Abstract

Novel methods are necessary to further increase the critical current density (Jc) and uniformity of (RE)Ba2Cu3Oy (RE-123; RE—rare earth element) materials. In this contribution we address several issues of infiltration growth (IG) and melt-growth (MG) processing of RE-123 bulks and show recent progress: (i) optimization of 211 composition in IG-processed mixed YGd system type for the production of good-performance RE-123 bulks (RE: YGd), (ii) optimization of the thermal profile in IG processing of a mixed YEr-123 system for producing large bulks, and (iii) preparation of sharp-edge refined RE-211-phase particles by means of a high-energy ultra-sonication to improve performance of MG-processed Y-123. All products were studied by means of SQUID, SEM, TEM, and trapped field measurements at liquid nitrogen temperature. Our experimental results indicate that in an IG-processed mixed YGd-123 system, Y:Gd = 75:25 is the best ratio for optimum performance. In a YEr (Y:Er = 90:10) system, a series of isothermal experiments revealed that 990 °C is the optimum temperature for maximum growth and performance. On the other hand, in the MG-processed bulk, the Y-211-phase particles exposed to ultra-sonic energy of 300 W for 80 min are smaller than those produced by a conventional process, mainly due to shearing and high-speed collisions of particles. As a result, a doubled-trapped field was achieved at 77 K as compared to traditional reference bulk. We will summarize the improved electromagnetic properties of IG- and MG-processed RE-123 bulks and their relation to microstructure changes in the final products.

Export citation and abstract BibTeX RIS

Original content from this work may be used under the terms of the Creative Commons Attribution 4.0 license. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

1. Introduction

A few decades of ongoing evolution in fabrication techniques of the Y–Ba–Cu–O system has made it possible to achieve superconducting materials with a high critical current density (Jc), enabling several bulk-type applications such as non-contact magnetic bearings, levitation, trapped field magnets and current leads [1–3]. To facilitate such bulk applications, it is crucial to further improve Jc and irreversibility field. In the past, it has been revealed that the REBa2Cu3Oy (RE: Nd, Sm, Eu and Gd) systems exhibit, besides high superconducting transition temperature (Tc), enormous Jc values when they are fabricated by the oxygen-controlled melt-growth (OCMG) process. In contrast to regular melt-growth processes, the OCMG process is carried out in a reduced oxygen atmosphere [4–7]. The OCMG-processed RE123 bulks exhibit Tc exceeding 96 K and a high irreversibility field above 7 T at 77 K for fields parallel to the c-axis. In addition to high performance, the OCMG-processed RE123 superconductors commonly exhibit the secondary peak effect, which is because of the presence of field-induced pinning by RE-rich 123 clusters and also presence of RE-Ba solution [8]. However, the OCMG process is quite expensive, time consuming and not well scalable to bench fabrication. The MG process itself has some drawbacks, e.g. presence of rests of unreacted liquid phases in the matrix and a non-uniform RE-211 distribution. In attempt to overcome this, the researchers proceeded to infiltration growth (IG) techniques [9]. The IG process involves melting of the liquid phase (BaCuO2 + CuO), its infiltration into the solid precursor (RE-211) placed on top, and subsequent formation of RE-123 during slow cooling. During the grain growth, the RE-123 phase traps unreacted RE-211, inhibiting its further reaction with the liquid phase, leading thus to a homogeneous nucleation of RE-123 in the melt [10, 11]. The trapped RE-211 phase enhances flux pinning in the matrix. RE-Ba-Cu-O superconductors with more than one RE element showed a higher critical current density [12–17] due to composition variations. Disordered regions can serve as effective flux pinning centers for flux line lattice [18]. It is interesting to study the combined effect of IG processing when using two RE elements.

There are several other ways to improve the performance of this superconducting material. For example, it is known that the trapped RE-211 inclusions act as effective pinning centers. Until now, RE-211 particles have been refined by dopants like Pt, PtO2, CeO2 [19–21]. In a given constant volume of RE-123 matrix, the critical current density is inversely proportional to the size of secondary-phase RE-211 inclusions, and thus Jc can be enhanced by simply decreasing the size of RE-211 inclusions [22]. So far, ball milling of Y-211 inclusions was performed to reduce the particles' size, but it is well known that this technique imparts impurities into the system and is expensive. We tried to achieve a similar effect using an inexpensive and new technique of 'ultra-sonication'.

In this work, we go through various systems involving IG as well as MG-grown bulk superconducting REBCO materials. The IG-grown bulk involves inclusion of mixed RE element systems such as Y and Gd, and Y and Er. In the mixed system of Y and Gd we optimized the ratio of elements in which high performance was observed. In the Y and Er system we optimized the sintering pattern to obtain fully grown bulk for a particular ratio of Y and Er, which was 90:10 of Y-211:Er 211. With the optimized sintering pattern, we were able to grow large bulk. In the MG-grown bulk we used ultra-sonicated Y-211 refined particles, which improved microstructure. We report on the recent progress in aim to improve superconducting performance of REBCO bulk materials.

2. Experiment

We prepared three sets of bulk systems to explain the progress in this bulk superconductor field. These sets comprise mixed dual RE systems and novel processing techniques.

2.1. System I: YG-123 top-seeded IG-processed bulk, composed of Y-211 and Gd-211

The first step is to prepare Y-211 and Gd-211 powders. High-purity commercial powders of Y2O3, Gd2O3, BaO2, and CuO were mixed in stoichiometric compositions to obtain Y2BaCuO5 and Gd2BaCuO5, and calcined three times at 840, 870, and 890 °C for 12 h to achieve high-quality 211 powders. Simultaneously, BaCuO2, BaO, and CuO were mixed in a nominal composition of Ba3Cu5O8 (Y-035), which is also known in its liquid form. It was used as a part of the liquid source in later stages of synthesis. To study the mixed system, 6 g of calcined Y-211 and Gd-211 (micron size) powders were then mixed in several Y:Gd ratios and ground for 1 h. Four mixtures were prepared with solid precursor having Y-211:Gd-211 ratios of 100:0, 80:20, 75:25 and 70:30, which will be denoted as A1, A2, A3 and A4, respectively. Then pellets of 20 mm diameter were made of these powder mixtures. Similarly, Y-035 and Y-123 powders were mixed at the ratio of 1:1 in weight to prepare liquid + Y-123 pellets, which served as a liquid source during the IG process. The YG-211 pellet was placed on top of the liquid source, followed by placing a Nd-123 seed on the center of the top of the whole setup to ensure single-domain growth. A Y2O3 powder plate and MgO single crystalline sheet were placed at the bottom. The whole arrangement was set up on an alumina plate and subjected a special heat cycle, such as 820 °C in 5 h, held there for 10 min, raised to 1050 °C, held there for 1 h for formation of Y-035 melt to ensure that sufficient melt infiltrates into the YG-211 precursor. Then the temperature was lowered for 15 min to 1005 °C and then to 1000 °C for 5 min and subjected to slow cooling at the rate of 0.2 °C h−1 to a temperature of 980 °C and then to 100 °C for 5 h, and finally, the furnace was left to cool down to room temperature. In the end, the IG-processed YG-123 bulks were annealed at 450 °C for 250 h in pure O2 gas flow to oxygenate the bulk. Further details can be found in [23].

The microstructure of these products was studied with an atomic force microscope (AFM) operating in tapping mode. Magnetic measurements were performed using a SQUID magnetometer (Quantum design, model MPMS5). Small platelets with dimensions of around 1.5 × 1.5 × 0.5 mm were cut from the bulk samples (approximately 1 mm below the seed) and polished. Critical transition temperature (Tc) and magnetization loops (M versus H) were measured over the field range of 0 to 5 T at 77 K. Critical currents were estimated using the extended Bean's critical state model for a cuboidal shaped sample [24],

In equation (1), d is the cut sample thickness along c-axis, while a and b are cross-sectional dimensions with b ⩾ a, and Δm is the difference of magnetic moments in the course of decreasing and increasing magnetic field during measurement, respectively.

2.2. System II: YEr-123 top-seeded IG-processed bulk made of Y-211 and Er-211

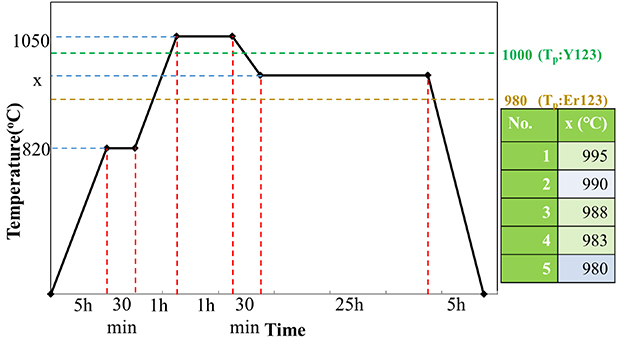

The bulk YEr-123 was synthesized using the same methodology as for YG-123. However, in this system the goal is to find an optimized heating cycle enabling fabrication of large single domain bulks. Several samples were isothermally grown to capture the growth mechanics in this system. For this purpose, YEr-211 (Y:Er = 9:1) composition was chosen and the optimum growth temperature was studied. In brief, 5 g of the mixture of 90 wt% of Y-211 and 10 wt% of Er-211 along with 0.2 wt% of Pt and 0.25 wt% of CeO2 as grain refiners were utilized. The precursor pellets of YEr-211 and Y-123 + liquid phase (Ba3Cu5Oy) were uniaxial pressed in a 20 mm diameter die. A typical arrangement employed in the IG experiment was used in our synthesis. The samples were heat-treated using isothermal sintering cycles with various growth temperatures such as 995; 990; 988; 983; and 980 °C for 25 h followed by rapid cooling (figure 1). They will be referred as B1, B2, B3, B4, and B5, respectively. After obtaining the growth window, it was used to grow large bulks. In order to obtain large single-grain bulk samples, a slow cooling process was employed. 5 g bulk and 12 g bulk samples were fabricated using a tailored sintering cycle that can be found in figure 2. These samples are called BL1 and BL2, respectively. To ensure good oxygenation, the two bulks (BL1 and BL2) were heated at 450 °C for 250 h. Superconducting properties were measured in the same manner as in the system I. In addition, the trapped field was measured using a Hall probe, at 77 K.

Figure 1. Thermal profile for isothermal rapid cooling process. 990 °C seemed to be the optimum growth temperature in Y:Er = 90:10 system.

Download figure:

Standard image High-resolution imageFigure 2. Thermal profile for slow cooling IG process, YEr-123 (Y:Er = 90:10) system. 5 g and 12 g bulks were produced using the same profile but the amount of cooling time was varied as 100 and 150 h respectively.

Download figure:

Standard image High-resolution image2.3. System III: Y-123 top-seeded MG-processed bulk, comprised of the ultra-sonicated Y211

First, Y-211 powders were self-made, in a similar fashion as in system 1, i.e. by mixing raw powders in the stoichiometric ratio processed then by multiple calcination. Next, the just-prepared Y-211 powder was ultra-sonicated for various durations (from 20 to 100 min) in order to reduce the particle size. For this, we employed a Mitsui ultra-sonic homogenizer UX-300. Processing parameters such as power (300 W) and frequency (20 kHz) were kept constant. Ethanol was used as a dispersion medium and the dispersion was ultra-sonicated for various durations. The Y-211 and Y-123 powders were mixed at a 1:2 ratio, together with 0.5 wt% of Pt (as a grain refiner) and mixed rigorously for a couple of hours. In addition, another series of samples were fabricated without use of Pt, just to highlight the effect of ultra-sonication on the bulk performance. This powder was then pressed into pellets of 20 mm diameter using a uniaxial press. Like in the previous systems, Nd-123 seed was placed on the top of pelletized precursor mixture. The temperature profile used for fabricating samples for TSMG was similar to the typical MG process. Crucial was the slow cooling chosen, between 1005 and 985 °C. After melt processing, the Y123 samples were annealed at 450 °C for 400 h in a controlled oxygen atmosphere for oxygenation.

Basic superconducting performance of all the bulks was tested using SQUID magnetometer. For magnetic measurements, samples of 1.5 × 1.5 × 0.5 mm were cut from the bulks below the seed with the platelet thickness along the c-axis. Superconducting transition temperature (Tc) and magnetization loops in field from 0–5 T were measured at 77 K using a SQUID magnetometer (model MPMS5). Trapped field measurements were done using an electromagnet of 1 T to activate the Y123 bulk superconductor. Field distribution was tested by an automatic scanning Hall probe sensor at a distance of 0.3 mm (surface touched) and 1.3 mm (1 mm above surface) above the superconductor surface. This is because of the 0.3 mm difference between probe's epoxy surface and the hall probe. The microstructures were studied with a field emission scanning electron microscope (FE SEM).

3. Results and discussion

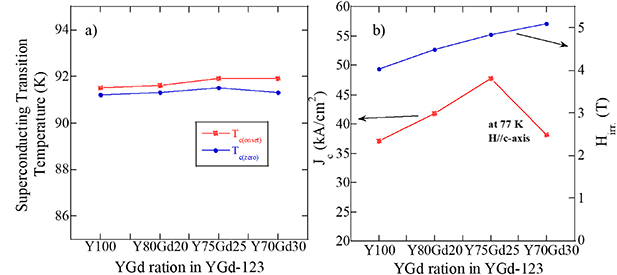

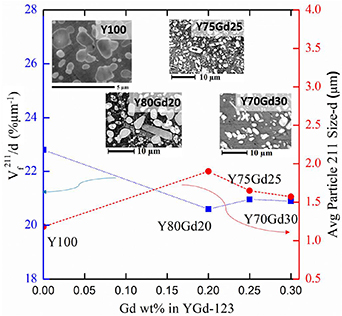

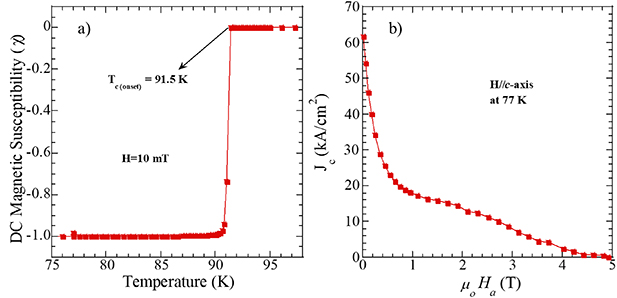

The top surfaces of the top-seeded IG-processed bulk YG-123 samples (A1, A2, A3, and A4 with Y:Gd ratio of 100:0, 80:20, 75:25, and 70:30, respectively) are displayed in figure 3. The temperature dependence of DC magnetic susceptibility was measured for all the bulk YG-123 at 10 Oe. Figure 4(a) depicts the superconducting critical transition onset temperature (Tc, onset) values of all specimens. It lies close to 92 K for all the samples, near the typical value of a pure Y-123 superconductor. The superconducting critical current density (Jc) is shown in figure 4(b). The highest self-field Jc value of 47.4 kA cm−2 at 77 K was recorded in the A3 bulk (Y:Gd = 75:25). We note that no grain refiners such as platinum, cerium, or platinum oxide were used in this case. Such a value obtained without grain refiners is a great improvement. More details can be found in [23]. This brings us to an optimum Y:Gd ratio to produce a high-performance REBCO-based superconductor. Microstructural studies were executed using an AFM and SEM. Figure 5 depicts the micron-sized YG-211 particles (bright yellow) distributed almost uniformly in the YG-123 matrix (dark yellow). AFM 3D image observations revealed that the average size of the YG-211 particles was reduced with increasing Gd-211 content. In addition, the volume fraction of YG-211-phase particles calculated from SEM images of these YG samples also decreased. While the size of YG-211 decreased with increasing content of Gd211 in the matrix, the Vf211/d exhibited a maximum for A3 (Y:Gd = 3:1), the best system among the Gd211-added samples. This is clearly seen in figure 6. This was already reported in [25, 26]. There, the Gd-211 volume fraction present in Gd-123 matrix was reduced with growing barium content in the liquid source. The reason for lower Jc in A1 could be due to the low V211% in the matrix. The product of V211/d (left axis) and d (right axis) in figure 6 can aid in understanding the effective V211%, which was <30 for A1 and >30 for Gd211 added bulks (A2, A3 and A4).

Figure 3. Grown bulk top surfaces of YG-123 with various Y: Gd ratios such as 100:0, 80:20, 75:25, and 70:30.

Download figure:

Standard image High-resolution imageFigure 4. Superconducting parameters for various Y:Gd-based YG-123 bulks. (a) Depicts the Tc characteristics; Tc, onset is close to 91.5 K, while Tc, zero is close to 91 K. (b) Displays the trends of Jc as well as irreversibility fields. Y:Gd = 75:25-based bulk shows the best performance.

Download figure:

Standard image High-resolution imageFigure 5. AFM images of the bulk samples with various Y:Gd ratios. (a), (e) Y:Gd = 100:0; (b), (f) Y:Gd = 80:20; (c), (g) Y:Gd = 75:25; (d), (h) Y:Gd = 70:30. The top row consists of two-dimensional images, while the bottom row comprises three-dimensional images to give an overview of size and shape of a 211-particle distribution.

Download figure:

Standard image High-resolution imageFigure 6. Vf211/d and YG-211 particle size plotted against various Y:Gd-based bulks along with SEM images.

Download figure:

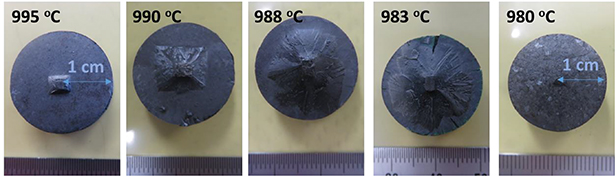

Standard image High-resolution imageBefore starting the YEr-123 synthesis, heating pattern optimization was necessary. In order to do so, Y:Er = 90:10 was chosen as a test composition. The heating cycle was like that shown in figure 1, where x is the parameter needed to be optimized to obtain maximum growth. This process is called an isothermal experiment as temperature is kept constant over the whole time, 25 h in this case. x varied between 980 and 995 °C. The growth morphology of the specimens was observed by an optical microscope (figure 7). Tc,onset was around 91 K for all the samples (figure 8(a)); Jc was highest in bulk B2 (x = 990 °C), reaching 57 kA cm−2 at 77 K and self-field (figure 8(b)). As can be seen in figure 9, SEM analysis revealed that numerous extremely fine Y211 particles were present in the matrix of the bulk B2, when compared to other bulks. Having data on the optimized growth rate heating pattern, we fabricated two 20 mm in diametric YEr-123 bulks, one 5 g and the other 12 g. The heating cycle time was slightly modified (figure 2), applying slow cooling to obtain full growth; 100 h for BL1 and 150 h for BL2 specimen. Figure 10 shows the fully grown bulk YEr-123 BL1 and large BL2 samples. After sufficient oxygenation, Tc, Jc, and trapped field measurements were performed. As shown in figures 11(a) and (b), Tc,onset was around 91.5 K, while the Jc values at 77 K and in self-field and 2 T of H//c-axis were around 63 kA cm−2 and 13 kA cm−2, respectively, in both bulks. A Hall probe was used to measure trapped field. The results indicate that both bulk BL1 and BL2 exhibited single-grain growth and uniform trapped field distributions with a perfect cone shape, when scanned at 1.3 mm above the bulk's surface (see figures 12(a) and (b)). The trapped field at the center was 0.23 and 0.39 T for the bulks BL1 and BL2, respectively. The trapped field around 0.44 T was detected at the center of the 12 g sample (BL2), when the Hall probe touched sample surface. As the epoxy coating of the Hall-probe is 0.3 mm thick, this situation corresponded to an effective 0.3 mm distance of the probe from the sample surface. The trapped field at the center of 5 g bulk sample (BL1) was around 0.34 T. The high trapped field was due to a longer growth along c-axis [27].

Figure 7. Exterior growth morphology observed using an optical microscope for isothermally grown YEr-123 (25 h) with varying temperature. 990 °C showed the best growth.

Download figure:

Standard image High-resolution imageFigure 8. (a) Superconducting critical temperature for all samples are close to 91 K. (b) Critical density of samples produced isothermally at various temperatures. Bulk produced at 990 °C showed the highest Jc value at low and high fields.

Download figure:

Standard image High-resolution imageFigure 9. SEM images of bulks grown at various temperatures such as 983 °C, 988 °C, and 990 °C. Numerous fine particles can be observed in bulk grown at 990 °C.

Download figure:

Standard image High-resolution imageFigure 10. Fully grown bulk YEr-123 small and large samples. (a) 5 g, small thickness bulk (20 mm diameter), (b) 12 g, large thickness bulk (20 mm diameter).

Download figure:

Standard image High-resolution imageFigure 11. Superconducting properties of slow-cooled 12 g YEr-123 bulk. (a) Tc, onset was close to 91.5 K; (b) High Jc values around 63 kA cm−2 and 13 kA cm−2 were obtained in self field and 2 T at 77 K for H//c-axis.

Download figure:

Standard image High-resolution imageFigure 12. Trapped field distribution of YEr-123 (Y:Er = 90:10) bulk measured under 10 000 G field, at 77 K and 1.3 mm above surface. (a) 5 g bulk, (b) 12 g bulk. TFs—surface touched, TF1.3—1.3 mm above surface.

Download figure:

Standard image High-resolution imageAs regards system III, the top surface view of TSMG-grown Y-123 bulks (20 mm diameter samples), fabricated with refined Y-211 and Pt added, can be seen in figure 13. All the samples showed full growth. The ultra-sonication time was varied and the effect on superconducting performance was studied. The temperature dependence of the DC susceptibility was calculated using a SQUID magnetometer. All samples exhibited a sharp superconducting transition around 90–92 K and a transition width of less than 1.5 K. This indicated that all bulks were of high quality (table 1). The highest self-field Jc value was observed in the bulk based on 80 min ultra-sonicated Y-211. Its value was around 47 kA cm−2 at 77 K, high above the reference value (table 1). The reason might be the formation of smaller Y-211 particles in the matrix when refined by means of ultra-sonication for an optimum time. This is possible because ultra-sonication can produce very fine particles, while regular particles shear along surfaces. This effect seems to get saturated after 80 min, and further ultra-sonication only drags down the performance of the bulk. As a result, the trapped field was 0.42 T at 77 K, 0.3 mm away from the top surface, when field-cooled at 1 T field (table 1). The trapped field profile of a uniform single cone indicated that the sample was a uniform single grain without cracks and underwent good oxygen treatment. In the case when Pt was not added, the optimum performance shifted to 100 min of Y-211 ultra-sonication. In the best sample of this kind, the trapped field was 0.3 T at 77 K, 0.3 mm away from the top surface, when field-cooled at 1 T, which is better than a regular bulk (0.2 T). The particle size analysis of Y123 bulks is presented in figure 14 along with the inset SEM images, which explain the effect of the ultrasonicated Y211 on the final microstructure. This in turn also supports the well-known phenomenon that precursor Y211 particles have a great contribution to the final bulk's microstructure and properties. This implies that although ultra-sonication has a positive impact on performance, Pt addition enhances it further.

Table 1. Superconducting properties of the best bulks prepared from ultra-sonicated powders without Pt and with Pt. Tc was measured at a magnetic field of 1 mT; Jc was measured at 77 K, 0 T; trapped field was measured at 77 K, at 1 T magnetic field.

| Bulk sample | Trapped | ||

|---|---|---|---|

| name | Tc, onset (K) | Jc (kA cm−2) | field (T) |

| Normal/pure | 91.2 | 29.2 | 0.225 |

| Ultrasonicated best (without Pt) | 91.46 | 37.6 | 0.287 |

| Ultrasonicated best (with Pt) | 91.47 | 47.4 | 0.412 |

Figure 13. Top surface view of TSMG-grown Y-123 bulks (20 mm diameter samples). (a) Pure normal Y-123 bulk; (b) ultra-sonicated (without Pt addition) best-performance bulk Y-123 (100 min ultra-sonicated Y-211); (c) ultra-sonicated (with Pt addition) best-performance bulk Y-123 (80 min ultra-sonicated Y-211).

Download figure:

Standard image High-resolution imageFigure 14. Particle size analysis along with inset SEM images of TSMG-grown Y-123 bulks. (a) Pure normal Y-123 bulk; (b) ultra-sonicated (without Pt addition) best-performance bulk Y-123 (100 min ultra-sonicated Y-211); (c) ultra-sonicated (with Pt addition) best-performance bulk Y-123 (80 min ultra-sonicated Y-211).

Download figure:

Standard image High-resolution imageIn the past, extensive research has been done on mixed binary, ternary and quaternary systems prepared by the melt-growth technique [16, 28–32]. Among them, especially bulk ternary RE-123 materials, produced by an oxygen-controlled melt-growth (OCMG) process, showed a tremendous improvement in microstructure as well as in critical current density [13, 33]. In this material, the pinning performance due to secondary-phase particles is inversely proportional to the average particle size, a successful refinement of the secondary-phase particles up to the nanometer level resulting in a considerable increase of super-current density at 77 K. The samples exhibited not only the highest Jc ever reported for bulk melt-processed samples; this also enabled levitation at liquid oxygen temperature (90.2 K) [34]. Additionally, chemical composition variation in this material led to an enhancement of flux pinning at high magnetic fields. The irreversibility field was enhanced at 77 K by nearly double, up to 15 T [35]. However, these mixed systems were never produced utilizing the IG techniques.

In fact, the IG technique itself is quite a new, emerging process and has not yet been optimized. Especially binary systems I and II, prepared by the IG technique, are new. Although the Jc values of system I, when compared to YGd-123 produced via OCMG technique, are low, it is because the IG technique has not yet matured. Comparing these two routes, the best values were found in Y:Gd ~ 3:1 prepared by IG and in Y:Gd ~ 3:7 prepared by OCMG [36]. The Jc value exhibited by system II (YEr-123) is superior to system I (YGd-123) in the respective mixing ratios, as discussed in the literature much earlier. For optimizing the Y:Er ratio and preparation conditions to obtain maximum Jc, further studies are needed. System III was synthesized to test another technological issue. For several years, expensive metals and metal oxides such as Pt, Ce have been added to control the Y2BaCuO5 (211) particle size inside the 123 matrix [19, 21]. System III was studied to test if Y-211 particle control in the final microstructure can be achieved via high-energy ultra-sonication of precursor Y-211 powder, even without usage of expensive Pt and CeO2 additions. The Jc values of system III, despite the absence of external particle refiners (Pt, CeO2), are comparable to those of systems I and II. Hence, all three parts give an insight into the progress in bulk REBCO superconductor technology for upcoming customization at a reasonable cost.

4. Conclusion

We successfully grew (Y,Gd)Ba2Cu3Oy (YG-123) bulk samples with a top-seeded IG method with various contents of (Y,Gd)2BaCuO5 (YG-211). We optimized the Y:Gd ratio in the 211 phase to obtain the best possible performance. Addition of Gd-211 to Y-211 in the precursor increased the critical current density Jc compared to the reference bulk YBa2Cu3Oy (Y-123). Volume fraction and particle size of YG-211 in the YG-123 matrix decreased with increasing content of Gd-211 in the precursor. The Jc value achieved a maximum of 47.4 kA cm−2 at 77 K, and with the self-field in the bulk of Y:Gd = 3:1. We also produced single-grain bulk YEr-123 superconductor via the IG process combined with controlled growth process and optimized the heating pattern. Magnetization experiments showed that the samples produced by an isothermal growth and slow cooling process exhibited a sharp superconducting transition with Tc at around 91 K. The highest self-field Jc value of around 63 kA cm−2 was obtained at 77 K. A single-grain nature with a trapped field around 0.44 T was achieved. Ultra-sonication is a new technique for refining Y-211 particles. We successfully applied this technique in the melt-growth method to produce Y-123. This resulted in improvement of superconducting performance such as for the trapped field (0.3 T, at 77 K). The trapped field further increased to 0.4 T at 77 K when Pt was added in conjunction with ultra-sonication. Although a series of methods and their steps were already optimized, both IG and MG processes still have a long way to mature. In any case, the mixed systems are a successful technique in attaining high performance in a REBCO system. Ultra-sonication appears to be a promising new technique in improving superconductor performance; however, it still also needs further study to use it at the industrial level.

Acknowledgments

This work was partly supported by the Shibaura Institute of Technology (SIT), Research Center for Green Innovation, and a Grant-in-Aid, FD research budget code: 112282. Two of the authors (Sai Srikanth Arvapalli and Sunsanee Pinmangkorn) acknowledge financial support from SIT for their doctoral programs. Milos Jirsa acknowledges financial support from the program Strategy AV 21-VP3 'Energy storage in flywheels'