [175–177] and so extensive studies of the YBCO/CeO2/sapphire multilayer architecture have been performed in the past. In the case of MW applications, the required film thickness is quite limited (few hundred nm), while in the case of fault current limiters the film thickness should be as large as possible to reach high total critical current (Ic ) values [177]. Since early growth studies, however, it was found that, whatever film growth technique is used, the YBCO films displayed the formation of in-plane cracks when the film thickness goes beyond ∼250 nm, which was an evidence of the generation of an important tensile strain in the film. On the other hand, no equivalent tendency to generate cracks was detected when other substrates were used. The origin of this unique behavior of sapphire substrate remained obscure and it was generally associated to a strong difference in the thermal expansion of both phases (YBCO and sapphire). In a recent work, however, it was shown that the multilayer YBCO/CZO/YSZ/sapphire could be grown with thicknesses beyond 400 nm without crack formation and that, actually, the cracks appeared during the tetragonal–orthorhombic transition occurring during the oxygenation step [178]. A thorough analysis of the strain state of the different layers of this heterostructure showed that, while in the YBCO/CZO/YSZ multilayered structure the YBCO films keep a compressive state (no tendency to generate cracks) in the case of the sapphire substrate architecture the tetragonal YBCO films also keeps a compressive state but during the orthorhombic transition the decrease of the a-axis parameter is reduced versus the bulk value and so a tensile strain remains along this direction in the YBCO film and so a tendency to form cracks.

A final topic to handle is that related to the last step of the whole process of preparing REBCO superconducting films: the oxygenation process. It is well known that the oxygenation process of films is a complex problem which has been widely investigated mostly in the scope of the attractive properties of ionic and mixed ionic-electronic conductors [179–184]. However, the mechanisms responsible of the oxygenation process of YBCO films still remained poorly understood [185, 186]. In recent years, the particular case of YBCO CSD films has been extensively investigated by means of electrical resistivity relaxation measurements [158, 185, 186]. From the analysis of the temperature and PO2 dependences of the oxygen exchange kinetics for in-diffusion and out-diffusion processes it was concluded that the rate limiting step in thin films for the in-diffusion process is not the bulk diffusion of O2− ions. Instead, it was shown that the oxygen surface exchange is the slowest step and so it was shown that a catalytic effect accelerating the oxygenation kinetics (decrease of the activation energy) was achieved when Ag islands were included at the surface of the films. The study of oxygenation kinetics was later extended to other REBCO films and it was shown that a systematic shift in the activation energies and the optimal oxygenation temperatures exist for different REBCO films and also that the activation energies are modified by the oxygen chain ordering (O-I and O-II phases) of the oxygen deficient REBCO structure, thus suggesting that there is a crossover from the surface dominated domain to a bulk dominated domain [186]. Achieving a full understanding of the oxygenation kinetics in REBCO films is actually a very important issue because, as it has been recently demonstrated [187], the critical currents of the YBCO films in the OD state are strongly enhanced. Therefore, the determination of the rate limiting steps may allow to maximize the superconducting performance of films and CCs [188].

Summarizing, a steady progress in understanding the nucleation, growth and oxygenation stages of REBCO films preparation has been made in recent years which has been effectively used to improve the performance of CCs and technical substrates like sapphire. An important issue which still requires further progress is to develop procedures to increase the REBCO film growth rate in order to enhance the throughput in film manufacturing and so keep a strong competitiveness with other techniques where the growth rate is continuously increasing [8].

3.2. Nucleation and growth of REBCO with spontaneously segregated NPs

After the first reports of YBCO nanocomposite film growth by PLD [12, 189], the search of a suitable approach to grow nanocomposite YBCO films by CSD was immediately started. The first reports were based on an increase of the RE salt content in the starting solution (leading to Dy2O3 NPs in a YBCO films) [29, 30] while YBCO nanocomposites including BaZrO3 perovskite NPs were achieved in 2007 using complex solutions [22]. Extensive analyses of the nanostructure of these CSD films immediately confirmed that it completely differs from that generated by the techniques based on simultaneous growth of both phases (PLD or MOCVD) [22–24]. The main difference among both types of nanocomposites arises from the fact that the secondary NPs generated by CSD are mainly randomly oriented and randomly distributed. On the other hand, the growth techniques with a simultaneous growth of YBCO and the secondary NPs a self-assembled nanostructure of nanorods oriented perpendicular to the film substrate may be achieved [3, 14, 117, 121]. The driving force of the self-assembly phenomenon is the strain generated during the epitaxial orientation of both phases. This topic has been reviewed by several authors and it is not in the scope of the present manuscript [121–123]. Here we will focus our attention on the growth mechanisms of nanocomposites prepared by CSD using TFA or low fluorine precursors as an example of sequential method.

As we have previously described, the first SS strategy to prepare CSD nanocomposites was based on the use of complex metalorganic solutions including the elements required to form a specific secondary phase, for instance BaZrO3, BaCeO3, BaHfO3, RE2O3 or Ba2YTaO6 [22, 30, 89, 90, 190, 191] (figure 15(a)).

Figure 15. Schematics of the processes followed in chemical solution deposition to grow YBa2Cu3O7 nanocomposite films: (a) route based on the spontaneous segregation process where the metalorganic precursors include all the metal ions to be included in the final films; (b) route based on the preparation of preformed nanoparticles and a multifunctional colloidal solution including the metalorganic precursors and the stabilized nanoparticles.

Download figure:

Standard image High-resolution imageThe main question was to comprehend how the secondary phases nucleate and grow. In the SS approach to grow CSD nanocomposites the standard heating process (CTA) was applied and it was concluded that the NPs were embedded in the YBCO matrix with a high percentage randomly oriented (∼50%–90% depending on the concentration), except for the case of Y2O3 where the random fraction was smaller (<30%). From these results it was immediately suggested that the secondary phases (NPs) were created through homogeneous nucleation at lower temperatures than the epitaxial YBCO and so they were essentially randomly oriented [22, 23, 192]. Actually, a small percentage of the NPs was found to nucleate heterogeneously at the substrate interface and then they kept the epitaxy with YBCO (figure 16). In these cases, more complex textures were discerned by means of texture analysis with synchrotron x-ray diffraction. For instance, BaCeO3 NPs which have a large lattice misfit with YBCO display axiotaxy, i.e. a fiber axis preferential orientation versus the YBCO matrix [193].

Figure 16. XRD analysis to quantify the random and epitaxial fraction of nanodots in the nanocomposite films. (a) The 2D-XRD images centered at the (110) Bragg reflections of the BZO epitaxial nanodots allowing the quantification of the fraction of randomly oriented nanodots; (b) percentage of random nanodots versus nominal molar concentration Np in the YBCO nanocomposites with Y2O3, BaZrO3, BaCeO3 and Ba2YTaO6. Reproduced from [23], with permission from Springer Nature.

Download figure:

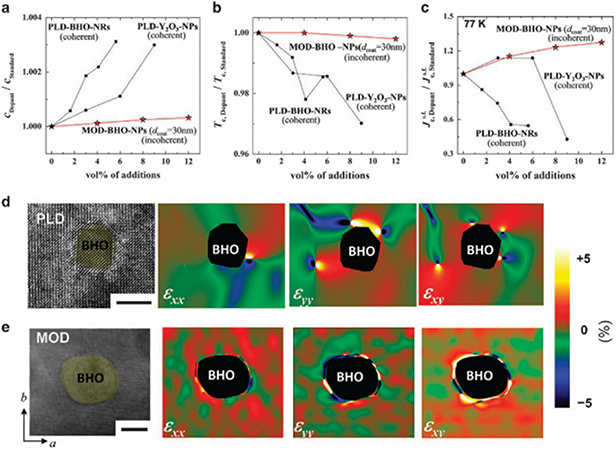

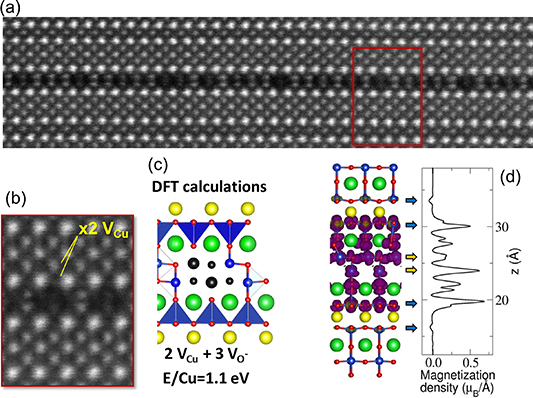

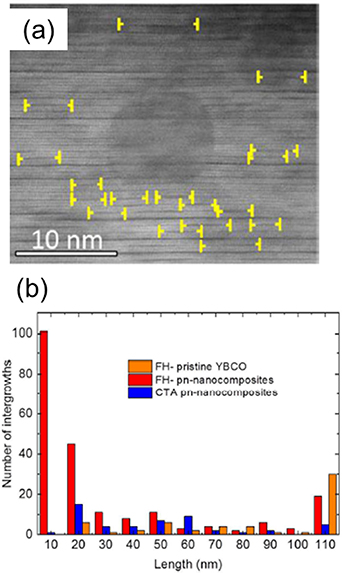

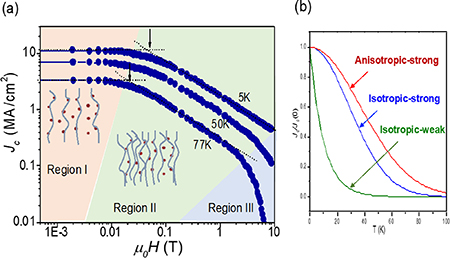

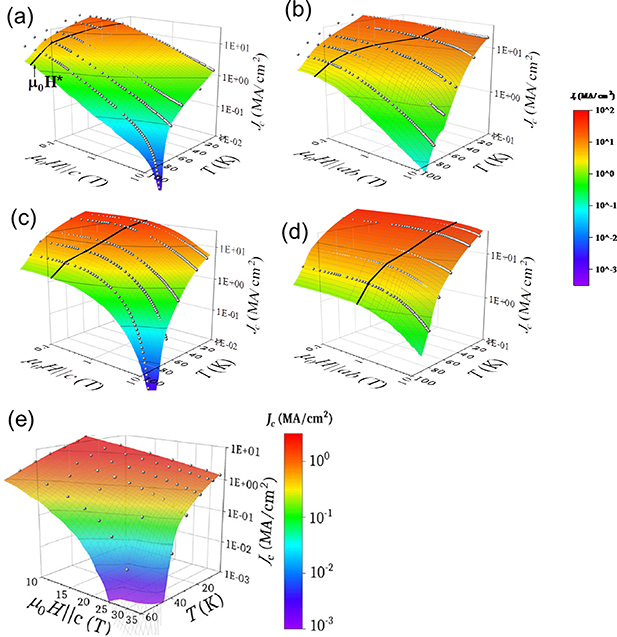

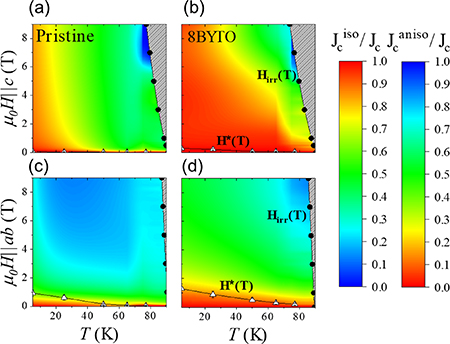

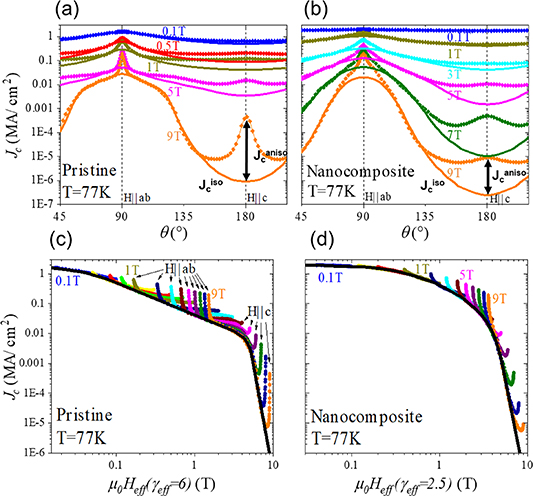

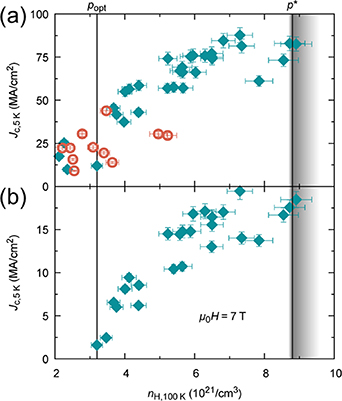

Standard image High-resolution imageAn important goal of the SS approach was the control of the NP size because their incoherent interface with YBCO is the source of induced defects in the YBCO matrix. The typical particle sizes achieved through the CTA growth process was in the range of ∼15–25 nm, depending on the composition and lattice misfit with YBCO, and it was concluded that there is a certain tendency to agglomerate the NPs at high concentrations [91]. The achieved particle size is very likely too large to have a direct effect on vortex pinning while the agglomeration effect decreases the specific interface with the YBCO matrix and so it decreases the positive influence on vortex pinning of the induced defects and it reduces the percolating critical current density Jc . The NP sizes were later studied and the influence of modified thermal treatments was undertaken by several authors to decrease the particle size and improve the distribution homogeneity [40, 80, 81, 91, 155, 194].