Abstract

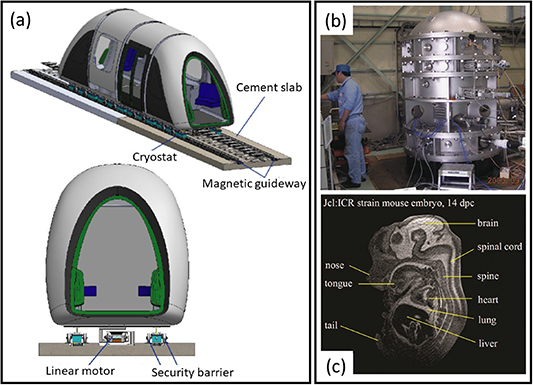

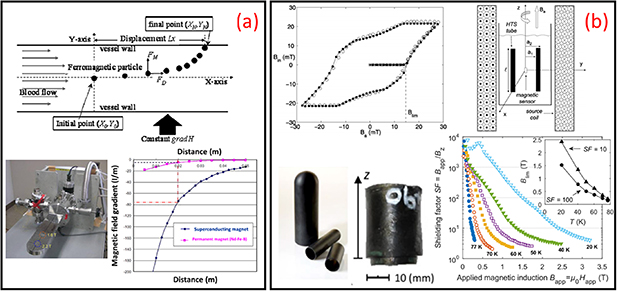

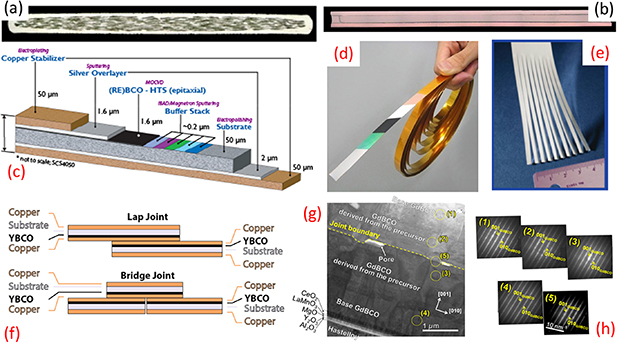

Bulk (RE)-Ba-Cu-O [(RE)BCO] cuprate HTS have been developed steadily towards a wide range of sustainable engineering and technological applications since their discovery in 1986 based primarily on their unique potential to trap very large magnetic fields (>5 T) at temperatures that are accessible potentially by thermo-electric cooling techniques. Trapped fields of ∼10 T at the surface of individual (RE)BCO bulk single grains and in excess of 17 T in a reinforced two-sample stack are now being achieved reliably. This paper reviews the current state of the art of the processing of large, single grain (RE)BCO bulk superconductors required to trap fields of this magnitude, and specifically via two advanced fabrication approaches; the traditional TSMG process and the more recently developed TSIG technique. The focus of the review is on optimising the critical processing parameters to achieve high-quality, high performance single grain (RE)BCO bulk superconductors specifically for high-field applications. The review also summarises recent advances in processing, such as the integration of the so-called buffer technique into the TSMG and TSIG processing methodologies to achieve improved reliability in single grain growth with a success rate exceeding 90%, the development of a Mg-doped NdBCO generic seed crystal for the successful growth of all rare-earth and light-rare earth based bulk superconductors [(RE)BCO and (LRE)BCO] and the introduction of nano-size stable, non-superconducting phase(s) to the bulk microstructure to improve the intrinsic flux pinning strength of the material, and hence trapped magnetic field. Details of the two-step buffer-aided TSIG technique developed recently that yields dense, near-net shaped, high performance (RE)BCO bulk superconductors with improved superconducting and mechanical properties are also presented. Suitable sample-seed configurations for effective multi-seeding are discussed, which enables the production of high aspect ratio, bar-shaped (RE)BCO quasi-single grains that exhibit improved levitation forces required in Maglev-based applications, for example, are discussed. The electrical, mechanical, microstructural and magnetic properties (including those achieved from a pulsed-field magnetisation approach) of the different (RE)BCO systems are presented and the relevant correlation in properties and performance highlighted, accordingly. Finally, a brief summary of existing applications and prospects for near-future exploitation of these remarkable, technologically important materials, and particularly in the medical and pharma-industries, is provided.

Export citation and abstract BibTeX RIS

Original content from this work may be used under the terms of the Creative Commons Attribution 4.0 license. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

Acronyms—expansions and symbols, as they appear in the article

| TSMG | top seeded melt growth |

| TSIG | top-seeded infiltration and growth |

| HTS | high temperature superconductors |

| Hirr | irreversibility field |

| (RE)BCO | RE–Ba–Cu–O |

| Tc | critical temperature |

| Jc | critical current density |

| Hc | critical magnetic field |

| λ | penetration depth |

| ξ | coherence length |

| κ | Ginzburg–Landau parameter |

| BCS theory | Bardeen–Cooper–Schrieffer theory |

| Y-211 | Y2BaCuO5 |

| Y-123 | YBa2Cu3O7−δ |

| Tp | peritectic temperature |

| QMG | quench melt growth |

| MPMG | melt powder melt growth |

| OCMG | oxygen controlled melt growth |

| MG | melt growth |

| RE-123 | REBa2Cu3O7−δ |

| RE-211 | RE2BaCuO5 |

| IG | infiltration and growth |

| Tmax | maximum processing temperature |

| Tiso | isothermal temperature |

| Tg1 | growth start temperature |

| Tg2 | growth final temperature |

| Tg | growth temperature |

| R or R* | single-grain growth rate |

| ΔT | undercooling temperature |

| L | single grain length |

| Ra | single grain growth rate along a/b-axis |

| Rc | single grain growth rate along c-axis |

| Y-2411 | Y2Ba4Cu1M1Oy |

| ts and tf | are the growth time(s) associate with start and end of the continuous cooling period, respectively |

| Rcc | single grain growth rate during continuous cooling |

| Rih | single grain growth rate during isothermal hold period |

| CCIH | continuous cooling and isothermal holding |

| BA-TSMG | buffer-assisted top-seeded melt-growth |

| (NSG)BCO | (Nd,Sm,Gd)1Ba2Cu3O7 |

| (NEG)BCO | (Nd,Eu,Gd)1Ba2Cu3O7 |

| (SEG)BCO | (Sm,Eu,Gd)1Ba2Cu3O7 |

| (YSN)BCO | (Y,Sm,Nd)1Ba2Cu3O7 |

| (YGd)BCO | (Y0.5,Gd0.5)1Ba2Cu3O7 |

| LA-TSMG | liquid-assisted top-seeded melt growth |

| Ic | critical current |

| APC | artificial pinning centres |

| TEM | transmission electron microscopy |

| Jc(H) | field dependence of Jc |

| Bt | trapped field |

| Hp | peak field |

| flux quantum (=h/2e) |

| h | Planck's constant (6.62 × 10−34 m2 kg s−1) |

| e | charge of electron (1.6 × 10−19 C) |

| af | Vortex lattice spacing |

| Fd | drag force |

| Fi | interfacial force |

| interfacial energy |

| surface energy at the solid/particle interface |

| surface energy at the liquid/particle interface |

| surface energy at the solid/liquid interface. |

| r* | critical size of the RE-211 particle |

| η | viscosity of the melt |

| ρ | electrical resistivity |

| FC | field-cooling |

| ZFC | zero-field cooling |

| PFC | pulsed-field cooling |

| PFM | pulsed field magnetisation |

| σ | tensile stress |

| B0 | maximum trapped field in the sample |

| µ0 | permeability of space/vacuum permeability (4π × 10−7 H m−1) |

| Gd210 | Gd2BaO4 |

| RT | room temperature |

| K1C | fracture toughness |

| LNT | liquid nitrogen temperature |

| MRI | magnetic resonance imaging |

| NMR | nuclear magnetic resonance |

| MAGLEV | magnetic levitation |

| LTS | low temperature superconductor |

| F | magnetic force |

| B | magnetic induction |

| F L | Lorentz force |

| U | mean flow velocity of the liquid/fluid |

| V | Characteristic volume. |

| SF | shielding factor |

| Blim | threshold induction or limiting field |

| Bappl | applied magnetic field |

| Bin | induced field |

| RABiTS | rolling-assisted biaxially textured substrate |

| MOCVD | metal-organic chemical-vapor deposition |

| PLD | pulsed laser deposition |

| LHC | Large Hadron Collider |

| ITER | international thermonuclear experimental reactor |

| FCC | future circular colliders |

| SAED | selected area electron diffraction |

1. Introduction

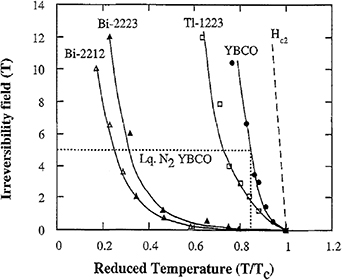

HTS fabricated in the form of large, single grain bulk samples have the potential to carry large macroscopic currents and therefore to generate some of the largest magnetic fields ever recorded in the history of the planet. This makes these technologically important materials particularly attractive for wide variety of engineering applications, including trapped field magnets, flywheel energy storage, magnetic separation and compact motors and generators [1]. The magnetisation of bulk, single grain superconductors scales with sample volume, unlike conventional permanent magnet materials, such as Sm–Co or Nd–Fe–B, for which magnetisation is generally independent of sample size. As a result, the larger the single grain and the higher its current carrying ability, the greater the magnitude of magnetic field the material can trap. Furthermore, and interestingly, the potential of a bulk superconductor for trapping magnetic field increases significantly as temperature is reduced due to its enhanced associated superconducting properties. One key figure of merit that determines generally the overall potential of a superconducting material for practical applications at a given temperature, and particularly in the presence of applied magnetic field, is its so-called irreversibility field, Hirr. The temperature dependence of Hirr, Hirr(T), is referred to conventionally as the 'irreversibility line'. The irreversibility lines for a selection of high-temperature superconductors are shown in figure 1, which shows clearly that (RE)–Ba–Cu–O ((RE)BCO, where RE is a rare earth element or Y) materials are operable practically at LNTs (77 K) and offer a significant potential performance advantage over other HTS materials [2]. This review focusses on the processing, properties and applications of bulk high temperature superconducting materials with a particular emphasis on the (RE)BCO family of superconductors.

Figure 1. Hirr as a function of reduced temperature 'T/Tc' (i.e. the so-called irreversibility line) for selected high-temperature superconducting materials [2]. Here Tc indicates critical temperature. Reprinted from [2], with the permission of IOP Publishing.

Download figure:

Standard image High-resolution image1.1. Superconductivity: basic concepts

Superconductivity, which was first discovered in mercury [3] by the Dutch Physicist Heike Kammarlingh-Onnes in 1911 at 4.2 K, is now observed in many thousands of metals and alloys [4–6]. A material is classed as superconducting if it exhibits two basic properties; zero resistance to the flow of dc electrical current and complete magnetic flux expulsion at low magnetic fields, leading to perfect diamagnetism (the latter is known as the Meissner effect). The superconducting state is known to exist below certain thermodynamic limits defined by Tc, Jc, and Hc. The quest to enhance the magnitude of these critical parameters, and therefore to improve the potential for practical applications employing superconducting materials in their various forms has been on-going since their discovery more than 100 years ago.

Superconductors, in general, are classified as either type-1 or type-2 based on their intrinsic properties such as magnetic λ and ξ. In practice, the ratio  , referred to as Ginzburg–Landau parameter and denoted as 'κ', determines the class into which superconductors fall. Typically, if κ >

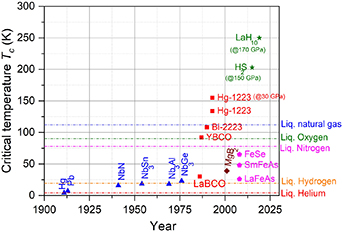

, referred to as Ginzburg–Landau parameter and denoted as 'κ', determines the class into which superconductors fall. Typically, if κ >  then the material is classified as type-II, otherwise it is type-I. Typical values of Tc, Hc, λ and ξ of some type-I and type-II superconducting materials are shown in table 1, with other basic properties of superconducting materials reported elsewhere [7–9]. The evolution with time of the discovery of various superconducting materials with respect to Tc is shown in figure 2.

then the material is classified as type-II, otherwise it is type-I. Typical values of Tc, Hc, λ and ξ of some type-I and type-II superconducting materials are shown in table 1, with other basic properties of superconducting materials reported elsewhere [7–9]. The evolution with time of the discovery of various superconducting materials with respect to Tc is shown in figure 2.

Figure 2. Discovery of superconductors with increasing Tc as a function of time (inspired from [10]). The cuprate-based HTS that are the prime focus in this review are indicated by the squares (red, online).

Download figure:

Standard image High-resolution imageTable 1. Characteristic parameters of some type-I and type-II superconducting materials.

| Category | Material | Critical temperature Tc (K) | Critical field Hc (T) | Coherence length ξ0 (nm) | Penetration depth λ0 (nm) |

|---|---|---|---|---|---|

| Type-I superconductors | Al | 1.2 | 0.01 | 1600 | 16 |

| In | 3.4 | 0.03 | 400 | 25 | |

| Sn | 3.7 | 0.03 | 300 | 28 | |

| Pb | 7.2 | 0.08 | 110 | 37 | |

| Nb | 9.3 | 0.2 | 38 | 85 | |

| Type-II conventional superconductors | NbTi | 10 | 11 | 6 | 300 |

| V3Ga | 15 | 23 | 3 | 90 | |

| NbN | 15.7 | 15 | 6.5 | 200 | |

| V3Si | 16 | 20 | 3 | 60 | |

| Nb3Sn | 18 | 26 | 4 | 50 | |

| Nb3Al | 17.5 | 32.4 | 4 | ||

| Nb3Ge | 23.2 | 38 | 3 | 90 | |

| Type-II non-conventional high-temperature superconductors | LaBCO | 30 | 65 | 1.5 | |

| YBa2Cu3O7−x (Y-123) | 92 | 120 | ξa –b : 2 ξc : 0.4 | 150 800 | |

| Bi2Sr2Ca2Cu3O10 (Bi-2223) | 110 | 100 | 1.4 | 200 | |

| TlBCCO | 125 | 33 | ξa –b : 8 ξc : 280 | 220 | |

| MgB2 | 39 | 40 | ξa –b : 4–12 ξc : 1.6–3.6 | 85–180 | |

| H2S | Tc: 200 K (under a pressure of 150 GPa) | ||||

| LaH10 | Tc: 250 K (under a pressure of 170 GPa) | ||||

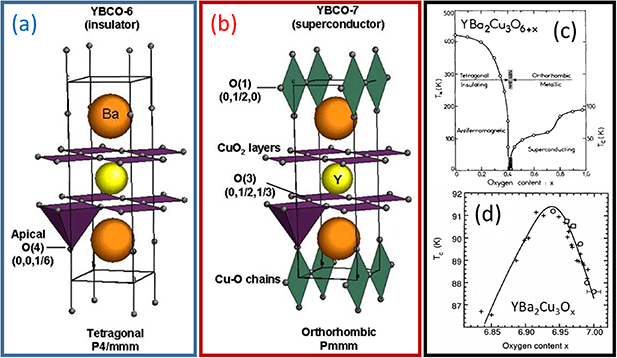

Prior to 1986, the compound Nb3Ge exhibited the maximum Tc of 23 K [11] of any known superconductor, which is consistent with the limit of the popular and successful Bardeen–Cooper–Schrieffer theory (the so-called BCS theory) [12]. The discovery of superconductivity in the barium-lanthanum-cuprate oxide system by Bednorz and Müller in 1986 [13] with a relatively high Tc of ∼33 K, however, exceeded significantly the theoretical BCS limit and produced great excitement broadly within the fields of physics, chemistry and applied science. Soon after this discovery, in 1987, Wu et al [14] observed superconductivity in the YBa2Cu3O7−δ (YBCO or Y-123) system with Tc ∼ 92 K, which formed a very important step forward, since, significantly, this material was the first to exhibit superconductivity above 77 K, the boiling point of liquid nitrogen. Hg-1223 with a Tc as high as 153 K (and 163 K under pressure), H2S with a Tc approaching 200 K (under a pressure of 150 GPa) and LaH10 with Tc as high as 250 K (again, under a pressure of 170 GPa) have emerged subsequently with even higher superconducting temperatures [15, 16]. In parallel, new superconducting systems, described as intermediate superconductors with Tc in the range 30 K–60 K, including MgB2 [17] and several Fe-based materials (LaFeAs, SmFeAs, FeSe and more) [18–20], have emerged over the last two decades that are fascinating from physics point of view and are being researched further to explore their suitability for applications. Detailed reviews on these topics can be found elsewhere [21, 22]. To date (2020) as many as seven Nobel Prizes have been awarded for different aspects of superconductivity, from the discovery of superconductivity to their application (including Josephson junctions [23]), which is unprecedented in field of applied science. In the present review, we will present mainly the various processing, characterisation and applied properties of rare-earth based bulk, HTS cuprate materials. Of particular focus will be the processing of these materials into large, single grains by techniques based on melt-growth and infiltration-growth, which will be described in detail. Recent developments in these fabrication methodologies will be summarised with the important results highlighted on a (RE)BCO material-by-material basis. Finally, the superconducting and mechanical properties of bulk (RE)BCO superconductors fabricated by these techniques and the potential pathways for their practical application will be presented.

1.2. Phase diagram, peritectic temperature and flux pinning

The rich information contained within the relevant phase diagram provides an easy path, not only to understanding the phase kinetics of the relatively complex (RE)BCO system, but also for formulating a compositional route for the growth of individual single grains by a variety of available melt-growth processing techniques. Details of the complex ternary phase diagrams for different (RE)BCO compositions have been described previously in several reports [24–27]. Here, we provide only a broad and general overview of the use of phase diagrams for materials processing purposes for readers new to this field in order to aid understanding of the (RE)BCO system and to inform subsequent discussion. Further details and understanding of the (RE)BCO phase diagrams can be found in the above references.

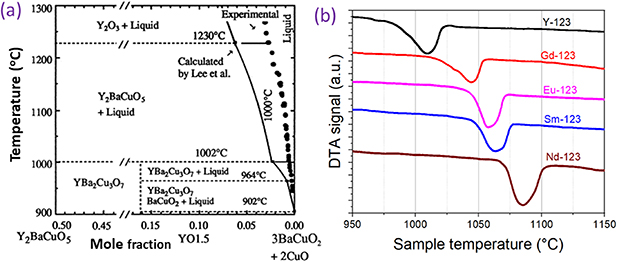

The thermodynamic behaviour of YBCO has been studied extensively from equilibrium phase diagrams for the Y2O3–BaO–CuOx system over a broad temperature range. In particular, a pseudo-binary phase diagram has been developed based on the solidification of different phases in the system (YBa2Cu3O7−δ (Y-123), Y2BaCuO5 (Y-211) and BaCuO2–CuO) at different temperatures, which has provided an in-sight into, and appreciation of, fine-tuning of the parameters that then enable the single grain growth of YBCO via different melt-growth techniques. The oxygen partial pressure is known to influence strongly the phase diagram of oxide, with particular emphasis on the SmBCO and NdBCO systems, within which LRE/Ba solid solutions can form easily due to the comparability of the sizes of the RE and Ba ions. The pseudo-binary phase diagram for YBCO is shown in figure 3(a), which indicates the temperature window for liquid phase formation and provides information on the peritectic temperature in the phase region where Y-123 melts incongruently to form Y-211 and a liquid phase. This reversible reaction also provides valuable information of when to seed the system (as in the so-called hot-seeding approach) to enable heterogeneous nucleation and to fine-tune the heat treatment conditions to enable the growth of a single grain. Lee and Lee [28], carried out experiments and studied liquidus line formation in the Y2O3–BaO–CuOx system at 1223 K and 1273 K at 0.21 atm oxygen pressure. DTA thermal scans showing the decomposition temperatures of some of the cuprate-based materials are shown in figure 3(b). Finally, the Tp, for (RE)BCO compounds are summarised in table 2.

Figure 3. Pseudo-binary phase diagram of the YBCO system providing information on the peritectic temperature of the compound and on fine-tuning the heat treatment parameters to obtain a single grain of YBCO, by a controlled seeding process. The isothermal line, reaction zone and the liquidus line can also be seen in the figure. Reprinted from [29], with the permission of Elsevier. (b) DTA scans of some of the cuprate-based high temperature superconducting materials exhibiting a peritectic temperature.

Download figure:

Standard image High-resolution imageTable 2. Peritectic temperatures of various rare-earth based (RE)BCO superconductors, measured in air.

| RE in (REBa2Cu3O7−δ ) | Peritectic temperature Tp (°C) (error: ±5 °C) |

|---|---|

| Nd | 1068 |

| Sm | 1054 |

| Eu | 1046 |

| Gd | 1030 |

| Dy | 1010 |

| Y | 1005 |

| Dy | 1005 |

| Er | 990 |

| Yb | 960 |

2. Practical and economic processing of (RE)BCO for engineering applications

The ability of a bulk superconductor to trap a large magnetic field is determined generally by the product of the critical current density, Jc, and the length-scale over which the current flows (usually the sample grain size 'd'), Jc d [1, 2]. It is essential, therefore, that (RE)BCO is processed in the form a large, single grain with a uniform, high Jc if it to be used in practical applications, with state of the art (RE)BCO materials exhibiting current densities in excess of 10 000 A cm−2 at 77 K and single grain sizes of up to 6 cm. Extensive work was carried out between 1987 and 2003 to fabricate (RE)BCO bulk superconductors as individual single grains. As a result, a variety of successful melt processing techniques had been developed by 2003, with the thermal profiles for the different systems almost fully optimised, albeit under a reduced-oxygen atmosphere, and particularly for Sm and Gd based (RE)BCO compositions. A detailed account of the processing of (RE)BCO bulk, single grain superconductors prior to 2003 can be found in several publications, including review articles and handbook chapters [30–33]. This review article addresses primarily the development of the processing of (RE)BCO single grains since 2003, during which substantial progress has been made towards the reliable growth of bulk (RE)BCO superconductors with increased trapped field and processed, more practically, under an air atmosphere.

2.1. Fabrication techniques based on MG: TSMG

Bulk (RE)BCO HTS tend to be granular in nature, with their current carrying capacity limited severely by the weak-link nature of any grain boundaries and the presence of pores and other macro-defects present in the sample microstructure. To overcome the grain boundary problem, concerted attempts have been made to develop a number of effective melt processing routes, including QMG [34], MPMG [35], OCMG [36] and TSMG [37] to transform the entire sample into one large, single grain. TSMG has emerged over the past two decades as the most practical and successful process for the fabrication of (RE)BCO single grains that can support current densities in excess of 10 000 A cm−2 at 77 K (note this current-carrying ability is enhanced further at lower temperatures).

The fundamental MG process was proposed originally by Jin et al [38] and developed further by Murakami et al [37, 39–43]. This general process involves the textured growth of the superconducting (RE)Ba2Cu3O7−δ (RE-123) phase from the peritectic solidification of the (RE)2BaCuO5 (RE-211) solid phase and a liquid phase (comprising of BaCuO2 and CuO), generated by the peritectic decomposition of RE-123, as the sample is cooled through its peritectic temperature, Tp, via the following reaction, which occurs between 1000 °C and 1100 °C;

The use of a seed crystal to control heterogeneous grain nucleation and growth can be used further to reduce substantially the number of grain boundaries formed during the MG process. The pre-form compact for the TSMG fabrication route, or green body, is prepared using precursor powder comprised mainly of RE-123 enriched with added RE-211 to constitute a mixture corresponding typically to RE-123: RE-211 ∼ 75: 25 by weight. A seed crystal (of higher melting temperature, such as NdBCO or SmBCO for YBCO) is used to nucleate and grow a single grain of (RE)BCO. The addition of RE-211 to the RE-123 precursor powder prior to melt processing serves three purposes:

- (a)To provide a greater concentration of RE-flux at the growth-front to propagate growth more rapidly;

- (b)To minimise the out-flow of liquid phase during the precursor melting stage and;

- (c)To provide extra RE-211 phase in the final, as-grown sample, which generates flux pinning centres and enhances the current density of the single grain (to be discussed later).

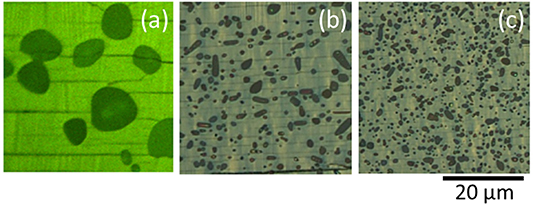

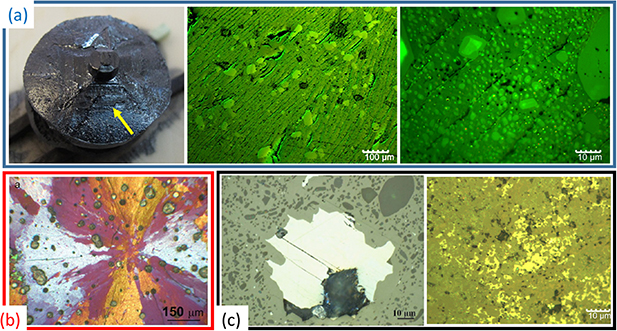

Various grain-refiners are also used in the TSMG process to refine the size and distribution of RE-211 inclusions within the final sample microstructure in order to optimise its superconducting properties and to increase microstructural homogeneity. Pt and CeO2 have emerged as successful grain-refining agents for YBCO, in particular. Of these, CeO2 is significantly more cost-effective than Pt, which is important for the development of a large-scale production process. Microstructures of a typical single grain of SmBCO sample fabricated by TSMG are shown in figure 4. This figure illustrates the influence of grain refining agents on the size of RE-211 phase inclusions embedded within the superconducting RE-123 phase matrix (CeO2 refines the Sm-211 phase efficiently compared to Pt in the case of SmBCO [44]).

Figure 4. The influence of grain-refining agents on the bulk (RE)BCO single grain microstructure. (a) Standard SmBCO with no added grain-refiner, (b) SmBCO containing added Pt and (c) SmBCO containing added CeO2. The micrographs show the presence of Sm-211 inclusions in a superconducting Sm-123 phase matrix. CeO2 has emerged as a more effective Sm-211 grain-refining agent than Pt for the SmBCO system. Images in this figure are reprinted from [44], with necessary permissions.

Download figure:

Standard image High-resolution image2.2. Seeding

Seeding is a critical step for heterogeneous nucleation and single grain growth of (RE)BCO bulk superconductors via a melt process. The following three important characteristics qualify a material to function as an effective seed crystal, at least in the so-called cold seeding process:

- (a)A higher melting temperature than the (RE)BCO system being grown into a single grain;

- (b)A similar crystal structure to the material being fabricated and;

- (c)Phase-stability with the melt.

Cleaved seed crystals either of the same system (as used in so-called hot seeding) or of systems with higher peritectic temperature (as used in so-called cold seeding) form the site where the single grain nucleation process occurs in the semi-molten, or peritectically-decomposed, (RE)BCO material. Cleaved seed crystals with perfect a–b crystallographic plane alignment are therefore employed to fabricate (RE)BCO bulk superconductors in the form of single grains. Both MG and IG techniques employ seed crystals to grow large, single grain, as will be discussed later. The influence of morphology and size of seed crystal on single grain growth via the TSMG process has been studied by Sudhakar Reddy et al [45]. It was observed that the use of small, square-shaped seed crystals to nucleate MG results characteristically in point nucleation with the usual habitual growth symmetry, whereas circular- and triangular-shaped seeds modify the initial growth sector geometry of the (RE)BCO single grain. The use of a large seed decreases significantly the processing time associated with single grain fabrication, although, on a microscopic scale, large-sized seeds are susceptible to containing numerous defects, which can cause the nucleation of unwanted sub-grains. Practical melt processes, therefore, use small, perfectly aligned seed crystals (with higher melting temperature) to obtain single grains of (RE)BCO. An example of a YBCO single grain fabricated using such a seed, with the growth directions marked schematically, is shown in figure 5.

Figure 5. (a) The top surface of an YBCO single grain from which faceted growth can be seen clearly. Growth facet lines as observed experimentally in YBCO sample along the a–b plane and along the c-axis are shown in (a) and (b). These features are represented schematically in (c) and (d), respectively. Cross-sectional image in (b) is reprinted from [46], with necessary permission.

Download figure:

Standard image High-resolution image2.3. Isothermal vs undercooling—growth rate studies and misorientation studies

TSMG processing usually involves two distinct heat-treatment techniques:

- (a)Isothermal decomposition and nucleation, and

- (b)Controlled undercooling.

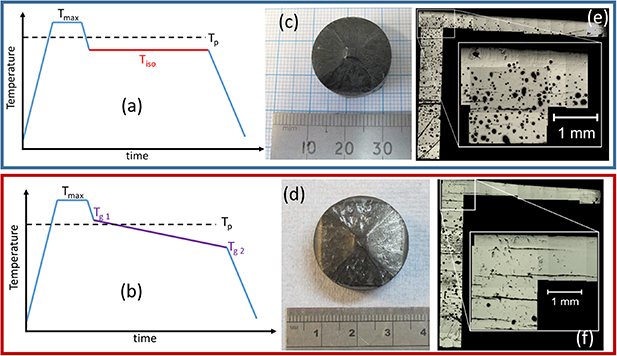

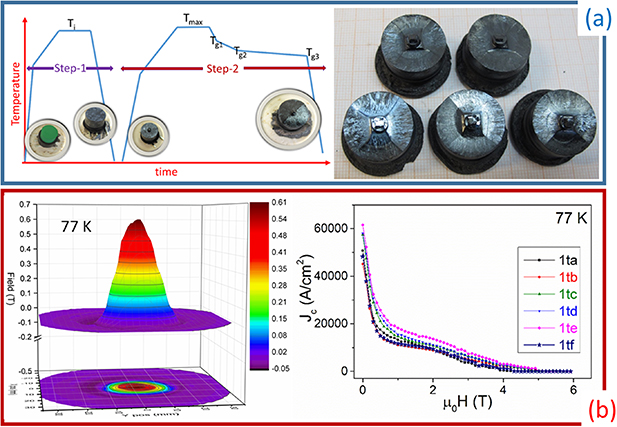

The isothermal process involves cooling the system from the maximum temperature of the melt (Tmax, as illustrated schematically in figure 6(a)) to a temperature typically of 6 °C–10 °C below the Tp of the target RE-123 phase. The system is then held at this temperature, Tiso, for between 100 and 150 h to enable the nucleated growth front to propagate and transform the entire sample into one single grain. In the undercooling process, on the other hand, the sample assembly is cooled slowly through the Tp of the compound (i.e. from the growth temperature Tg1 to the growth temperature Tg2) until single grain growth is complete. Undercooling involves slow cooling the entire sample assembly at a rate typically between 0.2 °C h−1 and 0.5 °C h−1 from Tp to a temperature of about 25 °C–30 °C below Tp. The combination of the various steps in the respective processes enables the growth of a single grain, although each has a unique influence on the microstructure and associated superconducting properties of the fully processed single grain. For example, the effects of crystallographic misorientation (small angle mis-alignments within an individual single grain) are typically more severe in samples processed using the undercooling approach. However, the number and density of pores and cracks generated by the undercooling technique is generally lower than that of the isothermal method. The undercooling technique also yields a finer and well distributed RE-211 phase within the superconducting RE-123 phase matrix, which is desirable for enhanced flux pinning, and is a particular strength of this approach. Hlásek et al [47] recently carried out a further comparison of these fabrication techniques; the characteristics of the two processes are illustrated in figure 6. TSMG based on the undercooling approach is now accepted generally as the preferred fabrication methodology for obtaining large, single-grain bulk superconductors with the best properties for practical applications.

Figure 6. Schematic illustration of the heat profiles used to grow single grains of (RE)BCO via (a) isothermal and (b) undercooling approaches via TSMG. YBCO samples grown by these techniques are shown in (c) and (d), respectively. Optical micrographs obtained from the cross-sections of the samples in (c) and (d) are shown in (e) and (f). Images shown in (e) and (f) are reprinted from [47], with necessary permissions.

Download figure:

Standard image High-resolution image2.4. Growth rate studies

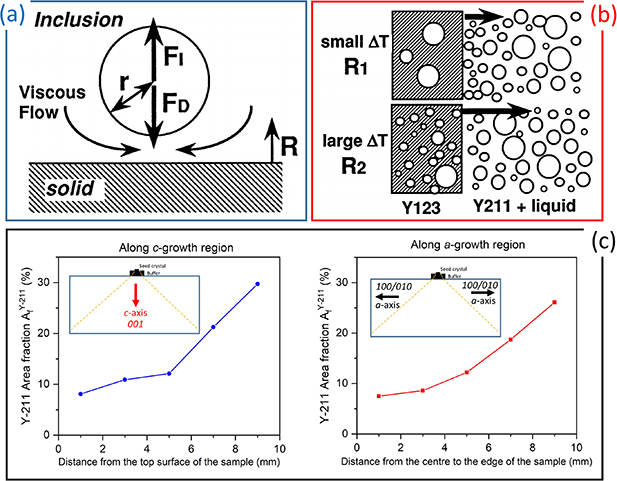

Isothermal processing of bulk samples carried out at several temperatures with different dwell times provides a pathway to measuring the growth rate of the various (RE)BCO and (RE)BCO + Ag single grain systems. This information is fundamental to the formulation of appropriate and effective heat treatment profiles, both to enable single grain growth whilst, simultaneously, retaining the liquid phase component within the sample during undercooling via both TSMG and TSIG techniques. The growth rate 'R' is usually modelled by the expression , where ΔT is the undercooling temperature and α, β are constants (i.e. fitting parameters). The growth rates along the a–b and a–c planes are very different due to the fact that the RE-123 phase is anisotropic. Experiments performed to date indicate that the growth rate along the ac-plane (referred to as Ra

) and along the ab-plane (referred to as Rc

) have produced values for Ra

and Rc

of

, where ΔT is the undercooling temperature and α, β are constants (i.e. fitting parameters). The growth rates along the a–b and a–c planes are very different due to the fact that the RE-123 phase is anisotropic. Experiments performed to date indicate that the growth rate along the ac-plane (referred to as Ra

) and along the ab-plane (referred to as Rc

) have produced values for Ra

and Rc

of  and

and  [29, 48]. Significantly, the growth rate of YBCO when additional Y-211 is added to the precursor powder increases from about 0.1 mm h−1 to ∼0.3 mm h−1 at an undercooling temperature of 10 °C [49] (this rate is increased further at higher undercooling), as shown in figure 7.

[29, 48]. Significantly, the growth rate of YBCO when additional Y-211 is added to the precursor powder increases from about 0.1 mm h−1 to ∼0.3 mm h−1 at an undercooling temperature of 10 °C [49] (this rate is increased further at higher undercooling), as shown in figure 7.

Figure 7. Growth rate studies of (a) YBCO with varying Y-211 (20%, 30% and 40%) content, (b) YBCO with different additives (Y2O3 and Y-2411) and (c) YBCO + Ag. Growth rates both along a/b- and c-axes are also shown. The nomenclature is as follows. In figure (a), Tg and tg represent isothermal growth temperature and growth time (in hours). The corresponding growth lengths are measured and the growth rates plotted as a function of undercooling temperature (ΔT). In figure (b), the growth rates measured in the a/b-direction (both the experimental data and theoretical predictions) in YBCO bulk superconductors containing different phases namely Y-211, Y2O3 and Y-2411(M) are shown. In this figure: 1 represents the composition: 1 mole Y-123 + 0.25 mole Y-211 + 0.1 wt% Pt, 2 represents the composition: 1 mole Y-123 + 0.25 mole Y2O3 + 0.1 wt% Pt, 3 represents the composition: 1 mole Y-123 + 0.25 mole Y2O3 + 0.1 wt% Pt + 4 wt% Y-2411 (M = Bi), 4 represents the composition: 1 mole Y-123 + 0.25 mole Y-211 + 0.1 wt% Pt + 4 wt% Y-2411 (M = Bi). Images in this figures are reprinted from [49–51], with necessary permissions.

Download figure:

Standard image High-resolution imageSimilar growth studies carried out for YBCO with specific phase additives to enhance flux pinning, such as Y2O3 and Y2Ba4Cu1M1Oy (Y-2411) [50], also indicate an increase in the growth rate by ∼0.1–0.2 mm h−1 at an undercooling temperature of 12 °C, associated with the additional supply of Y-ions to the growth front, which aids the growth of the Y-123 phase. Determination of the growth rate is more complex for the YBCO + Ag system and resulted in the development of the CCIH approach adopted by Congreve et al [51] to measure growth rates for this system. In this, the growth length 'L' is determined from the following equation (equation (2)):

where ts and te are the times associated with the start and end of the continuous cooling period, Rcc is the growth rate during continuous cooling and Rih is the growth rate during the isothermal hold period. As a result, the growth rates for the YBCO + Ag system have been reported as:

and

Based on the results of these growth studies, it was concluded that the growth rate is higher but often exhibits undesirable steps at the growth front if the sample assembly is subjected to large undercooling (i.e. greater ΔT). Hence, the processing temperatures are usually selected to produce a moderate growth rate and improved crystallinity at the propagating growth front. Any residual un-solidified component of the sample during melt processing transforms typically into a solid via a spheroidal growth process [52]. The growth rates were also used to inform the configuration of the sample assembly. For example, as observed in the interior seeding approach [53], the growth rate along the c-direction was found to be higher than that along the a-direction during the initial growth step. However, these growth rates reversed as the sample grew larger. It should also be emphasised that the presence of impurities or unwanted defects in the precursor mixture can affect significantly the growth of the RE-123 phase, which eventually leads to the formation of unwanted sub-grains in the bulk (RE)BCO microstructure.

2.5. BA-TSMG

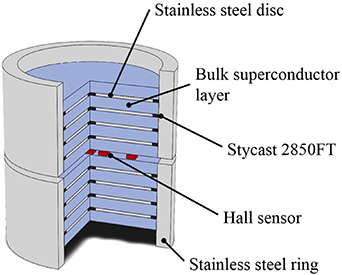

The TSMG technique enables the fabrication of high-quality, single grains of (RE)BCO with improved applied superconducting properties, although, historically, the reliability of the process has been poor. In particular, the success rate for producing single grains by TSMG was limited initially to ∼30%–40% [54], resulting in several, fairly recent, attempts to improve the process significantly. Integrating TSMG with the so-called buffer technique [55, 56], for example, has emerged as a successful modification to the process, for the reliable fabrication of both (RE)BCO and the more technically challenging (RE)BCO + Ag bulk superconductors in single grain form (Ag is usually added to the precursor powder to improve the mechanical strength of the single grain). The buffer technique involves placing a small buffer pellet between the seed crystal and the (RE)BCO precursor pre-form to be grown into a single grain prior to melt processing. The buffer pellet works in two ways: (a) It minimises or eliminates any diffusion of the seed crystal elements into the bulk (RE)BCO sample being melt processed, thereby reducing the formation of any low Tc phase material beneath the position of the seed crystal and; (b) it inhibits infiltration of the seed crystal by Ag within the (RE)BCO pre-form to avoid the partial/complete melting of seed crystal element [the presence of Ag reduces the (RE)BCO peritectic temperature significantly]. Various features of TSMG and buffer-assisted TSMG (BA-TSMG) are shown in figure 8. Detailed research [55–60] has been performed more generally to optimise the composition and aspect ratio of the buffer pellet to aid specifically the growth of (RE)BCO single grains.

Figure 8. The sample-buffer arrangement for TSMG: (a) schematic illustration of the sample assembly, (b) sample assemblies with and without a buffer pellet and (c) the samples in (b) after TSMG growth. Figures (d) and (e) show the cross-sections of the samples processed by TSMG and BA-TSMG. Figure (f) shows EDX data confirming that the diffusion of the Nd-element from the seed crystal is limited to within the buffer pellet region. The direction, indicated with an arrow (yellow in colour), along the thickness of the sample where the EDX data is obtained and plotted are represented in the inset of (f). Images in this figure are reprinted from [57], with necessary permissions.

Download figure:

Standard image High-resolution imageThe buffer pellet provides sufficient volume to contain elements diffusing from the seed crystal (diffusion is unavoidable at elevated temperature), thereby providing an effective barrier and preserving the composition of the bulk (RE)BCO sample during the growth process. The buffer acts effectively as a one-way channel that allows the propagation of crystallographic texture through its thickness, a shield for the diffusion of elements from the seed crystal and minimises simultaneously the transport of Ag to the seed crystal for (RE)BCO + Ag systems. The BA-TSMG process has improved dramatically the reliability of the TSMG process over recent years, and has increased the success rate for the growth of large, (RE)BCO and (RE)BCO + Ag single grains to greater than 90%, which is particularly significant for the commercial production of bulk superconductors. BA-TSMG is now an established process for batch processing, with a selection of single grains fabricated by this technique shown in figure 9.

Figure 9. (RE)BCO single-grain bulk superconductors obtained via the BA-TSMG process. (a) YBCO and (b) GdBCO + Ag, (c) optical micrographs of the GdBCO + Ag sample cross-sections taken within the extended c-growth regions are shown schematically in (c). Images in this figure are reprinted from [57, 58], with necessary permissions.

Download figure:

Standard image High-resolution image2.6. Generic seed crystals and the suppression of solid solution formation

The compounds Nd-123 and Sm-123 have a higher Tp than Y-123 and are therefore suitable for use as seed crystals for the YBCO system. However, the availability of seed crystals is a major issue for the growth of single grains of other (RE)BCO systems, including GdBCO, SmBCO, and NdBCO [i.e. the so-called light rare element (LRE) in (RE)BCO compounds]. Initial attempts using MgO as a seed crystal were only partially successful, however, due to the significant mis-match (of around 11%) between the MgO crystal structure and that of the RE-123 phase compounds, chemical incompatibility, resulting in Mg contamination/diffusion into the (RE)BCO bulk sample and the formation of low Tc phases during the MG process. In 2005, it was observed that the addition of up to 1% Mg to the NdBCO system enhanced the Tp of the doped Nd-123 phase by 20 °C [61, 62] (as can be seen in figure 10), which was an important step towards developing an effective TSMG process for the fabrication of (LRE)BCO single grain, bulk superconductors. The new Mg-doped NdBCO seed crystals were termed 'generic seeds' since they were used successfully to seed every known superconducting (RE)BCO system. The development of generic seeds opened pathways for exploring the fabrication of single grain (LRE)BCO on a large scale, which is significant due to their higher Tc and higher Hirr, which leads directly to greater potential for enhanced engineering performance. On a parallel track, a second important contribution to improving the reliability of the general melt process was the development of a NdBCO thin-film seed by Yao et al [63, 64], which, due to super-heating phenomenon, exhibited a higher melting temperature and hence could also be used successfully to seed every (RE)BCO system. Both these important seed-related developments enabled single grain (LRE)BCO systems to be fabricated reliably and developed specifically for practical applications.

Figure 10. DTA scans with respect to temperature for the NdBCO system, with and without added MgO. Data for Mg-doped NdBCO crystal +5 wt.% Ba3Cu5O8 are shown for purposes of comparison. The melting temperatures of RE-123 compounds based on Y, Gd, Eu, Sm and Nd are shown as individual points (circles). Figure reprinted from [62], with necessary permission.

Download figure:

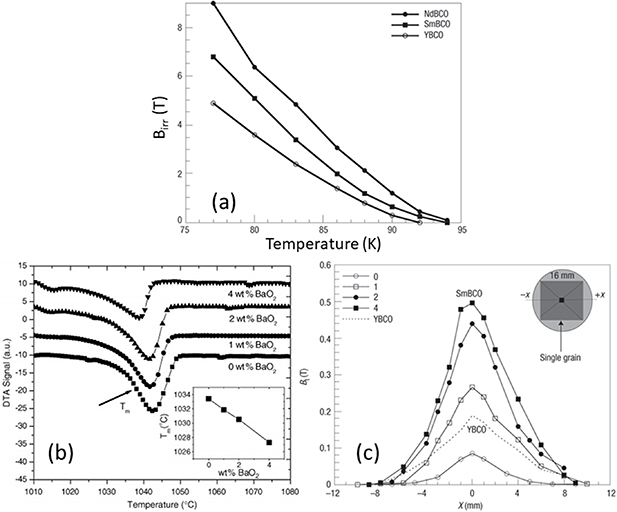

Standard image High-resolution imageLight rare-earth (LRE)BCO systems have a higher Tc, and hence higher Jc(H) and associated higher trapped field at a given temperature (and at LNT, in particular) when compared to YBCO, as shown in figure 11(a). However, solid solutions of the type of LRE1+x Ba2−x Cu3Oy can form easily in these systems, due to the comparable ionic radii of LRE and Ba, and because the Tp of (LRE)BCO systems is highly sensitive to the oxygen partial pressure during melt processing (a small change in the composition of the furnace atmosphere during growth process can disturb the growth kinetics significantly). The effects of substitution result generally in the formation of superconducting phase regions of low Tc within the bulk microstructure, thereby reducing significantly the values of Tc and Jc(H). The solid solution formation problem in different (RE)BCO systems, and particularly those based on Gd, Eu, Sm and Nd, has been addressed since 2000 primarily by adding extra BaO2 (1–4 wt.%) to the precursor powder, which, desirably, enables bulk samples to be processed in an air atmosphere. The influence of the addition of BaO2 to the GdBCO system, as reported by Shi et al [65], can be seen in figure 11(b). Similarly, the influence of the addition of BaO2 on trapped field in SmBCO is shown in figure 11(c). It can be concluded from these studies that 1–2 wt. % of BaO2 addition to the GdBCO system and 3–4 wt.% of BaO2 addition to SmBCO is effective in minimising the formation of solid solutions in these systems, thereby defining a processing route for the fabrication of bulk samples with significantly improved superconducting properties. Subsequent work on Ba-rich precursor powders has yielded high-quality (LRE)BCO bulk superconductors [66–68] with self-field current densities of up to ∼50 000 A cm−2 at 77 K. More recently, cost-effective attempts have been made to produce YBCO and (LRE)BCO bulk superconductors directly from the raw oxide powders (RE2O3, BaO2 and CuO) [69]. This enables the characteristics of the precursor powder to be tuned and optimised to yield a reliable melt process and consistent superconducting properties in the fully processed bulk single grains. Further information on the powder preparation process and the influence of the composition, morphology and properties of the precursor can be found in the review by Pathak et al describing several synthesis processes to obtain Y–Ba–Cu–oxide powder precursor powders [70].

Figure 11. (a) Increased potential of NdBCO and SmBCO (LRE)BCO bulk superconductors compared to YBCO for the field-dependent generation of trapped field. (b) Temperature dependence of DTA signals in GdBCO with added BaO2 (0–4 wt.%). The reduction in melting temperature with increased BaO2 content of the precursor powder in the GdBCO system is shown in the inset. (c) Enhancement of trapped field for SmBCO system with added BaO2 (2 and 4 wt.%). Images in this figure are reprinted from [62, 65], with necessary permissions.

Download figure:

Standard image High-resolution image2.7. Growth of mixed binary and ternary RE-systems (YGd, NSG, NEG, YSN)

Attempts to fabricate binary '(RE1,RE2)BCO' and ternary '(RE1,RE2,RE3)BCO' bulk superconductors comprising of a mixture of multi RE-elements have been made with the objective of introducing additional flux pinning centres to the (RE)BCO matrix in the form of discrete regions of lattice mismatch. As a result, several systems, including (YGd)BCO [71] (NSG)BCO [72], (NEG)BCO [73], (SEG)BCO [74] (YSN)BCO [75], have been reported to exhibit record values of various superconducting properties. In each of these systems, the ratio RE1:RE2:RE3 was maintained as 1:1:1. (NEG)BCO bulk superconductors containing 40 mol% NEG-211 inclusions, for example, exhibit values of Jc in excess of 68 kA cm−2 at 77 K and record values, in general, in applied magnetic field of up to 2.5 T [73]. It has been observed that RE-211 secondary-phase particles are distributed homogeneously in the (Nd,Eu,Gd)Ba2Cu3O7 phase matrix during melt processing, which is desirable for effective flux pinning, with a particle size of ∼0.8 µm and a typical volume content of between 16% and 18%. Large, single grain (SmEuGd)BCO bulk superconductors, in particular, have been prepared successfully by the OCMG process [74] and a Tc of 93 K has been reported for a (YSN)BCO single grain with (00l) texture [75]. TEM studies carried out on ternary (RE)BCO systems have indicated the presence of dislocations and stacking faults within the superconducting matrix, resulting in an enhancement of Jc(H), as shown in figure 12.

Figure 12. (a) and (b) The presence of fine Gd-211 and NEG-211 inclusions in the size range ∼500–800 nm in the matrix of NEG-123. The twinned structure can also be seen in these figures. (c) High-resolution TEM image obtained at the RE-123/RE-211 interface. (d) Field dependence of Jc, including the peak/fishtail effect, for (NEG)BCO single grains prepared with different mol% NSG-211 content. Images in this figure are reprinted from [72], with necessary permissions.

Download figure:

Standard image High-resolution image2.8. Infiltration growth strategy

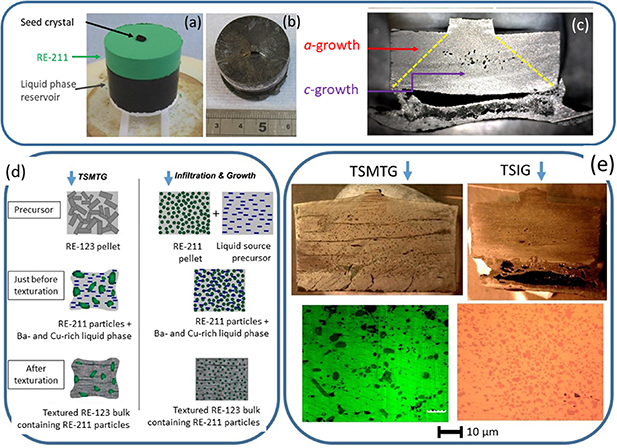

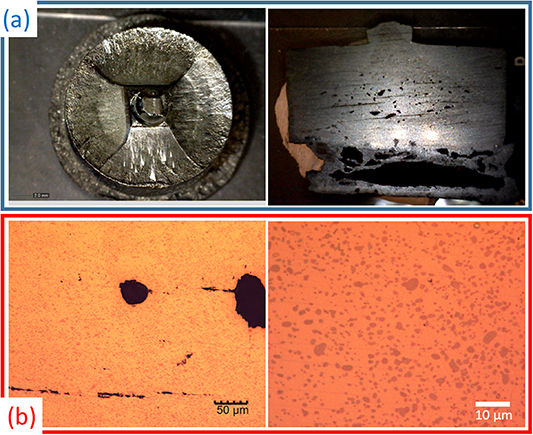

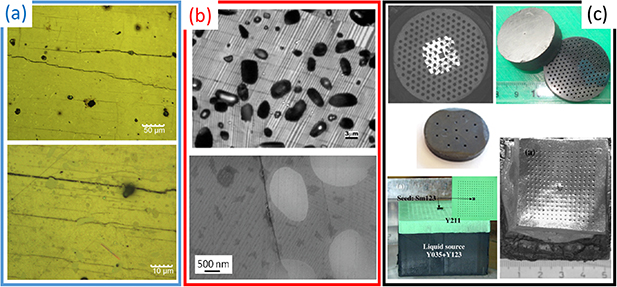

The IG melt process has emerged as an alternative and viable approach to conventional MG processing since it addresses many of the limitations inherent to the general MG technique [76–78], including near-net shape processing and the formation of a dense single grain microstructure. The fabrication of (RE)BCO single grains via the TSIG approach is shown in figures 13(a) and (c). Here, the RE-211 pre-form is capped with a seed crystal and is placed in intimate contact with the liquid phase reservoir pellet. A copper-rich liquid phase comprising BaCuO2 and CuO forms in the liquid phase reservoir during the heat treatment in the TSIG approach, which infiltrates subsequently into the porous RE-211 pre-form at a temperature below Tp of the compound, ultimately reacts with RE-211 to form the RE-123 phase, as described by equation (3). Heterogeneous nucleation occurs at the seed crystal as the sample assembly is cooled slowly back through Tp and the single grain growth front propagates throughout the entire bulk material as the sample is cooled further. Unlike other MG techniques, no oxygen gas is evolved during the heat treatment, resulting in the formation of fewer pores in single grains processed by TSIG compared to samples fabricated by conventional melt-growth (thereby producing a much denser microstructure). A schematic comparison between the TSMG and TSIG processes is shown in figure 13(d). Cross-sections of YBCO single grains fabricated via these two processing techniques are shown in figure 13(e). The fabrication of (RE)BCO bulk superconductors via the IG process is now established, and there are many reports of the successful application of this technique to fabricate bulk, single grain samples [76, 79–83].

Figure 13. Single grain (RE)BCO bulk superconductors fabricated via the TSIG technique. (a) Assembly comprising of a Y-211 pre-form (green in colour, on-line version) placed in contact with the liquid phase reservoir pellet (comprising of BaCuO2 and CuO), which is supported by a thin plate of Yb2O3. (b) Single grain YBCO fabricated by the TSIG process. (c) Typical cross-section of the sample, including the formation of a-growth and c-growth regions (separated by the yellow dashed lines). (d) Schematic comparison of the TSMG and TSIG processes at several stages: Precursor, just before texturing and in the final product [81]. (e) Cross-sectional optical micrographs and RE-211 particle size distribution in the matrix of RE-123 for both TSMTG and TSIG fabrication processes.

Download figure:

Standard image High-resolution imageThe fabrication of single-grain (RE)BCO bulk superconductors via TSIG is significantly more challenging than other MG-based techniques for two main reasons: (a) the liquid phase infiltration and seeding processes progress simultaneously, which can easily cause single grain growth failure and; (b) sub-grains can form readily, including at sites within the liquid phase reservoir pellet if its composition is not tuned and optimised appropriately. Furthermore, given that (RE)BCO processed by TSIG tended historically to exhibit inferior superconducting properties than samples fabricated by TSIG, only limited effort had been made until recently to fabricate (RE)BCO bulk superconductors via IG processing. As a result, the focus of IG research prior to 2015 was on the fabrication of near-net shapes and on scoping the processing domain of Y, Sm, Gd and Dy-based systems [82–86]. Significant improvements were made to the TSIG fabrication approach between 2015 and 2017, however, by tuning and optimising a number of processing parameters, which enabled the reliable production of (RE)BCO single grains with superior microstructural and superconducting properties required for practical applications, and typical (RE)BCO bulk superconductors fabricated by TSIG now exhibit current densities of ∼20–50 kA cm−2 and trapped fields of ∼0.5–0.9 T at 77 K. Three particularly important contributions made to the development of the TSIG technique are:

- (a)The introduction of the buffer technique;

- (b)Control of RE-211 content and;

- (c)The use of a two-step BA-TSIG process.

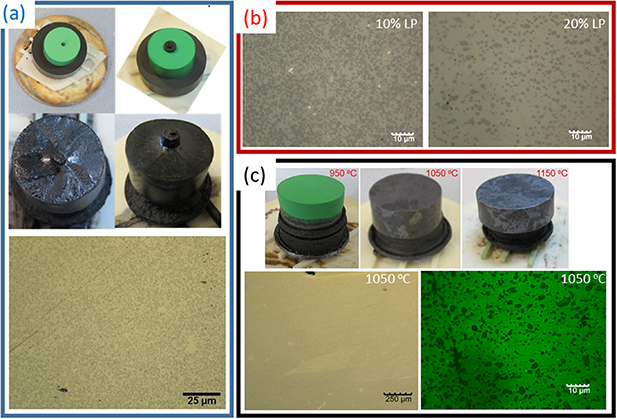

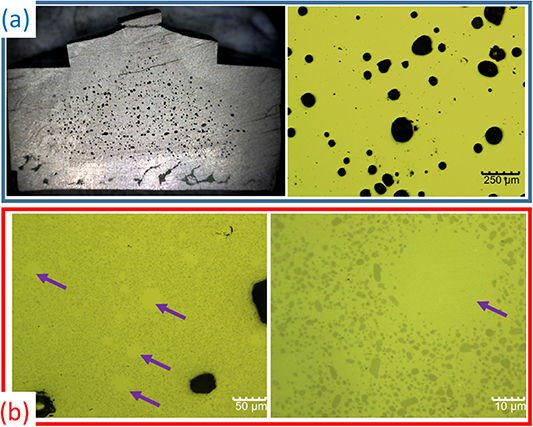

The use of a buffer pellet to increase the reliability of the single grain growth process has been observed to be more critical to TSIG than TSMG, due primarily to the presence of a relatively large quantity of aggressive, Cu-rich liquid phase that forms during the melt process in the former. The liquid phase, which initiates in the reservoir pellet and infiltrates subsequently into the RE-211 pre-form, can reach and react with the seed crystal relatively easily, thereby compromising its ability to act effectively as a seed, resulting in multiple grain nucleation sites and, as a result, severe sub-grain formation. Failed and successful attempts to grow a single grain sample by the TSIG process without and with a buffer are shown in figure 14(a). The effect of a suitable buffer pellet positioned between the sample and the seed crystal is to minimise the diffusion of seed crystal element (such as Nd or Sm) into the bulk sample and, more importantly, to limit the extent of liquid phase component reaching the seed crystal, which is essential to achieve single grain nucleation and growth. Systematic studies have been performed to identify the most appropriate liquid phase composition for the reservoir pellet that avoids any sub-grain formation, whilst, at the same time, enabling the appropriate growth kinetics (i.e. at an appropriate temperature) for faster RE-123 growth. A Yb-based liquid phase (corresponding to a composition of Yb2O3:CuO:BaCuO2 = 1:6:10 [87]) works well for most (RE)BCO systems, although a Y-based liquid phase is effective for the single grain growth of higher Tp materials, such as SmBCO and NdBCO. More detailed studies on the optimisation of the buffer pellet and composition of the liquid phase can be found elsewhere [57, 60, 86].

Figure 14. (a) YBCO samples processed without, unsuccessfully, and with, successfully, a buffer via TSIG. Optical micrograph illustrating excess Y-211 present in YBCO processed by TSIG. (b) Control of Y-211 content is possible by the addition of the liquid phase component to the Y-211 pre-form prior to processing. (c) The effect of infiltration temperature within the range 950 °C–1150 °C. An optimum infiltration temperature/time of 1050 °C/1 h was identified for obtaining good superconducting properties at 77 K by considering RE-211 size and distribution in the fully processed single grain. Images in this figure are reprinted from [88–90], with necessary permissions.

Download figure:

Standard image High-resolution imageAttention turned to understanding the underlying reasons for the inferior superconducting properties of (RE)BCO bulk superconductors fabricated by TSIG following the development of a successful, single grain melt process. It was observed, in a series of careful and detailed microstructural studies, that the presence of a significant excess amount of RE-211 in the RE-123 phase matrix (i.e. greater than 40%) was the primary reason for this poor performance. A typical optical micrograph showing excess Y-211 content and its distribution within a single grain processed by TSIG is shown in the bottom half of figure 14(a). Unlike TSMG (where the size and distribution of RE-211 inclusions is relatively easy to engineer), the control of RE-211 phase formation is much more difficult in TSIG given the nature of the liquid phase infiltration process and the subsequent reaction of liquid with RE-211 to form RE-123, which determines critically the residual content of RE-211 in the final sample. As a result, it is extremely challenging to tune the processing parameters in TSIG, since several processes such as liquid infiltration, the peritectic reaction, heterogeneous nucleation and single grain growth all occur either simultaneously or within a small temperature-time window during the heat treatment. As a result, two primary approaches to enable control the RE-211 content in IG processed material have been investigated: (a) The provision of additional liquid phase component within the RE-211 pre-form (optical micrographs from these samples containing 10 wt% and 20 wt% liquid phase added to Y-211 pre-form are shown in figure 14(b)) and; (b) varying the infiltration temperature and time to enable prolonged and suitable infiltration of liquid phase to yield optimum RE-211 content in the fully grown single grain (see figure 14(c)). Although both approaches have enabled improved control of RE-211 content in the sample microstructure, the second approach optimising infiltration temperature and time has proved to be the most successful, yielding a dense microstructure containing relatively few pores and cracks, as shown in figure 14(c). This figure demonstrates the novelty and inherent advantages of the IG process, whilst controlling simultaneously the Y-211 content in the single grain. The long-standing issue of inferior superconducting properties of samples fabricated by IG has therefore been addressed successfully and hence now both MG and IG processes are able to yield single grain samples that are comparable in terms of both their microstructure and superconducting properties. The reliability of the TSIG process for the fabrication of (RE)BCO single grains with enhanced superconducting properties has been improved further by the development of a two-step BA-TSIG process [90], as shown in figure 15. In this advanced version of the TSIG process, the two critical steps of infiltration and single grain growth have been separated and performed sequentially to make the process more effective, easy to control and more reliable. As a result, a success rate in excess of 95% has been observed in the processing of single grains of (RE)BCO bulk superconductors by this relatively novel two-step BA-TSIG fabrication technique. More recently, the process has been extended to (RE)BCO + Ag systems, which are currently under investigation and have already produced some promising initial results. GdBCO [91–93], SmBCO [94] and even binary systems such as (Y,Gd)BCO [95] bulk superconductors have been fabricated by TSIG-based techniques. In addition, the TSIG approach is suitable for the fabrication of dense generic seeds [96], which has enabled directly the manufacture of Mg-doped NdBCO seed crystals that are characterised by both a higher melting temperature and by reduced porosity in their microstructure, therefore limiting dramatically the possibility of liquid phase segregation within the seed crystal and hence avoiding possible melting of the seed. The availability of these dense generic seed crystals now enables the reliable single grain growth of (RE)BCO and (LRE)BCO systems, including those containing Ag, which provides a potential pathway for the commercial production of bulk, single grain superconductors for practical applications.

Figure 15. (a) Schematic illustration of the two-step BA-TSIG process. Batch-processing of GdBCO samples establishing the reliability of single grain growth by the two-step BA-TSIG process can be seen. (b) An observed trapped field of 0.6 T and relatively high Jc(H) over a wide field range at 77 K, further with uniformity in superconducting properties can be observed in YBCO samples fabricated by the two-step BA-TSIG. Images in this figure are reprinted from [90], with necessary permissions.

Download figure:

Standard image High-resolution imageSignificantly, the individual merits of TSMG and TSIG advanced processing techniques have motivated additional effort to bridge these two approaches and to optimise the processing and performance of (RE)BCO single grains. In this hybrid approach, which is referred to as the LA-TSMG process [97], liquid phase enrichment is provided by supporting the TSMG sample assembly with a small layer of liquid phase compact, which leads to the formation of a higher concentration of RE-species at the growth front and speeds-up significantly the single grain growth process. This, in turn, leads to a homogenous distribution of RE-211 particles within the RE-123 superconducting phase matrix, thereby increasing the uniformity of superconducting properties, the reliability of single grain growth and reducing porosity in the as-processed bulk sample. Congreve et al [97] recently fabricated YBCO and YBCO + Ag bulk superconductors successfully by the LA-TSMG process to combine the merits of both MG and IG techniques.

2.9. Flux pinning in (RE)BCO—peak effect

The theoretical depairing current density in (RE)BCO superconductors, at which currents circulating in the material cause the Cooper pair charge carriers to break, resulting in the disappearance of the superconducting state (Ic varies as  , where Hc is the thermodynamic critical field), is ∼108 A cm−2 at 77 K, which is nearly 3–4 orders of magnitude higher than the critical current densities observed experimentally. The primary reason for the difference in observed and predicted performance is associated primarily with the movement of magnetic flux within the interior of the superconductor. For type-II superconducting materials, when the magnetic field is applied and the system is in the so-called mixed state, quantised magnetic flux lines in the form of individual flux vortices enter the body of the superconductor (the interfacial energy between superconducting and non-superconducting regions of the sample is minimised in type-II superconductors in the mixed state). In this case, one quantum of magnetic flux, Φ0, is equivalent to 2.1 × 10−15 T m2. Flux vortices, as predicted by Abrikosov [98], are known to form a triangular lattice when no pinning centres are present within the superconducting material. These flux lines can move easily under the influence of the Lorentz force (which is directly proportional to magnetic field), resulting in flux-flow and, therefore, the dissipation of energy. This, in turn, reduces significantly the current carrying ability of these materials. The presence of flux pinning sites, associated generally with defects in the superconducting matrix, can reduce locally the energy of a flux line and, therefore, further minimise its energy, effectively pinning the fluxon to the pinning site and limiting the extent of flux flow. Magnetic flux pinning, therefore is both a critical and fundamental phenomenon for generating enhanced current densities in type-II superconductors, even in the presence of applied magnetic field. Effective flux pinning is achieved typically when the size of the defect is of the order of the superconducting coherence length. Specific defects that constitute effective flux pinning sites include oxygen defects, stacking faults, dislocations, twins, twin boundaries and columnar defects (such as those created by irradiation) [99–102]. The influence of APC on, and their presence in, the RE-123 phase creates a variety of defects within the superconducting matrix, as shown in figure 16. The enhancement in Jc(H) due to the presence of pinning centres is also illustrated in this figure.

, where Hc is the thermodynamic critical field), is ∼108 A cm−2 at 77 K, which is nearly 3–4 orders of magnitude higher than the critical current densities observed experimentally. The primary reason for the difference in observed and predicted performance is associated primarily with the movement of magnetic flux within the interior of the superconductor. For type-II superconducting materials, when the magnetic field is applied and the system is in the so-called mixed state, quantised magnetic flux lines in the form of individual flux vortices enter the body of the superconductor (the interfacial energy between superconducting and non-superconducting regions of the sample is minimised in type-II superconductors in the mixed state). In this case, one quantum of magnetic flux, Φ0, is equivalent to 2.1 × 10−15 T m2. Flux vortices, as predicted by Abrikosov [98], are known to form a triangular lattice when no pinning centres are present within the superconducting material. These flux lines can move easily under the influence of the Lorentz force (which is directly proportional to magnetic field), resulting in flux-flow and, therefore, the dissipation of energy. This, in turn, reduces significantly the current carrying ability of these materials. The presence of flux pinning sites, associated generally with defects in the superconducting matrix, can reduce locally the energy of a flux line and, therefore, further minimise its energy, effectively pinning the fluxon to the pinning site and limiting the extent of flux flow. Magnetic flux pinning, therefore is both a critical and fundamental phenomenon for generating enhanced current densities in type-II superconductors, even in the presence of applied magnetic field. Effective flux pinning is achieved typically when the size of the defect is of the order of the superconducting coherence length. Specific defects that constitute effective flux pinning sites include oxygen defects, stacking faults, dislocations, twins, twin boundaries and columnar defects (such as those created by irradiation) [99–102]. The influence of APC on, and their presence in, the RE-123 phase creates a variety of defects within the superconducting matrix, as shown in figure 16. The enhancement in Jc(H) due to the presence of pinning centres is also illustrated in this figure.

Figure 16. (a) Schematic representation of magnetic flux pinning (with 1D, 2D and 3D APC). (b) TEM micrographs showing the presence of dislocations and stacking faults at the RE-211/RE-123 interface in (RE)BCO single grain. Effect of Gd-211 on the trapped field performance (at 77 K) of GdBCO single grain is shown. (c) Nano-sized pinning centres that are known to enhance current carrying capacity in (RE)BCO thin-films. Images in this figures are reprinted from [101, 102], with necessary permissions.

Download figure:

Standard image High-resolution imageIdeally, the size of a pinning centre should be of the order of the superconducting coherence length, i.e. 2ξab of the material (for YBCO, for example, ξ(0 K) ∼ 1.5 nm and ξ(77 K) ∼ 4.5 nm) [103, 104]. The presence of RE-211 phase inclusions within the RE-123 matrix naturally forms a source of flux pinning in (RE)BCO bulk superconductors. In reality, stacking faults and dislocations formed at the RE-211/RE-123 interface (shown in figure 16(b)), enhance the current carrying ability of these materials significantly. As a result, considerable effort has been made to refine and control the size of the RE-211 particles in order to improve the flux pinning density and therefore to enhance Jc (H). For example, the refinement of Y-211 in YBCO was achieved by employing different Y-211 synthesis routes, including the fabrication of nano-whiskers via electrospinning [105], the milling of coarse Y-211 particles and by ultrasonication [106]. All these approaches have enabled enhancement in Jc(H) in single grain YBCO bulk superconductors. Hari Babu et al synthesised a new type of nano-scale flux pinning centre based on the Y2Ba4Cu1M1Oy (Y-2411) phase (with M as Bi, Mo, Nb, Ta, Ti, W and Zr) and subsequently added this phase to various (RE)BCO systems, which enabled a significant improvement in flux pinning strength [107]. Gd-211 particles of size in the range ∼20–50 nm produced by ball-milling with Zr2O3 were introduced into the superconducting matrix of (NEG)BCO to create numerous point-like flux pinning centres to generate current densities of up to 80 kA cm−2 at 77 K and up to ∼10 kA cm−2 at 90 K [108]. Engineering the flux pinning within the bulk microstructure by these techniques has enhanced significantly the superconducting properties of these technologically important materials at temperatures as high as 90 K, both in the low and intermediate magnetic field ranges, which effectively extends their application to temperatures that may be achieved using liquid oxygen [109, 110]. TEM studies of (SEG)BCO have revealed the presence of nano-scale precipitates of size ∼100 nm that produce Jc in excess of 150 kA cm−2 at 77 K and up to 104 A cm−2 to 86 K [111]. Furthermore to the addition of RE-211, efforts have been made to introduce other chemical pinning centres into the superconducting matrix in the form of dopants. Doping (RE)BCO with Mo (from a MoO3 source) and Nb (from NbO3), for example, yields a significant enhancement in Jc via a striking peak effect at 77 K at around 4.5 T and improving the Hirr significantly [112, 113]. Samples irradiated in an attempt to create columnar nano-defects in order to improve (directional) flux pinning strength have also produced a significant enhancement in Bt and associated Jc(H). Other approaches to introduce suitable micro- and nano-scale inclusions to the bulk RE-123 phase matrix have yielded an improvement in the overall flux pinning strength in (RE)BCO bulk superconductors and hence the field dependence of Jc. A recent review by Bartunek et al [114] on flux pinning in bulk materials describes other approaches for enhancing the pinning strength in these materials not addressed here in this more general overview.

The thermodynamic nature of flux pinning causes critical current density to reduce with increasing magnetic field, with the rate of decay depending on the strength of pinning present in the system. This mechanism of reduction in Jc, which is observed typically in undoped YBCO, is termed as 'δl-pinning' [115]. The pinning mechanism, however, is very different in other RE-based systems, including (LRE)BCO and YBCO containing specific dopants, and results in an enhancement in critical current density at intermediate fields within the range 1–4 T. This re-entrant behaviour in Jc is known as the peak, or fish-tail, effect and this type of flux pinning is known as 'δTc pinning'. The presence of oxygen deficient phases and/or solid solutions in the RE-123 phase matrix are also known to enhance Jc further at intermediate fields, as illustrated by the Jc(H) data shown in figure 17(a) (schematic version) and figure 17(b) (experimental data at 77 K). Furthermore, defects within various ranges of size and the vortex lattice spacing, af, are also known to influence the peak field, Hp, at the peak in Jc, with the latter given by the relation [116]:

Figure 17. (a) Schematic representation of the variation of Jc with increasing magnetic field, illustrating the influence of 'δl-pinning' and 'δTc pinning'. (b) Experimental Jc(H) for YBCO and GdBCO at 77 K. Image shown in (a) is reprinted from [117], with necessary permission.

Download figure:

Standard image High-resolution imagewhere  0

is the flux quantum (=h/2e).

0

is the flux quantum (=h/2e).

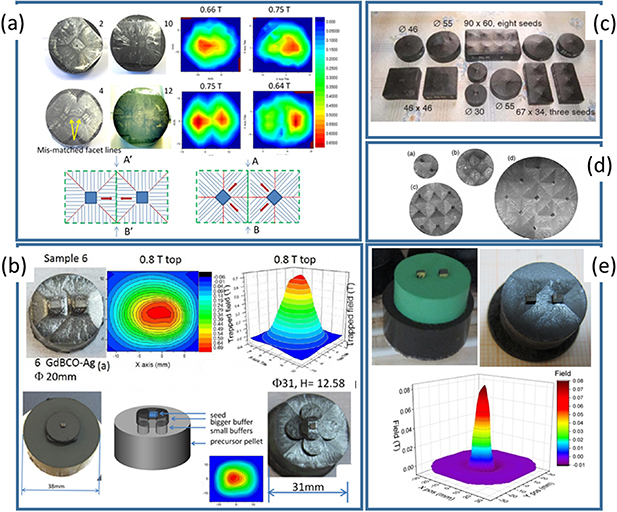

2.10. Multi-seeding (0–0, 45–45) and interior seeding

The relatively small growth rate of the superconducting RE-123 phase compound has motivated research towards a multi-seeding approach, in which two or more seeds are employed in a controlled heterogeneous nucleation process, and particularly for the fabrication of large samples. In multi-seeding, the alignment of the seeds and their positioning on the pre-form compact is critical for obtaining a quasi-single grain of (RE)BCO. Shi et al [118] employed NdBCO seed crystals arranged in different configurations, including the size of seed, distance between seed and, more significantly, their ab-plane alignment (either with 0°–0° or 45°–45°) to grow successfully quasi-single grains with good superconducting and microstructural properties in the fully processed samples. It was observed in these studies that regions containing non-superconducting phases form generally at grain boundaries and that this undesirable build-up of impurity phase could be minimised by adjusting the configuration of the seed crystals. The use of a buffer layer enabled further control of the orientation of the seed crystals in a multi-seeding process, thereby enabling a route for the successful production of high quality, large quasi-single grains. Some of the key results from the multi-seeding research are shown in figure 18. Many further successful attempts have been made subsequently to develop the multi-seeding process based on the potential of this approach [119–126].

Figure 18. (a) Multi-seeded YBCO with the ab-planes of seeds oriented at 0°–0° and 45°–45° to one another. (b) Quasi GdBCO bulk superconductors fabricated via a multi-seeding process integrated with the buffer technique. (c) Multi-seeded YBCO fabricated by ATZ GmbH. (d) Multi-Seeded bulk YBCO superconductors (28 mm, 46 mm, 65 mm and 100 mm diameter) and (e) Multi-seeded YBCO fabricated by the infiltration growth technique. Images in this figure are reprinted from [118, 122–126], with necessary permissions.

Download figure:

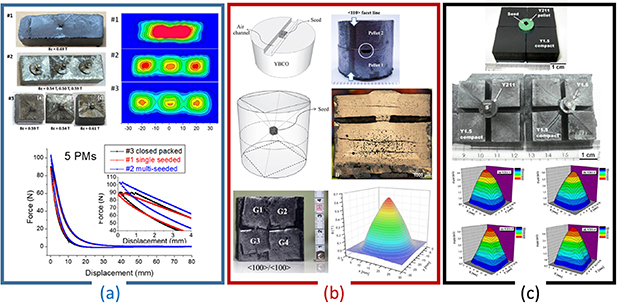

Standard image High-resolution imageShi et al [127] reported a study that compared the properties of a single-seeded and multi-seeded YBCO bar-shaped bulk samples of dimensions ∼60 × 20 × 12 mm3. In addition, three square-shaped samples packed together closely in an array to constitute a similar geometry to that of the single and multiple seeded samples was studied to provide a reference. Magnetic levitation measurements carried out at 77 K using different permanent magnet arrays indicated that the multi-seeded sample and that assembled from individual, single-seeded grains exhibited better performance than that of the single-seeded, bar-shaped sample. This is encouraging for the development of levitation devices, in particular, given the challenge associated with growing large single grains due to the relatively low growth rates of the RE-123 phase. The trapped field distribution and levitation force measurements for these samples are shown in figure 19(a).

Figure 19. (a) Single and multi-seeding in bar-shaped YBCO samples showing the influence of one or three grains on trapped field and levitation force. (b) Interior seeding approach with one seed crystal enabling the simultaneous growth of two single grains (one growing downwards and the other upwards to the top pre-form). (c) A single seed crystal supported by a buffer pellet for the simultaneous growth of four YBCO blocks. Each block constitutes a single grain. Images in this figure are reprinted from [53, 127, 129], with necessary permissions.

Download figure:

Standard image High-resolution imageKim et al [128] developed a novel 'interior seeding' approach in which two (RE)BCO samples can be grown simultaneously from a single seed placed at their interface, as shown in figure 19(b). In this study, an open channel was created in the compacted pre-form to enable simultaneously air/oxygen to reach the seed crystal during growth whilst minimising the contact area between the seed and the liquid phase. A Y1.5Ba2Cu3Oy bulk single grain (42 mm in diameter) produced by this approach trapped a magnetic field of 0.64 T at 77 K [53]. Lee et al [129] further proposed a buffer-bridge process for the growth of multiple YBCO single grains from a single seed. Significantly, each of the individual blocks constituted a single grain, as shown in figure 19(c).

2.11. Reliability in growth, batch processing, commercial production and recycling techniques

The development of buffer-aided TSMG and TSIG approaches has enabled bulk, single grains of (RE)BCO to be fabricated reliably with a success rate in excess of 90%. Batch processing has been used successfully to produce several single-grain (RE)BCO bulk superconductors in conventional box furnaces at both at the research laboratory scale and at industrial level. The batch-processing of YBCO, GdBCO, GdBCO + Ag and (NEG)BCO and bulk sample by various laboratories around the world, are shown in figure 20 [130–135].

Figure 20. Batch-processed (RE)BCO single grains by different research groups. (a) Shi et al, (b) Muralidhar et al, (c) Plechacek et al (CAN Superconductors), (d) Adelwitz Technologiezentrum GmbH (ATZ), and (e) Namburi et al. Images in this figure are reprinted from [88, 90, 130–135] with necessary permissions and also with courtesy of CAN Superconductors and ATZ GmbH.

Download figure:

Standard image High-resolution imageFailure in the (RE)BCO single grain growth process has been an unavoidable due to the complexity of the processing. Many critical processing parameters, such as the selection of an appropriate composition, mixing and homogenisation of the precursor powders, choice of the seed crystal with appropriate texture and orientation, heat treatment profiles and temperature distribution within the furnace, are fundamental to determining the success or failure of the single grain growth process. Every step of processing is equally important and critical to the fabrication of a single grain, and, if not selected appropriately, can lead to either partial or complete failure of single grain growth, as illustrated in figure 21(a). The success rate of single grain growth in (RE)BCO to date has been limited historically to 30%–40%, although this has increased significantly to around 90% following the more recent incorporation of a buffer strategy within MG processes. However, there remain tonnes of failed (RE)BCO bulk superconductors in both industrial and academic research laboratories around the world.

Figure 21. (a) Partial/complete failure of single grain growth as observed in several (RE)BCO systems. (b) Two failed GdBCO + Ag samples (shown in b(i)) that were subsequently recycled by polishing their top surfaces (shown in b(ii)) and performing secondary MG processing to yield a single grain, as evidenced by the four-faceted growth characteristic observed on the top surface of the sample (shown in b(iii)).

Download figure:

Standard image High-resolution imageThe recycling approach developed to transform failed, multi-grain bulk samples into single grains is particularly significant within this context. Broadly speaking, two techniques have been developed for this purpose. The first version of the recycling method [136] developed almost a decade ago involved initially crushing mechanically failed bulk samples for several hours using a high energy mill and repeating this process 2 or 3 times to obtain fine-sized powders. The crushed powders were further subjected to homogenisation and mixing, compacted into cylindrical preforms and melt processed. This approach transformed the failed samples into individual, recycled single grains that were observed to exhibit superconducting properties (including values of trapped field) of ∼80%–90% compared to those observed in primary grown (RE)BCO. However, this recycling approach is time consuming and requires access to specialised equipment, such as high energy mills/auto mixers, with appropriate calibration and optimisation of the crushing parameters and homogenisation processes, which further complicate the single grain growth process. The second approach to recycling, which has been investigated by several research groups, is more straightforward and is applicable to a wider range of (RE)BCO sample compositions [137–141]. In this approach, the top surface of the failed sample is simply polished, supported on a liquid-phase reservoir pellet and heat treated using the buffer-aided TSMG heating profile. This approach has already addressed the relatively low yield rate in the production of single grain (RE)BCO bulk superconductors.

The recycled single grain samples, as shown in figure 21, obtained by this second approach typically exhibit trapped fields of ∼70%–80% of those observed in primary-grown samples. Furthermore, as with those processed by infiltration growth, the recycled samples exhibit a moderate improvement in their mechanical properties, which makes them potentially suitable for application in levitation-based vehicles, levitation demonstration kits and in applications where mechanical properties may limit the overall performance of the device. These developments in recycling further increase the cost-effectiveness of the production technology and decrease the overall environmental impact of the melt process.

3. Microstructure and properties

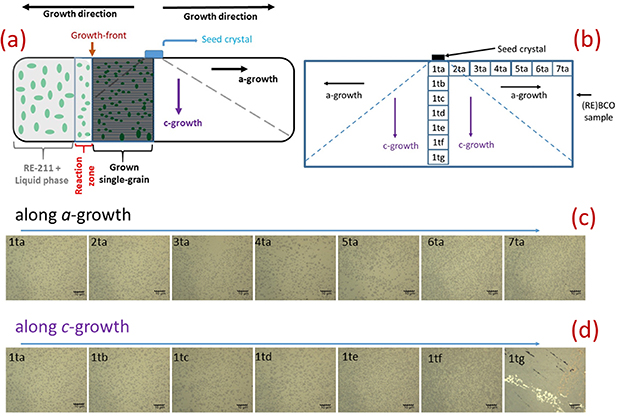

Microstructure plays a fundamental role both in the processing of single grain bulk (RE)BCO superconductors and in determining their superconducting and mechanical properties. The key microstructural features of these materials are presented in this section, including anisotropy, the a- and c-growth regions, growth facets, sector boundaries, misorientation, crystal structure, the role of oxygen in the crystallographic lattice and inclusions and other microscopic features in the superconducting phase matrix.

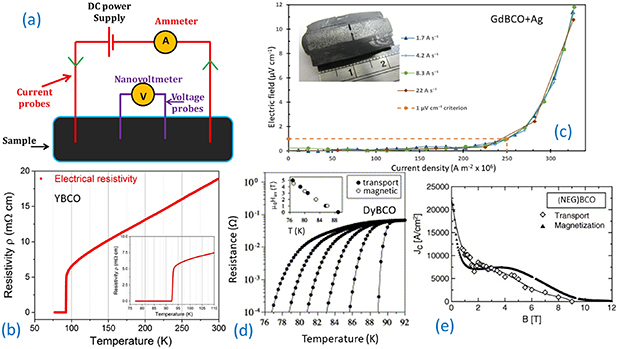

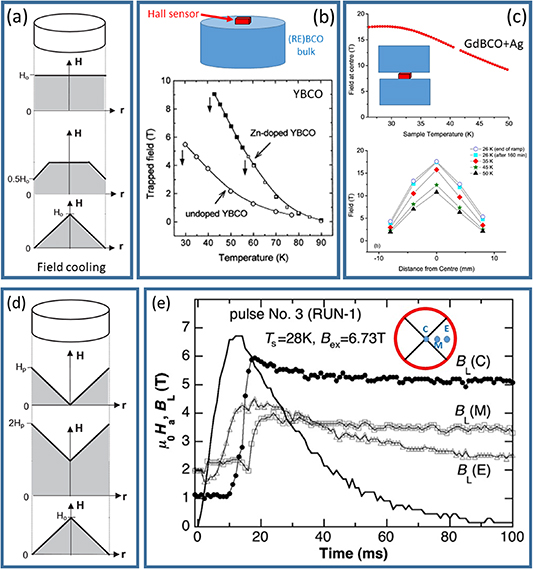

3.1. Influence of microstructure on the properties of (RE)BCO