Abstract

Bulk high-temperature superconductors (HTSs) that act as a trap field magnet establish a novel type of magnetic field source, which is significantly different from that of a permanent magnet or solenoid; therefore, they can be potentially used in magnetic-force-based applications. However, the primary issues related to the commercial use of the bulk HTS technology are established on the enhancement of trapped magnetic fields, as well as their reliability and reproducibility at temperatures achievable with off-the-shelf cryocoolers. This study presents experimental investigations on the strong trapped magnetic fields observed in commercial Y-Ba-Cu-O bulk HTSs produced as a double-sample stack, a cylindrical bulk, and a ring-shaped bulk. Consequently, a reliable and reproducible magnetic field of 9.5 T at 50 K was trapped in commercial Y-Ba-Cu-O assembled as a double-sample stack. In this case, shrink-fit encapsulation with either aluminum or stainless steel tube ensured equally effective reinforcement. Higher magnetization, although accompanied with partial flux jumps, yielded a trapped field of 16.85 T at 30 K, which is comparable to the reported record trapped fields. Finally, a maximum trapped field of 9.78 T - the strongest trapped field reported to date - was attained in the 6 mm hollow space of the ring-shaped bulk HTS.

Export citation and abstract BibTeX RIS

Original content from this work may be used under the terms of the Creative Commons Attribution 4.0 license. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

1. Introduction

Single-grain LRE-Ba-Cu-O (light rare earth, here Y, Sm, Nd, Gd) bulk high-temperature superconductors (HTSs), acting as a trap field magnet, establish a novel type of magnetic field source that is drastically different from that of a permanent magnet (PM) or solenoid. When appropriately cooled and magnetized, bulk HTSs can trap magnetic fields that are one order of magnitude stronger than those that can be provided by the best-performed Nd-Fe-B PMs [1]. In comparison to conventional or superconducting solenoids, bulk HTSs are much more compact and do not require direct and continuous power. Furthermore, in bulk HTSs, strong magnetic fields are generated in a free space, instead of being confined within a solenoid bore [2–4]. By comparing the performance of PM, solenoids, and bulk HTS devices, Oka [5] identified that bulk HTSs are advantageous magnet sources if the prioritized requirements include the generation of the magnetic fields ranging from 1 T to 10 T, as well as the size and cost. The utilization of bulk HTSs in industrial applications was slowly yet steady, as demonstrated in [4–12].

Top seeded melt growth (TSMG) has been intensively studied over the past decades [6, 13]; it has been proved to be a practical approach for the fabrications of bulk HTSs [14]. Current state-of-the-art bulk HTSs can trap magnetic fields over 16 T [15–18]. In particular, strong trapped fields were obtained in the gap between two single bulk superconductors, following field cooling (FC) magnetization and are compiled in table 1. To achieve such strong trapped fields, significant experimental efforts were made to improve the mechanical and thermal stability of bulk HTSs, instead of improving their superconducting properties. Foremost, bulk HTSs are brittle ceramics featuring low tensile strength in the range of 20–50 Pa [10, 14]. During 18 T magnetization, the arising Lorentz force induces a large tensile stress (>90 Pa [18]) on bulk HTSs, which can easily lead to sample fracture [17–21]. Another issue is magneto-thermal instability that arises from the heat generated by magnetic flux motion and can lead to an increase in the local temperature with subsequent flux jumping or quenching [2, 15, 17].

Table 1. Record trapped magnetic fields achieved in state-of-the-art bulk HTSs.

| Trapped field | Temperature | Bulk HTS | Reference |

|---|---|---|---|

| 16.0 T | 24 K | Y-Ba-Cu-O | [16] |

| 17.2 T | 29 K | Y-Ba-Cu-O | [17] |

| 17.6 T | 26 K | Gd-Ba-Cu-O | [18] |

To prevent fracturing, improvements were proposed in the mechanical strength of the bulk HTS via resin impregnation [22], resin impregnation combined with copper deposition [23] silver addition [24, 25], and, recently, incorporating hybrid SiC fibers [26]. These treatments reduced the number and size of microcracks and enhanced the fracture strength of bulk LRE-Ba-Cu-O from 30 Pa up to 70 Pa [22, 24, 25]. Nevertheless, the addition of silver demands extra modifications to many inter-dependent TSMG process parameters [27], such as increasing the peritectic decomposition temperature by 30 K. Alternatively, the mechanical properties of bulk Y-Ba-Cu-O were improved by reducing the number of initial macro defects by increasing the oxygen pressure during post-annealing [28] or using a two-step, buffer-aided top seeded infiltration and growth (BA-TSIG) technique [29] instead of TSMG.

An external action of reinforcement was to encapsulate the bulk HTS within a metal tube [15, 20]. In this case, the sample is compressed in the ab-plane at the interface between the bulk HTS and metal tube owing to the thermal contraction difference during cooling from room temperature to the prescribed cryogenic temperature. Compression of the bulk HTS was also improved by shrink-fitting [18]. Further modifications to the bulk and ring bulk HTS reinforcements were experimentally (up to 8 T) [30, 31] and numerically (up to 20 T) [32–35] investigated by Fujishiro's group.

In contrast to bulk HTS, Patel et al [36] engineered thick magnet stacks using two types of commercially-available HTS tapes, which ultimately trapped 17.7 T at 8 K. The large metallic volume fraction (>90 Vol %) and layered structure of the stacks of the HTS tape provide better mechanical and thermal stability in comparison with the bulk HTS. However, owing to the low engineering current density, temperatures below 10 K are required to achieve a trapped field over 17 T. Recently, Huang et al [37] offered a practical compromise between stacked HTS tapes and bulk HTS magnets by engineering a Gd-Ba-Cu-O/Ag bulk HTS composite with stainless-steel laminations and shrink-fit reinforcement. This bulk HTS composite survived two sequential 18 T FC magnetizations at 26 K and 22.5 K, trapping 16.8 T and 17.6 T, respectively. The latter result was significant because it yielded trapped fields in order of 17 T twice on the same sample without any mechanical or thermal failure.

The discussed trapped field values were obtained in the middle of two or several bulk HTSs as well as in stacked HTS tapes and, in principle, >20 T can be reached in the near future [34, 36–38]. Foremost, this geometry allows indicating the maximum possible trapped field and can be used in neutron scattering research to manipulate the neutron beams. Intriguingly, the neutron-irradiated Y-Ba-Cu-O yields higher critical current (i.e. stronger achievable trapped field) with time due to the improved pinning [39].

However, practically, magnetic fields generated at the surface of bulk HTSs at temperatures that can be obtained with off-the-shelf cryocoolers are more valuable for bulk HTS compact magnetic systems, which can be used for magnetic separation [40], Maglev transportation [7], magnetic bearing [7–9, 41], electrical rotary machines [12], Lorentz Force Velocimetry [42], and portable bulk HTS magnets [43–46]. The highest surface trapped field performance, i.e. 12.5 T at 20 K and 9 T at 40 K, was achieved with a silver-added and Zn-doped Y-Ba-Cu-O superconductor by the Dresden group [16] who employed the same reinforcement strategy as that used for double-sample stack. Moreover, ring-shaped bulk HTSs can provide a homogenous field inside the hollow space; therefore, they can potentially build compact and cryogen-free nuclear magnetic resonance (NMR) and magnetic resonance imaging (MRI) devices. Indeed, an NMR proton signal at 2.89 T (123 MHz) [47] and MRI prototype operating at 4.7 T [48] were demonstrated. To further improve the NMR/MRI resolution, a trapped field as high as 9.4 T (400 MHz) is required [31, 35, 49]. However, under the corresponding magnetization, the ring bulk HTSs are more susceptible to fracture during magnetization because the tensile stress is concentrated at the inner peripheral edge of the ring bulk, twice as high as that of the disk bulk [50, 51]. Researchers from Nippon Steel [52] were the first to propose and test a post-melt-processing composite reinforcement technique comprising ring bulk HTS sheets layered with high-strength metal sheets and an inner circumferential metal ring used for reinforcing the inner circumference. FC magnetization tests revealed that the 72 mm composite ring bulk HTSs can trap a magnetic field of up to 9.59 T at 20 K in the middle of the 28 mm hollow space.

Although the trapped magnetic field over 17 T was achieved, it could not be reproduced with the same sample or for the same sample batch. Nevertheless, the practical use of bulk HTSs with several-Tesla trapped fields was realized in magnetic-force-based applications. Currently, such bulk-HTS-based devices continue to be developed as a holistic engineering solution addressing equipment miniaturization, adopting commercial cryocooler technology [43, 45, 46], and deploying compact pulse magnetization [53–55]. However, the primary issues related to the commercial use of the bulk HTS technology are established on the enhancement of trapped magnetic fields, as well as their reliability and reproducibility at temperatures achievable with off-the-shelf cryocoolers. The cryocooler performance at temperatures ranging from 50–30 K is the most efficient (in terms of a fraction of Carnot), while the cryocooler efficiency significantly degrades below 30 K [56]. Another important aspect is cost-effective fabrication of bulk HTSs at a large scale considering the ease of reinforcement, post-melt-processing treatments, and near net-shaped manufacturing [6, 14].

This study presents the measurement results of the strong (>10 T) trapped magnetic field in commercial silver-free Y-Ba-Cu-O bulk HTSs. The choice of silver-free Y-Ba-Cu-O system depended on economic factors, considering the cost of raw materials, their recycling, fabrication time, and efforts, as well as logistics. As a result, a maximum magnetic field of 16.85 T at 30 K, almost similar to the record trapped fields, was trapped in the double-sample stack despite exhibiting magneto-thermal instability. Furthermore, this study discusses the reproducibility and field trapping capability, as well as compares the reinforcement effect of the aluminum and stainless steel shrink-fitting for double-sample stack and single bulk HTS. Finally, FC magnetization with an applied field of up to 10 T was used to exterminate the ring-shaped bulk HTS. Consequently, a trapped field of 9.78 T was obtained in the middle of the hollow space, thereby encouraging the use of such ring bulk HTSs in compact and cryogen-free NMR/MRI devices.

2. Experiments

Commercial off-the-shelf Y-Ba-Cu-O bulk HTSs produced by ATZ Ltd [57] were used in this study. All bulk HTSs were fabricated using TSMG without the addition of silver, but they were impregnated with resin epoxy in the near bulk surface. The bulk HTSs were machined accurately to the cylindrical form and characterized via Hall mapping at a distance of 1 mm following the FC magnetization at 77 K, and exhibited cone-shaped magnetic flux distribution with the peak trapped field BT documented in table 2.

Ltd [57] were used in this study. All bulk HTSs were fabricated using TSMG without the addition of silver, but they were impregnated with resin epoxy in the near bulk surface. The bulk HTSs were machined accurately to the cylindrical form and characterized via Hall mapping at a distance of 1 mm following the FC magnetization at 77 K, and exhibited cone-shaped magnetic flux distribution with the peak trapped field BT documented in table 2.

Table 2. Geometrical and physical parameters of bulk HTSs and reinforcing tubes.

| double-sample stacks | single bulks | ||||

|---|---|---|---|---|---|

| Samples | stack-SS | stack-Al | bulk | 2seed-bulk | ring-bulk |

| Bulk parameters | |||||

| BT at 77 K (T) | 1.14/1.13 | 1.14/1.13 | 1.10 | 1.10/1.05 | 1.13 |

| Outer diameter (mm) | 28.08/28.07 | 28.06/28.06 | 28.30 | 28.08 | 28.10 |

| Inner diameter (mm) | 06.00 | ||||

| Thickness (mm) | 17.50/17.50 | 17.50/17.50 | 16.00 | 19.40 | 17.30 |

| Tube parameters | |||||

| Material | aluminum | steel | steel | aluminum | steel |

| Alloying | AW 7075 | AISI 316 | AISI 316 | AW 7075 | AISI 316 |

| Inner diameter (mm) | 27.98/27.97 | 28.00/28.00 | 28.03 | 28.01 | 28.00 |

| Outer diameter (mm) | 32.08/32.07 | 32.06/32.06 | 29.78 | 32.08 | 32.10 |

| Tshrink (°C) | 300 | 100 | 300 | 100 | 300 |

Five individual Y-Ba-Cu-O bulk HTS samples were prepared for the trapped field measurements, as presented in figure 1. Two samples (referred to here as stack-SS and stack-Al) were assembled as a double-sample stack, where three Hall probes and one temperature sensor were fixed in the gap between the two single Y-Ba-Cu-O bulk cylinders using a Stycast epoxy. The gap is about 1 mm for both double-sample stacks. An entire double-sample stack was wrapped with a thin G10-CR fiberglass layer, while a G10-CR fiberglass lid was required to mount the double-sample stack on the measuring setup. Other three samples included single Y-Ba-Cu-O bulks produced as a standard Y-Ba-Cu-O cylindrical bulk, referred to here as bulk, and double-seeded Y-Ba-Cu-O bulk cylinder, referred to here as 2seed-bulk. The 2seed-bulk sample was fabricated using a top/bottom double seed melt growth (DSMG) technique [58] to increase the trapped field homogeneity in comparison to the standard TSMG. The last sample is a ring Y-Ba-Cu-O bulk, referred to here as ring-bulk, with outer and inner diameter of 28 mm and 6 mm, respectively. Five Hall probes were used for the bulk sample that were separated from the sample surface with a G-10 2.5 mm thin plate, as schematically sketched in figure 4(a). The three Hall probes as well as one temperature sensor were placed at the top surface for the 2seed-bulk sample, whereas for the ring-bulk, the central Hall probe was fixed in the middle of the hollow space, as sketched in figure 5. Further details about Y-Ba-Cu-O bulk geometry are compiled in table 2.

epoxy. The gap is about 1 mm for both double-sample stacks. An entire double-sample stack was wrapped with a thin G10-CR fiberglass layer, while a G10-CR fiberglass lid was required to mount the double-sample stack on the measuring setup. Other three samples included single Y-Ba-Cu-O bulks produced as a standard Y-Ba-Cu-O cylindrical bulk, referred to here as bulk, and double-seeded Y-Ba-Cu-O bulk cylinder, referred to here as 2seed-bulk. The 2seed-bulk sample was fabricated using a top/bottom double seed melt growth (DSMG) technique [58] to increase the trapped field homogeneity in comparison to the standard TSMG. The last sample is a ring Y-Ba-Cu-O bulk, referred to here as ring-bulk, with outer and inner diameter of 28 mm and 6 mm, respectively. Five Hall probes were used for the bulk sample that were separated from the sample surface with a G-10 2.5 mm thin plate, as schematically sketched in figure 4(a). The three Hall probes as well as one temperature sensor were placed at the top surface for the 2seed-bulk sample, whereas for the ring-bulk, the central Hall probe was fixed in the middle of the hollow space, as sketched in figure 5. Further details about Y-Ba-Cu-O bulk geometry are compiled in table 2.

Figure 1. Top: Schematics (left) and photographs (right) of the double-sample stack which is assembled from (1) two Y-Ba-Cu-O cylinders and (bottom) single bulk HTS. Each cylinder is reinforced with (2) AISI 316 stainless steel or aluminum tube. Three (3) Hall sensors (HGT-2101, Lakeshore ) and the (4) temperature sensor (CX-1030-SD, Cernox

) and the (4) temperature sensor (CX-1030-SD, Cernox ) are fixed at the center of the stack using a Stycast epoxy. An entire stack is wrapped with (5) thin G10-CR fiberglass layer, whereas a (6) G10-CR fiberglass lid is needed for mounting on measuring setup. Bottom: Schematics (left) and photographs (right) of single bulk HTSs.

) are fixed at the center of the stack using a Stycast epoxy. An entire stack is wrapped with (5) thin G10-CR fiberglass layer, whereas a (6) G10-CR fiberglass lid is needed for mounting on measuring setup. Bottom: Schematics (left) and photographs (right) of single bulk HTSs.

Download figure:

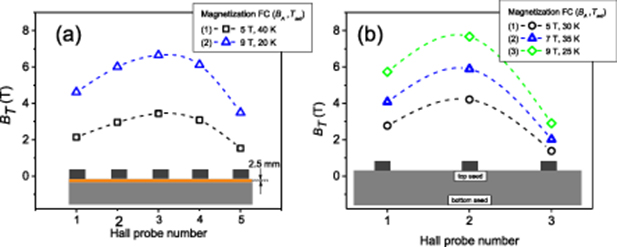

Standard image High-resolution imageFigure 4. The trapped magnetic field evolutions of (a) bulk (reinforced with AISI 316 steel) and (b) 2seed-bulk (reinforced with EN AW 7075 aluminum) single bulk HTS samples followed separate sequential FC (BA; Tset) magnetizations.

Download figure:

Standard image High-resolution imageFigure 5. The trapped magnetic field evolution of the ring-bulk (with outer diameter of 28 mm and inner diameter of 6 mm) reinforced with AISI 316 steel followed separate sequential FC (BA; Tset) magnetizations.

Download figure:

Standard image High-resolution imageEach sample was shrink-fit reinforced with a metal tube with the same height as the Y-Ba-Cu-O bulk cylinders. Besides austenite stainless steel (AISI 316), an aluminum (AW 7075) tube was used for bulk HTS reinforcement owing to the ease of machinability. The thermal expansion coefficient of aluminum is comparable to that of AISI 316 steel in the 300–30 K temperature range; however it has lower yield strength. Admittedly, the weight of aluminum is approximately one third of that of stainless steel, which is a clear benefit when designing bulk HTS devices. The used aluminum and stainless steel tubes were commercially available but they were re-machined to provide precise inner diameter tolerance up to 10 µm. Then, the tubes were heated to Tshrink, thereby allowing the bulk HTS samples to fit inside.

To measure the magnetic field, each sample was equipped with one central and two peripheral Hall probes (HGT-2101, Lakeshore ), which were calibrated at 110 K before each magnetization and driven with a 77 H, 50 µA root-mean-square signal using a current source (Keithley

), which were calibrated at 110 K before each magnetization and driven with a 77 H, 50 µA root-mean-square signal using a current source (Keithley 6221). The Hall voltage of each Hall probe was measured using a lock-in amplifier. The temperature sensor (CX-1030-SD, Cernox

6221). The Hall voltage of each Hall probe was measured using a lock-in amplifier. The temperature sensor (CX-1030-SD, Cernox ) combined with Manganin wire heater were used to monitor and control the sample temperature.

) combined with Manganin wire heater were used to monitor and control the sample temperature.

An 18 T superconducting magnet (SCM-2) at the National High Magnetic Field Laboratory (NFMFL) at Florida State University, Tallahassee, USA [59] was utilized to magnetize the samples. The experimental procedure involved the FC process; an applied magnetic flux density, BA at T = 110 K, with successive cooling to a set temperature,  . Therefore, hereafter each magnetization is referred to as FC (BA; Tset). When the thermal equilibrium was achieved, the BA was reduced to zero at a ramp rate of 0.1 T min−1. The trapped magnetic flux density BT presented in this study is the field value recorded at BA = 0.

. Therefore, hereafter each magnetization is referred to as FC (BA; Tset). When the thermal equilibrium was achieved, the BA was reduced to zero at a ramp rate of 0.1 T min−1. The trapped magnetic flux density BT presented in this study is the field value recorded at BA = 0.

3. Result and discussions

3.1. Double-sample stacks

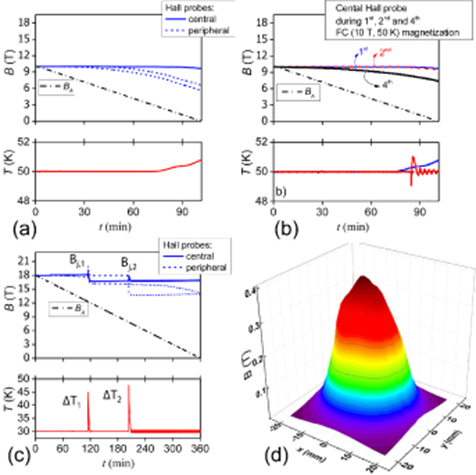

FC (10 T; 50 K) was applied initially to magnetize stack-SS. The top of figure 2(a) shows the time dependence of the field measured by the Hall probes during BA decrease. When BA = 0, a trapped field of BT,c = 9.63 T at the sample center, as well as BT,p1 = 6.55 T and BT,p2 = 5.54 T at the sample periphery were obtained. At the end of the BA decrease, the measured Tset slightly increased by 0.7 K, but did not impact the obtained trapped fields, as shown in the bottom of figure 2(a). Such temperature increase is related to the continuous heat generated by magnetic flux movement [30]. In the subsequent experiment, the FC (10 T; 50 K) magnetization on stack-SS was repeated, thereby reproducing the trapped magnetic field of [BT,p1; BT,c; BT,p2] = [6.74; 9.53; 5.45] T. The time dependent behavior of the measured magnetic flux density of the second FC (10 T; 50 K) during BA decrease was almost consistent with the first FC (10 T; 50 K) magnetization process, as compared in figure 2(b). Then, stack-SS was re-magnetized by the FC (18 T; 30 K). When BA was reduced to 12 T, two abrupt temperature spikes of Δ T1 = 15 K and Δ T2 = 17 K where observed; this caused the corresponding drop in the measured field at Bj,1 = 12 T and Bj,2 = 7.7 T, respectively. When BA reached zero, the final trapped field was [BT,p1; BT,c; BT,p2] = [13.90; 16.85; 14.70] T (see figure 2(c). Such a scenario is a hallmark of the partial self-terminating flux jump due to thermal instability, which was also observed in previous high trapped field experiments [15, 17, 19]. In this case, partial magnetic energy was released and the stack-SS sample remained in the superconducting state [6].

Figure 2. (a) Measured magnetic field and temperature of stack-SS as function of time during BA decrease applying FC (10 T; 50 K). (b) Comparison of the central Hall probe measured field and temperature of stack-SS during the first, second and fourth FC (10 T; 50 K) magnetization processes. (c) Measured magnetic field and temperature of stack-SS as function of time during BA decrease applying FC (18 T; 30 K) magnetization. (d) Magnetic flux density distribution at the bottom of stack-SS performed via the Hall mapping at 77 K after high field experiments.

Download figure:

Standard image High-resolution imageTo identify the repercussions of the observed flux jumps, the stack-SS was immediately re-magnetized using the initial FC (10 T; 50 K) magnetization trapping [BT,p1; BT,c; BT,p2] = [4.87; 7.40; 3.99] T. Although the time dependent behavior of the measured field resembled that of the initial magnetization, the obtained trapped fields were lower than those observed in the initial magnetization. Figure 2(b) compares the measured field of the central Hall probe for the first, second, and fourth FC (10 T; 50 K) magnetization, suggesting that the stack-SS sample was affected during the third FC (18 T; 30 K). The visual inspection that followed did not indicate any obvious damage. Further inspection was performed on the stack-SS via Hall mapping at 77 K. Because the sample was covered with the G-10 lid at the top and glued with the Stycast epoxy in between (see figure 1), it was examined only from the bottom, thereby revealing asymmetrical magnetic flux density distribution (see figure 2(d), instead of the symmetrical cone-shaped distribution obtained before high field experiments; this confirmed that stack-SS damaged.

epoxy in between (see figure 1), it was examined only from the bottom, thereby revealing asymmetrical magnetic flux density distribution (see figure 2(d), instead of the symmetrical cone-shaped distribution obtained before high field experiments; this confirmed that stack-SS damaged.

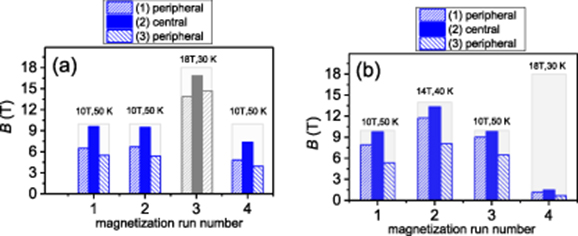

To summarize, the stack-SS was subsequently magnetized four times using FC (BA; Tset) magnetization. Figure 3(a) compares the obtained trapped magnetic flux densities. The peak field of 9.63 T at 50 K was successfully trapped; it was then reproduced in the subsequent experiment by applying identical FC (10 T; 50 K) magnetization. Further FC (18 T; 30 K) magnetization was accompanied by partial flux jumping that resulted in a maximum trapped field of 16.85 T at 30 K, which is comparable to the record trapped fields.

Figure 3. Trapped field measured by central and peripheral Hall probes in the gap between two Y-Ba-Cu-O bulk HTSs for (a) stack-SS (reinforced with AISI 316 steel) and (b) stack-Al (reinforced with EN AW 7075 aluminum) as function of separate sequential FC (BA; Tset) magnetizations.

Download figure:

Standard image High-resolution imageHigh-field measurements on the stack-Al involved the following FC (BA; Tset) magnetizations:

- (1)BA = 10 T, Tset = 50 K,

- (2)BA = 14 T, Tset = 40 K,

- (3)BA = 10 T, Tset = 50 K,

- (4)BA = 18 T, Tset = 30 K.

Figure 3(b) presents the trapped field obtained for stack-Al. First, the FC (10 T; 50 K) magnetization resulted in a trapped field of [BT,p1; BT,c; BT,p2] = [7.94; 9.77; 5.39] T. Next, stack-Al was re-magnetized by applying higher FC (14 T; 40 K) magnetization and resulted in [BT,p1; BT,c; BT,p2] = [11.76; 13.35; 8.12] T. Then, stack-Al was magnetized again by applying FC (10 T; 50 K) and trapped field of [BT,p1; BT,c; BT,p2] = [9.03; 9.83; 6.50] T, thereby reproducing the trapped field observed the initial magnetization. However, during successive FC (18 T; 30 K) magnetization, the sample suffered partial flux jumps and only trapped BT,c = 1.5 T. To summarize, stack-Al survived three sequential FC magnetizations (i.e. BA = 10 T; 14 T; 10 T), thereby trapping a maximum field of BT,c = 13.35 T at 40 K.

The experimental results obtained for stack-SS and stack-Al proved that i) a reliable and reproducible magnetic field without failure can be trapped in commercial Y-Ba-Cu-O double-sample stacks by applying FC (10 T; 50 K) magnetization and ii) encapsulation with either aluminum or stainless steel tube ensured equally effective reinforcement when magnetizing with BA = 10 T (or even with BA = 14 T in the case of stack-Al). Higher magnetizations with BA = 18 T still lead to partial flux jumping. A possible reason for flux jumping could be a relatively fast BA decrease at ramp rate of 0.1 T min−1 (in comparison to 0.015 T min−1 in [18]) because flux redistribution and its temperature dynamics depend on the flux and thermal diffusion time constants [6, 60]. Nevertheless, as-grown silver-free commercial Y-Ba-Cu-O samples can trap magnetic fields over 16.85 T at 30 K which is slightly lower than the record trapped field reported in Gd-Ba-Cu-O/Ag samples [18, 37]. Therefore, Y-Ba-Cu-O compounds seem to be comparable to Gd-Ba-Cu-O/Ag in terms of the superconducting properties at temperatures below 77 K. Additionally, with further systematic reinforcement treatment (e.g. addition of silver) they can trap even stronger (>17 T) trapped fields.

3.2. Single bulks

Trapped field measurements on single bulk HTSs were performed via sequential FC (BA; Tset) magnetization. For every subsequent magnetization, BA was increased and Tset was decreased to determine the maximum trapped field. The obtained trapped field evolutions for cylinder and 2seed-bulk are plotted in figures 4(a) and (b), respectively.

The maximum trapped fields of 6.65 T and 7.70 T were achieved by applying BA = 9 T. The measured BT exhibited plane profiles for both samples, suggesting that its performance can be markedly enhanced by lowering and/or applying a higher BA. However, during successive magnetizations with higher BA = 13–14 T, both samples underwent flux jumping and were deteriorated.

Figure 5 presents the evolution of the trapped field in ring-bulk with a maximum trapped field of 9.78 T at 25 K - the strongest field trapped in a ring bulk superconductor at any temperature reported in the literature, to the best of our knowledge. The significance of the results is that the trapped field was obtained in commercial off-the-shelf Y-Ba-Cu-O without silver addition or any complex post-treatment reinforcement (e.g. composite ring bulk HTS [52]). This introduces the potentiality of using such ring bulk HTSs to realize a compact and cryogen-free 9.4 T (400 MHz) NMR However, further investigations are essential wherein the inner and outer diameters are varied.

4. Conclusion

This study presents experimental investigations regarding the ability of the trapped fields and reproducibility of commercial off-the-shelf Y-Ba-Cu-O bulk HTSs that were prepared as a double-sample stack, a cylindrical bulk, and a ring-shaped bulk. The approach used in the investigations as well as the important results and conclusions are summarized as follows.

- 1)In the double-sample stack experiments, two samples, namely stack-SS (reinforced with AISI 316 steel) and stack-Al (reinforced with EN AW 7075 aluminum) were measured via separate sequential FC (BA; Tset) magnetizations. This revealed that a reliable and reproducible magnetic field of BT = 9.5 T at 50 K without failure can be trapped in commercial Y-Ba-Cu-O. In this case, encapsulation with either aluminum or stainless steel tube ensures equally effective reinforcement.

- 2)A higher magnetization process with BA = 14 T resulted in a maximum trapped field of 13.3 T for the stack-Al sample. Although accompanied with partial flux jumps, 16.85 T was obtained for the stack-SS sample following FC (18 T; 30 K). The obtained values are comparable to the reported record trapped fields; however they were measuredin as-grown silver-free commercial Y-Ba-Cu-O samples, which suggests that further systematic reinforcement treatment (e.g. the addition of silver) can lead to even stronger (>17 T) trapped fields.

- 3)Similar shrink-fit encapsulations using AISI 316 steel and 7075 aluminum tubes were then used to evaluate the trapped field capability of the single bulk HTS, resulting in 6.65 T and 7.70 T measured at the surface of the standard and double-seeded bulk HTSs, respectively.

- 4)Finally, a maximum trapped field ranging from 5–9.78 T at 45–25 K, respectively, was obtained in the 6 mm hollow space of the ring-shaped bulk HTS. The 9.78 T value, to the best of our knowledge, indicates the strongest field trapped in a ring bulk superconductor at any temperature reported in the literature thus far. The significance of these results is that the trapped field was obtained in commercial off-the-shelf Y-Ba-Cu-O without the addition of silver or any complex post-treatment reinforcement. Thus, such ring bulk HTSs can be potentially used to realize a compact and cryogen-free 9.4 T (400 MHz) NMR However, further investigations are essential wherein the inner and outer diameters are varied.

Acknowledgments

The authors Oleksii Vakaliuk and Bernd Halbedel acknowledge the German Research Foundation (DFG) within the Research Training Group "Lorentz Force Velocimetry and Lorentz Force Eddy Current Testing" (RTG-1567/3) for providing financial support. A portion of this work was performed at the National High Magnetic Field Laboratory, which is supported by the National Science Foundation Cooperative Agreement No. DMR–1644779 and the State of Florida. The authors also thank Dmytro Abraimov for helping us during the trapped field measurements on single bulk HTS.