Abstract

The two-step top seeded infiltration and growth (TSIG) melt process has emerged as a successful and reliable technique for the fabrication of single grain (RE)Ba2Cu3O7−δ (where RE is a rare-earth element or yttrium) bulk high temperature superconductors with engineered microstructures that exhibit improved superconducting properties. In this study, the performance of these materials in large applied magnetic fields has been investigated by field cooling single grain samples in a magnetic field of 18 T. YBa2Cu3O7−δ samples processed without added Ag by the TSIG technique, in the two-sample stack configuration, trapped a magnetic field of 14.3 T at 28 K after field cooling from 100 K and subsequent removal of the applied field. This result is particularly significant in that, previously, only single grain (RE)Ba2Cu3O7−δ bulk superconductors containing Ag have been reported to be able to tolerate the large stresses on the samples inherent in the magnetisation process at large fields. The samples prepared in the present study were pre-stressed using a reinforcing stainless-steel ring, although, otherwise, they did not contain any additives, dopants or resin impregnation. The ability of samples processed by TSIG to withstand large tensile forces without Ag addition is attributed to the reduced incidence of intrinsic cracks/pores in the single grain microstructure.

Export citation and abstract BibTeX RIS

Original content from this work may be used under the terms of the Creative Commons Attribution 3.0 licence. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

1. Introduction

(RE)Ba2Cu3O7−δ (RE-123, where RE is a rare-earth element like yttrium) bulk, single grain superconductors could potentially transform a range of high magnetic field engineering applications at cryogenic temperatures. These include trapped field magnets, friction-free, self-stabilising bearings for energy storage flywheels and magnetic separation devices [1, 2]. Over the past 30 years, there has been a concerted effort to develop effective and economical fabrication techniques to manufacture (RE)Ba2Cu3O7−δ bulk superconductors in the form of large, single grains. As present, the top seeded melt growth (TSMG) process is the most established technique for fabricating high quality, single grain bulk samples [3–5], although, due to the relatively large forces inherent during sample magnetisation, it has proved challenging to reliably trap large magnetic fields in these samples. Over the years, a number of high trapped fields have been reported in bulk, single grain samples, including 16 T at 24 K achieved in 2002 [6], 17.24 T at 29 K achieved in 2003 [7] and the current record field of 17.6 T at 26 K achieved in 2014 [8]. In each case, these relatively high fields were the direct result of a combination of external reinforcement, using a variety of techniques, and the addition of Ag to the TSMG process to increase the intrinsic strength of the bulk superconductor [6–9].

Although the TSMG technique enables the fabrication of high quality RE-123 bulk single grains, there are a number of intrinsic problems [10–15] associated with the fabrication process itself. These include considerable sample shrinkage after processing, the presence of detrimental macro-defects, such as extensive porosity and cracks, in as-processed TSMG samples and the presence of regions free from non-superconducting (RE)2BaCuO5 (RE-211) phase inclusions in the large grain microstructure that produce non-uniformity in the field dependence of the critical current density, Jc, throughout the sample volume [13–16]. The effect of these defects, variously, is to increase the susceptibility of bulk (RE)BCO samples to mechanical failure under the influence of the large Lorentz forces that are typically generated during the field cooling process. Indeed, unreinforced RE-123 bulk superconductors cannot typically withstand field cooling in fields larger than around 8 T [17–19].

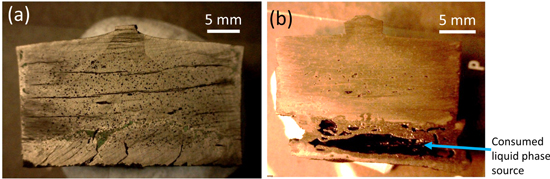

The infiltration and growth (IG) technique is a practical alternative to TSMG that overcomes many of the limitations inherent in this process [10–15, 20–28]. The significant reduction in macro-defects i.e. pores and cracks in TSIG samples, as compared to TSMG, may be appreciated from figure 1. Unfortunately, however, the superconducting properties of IG-processed bulks have been generally inferior to those obtained via the TSMG technique.

Figure 1. Cross-sectional optical micrographs of YBCO samples fabricated employing (a) top seeded melt growth and (b) buffer-aided top seeded infiltration and growth techniques.

Download figure:

Standard image High-resolution imageRecently, however, systematic studies have been carried out to investigate and understand the origin of the severe problems that affect the mechanical stability of melt processed single grains, in general, and a number of likely reasons have been identified for the observed inferior performance of IG-grown samples compared to those fabricated by TSMG, including the presence of a large fraction (∼40%) of non-superconducting phase present in the final IG sample microstructure [15]. Consequently, a two-step, buffer-aided top seeded infiltration and growth (BA-TSIG) technique has been developed [20] that enables better control over infiltration temperature and time, which, in turn, has enabled the content and distribution of the non-superconducting phase in the bulk microstructure, fundamental to flux pinning, to be optimised. As a result, the superconducting properties of single grain BA-TSIG samples are significantly better than the standard samples produced via conventional TSMG, with trapped fields as high as 0.85 T observed in a 25 mm diameter sample with an associated critical current density of ≥60 kA cm−2 at 77 K being reported for Y–Ba–Cu–O (YBCO) [20]. The success of the technique is due to two crucial, and independent, steps: one which promotes the infiltration of liquid phase into the RE-211 preform while the other assists heterogeneous nucleation and single grain growth. Additionally, this technique has turned out to be greatly reliable and further enables the fabrication of near-net shaped bulk superconductors in the form of a large single grain with improved mechanical and superconducting properties, which is highly desirable from an applications perspective.

In the present work, we report the field trapping capability of a stack of two 25 mm diameter single grain bulk YBCO superconductors fabricated by the two-step BA-TSIG and magnetised by field cooling in an external magnetic field of 18 T, removal of the field and then subsequently measuring the trapped field and its decay with time.

2. Experimental details

Two single grain YBCO samples of diameter 25.0 mm and 10.2 mm height were fabricated by a two-step, buffer-assisted TSIG process as described elsewhere [20]. Commercial powders of Y2BaCuO5 (Y-211) and Ba3Cu5O8 each of 99.9% purity procured from Toshima Manufacturing Co. Ltd, Japan; and Yb2O3 (99.9% pure, Alfa Aesar), BaO2 (>95% pure, Sigma Aldrich) and CeO2 (99.9% pure, Sigma Aldrich) were used to prepare the precursor powders. The sample assembly comprises of a pre-form compact, fabricated from Y-211 powder enriched with 1 wt% CeO2, supported on a Yb-based liquid phase reservoir composed of a mixture of Yb2O3, Ba3Cu5O8 and BaO2 such that Yb2O3:CuO:BaCuO2 = 1:10:6, by molar ratio, again as described elsewhere [14, 15, 20]. The YBCO samples obtained by the two-step BA-TSIG process are shown in figure 2(a). More details about the two-step BA-TSIG processing technique and the associated heat treatment conditions may be found in [20] and here only a brief description of the procedure, is provided. In the first step, the sample assemblies were subjected to a thermal profile that included initial heating of the pre-form pellets (i.e. with no seed) to 1050 °C, holding at this temperature for about 1.5 h, followed by a rapid cooling to room temperature to achieve complete infiltration of the liquid phase into the Y-211 pre-form. A generic seed crystal [29] (cleaved along (00l)) supported by a buffer pellet (composed of 75 wt% Y-123 and 25 wt% Y-211) was then placed at the centre of the upper surface of the fully infiltrated precursor sample and the arrangement heated to 1055 °C, held at this temperature for 30 min, cooled rapidly to 1010 °C and then, finally, slow cooled at 0.7 °C–0.5 °C h−1 to 980 °C before cooling to room temperature. Both the fully grown, single grain YBCO samples were annealed in flowing oxygen with a gas flow rate of 100 ml min−1 over the temperature range 450 °C–430 °C for 200 h to transform the tetragonal, non-superconducting Y-123 phase to the orthorhombic, superconducting phase. It should be noted that infiltration grown samples require a longer oxygenation time (usually 50 h more than that used for bulk samples fabricated by TSMG) due to their particularly dense microstructure [28].

Figure 2. (a) As-grown YBCO single grains of diameter 25 mm fabricated via a two-step BA-TSIG technique. (b) The samples (labelled 621 and 673) after polishing and shrink-fitting with a steel reinforcing ring. (c) The actual positions of the Hall sensors on the seeded surface of one of the samples. (d) Photograph of the two reinforced YBCO sample stack prior to the trapped field measurement. The wires from the Hall probes can be seen in (d).

Download figure:

Standard image High-resolution imageThe YBCO samples, which were able to trap magnetic fields of ∼0.85 T at 77 K, were machined to a diameter of 24.15 mm. Stainless steel rings (304-grade) were heated to a temperature of 350 °C and shrink-fitted to the circumference of each of the single grain samples, as shown in figure 2(b). A linear array of five Hall sensors (Lakeshore, HGT-2101) were arranged between the two seeded contact surfaces of the YBCO samples, as shown in figure 2(c), to measure the trapped field. The two samples were then constituted into a single stack, as shown in figure 2(d). The experimental conditions used to perform the trapped field measurements at low temperature is similar to that followed by Durrell et al [8], so only a brief description of the experimental procedure is provided here. The Hall sensors supplied by Lakeshore were uncalibrated and exhibited some nonlinearity and, as a result, it was necessary to characterise each sensor at 100 K. The output voltages of the Hall sensors were measured at the temperature at which the field was applied (i.e. 100 K and below). The YBCO sample-stack temperature was measured using a Cernox® sensor and the sample temperature was controlled and stabilised by employing a wire-wound heater wrapped around the stack. A 22 Hz, 10 μA peak sine wave was used to drive the Hall sensors using a calibrated current source (Keithley 6221), and the Hall probe voltages were measured individually using a lock-in amplifier.

The two-sample stack was magnetised in the bore of an 18 T superconducting magnet (SCM-2) at the National High Magnetic Field Laboratory at Florida State University. The magnetic field was applied by maintaining the sample stack at 100 K, after which the sample arrangement was cooled to the experimental temperature of 28 K. The applied field was then ramped down at a rate of 0.02 T min−1. The relaxation of the magnitude of the trapped field was measured subsequently and continuously at 28 K over a period of about 200 min.

In order to assess the mechanical strength of the two-step BA-TSIG-processed single grain YBCO bulk superconductors, a secondary set of samples of different dimensions (16 mm in diameter and 8 mm in thickness) were grown and their tensile strength was measured by the Brazilian technique [30–32]. The circumferential surfaces of the oxygenated YBCO bulk samples were polished in order to remove any irregularities. The samples were then subjected to mechanical testing by applying a compressive force parallel to the growth sector directions in a tensile testing machine (Instron, model 5584) until a hairline crack formed along the principal axis due to induced tensile stress in the perpendicular direction to that of the applied force [30–32]. The indirect tensile strength σ was then computed from  where P is the applied load on sample when it fractures, and D and t are the diameter and thickness of the sample, respectively.

where P is the applied load on sample when it fractures, and D and t are the diameter and thickness of the sample, respectively.

3. Results and discussion

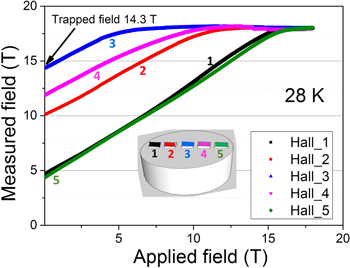

The trapped field measured by the Hall sensors at 28 K at different positions at the centre of the two-sample YBCO stack (see figure 2) as the applied field was removed is shown in figure 3.

Figure 3. The magnitude of the trapped field measured at the centre of the two-sample YBCO stack as the applied field was removed at 28 K. A schematic illustration indicating the position of the five Hall sensors (number 1–5) between the seeded sample surfaces is shown in the inset. A small offset in the position of Hall sensors 2 and 4 with respect to 3 is the cause for the difference observed in the trapped field.

Download figure:

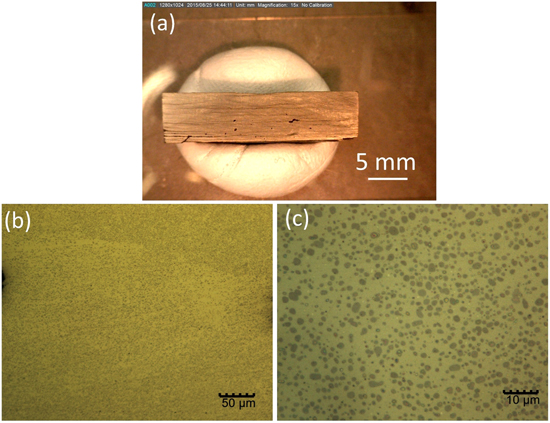

Standard image High-resolution imageIt can be seen from figure 3 that the two-sample YBCO stack trapped a magnetic field of 14.3 T following the complete removal of the applied field. This is relatively a large trapped field achieved for a Ag-free YBCO sample arrangement with relatively simple reinforcement (i.e. with no resin impregnation etc), obtained by the BA-TSIG technique. It can be noted from figure 3 that there is a notable difference in the trapped field values recorded by Hall sensors 2 and 4. This difference is attributed to a small offset in the position of the Hall sensors (2 and 4 with respect to 3), as shown in figure 2(c). To the best of our knowledge, this value of 14.3 T is the highest magnetic field trapped by simple (Ag-free/resin impregnation-free) (RE)BCO samples fabricated by any processing technique. Attempts to trap large magnetic fields in (RE)BCO bulks have so far been tried only employing samples obtained via melt growth techniques and this is the first attempt to carry out such a study at high fields using infiltration grown samples. Compared to reported values of (i) 7–8 T trapped by Ag-free YBCO stacks, (ii) 11.5 T trapped field in YBCO-Ag sample stack encapsulated and reinforced in steel tubes, (iii) 12.6 T trapped field in YBCO stack encapsulated in epoxy, impregnated in resin and further reinforced in steel tubes, and (iv) 13.3 T trapped field in a stack containing irradiated samples of YBCO with Zn, further reinforced with epoxy filling and resin impregnation [17–19], the present result of 14.3 T achieved in a simple, Ag-free YBCO sample stack shrink-fitted in steel represents a significant improvement. It is very encouraging, in particular, that samples that exhibit homogeneous and dense microstructures, as illustrated in figure 4, are able to trap such a large field of 14.3 T at 28 K and further with no cracking. Further work is in progress to fabricate and measure the trapped field abilities of GdBCO-Ag bulks obtained via the two-step BA-TSIG technique.

Figure 4. (a) Transverse cross-section of an YBCO sample fabricated by the two-step BA-TSIG technique. The growth-sector boundaries can also be seen. (b) and (c) show optical micrographs obtained under low (500×) and high (1000×) magnifications. It can be seen that the porosity is very low in the TSIG-processed samples and the distribution of Y-211 particles is homogeneous within the Y-123 phase matrix, in contrast to the microstructures of samples fabricated by TSMG [14, 15].

Download figure:

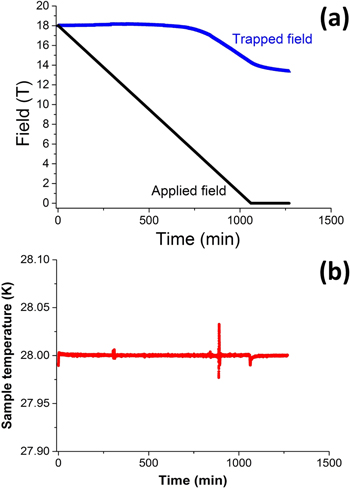

Standard image High-resolution imageThe two-step BA-TSIG in comparison to conventional TSIG or TSMG has an extra processing step associated with it, however, this makes the fabrication of single-grain (RE)BCO bulks greatly reliable with a success rate in excess of 92% as demonstrated elsewhere [20, 28]. Though the TSIG processed samples need extra oxygenation time in comparison to the TSMG-processed counterparts, due to their dense microstructure, they exhibit superior superconducting and mechanical properties and hence are attractive from an applications perspective. In the present study, the YBCO two-sample stack was not successful in trapping the full magnitude of the applied field (18 T), although no significant temperature rise was observed as the field was removed. This could be attributed potentially to either flux creep or to an intrinsic property of the sample (limited, for example, by current density, defects/inhomogeneity or incomplete oxygenation), which would account for incomplete trapping of the applied field.

The trapped fields measured at different positions (as indicated in the inset of figure 3) of the two-sample stack as the applied field was removed following magnetisation in the range 18 to 0 T at 28 K are shown in figure 5. The trapped field in the YBCO sample stack, as measured with respect to time, while the applied external magnetic field was removed, can be seen in figure 6(a). The sample arrangement did not undergo any dramatic temperature rise when the applied field was removed completely, as shown in figure 6(b).

Figure 5. Magnetic field trapped in the two-sample YBCO stack at 28 K as applied field was removed from 18 T. The lines drawn are a guide to the eye.

Download figure:

Standard image High-resolution imageFigure 6. (a) Applied (black curve) and trapped (blue curve, online) magnetic fields and (b) sample temperature measured as a function of time during removal of the field after field cooling of the two-sample YBCO stack at 28 K.

Download figure:

Standard image High-resolution imageThe Brazilian technique was used to characterise the mechanical properties of the YBCO bulk single grains grown by BA-TSIG at room temperature to determine whether the dense microstructure associated with this process (i.e. containing characteristically reduced porosity and cracks) led directly to an increased material strength. The results of this indirect test of tensile strength, as carried out on complete YBCO cylindrical bulk samples, are shown in figure 7, from which it can be seen that YBCO single grains processed by BA-TSIG exhibit enhanced tensile strength (∼24 MPa) compared to those fabricated by conventional TSMG (which exhibited a value of ∼19 MPa at room temperature).

Figure 7. Tensile strength 'σ' measured for the TSMG (black curve) and TSIG (curve in red colour, online) processed YBCO bulk single grains using the Brazilian technique [30–32].

Download figure:

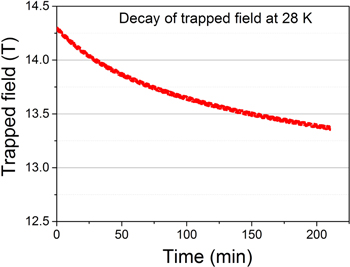

Standard image High-resolution imageThe time dependence of the trapped field (and hence the relaxation of magnetisation) of the two-sample YBCO stack at 28 K was measured, as shown in figure 8. It can be seen that the stack retained a field in excess of 13.4 T for at least 200 min at 28 K following the removal of the applied field. Once the applied field was removed, and after the inevitable initial re-distribution of magnetic flux, the trapped field started decaying slowly, as shown in figure 8, due to the effect of flux creep [33–38]. Flux creep is a well-known phenomenon in superconducting materials [33–38]. Large Lorentz forces are generated typically when large magnetic fields are applied to superconducting samples, resulting frequently in flux creep, which affects the net magnetisation. Flux creep itself is caused by the thermal activation and associated hopping of fluxons between adjacent pinning sites, and is particularly pronounced when large magnetic fields are applied to superconducting samples.

Figure 8. Decay of trapped field at 28 K with time in the two-sample stack of BA-TSIG YBCO.

Download figure:

Standard image High-resolution image4. Conclusions

We have shown that single grain YBCO superconductors fabricated by a two-step BA-TSIG technique, in the two-sample stack configuration, are able to trap large magnetic fields of up to 14.3 T at 28 K, which are almost as large as those generated by samples containing Ag processed via conventional melt growth techniques. The higher field trapping ability of samples prepared by the BA-TSIG technique (in comparison to the ones produced by conventional TSMG) is attributed directly to the reduced density of cracks and imperfections in the microstructure of these samples and the associated improvement in critical current density resulting from the recently developed two-step BA-TSIG process. The fact that the two-step BA-TSIG technique is enabling single grain bulk (RE)BCO sample production with a success rate better than 92% is promising and even further, the products by this technique exhibiting a dense and homogenous microstructure enabling improvement in both the mechanical and superconducting properties is greatly encouraging from applications perspective. In addition, the elimination of the need to add Ag to the single grain precursor composition, as in the present work, reduces the cost and increases the reliability of producing bulk (RE)BCO samples for high field applications. We anticipate that the marginally lower in-field performance (compared to record trapped fields) may well be fully compensated by the reduction of the cost of raw materials should applications of these technologically important materials become widespread.

Acknowledgments

This work was supported by Engineering and Physical Sciences Research Council (EPSRC, grant number EP/P00962X/1) and by the King Abdulaziz City for Science and Technology 'KACST'. Mark Ainslie would like to acknowledge financial support from an EPSRC Early Career Fellowship EP/P020313/1. Part of this work was performed at the National High Magnetic Field Laboratory, which is supported by National Science Foundation Cooperative Agreement no. DMR-1157490, the State of Florida. Tomáš Hlásek and Jan Plecháček of CAN Superconductors are acknowledged for getting some of the YBCO bulks machined which enabled mechanical property measurements. Additional data related to this publication is available at https://doi.org/10.17863/CAM.24728, in the University of Cambridge data repository. All other data accompanying this publication are available directly within the publication.