Abstract

Digital twins (DTs) have witnessed a paramount increase in applications in multidisciplinary engineering systems. With advancements in structural health monitoring (SHM) methods and implementations, DT-based maintenance and operation stages have been implemented significantly during the life cycle of civil infrastructure. Recent literature has started laying the building blocks for incorporating the concept of DTs with SHM of large-scale civil infrastructure. This paper undertakes a systematic literature review of studies on DT-related applications for SHM of civil structures. It classifies the articles based on thematic case studies: transportation infrastructure (i.e. bridges, tunnels, roads, and pavements), buildings, off-shore marine infrastructure and wind turbines, and other civil engineering systems. The proposed review is further uniquely sub-classified using diverse modeling approaches such as building information modeling, finite element modeling, 3D representation, and surrogate and hybrid modeling used in DT implementations. This paper is solely focused on applications relating DTs to SHM practices for various civil engineering infrastructures, hence highlighting its novelty over previous reviews. Gaps and limitations emerging from the systematic review are presented, followed by articulating future research directions and key conclusions.

Export citation and abstract BibTeX RIS

Original content from this work may be used under the terms of the Creative Commons Attribution 4.0 license. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

1. Introduction

In recent decades, structural health monitoring (SHM) has witnessed remarkable technological development in the field of infrastructure management and maintenance. In context, SHM refers to continuously or periodically assessing and monitoring the condition and performance of structures such as buildings, bridges, dams, and other infrastructure systems. It involves the use of various sensing technologies, data acquisition systems, and analysis techniques to detect and evaluate potential damage, deterioration, or changes in the structural integrity of these systems (He et al 2022). With the advent of next-generation sensing and visualization technologies (Sony et al 2019, Sadhu et al 2023), various SHM technologies, including optical fiber sensors, global positioning systems (GPSs), image processing techniques, radars, microelectromechanical systems, and accelerometers (Wang et al 2014) have evolved into vision-based non-contact sensors such as mobile sensors, unmanned vehicles, lidars, augmented reality, and high-speed cameras (AlHamaydeh and Ghazal Aswad 2022, Kaartinen et al 2022, Ranyal et al 2022, Awadallah and Sadhu 2023) to ameliorate the process of data acquisition. Research in SHM has intersected with various computer vision and artificial intelligence (AI) techniques (Smarsly and Hartmann 2007, Sun et al 2020, Sony et al 2021, Dunphy et al 2022, Zinno et al 2022, Zhao et al 2022b, Ranyal et al 2023, Samudra et al 2023), including machine learning (ML) and deep learning (DL) methods. In particular, DL applications deal with less human interaction as DL eliminates manual feature extraction with multiple computational layers between the input and output feed (Azimi et al 2020). Industry 3.0 has, therefore, proven to be a significant development in automation, computation, and robotics in SHM.

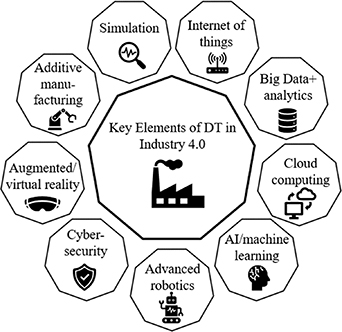

Nevertheless, the world has witnessed an unprecedented evolution in the past decade, crossing the gates leading to the Fourth Industrial Revolution. Computers and robotics evolved into smart machines that autonomously exchanged information and controlled each other independently. Industry 4.0 revolves around cyber-physical systems (CPSs) that are designed to interact and communicate with the physical environment (Lu 2017, Sakr and Sadhu 2023). They collect data through sensors, process it using computational algorithms, and take actions through actuators. CPS relies on the seamless integration of hardware, software, and networked communication to enable efficient and intelligent control and monitoring of physical systems (Legatiuk et al 2017). Figure 1 represents the elements that define the industry's advancements from internet-of-things (IoT) technology, cloud computing, Big Data, etc.

Figure 1. Key elements in Industry 4.0.

Download figure:

Standard image High-resolution image1.1. Overview of DT

Within a CPS framework, a DT serves as a virtual representation of a physical system, capturing its characteristics, behavior, and state in a digital format (Batty 2018). Until now, a unified consensus around the definition of a DT has been absent due to its multidisciplinary fields of implementation. However, some popular definitions exist, such as the one explained by Glaessgen and Stargel (2012): 'an integrated multiscale, multi-physics probabilistic simulation of a complex product that uses the best available physical model and sensing information to mirror the information of its physical twin'. Reifsnider and Majumdar (2013) explained DT as a 'high-fidelity simulation integrated with an onboard facility management system, maintenance log, and historical vehicle and aircraft fleet data'. A DT includes three main components: physical information, digital information, and data exchange between them. Unlike a digital model or a digital shadow, the data in DT is characterized by its two-way directional flow. A digital model is only attributed to the manual exchange of data and does not portray the real-time conditions of a physical structure.

In general, 'real-time' refers to the ability of the DT to provide instantaneous and up-to-date insights into the structural integrity of a physical system. This entails a synchronization of data acquisition, processing, and decision-making on a timescale that is sufficiently rapid to address potential structural issues promptly. In practical terms, 'real-time' implies continuous, high-frequency monitoring of the physical structure, with minimal latency in the transmission and processing of sensor data within the DT platform. Optimally, the DT must swiftly assimilate incoming information, update its model to accurately reflect the current state of the structure, and deliver actionable insights within a timeframe critical for making timely decisions. Therefore, a delicate balance between the timescales of data acquisition, the underlying processes and phenomena that the model in the twin describes, and the urgency of decision-making most influence the real-time characteristic. DT-based SHM implementation, thus, surpasses traditional approaches by offering real-time insights through accurate virtual replicas, facilitating predictive analytics and maintenance. Integrated with key elements of the Fourth Industrial Revolution, DTs provide comprehensive information on structural conditions, enabling remote monitoring and control. This leads to cost efficiencies by optimizing maintenance schedules and supporting data-driven decision-making. The detailed models and continuous monitoring contribute to accurate simulations, improving the overall understanding of structural behavior. In essence, DTs enhance the efficiency, accuracy, and proactive management of structural health compared to conventional monitoring methods, formulating the motive of this review.

From the perspective of civil engineering, this paper generates a description of a DT for an SHM application based on the accumulated literature implementations. A DT is a virtual real-time representation of the physical structure's past, current, and prospective behavior under exterior loading conditions while considering the structure's integrity and structural characteristics in the addressed period of study. For achieving a fully functional DT, a series of components are present in its framework of development, as represented in figure 2.

Figure 2. Framework of DT implementation in SHM.

Download figure:

Standard image High-resolution imageIoT highly contributes to the development of a DT for its ability to network internet-connected devices such as sensors to measure continuous real-time data from physical elements. In IoT ecosystems, a plethora of communication protocols exist. To state a few, transmission control protocol/internet protocol (TCP/IP) (Shang 2016), for example, ensures reliable connectivity, while Message queuing telemetry transport (MQTT) (Singh et al 2015) offers a lightweight and efficient publish-subscribe model. Representational state transfer (REST) application programming interfaces (APIs) (Garg and Dave 2019) offer a web-based architecture, and hypertext transfer protocol/hypertext transfer protocol secure (HTTP/HTTPS) (Da Cruz et al 2019) provide standardized protocols for data transfer over the internet, enabling seamless interaction between interconnected devices. The data is stored in data hubs prior to sending the vast amounts of information to a cloud server allowing the preprocessing and querying of data securely in the early phases of data transmittal (Lea and Blackstock 2014). Data security plays an important role in the protection of sensitive data from being lost or vulnerable to cyber-attacks (Sharma et al 2022). A meticulous selection process of suitable communication protocols is therefore needed. In the cloud server, the data undertakes various forms of processing from data learning processes using ML techniques such as DL (Bruno et al 2018), support vector machines (SVMs) (Liu et al 2020), neural networks (Kwon et al 2021), etc or condition-based assessments (Scianna et al 2022). ML is a subset of AI technology that is fed with input data to accurately predict an output. It aids in forecasting the behavior of physical information based on its current or historic state. For building the DT's base repository of data, multiple models are present to aid in accumulating the information required for achieving the end platform. The models, explained further in the following section, portray a crucial role in representing the structure's behavior, static physical attributes (geometry, material, and structural properties), and real-time sensory data. Finally, the product is projected to a visualization interface such as web-browsers, augmented reality (AR) applications, and software applications supporting 3D model visualizations. The user interface generates warnings, preventive maintenance, and predictive maintenance strategies to support the decision-making process toward the physical structure's necessities.

1.2. Background of repository base models for DT

A plethora of modeling approaches exist in the literature, driving the development of DTs. To state some, this section categorizes the diverse techniques implemented to serve DT-based SHM applications. For example, physics-driven modeling is another technique used to simulate and predict the behavior of physical systems based on fundamental physical principles and equations. It involves developing mathematical models that describe the relationships between different variables and parameters of the system. The physics-based models used in DT can be developed using various techniques, such as finite element modeling (FEM), or other numerical methods generated from advanced structural dynamics, such as state-space models (Kim et al 2023). FEM discretizes the system into a mesh composed of finite elements (FEs). It can predict how the system will respond to various inputs of structural characteristics. This prediction is crucial for the DT to simulate the behavior of the real-world system. Data-based models are other models that leverage available data from sensors, monitoring systems, historical records, or other sources to represent the behavior and characteristics of the physical system (Qi et al 2021). By analyzing and processing the data, data-based models can capture the patterns, correlations, and relationships to create a virtual representation of the system in the DT. Some common approaches to developing such models include ML algorithms (such as regression, classification, or clustering), statistical modeling, time series analysis, or artificial neural networks (ANNs). Wang et al (2023), for instance, utilized real-time numerical simulations, FEM updating, and DL for a DT-based SHM application.

On that note, recent research applications explore physics-guided ML techniques for SHM (Rizvi and Abbas 2023). The integration of both models brings DT's behavior closer to its real-life counterpart since reaching an accurate representation of real-life conditions while using single modeling techniques separately for complex infrastructure is unachievable. The combination of both data-driven information and physics-based models involves incorporating real-world data into the simulation to refine the model's predictions. It minimizes the inaccuracies from simplified and assumed mathematical models originating from traditional physics-based modeling. For example, Yin et al (2023) have recently explored physics-guided convolution neural networks (CNNs), while (De N Santos et al 2023) relied on ANNs. The process ameliorates damage identification accuracy with uncertainties in the developed numerical model. The accuracy was substantially improved compared to previous traditional ML approaches.

Surrogate models are additional simplified mathematical or statistical models that approximate the behavior of complex systems or processes using data-based approaches (Bárkányi et al 2021). They are introduced as a substitute when the physics of a structure is not fully understood. Physics-driven models are sometimes computationally expensive and time-consuming to obtain for complex systems. Therefore, surrogate models are constructed by training the model using the available input–output data obtained from simulations, experiments, or other sources. They aim to balance computational efficiency and reasonable accuracy.

Building information modeling (BIM) has emerged as a powerful tool for enhancing project quality, reducing costs, and increasing productivity (Azhar et al 2008). With the aid of BIM, data coordination is thus made easier through the collaboration of different disciplines under one single platform. In BIM-based SHM applications, Theiler and Smarsly (2018), among many others, explained the importance of a common semantic description for a structure's lifecycle operation and maintenance phases. The Industry Foundation Class (IFC) schema was developed to ensure interoperability between BIM (Laakso and Kiviniemi 2012). The IFC file format is a semantic approach that relies on an 'Entity-Relationship' concept where physical and virtual elements are linked to their corresponding attributes. Due to the presence of common definitions and attributes for both BIM and DTs, there exists some ambiguity around the distinction between the two concepts. As articulated by Deng et al (2021) and Opoku et al (2022), BIM deals with a structure's static information, while DTs are real-time representations of physical information. BIM is an effective tool for DT application for its rich data-fed models along with incorporating wireless sensor networks, data analytics, and ML to support the development of DTs in the construction industry. The relationship between both terms is shown in figure 3.

Figure 3. BIM forming the core of DT for SHM.

Download figure:

Standard image High-resolution imageOn another side of the spectrum, various methods such as 3D scanning, photogrammetry, laser scanning, or computer-aided designs (CAD) modeling are used in the literature to generate a 3D model of the physical structure. These models are isolated from previously mentioned modeling techniques for their use of schemas incompatible with BIM software and data querying procedures presented by the IFC. Open-source toolkits and game engines are tools adopted for modeling such models. Other models can include geographic information systems (GISs), which represents a technology that involves capturing, managing, analyzing, and visualizing spatial or geographic data of the structure and its environment (Park and Yang 2020).

The DT's leverage over the functions of the standalone modeling approaches is key for SHM applications. The real-time data and model updating characteristics drive the decision-making process and boost the inspection and maintenance processes with reduced human intervention and error. The real-time experience that DTs provide is absent in present modeling approaches (Bárkányi et al 2021), however, the power of such data-rich base models is harnessed to achieve final DT platforms. This paper, therefore, articulates all DT applications that are built on BIM, FEM, GIS, surrogate models, physics-driven models, data-driven models, mathematical models, and 3D models.

1.3. Existing review articles in DT

In the literature, there has been extensive research in DTs across many fields of study, such as aerospace, healthcare, education, smart cities, construction, manufacturing, automotive, energy, agriculture, and more (de Freitas Bello et al 2021, Singh et al 2022). DTs, in the perspective of civil engineering, are still considered in their stages of infancy. Moreover, SHM information has faced impediments when linked with a DT model to finally attain an automated real-time monitoring framework. The literature, therefore, demands a state-of-the-art systematic review of technical case implementations serving the development of DTs for SHM-based applications.

This section articulates existing review papers on DTs to depict the novelty of the current review paper. For example, several review papers exist regarding DT applications; however, they do not tackle the essence of SHM-oriented DT applications alone. Sharma et al (2020) shed light on the essential and elementary components of DTs and their leverage over existing technologies. The power of ML and Big Data in DT applications was highlighted, and its efficient use in multiple industries was demonstrated. Cao et al (2020) highlighted the efficiency of integrating IoT technology in improving the structural monitoring process by reviewing a series of applications. The study explored BIM applications and importance over the years and classified its maturity levels into four phases. Wang et al (2021) accumulated the DT studies revolving around off-shore wind turbines. Hämäläinen (2021) proposed a qualitative research methodology to explore the modern concept of DTs in smart city implementations. The importance and efficiency of CityGML used in Helsinki, which stored and exchanged multiple virtual 3D city models, was highlighted while stating its concluding benefits. Shahzad et al (2022) presented fields of implementing DTs in a real-life environment. They highlighted the use of DTs in smart cities, decision-making applications, manufacturing, facility management, and monitoring construction progress. Salem and Dragomir (2022) proposed a framework for developing a state-of-the-art literature review for DTs used in construction management. DT applications were classified based on their use of BIM, their use of existing monitoring technologies, and their use of AI. Pregnolato et al (2022) represented case studies of DT for multiple orientations over the whole architecture, engineering and construction (AEC) sector. Opoku et al (2022) concentrated on highlighting the motifs for adopting DT concepts, while Jones et al (2020) focused on representing the general characteristics of a DT.

Other recent existing review papers were more inclined toward SHM-oriented DT applications. The review developed by Hosamo et al (2022) specifically focused on studies that implemented 3D laser scanning for DT applications. The studies were classified into four categories: ML, bridge management system (BMS), bridge information modeling (BrIM), and 3D modeling. Saback et al (2022) reviewed the studies that integrated BIM for DT applications regarding the asset management of concrete bridges. The article divided studies into four themes: bridge inspection, BIM, DTs, and BMS. The key properties of creating a DT for BMS were highlighted, and the role of the IFC to manage and query data in a shareable file format was stressed. Hosamo et al (2022) proposed a literature review for DT applications in all of the AEC-facility management (FM) industry. Li et al (2022) discussed the implementation of advanced information technologies in phases of construction and maintenance of infrastructure. Zabin et al (2021) focused on finding papers that implemented ML techniques to data extracted from a BIM-based project. The fields of applications varied from all general stages of design, construction, operation and maintenance, and other areas related to safety, evacuation, and disaster management. Bado et al (2022) published an exploratory review regarding distributed sensing updating for creating a DT in civil engineering. The motifs of their use, the methodology for creating a DT, and the importance of distributed optical fiber sensing on DTs were highlighted throughout the review.

Previous related literature reviews of DTs have, therefore, dealt with general DT applications in multiple industries, tackled general stages of the structure's lifecycle, focused on specific types of infrastructures, and considered only specific technologies such as BIM, laser scanning, fiber optics, etc. This unprecedented review paper specifically reviews the state-of-the-art studies relating to the development of DTs for SHM for a wide range of civil engineering infrastructure. In addition, this paper extended to encapsulate all technologies used in DT-based SHM applications. Applications that incorporated the data repositories used (BIM, FEM, surrogate models, GIS, 3D representations), IoT, AI, and diverse types of sensory devices were all considered as part of the systematic review instead of focusing on one specific technology. This review, therefore, assembles the required studies for achieving prosperity in the field of SHM in civil engineering. As a result, the current systematic review provides the users with the outcome of experiencing the literature's use of technologies, their efficiency, and the attributes obstructing the creation of a fully developed DT for SHM.

Given the plethora of models used to accumulate DT-compatible information in the literature, the articles collected are classified thematically based on the types of data repositories used for building DT-based SHM applications. In the case of achieving DTs, the methods adopted to process acquired data are crucial in the framework. In the end, DT aims to twin the physical structure with the least uncertainty, computing power, and processing duration. Therefore, the entire methodology is highly sensitive to the type of data processing chosen. On that account, a corresponding table is generated to encapsulate the key data collection types and techniques along with the type of analysis used in the framework at the end of each section. The proposed categorization will help the readers to easily pinpoint the case study of interest by navigating to the corresponding section dealing with that specific type of infrastructure from all relevant papers' findings.

2. The proposed literature survey methodology

The search for technical papers occurs through manual stages of screening. The first step incorporates the retrieval of papers from academic and non-academic online databases: Elsevier, ASCE library, IEEE Xplore, Scopus, and Google Scholar. Keywords are used together in multiple combinations to gather 312 accessible articles. The combinations of the keywords include 'DT and SHM' 'DT and Civil Engineering and SHM' 'DT and bridges or buildings or structures' and 'BIM or surrogate or FEM or 3D models or model twinning and SHM'. The articles are then passed into three levels of filtering.

Level 1: this level of filtering accumulates all the obtained papers and disregards the applications outside the civil engineering industry. Examples of such disregarded DT applications include studies in the fields of manufacturing, aerospace, education, health, and other multidisciplinary fields that also include SHM as a technical word in their discipline. A total of 267 papers are retained at this level.

Level 2: at this level of filtering, the keyword 'civil engineering' in specific combinations accumulated results from various phases of a structure's lifecycle and for multiple purposes outside the scope of SHM. Therefore, the DT applications that include environmental, sustainability, traffic management, construction planning, workers' safety, and other orientations are disregarded. A total of 183 papers are retained at this level.

Level 3: this level of filtering refines the results of level 2. Some specific model-based SHM applications that neglect to incorporate the keyword 'DT' in their study are still included in this review. These specific studies successfully incorporate real-time data with a BIM database and, therefore, act as the fundamental motive needed to reach a DT implementation. These applications surpass the level of BIM in construction phases or sole numerical model development as they include dynamic sensory data for SHM purposes, one crucial component of DT characteristics. Other results that fail to represent DT characteristics and focus on modeling approaches solely without an SHM purpose were disregarded.

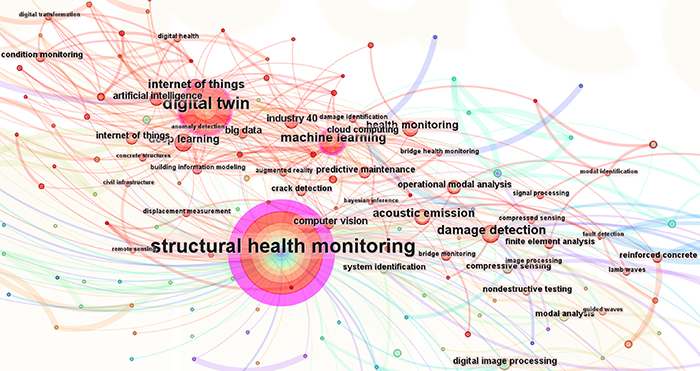

Finally, 97 remaining articles are classified systematically into four separate sections based on their type of infrastructure applications. Transportation infrastructure (i.e. bridges, tunnels, roads, and pavements), buildings, off-shore marine structures and wind turbines, and other structural or non-structural elements are the themes of each section. Figure 4 represents the flowchart of the filtering levels. Articles are subsequently cross-linked based on their use of modeling approach to serve DT platforms in each section and are reviewed chronologically. By the Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA)'s flow diagram (Page et al 2021), the proposed literature survey methodology provides a comprehensive visualization of the phases involved in identifying, screening, and including/excluding studies at each stage of the review. Starting with the initial identification of records through the database search, the process delineates the systematic progression of study selection, screening, eligibility assessment, and inclusion in the final analysis. Following the PRISMA flow diagram not only guarantees transparency in the selection process but also highlights a dedication to methodological accuracy and a clear synthesis of evidence in this systematic review. Using the CiteSpace software (MSEd et al 2005), a link between redundant keywords in the literature has been represented in figure 5. This figure concludes the growing interest in DTs and SHM applications while accompanied by multiple technological advancements in fields such as ML, DL, and IoT.

Figure 4. Flowchart of the proposed systematic literature search.

Download figure:

Standard image High-resolution imageFigure 5. Relationship between recurring keywords in the literature.

Download figure:

Standard image High-resolution image3. Systematic literature review of DT-based SHM

This section presents the classification of articles based on thematic case studies and technical research articles. The reviewed articles are then grouped as applications contributing to DTs for SHM. The studies are categorized as applications involving transportation infrastructures, building structures, offshore marine structures and wind turbines, and other civil engineering elements and assets. Within each section, the articles are accumulated under umbrellas dealing with the type of modeling approach to serve DT-based SHM applications.

3.1. DT applications involving transportation infrastructure

3.1.1. Bridges and tunnels

3.1.1.1. BIM approaches.

McGuire et al (2016) illustrated the effectiveness of BIM for bridge inspection and evaluation. A damage location tool (DLT) was used to locate the level and volume of damage on a certain element. Subsequently, knowledge (e.g. cross-section geometry and damage locations) generated from the DLT was used to fuel a damage evaluation tool. Based on the evaluation, the worst-case damage modes of certain elements were identified. Delgado et al (2016) (Davila Delgado et al 2017) explored the management of structural data using BIM. The authors extended the IFC schema to model the monitoring system and incorporate the sensor data into the defined property sets. Revit was used in this study to build the system since APIs aided in importing text files and spreadsheets. Data was then visualized directly from the BIM model, converting it from a static to a dynamic system to monitor the performance of the bridge. Davila Delgado et al (2018) ameliorated the user experience by creating an enhanced interactive model for the interpretation and management of data-driven SHM information directly at the BIM level using an automated parametric modeling approach. Grosso et al (2017) presented a framework for SHM using the BIM platform. The authors aimed to use system identification and model updating of a bridge modeled in Revit. Families defining sensors were created in Revit as a means of locating the sensors' location/orientation and linking external data sources such as Excel data or from other databases. BIM One, Navisworks, and Dynamo were tools used for data linking, visualization, and automating the transfer, respectively.

The study by Banfi et al (2017) utilized laser scanning and photogrammetry were used to build the as-built model and its irregularities. Geometric leveling was also applied to study the vertical deformation of the bridge under testing load. Many documents were stored as HTML files, and Autodesk A360 allowed stakeholders to visualize the data in real-time. The framework proved its efficiency in tracking SHM data among many parties using BIM. Lu and Brilakis (2019) proposed a slicing-based object-fitting method that concentrated on creating a geometric DT (gDT) of a bridge infrastructure using four types of labeled point clusters for IFC-compatible models. Jang et al (2021) proposed a web-based platform for the lifecycle management of infrastructure using BIM. The digital platform contained five critical milestones: the planning and design of the BIM model, 4D/5D construction management and monitoring using BIM, the use of unmanned devices for data collection (scan-to-BIM), health assessment using DL, and the periodic assessment of the damage and health of the structure. The authors highlighted the use of a web-based BIM platform for ease of access. Kwon et al (2021) proposed a framework for anomaly detection of a bridge structure while integrating BIM in the process. An ANN model was fed data based on a unique sensor ID from a large database containing GPS, acceleration, temperature, and earthquake datasets. The study showed low predictability levels for irregular changes in the applied load while proving effective for predicting normal behavior.

Scianna et al (2022) focused on linking BIM with IoT technology, such as sensors for real-time monitoring. The authors illustrated a case study of a lab schematic where they mounted a distance sensor to a structural frame and linked it to its relative BIM model. The methodology followed a scheme that included collecting sensor data, storing it in a remote server, and implementing an AI algorithm to detect if the beam deflects outside the limits using ML. Li et al (2021) proposed a method for SHM using a BIM platform to integrate sensor information with diagnostic results. The BIM model was established in Revit and extended to an IFC file format where sensor information and attributes were organized. The collected bridge data was queried, managed, and visualized using a plug-in that was developed with a Revit API through Visual Studio.

3.1.1.2. Physics-based and surrogate modeling approaches.

Ye et al (2020) explored the capabilities of a DT for bridge evaluation of a multi-girder steel stringer test bridge. Ambient and forced vibrations were implemented on the bridge, and five different teams estimated modal parameters, such as natural frequencies and mode shapes, through the measured data. In addition, controlled load testing was executed using three load stage levels to generate displacement profiles. The experimental data were used to update and calibrate the FE models both manually and automatically. Febrianto et al (2021) explored the ability to create a DT for a railway bridge using the statistical FE method (statFEM). The study aimed to converge the FE strains and the true data strains. The statFEM thus permitted the use of both physics-based and data-based models. The convergence was intended to be reached under a minimum number of collected data possible from fiber optic-based sensors. The authors proved the efficiency of collected strain data in improving mean strain estimates. Lin et al (2021) proposed a DT framework for the fragility assessment of a long-span cable-stayed bridge. FEM models were used for calculating the collapse fragility curves of the bridge by incremental dynamic analysis (IDA). The study highlighted the importance of nonlinear updating of the FEM in DT applications for improved accuracy.

Dan et al (2021) proposed a DT application fed from machine vision of bridge traffic load monitoring. They use weigh-in-motion (WIM) systems that are implanted in the pavement of both ends of the bridge to monitor the full-bridge traffic loads. Video images and LiDAR were used to capture vehicle positions while WIM obtained the vehicle weight and axle load data. Depending on the type of mechanical analysis, different modeling technologies, and DT models were proposed. They projected the traffic load monitoring data on three analysis cases of DT models. The models proved efficient in overturning early warning, decreasing analysis times, safety early warning, and long-term structural and statistical evaluation under steady-state traffic. Wenner et al (2021) developed a DT for bridge maintenance. BIM enabled the visualization of integrated real-time properties along with structural classification, and IoT technology transferred the data to the system through Wi-Fi connections. The users finally developed a human–machine interface for the visualization and navigation of the DT platform. Nguyen et al (2022) created a DT system for the maintenance of a bridge using mixed-reality technology. Azure IoT hub and Azure SignIR service were used to connect the dynamic data with BIM, while Unity 3D was used to link the DT with mixed-reality technology. The DT allowed users to visualize inspection data, analyze structural performance, and predict future performance. Kang et al (2021) for instance, utilized surrogate modeling (SM). They proposed a multimedia knowledge-based framework for bridge health monitoring using a hypothetical simulation-based modeling approach dependent on initial structural characteristics. They tested their framework on a case study where they compared the accuracy of their DT model with the physical information and found a minimal percentage of relative error.

3.1.1.3. Hybrid modeling approaches.

In the literature, the integration of both BIM and FEM approaches as data repositories has proven efficient in dynamic data enrichment. For example, Marzouk and Hisham (2012) presented a BrIM model for the structural assessment of bridges. The framework included the creation of a database that incorporated the properties of bridge components and elements with inspection logs. The evaluation of bridge condition was performed by simulating incremental loading on the bridge and finding the load factor. The corrosion of steel members was modeled in the 3D BrIM model and then exported to ANSYS for analysis and simulation. Jeong et al (2016, 2017) proposed a method for managing the SHM data of a bridge using not only SQL (NoSQL) database systems. The OpenBrIM data schema was utilized to represent the bridge model and SensorML to store sensor information in the main server. First, the sensor data was sent to the onsite computers for preliminary data storage before reaching the main server. The BrIM model was exported using CSiBridge as an FEM. In addition, the Gaussian process (GP) was used to predict the change in bridge behavior against temperature variations. Finally, a prototype IOS app was used for visualizing data from the main server at the user interface level.

Dang et al (2018) explored the creation of a DT for bridge maintenance. The object's 'attribute' contained all physical data, such as the geometry and material of the object, while the object's 'archive' contained info related to inspection and damage data. Using an API that integrated work between CAD and programming language, the authors proposed a photographic mapping concept for creating the DT model. Shim et al (2019) proposed a framework for bridge maintenance using a 3D DT model. The study focused on establishing a federated model that contained the historical data of the bridge and the as-built physical geometry of the physical structure. Bridge alignment, parametric modeling, 3D scanning, and Reverse Engineering were also considered for building the DT model. The federated DT model was linked with an interoperable finite element analysis (FEA) model for understanding and simulating structural behavior under its current conditions. Boddupalli et al (2019) discussed the fusion of SHM in a BIM environment, converting the traditional static model into a dynamic one. The study used sensors to acquire data off a bridge, and the data was analyzed to find the structural characteristics. When the BIM model was created, the ROBOT plugin was used for analysis and comparison of the FE results. The sensor parameters were created in the BIM model and linked with test data through URLs. Ye et al (2019) explored the process of creating a DT of a bridge infrastructure for SHM purposes. The authors discussed the key advantages and attributes of DTs for bridges which include utilization in visualization, monitoring, assessment, simulation, etc. It included a series of FEM (i.e. physics-based approach), BIM (i.e. real-time sensor data visualization), and statistical modeling (i.e. data-driven approach).

Kaewunruen et al (2021) explored the integration of BIM for a bridge risk inspection model. A data-analysis module contained results from risk inspection, natural hazard risks, and human risks that were integrated with the BIM model. With all the data present inside the BIM model, additional safety values and thresholds were proposed to be applied for generating warnings, thus enhancing risk management at the data-sharing module stage. Gunner et al (2021) proposed a DT for bridge maintenance. The users focused on accurately modeling the bridge elements under study and transformed the FEM results into a wider Python software environment using OpenSeesPy. After deploying the sensory systems on the bridge, the DT was validated by comparing real data with FE data. The DT was able to support the decisions of managers based on monitored threshold values of friction coefficients, achieving acts of preventive maintenance. Zhao et al (2022a) focused on creating a DT for assessing bridge behavior under random traffic movement. A physics-based DT model using load distribution factors and response functions was constructed. Identifying vehicle attributes and configurations (speed, axle number, and axle spacing) was achieved by strain sensor data. The DT aimed at finding responses from random traffic, separating mixed responses from multiple vehicle movements, determining the weight of passing vehicles, and updating real-time distribution factors and influence lines of the bridge. The DT model was validated using field tests and numerical simulations.

Dang et al (2022) proposed a methodology for a cloud-based DT for SHM (cDTSHM), which enabled the ongoing real-time data collection from the physical state to the virtual twin. The approach was then tested on an experimental model and one real bridge. The authors characterized the distinct attributes of the conventional SHM compared to the cDTSHM, highlighting the latter's key properties, such as continuous monitoring, historical data integration, simulation data, and physical entities. Artus and Koch (2022) aimed to create and test a damage information model to transfer damage data between authorized personnel. The semantic data were modeled to create the object-oriented model, and then photos or videos of damage were added. The authors relied on the IFC4 standard for defining the semantic, visual, and geometry data with xBIM Xplorer as its corresponding IFC viewer. Corrosion, cracks, spalling, and holes from drilling samples were visualized in the model through multiple measurements, photos, and geometry. The model was paired with an FEM to highlight the effect of the visualized damage on the elements.

GIS and BIM have also been integrated into a single platform in the literature. For example, Wan et al (2019) proposed a BIM-empowered bridge maintenance system using a GIS. They relied on extending the BIM-compatible schemas to define structural defects, inspection, and evaluation into the attribute set. The model was transformed into a lightweight model and linked with GIS to allow access to maintenance locations and repairs when users logged in via a mobile application. The system triggered warning signals when certain defects exceeded acceptable limits. Sofia et al (2020) proposed a DT framework to monitor and maintain a bridge structure. Dynamic laser scanning was proposed to create the point clouds of the physical structure that thereafter created the BIM model from GIS information. IoT technology and sensor data were proposed to feed ML algorithms for the bridge's damage detection. The DT was then modeled and analyzed based on the prior acquisition of data and levels driving the process of decision-making. Tian et al (2021) discussed the application of BIM technology on bridge infrastructures with a GIS-powered model. The process included reviewing auxiliary drawings, collision checks with the use of Navisworks or BIM, construction simulation, precise calculations, 5D simulation, QR code application, and quality and safety management. Most importantly, the paper emphasized the limitations and gaps of innovative BIM technology integrations. These integrations include BIM in operation and maintenance stages that deal with monitoring data for assessing structural health and damage.

3.1.1.4. 3D representation modeling approaches.

Omer et al (2019) introduced the combination of virtual reality (VR) and LiDAR for implementing inspection works on a masonry bridge. Data was collected by LiDAR stations to create the final point clouds that were imported to Unity. Using a VR headset for visualization, areas of leaching, areas of mortar loss, areas of vegetation, and cracks were detailed and identified in the DT. Furinghetti et al (2019) proposed a cloud-based framework for SHM. It acquired, stored, and post-processed sensor data for better decision-making. The authors linked different layers of data collection based on weak infrastructure points, modal analysis, building a software framework using LabVIEW, and manipulating the data in the cloud. The product created an SHM system for maintenance and damage avoidance. Lu et al (2021) discussed supplying a DT with a solid level of geometric accuracy for SHM. Twinning a structure using point clouds encountered difficulties due to geometric irregularities in as-built structures. The study reviewed existing LOD (e.g. level of development or level of detail) systems and their incompetence in achieving a gDT for SHM purposes. Point clouds and meshes were still limited in capturing non-rigid body deformations. The users, therefore, emphasized the need for a well-developed level of geometric accuracy for DTs created after construction.

Mohammadi et al (2021) proposed a DT point cloud creation based on the comparison of unmanned aerial vehicle photogrammetry and terrestrial laser scanning. Initial steps included bridge surveying, image and laser capturing, and 3D model construction. Point-to-point comparison and cloud-to-cloud distances were applied to evaluate the two methods highlighting the data qualities of each approach. Insa-Iglesias et al (2021) explored a framework for the visual inspection of SHM of a tunnel. A database of maintenance logs was created to evaluate the damage, including its location, type, and severity data collected by drones or other data acquisition systems. A 3D virtual inspector, containing a 3D model with the overlayed damage data, was fused with an analytics interface to permit stakeholders access and interpretation of the defects. Lei et al (2022) proposed a DT for bridge health monitoring under shock and vibration using BIM technology. Hubs and routers transferred the sensor data for preprocessing, analysis, and damage diagnosis using the k-nearest neighbors algorithm (supervised ML). The data was then managed in central database systems until it was sent for visualization at the user interface level. The system exerted an alarm when the load approached allowable limits, resulting in the cease of operations.

Meng et al (2022) portrayed the GeoSHM system used in Scotland to deliver the feasibility of developing a smart and cost-effective sensory network and establishing a successful technique to transfer large quantities of SHM data. The technique dealt with preprocessing raw data, integrating the processed data into a cloud, analyzing the data, and appointing data ownership. The users highlighted the strength of cloud-computing techniques for SHM and the use of DTs with AI technology for bridging the physical and digital worlds. A Bayes-based neural network was successfully used to identify the change in the structural behavior of the bridge. Gürdür Broo et al (2022) presented a DT application for a railway bridge. Fiber-optic, temperature sensor data and zipped files of train information from the local storage were transferred to a Postgre structured query language (SQL) open-source database. In the cloud-based cyber layer, a back-end module was composed of multiple containers working in parallel to achieve certain tasks. A front-end module enabled the interaction between the user and DT, while fast APIs aided in facilitating users' end requests. Table 1 summarizes the specific data collection tools and analysis procedures explored in bridge and tunnel applications related to DT-based SHM.

Table 1. Summary of DT-based SHM studies involving bridges and tunnels.

| Authors | Data collection types | Data analysis types |

|---|---|---|

| Marzouk and Hisham (2012) | Inspection spreadsheets | Structural analysis, FEA, condition assessment |

| McGuire et al (2016) | Damage parameters from inspections | Damage localization and evaluation |

| Jeong et al (2016) | Acceleration, strain, thermistor sensors | Sub-space identification, Gaussian process |

| Delgado et al (2016) | Distributed and point fiber-optic sensors (strain) | Not mentioned |

| Davila Delgado et al (2017) | Distributed and point fiber-optic sensors (strain) | Data management into spreadsheets, calculation of strain changes |

| Davila Delgado et al (2018) | Distributed and point fiber-optic sensors (strain) | Strain calculation, structural analysis |

| Jeong et al (2017) | Acceleration, strain, thermistor sensors | FEA |

| Grosso et al (2017) | Accelerometers | General system identification |

| Banfi et al (2017) | Laser scanning, photogrammetry | Non-uniform rational basis-splines |

| Dang et al (2018) | Structure photographs | Edge detection, image processing |

| Wan et al (2019) | Design and construction information, inspection data | Not mentioned |

| Shim et al (2019) | 3D scanning, photogrammetry, inventory of structural information | Edge detection, image processing/tracing, FEA |

| Boddupalli et al (2019) | Accelerometers, uniaxial vibration sensors | SOBI method, FEA |

| Ye et al (2019) | Fiber Bragg gratings (FBGs), Brillouin optical time-domain reflectometer | Linear dynamic statistical modeling, Gaussian process |

| Lu and Brilakis (2019) | Existing bridge point clouds | IFC object fitting, distance-based, cloud-to-cloud metrics |

| Omer et al (2019) | 3D scanning, LiDAR | Point cloud and image processing |

| Furinghetti et al (2019) | Strain gauges, accelerometers, inclinometers | Time-frequency analysis |

| Sofia et al (2020) | Laser scanning, LiDAR | Cloud point processing, RANSAC |

| Ye et al (2020) | Inspections, wind/radar/fiber-optic sensors | Manual and optimization functions |

| Lu et al (2021) | Laser scanning | Cloud-to-cloud analysis |

| Mohammadi et al (2021) | Photogrammetry, terrestrial laser scanning | Point-to-point comparison, cloud-to-cloud distances |

| Insa-Iglesias et al (2021) | Images | AI algorithms, structural condition marking index |

| Jang et al (2021) | Unmanned robot systems | Convolution neural network (CNN)-based damage classification |

| Febrianto et al (2021) | FBG | Statistical FEA |

| Kaewunruen et al (2021) | Stress/displacement sensors, damage images | SCC-MATS (concrete multifunction detector) |

| Kwon et al (2021) | GPS/acceleration/temperature/ earthquake sensors | ANN, backpropagation |

| Kang et al (2021) | Acceleration data, simulation parameters | Natural frequency extraction, ML |

| Lin et al (2021) | Accelerometers, displacement sensors, transducers | SSI, linear/non-linear model updating, IDA |

| Tian et al (2021) | 3D laser scanning, UAV images | Point cloud model generation |

| Dan et al (2021) | WIM, cameras | Vehicle weight synchro-matching, first image frame module, CNN |

| Gunner et al (2021) | Accelerometers, temperature sensors | Modal analysis via Python |

| Wenner et al (2021) | Inspection data, sensor-based monitoring | Criticality analysis, condition rating by structural analysis, data-based anomaly detection |

| Nguyen et al (2022) | Time-series of damaged records, sensor-based data | Not mentioned |

| Zhao et al (2022a) | Strain sensors, WIM | Calculation of influence lines and distribution factors |

| Meng et al (2022) | GPS, inclinometers, accelerometers, anemometers, thermometers, fiber-optics | Cloud-computing, Bayes-based neural network |

| Dang et al (2022) | Triaxle accelerometers | 1D-CNN |

| Lei et al (2022) | FBG, accelerometers | k-nearest neighbors |

| Scianna et al (2022) | Distance sensor | Threshold value analysis |

| Li et al (2021) | Tension sensors, accelerometers | Wagner–Ville distribution |

| Gürdür Broo et al (2022) | Strain/temperature FBG | Structural analysis, statistical FEA |

| Artus and Koch (2022) | Inspected damage data using text editors, images | Texture-mapping algorithm, geometry-based structural analysis |

| Yin et al (2023) | Uniaxial accelerometers, transducers | FEA, CNN, short-time Fourier transform |

3.1.2. Roads and pavements

Munasinghe and Pasindu (2021) focused on implementing a DT framework for road infrastructure. A data collection module focused on the non-dedicated (i.e. mobile phones) sensing technology by crowdsourcing and then dedicated sensing (permanent setup sensors) further empowered the module. Federated learning that uses mobile edge computing to study a shared prediction model was used in the performance prediction module. The methodology was predicted to enhance maintenance decisions and monitor the structure's performance. The study gave an unoriented focus to the modeling approach used. However other studies explicitly described their use of base models.

3.1.2.1. BIM approaches.

Meža et al (2021) explored a DT implementation for monitoring road performance using secondary raw materials in the road's construction. A 3D BIM model was built using an IFC-compatible modeling tool such as CIVIL3D generated from CAD drawings. Bexel Manager was used to establish the common data environment of all the sensor attributes and the created parametric BIM model or the federated BIM. Color-coded elements were portrayed in the road DT when the users successfully linked time ranges of datasets to the federated BIM model through Bexel Manager add-ins. Oreto et al (2021) explored a BIM-based tool for managing road maintenance. Information from on-site surveys and documentation were filled into Excel sheets and imported into their corresponding property sets in the BIM model with Dynamo. Based on the solutions and constraints available, Dynamo code scripts generated the timing of the needed maintenance, its priority, and the suitable solution on the damage states of color-coded BIM elements. The timing of maintenance was generated by degradation curves from the time series of each condition indicator.

3.1.2.2. Physics-based modeling approach.

The study by Sanfilippo et al (2022) explored the state-of-the-art knowledge of DTs for road infrastructure around the operation, management, and development objectives. They aimed to link the physical twin to the virtual by installing sensors along with the road network, which constantly collected data, or even dispatched mobile sensors on robots and UAVs.

3.1.2.3. 3D representation modeling approaches.

Sierra et al (2022) created a DT for the health monitoring of road pavement. The users adopted a manual collection of images from UAVs to yield the reality model. Real measurements and road defects were acquired and transformed into a central dataset. The study highlighted the accuracy of the proposed method in mirroring pavement deterioration and its cost-effective results over other traditional methods. Table 2 summarizes the specific applications and tools of data collection methods and analysis types that have been explored in road and pavement applications.

Table 2. Summary of DT-based SHM studies involving roads and pavements.

| Authors | Data collection types | Data analysis types |

|---|---|---|

| Munasinghe and Pasindu (2021) | Accelerometers, mobile sensors | Sample-based federated learning |

| Meža et al (2021) | Temperature, displacement, soil moisture, strain sensors, inclinometers, pressure pads | Condensing sample resolutions, key performance indicator extraction, aggregation of monitor readings |

| Sanfilippo et al (2022) | Mobile sensors, robots, UAVs, inspection reports, acoustic emissions, strain, vibrations | General model updating, modal analysis, general ML |

| Oreto et al (2021) | Paper-based documentation, on-site surveys | Threshold value analysis |

| Sierra et al (2022) | UAV images, photogrammetry | Image processing, CNN |

3.2. DT applications involving buildings

3.2.1. BIM approaches.

To reduce human judgments and interventions, Anil et al (2016) represented a BIM approach to assess damage in reinforced concrete walls. They followed a transformation mechanism to convert the data into a static BIM model. The data was a combination of visual assessment and structural analysis integrated with the raw damage data. The outcome was to create a damage model and strength analysis model to determine damage modes and severities of structural walls. Valinejadshoubi et al (2017) also focused on exploring the link between sensor data and the BIM model for SHM purposes. The process enabled the extension of BIM from a static model to a dynamic model by linking the real sensory data for managing information. Theiler et al (2017) proposed a BIM-based method for an SHM system. The authors described the limitation of the IFC schema regarding SHM sensors and proposed an integrated sensor node, sensor networks, and SHM control systems. The study was validated on a lab model prototype of a four-story shear frame structure. Frequencies from the modal analysis were studied, and the nodes, in turn, sent a damage detection signal to the host computer. Bruno et al (2018) proposed a framework structure for assessing the performance and managing the diagnosed information of a historic building using BIM. Primary surveys of drawings and historical records, along with generated point clouds from photogrammetry and 3D laser scanning, were pre-processed and imported to BIM. IoT sensors, UAVs, and other non-destructive testing methods were proven as intelligent technology to monitor and generate metadata.

Valinejadshoubi et al (2019) explored a BIM-based system for SHM for a modular building application. A strain sensor was linked to an Arduino Uno microcontroller, while a Wi-Fi shield system connected the data to the internet. A BIM model was built, including the sensor's parameters linked to a MySQL database. Dynamo automated linking the updated maximum strain value with its corresponding sensor parameter in the BIM model. Based on a threshold value set, the BIM model generated a color-coded alarm signal. Jouan and Hallot (2020) dealt with incorporating heritage BIM with simulation and real-time data toward implementing a DT approach for heritage conservation. The authors were able to publish a set of rules for implementing a DT in the process: the knowledgeable identification of the significant historical elements, the awareness of the potential risks imposed on such elements, and the actual monitoring of the degradation of the key elements. Musella et al (2021) focused on creating a framework for assessing seismic damage using BIM and AI. The processing of damage in images was handled using a CNN to detect the cracks. The BIM model was created using on-site surveys to build its geometry while the attributes of the damage detected by the neural network were stored under 'crack' objects in BIM. Two CNNs were used in the DL method, further trained, and then validated. Based on the vulnerability and these damage states, parametric costs were generated.

Hou et al (2021) explored a framework for SHM based on a WEB-BIM platform and integrated IoT technology to develop a visual pre-warning system based on fiber optic and strain gauge data. A database to store dynamic data was developed to attach sensor data to BIM using the IFC schema and a MySQL database. The framework was able to visualize monitoring data, visualize structural components, identify risk, and automate warnings. Angelosanti et al (2021) applied 3D digital image correlation (DIC), a technique for SHM using a BIM-based methodology on a lab-scale aluminum frame structure. Data from Excel sheets to the corresponding IFC parameters in Revit was imported through Dynamo. Frequency and displacement parameters from the phase-based motion magnification technique were imported for damaged and undamaged modes, and warning alarms were generated when shifts in frequencies or displacements exceeded a certain threshold value. Levine and Spencer (2022) explored the use of UAV imagery, component identification, and damage assessment with an integrated BIM platform. After an initial evaluation of structural analysis, a BIM model was built from the as-built structure, focusing on the sensitive components. A UAV survey generated a 3D point cloud of the structure using Reality Capture software and imported it to Python using Open3D. The BIM and the point cloud were imported to CloudCompare where a root-mean-square between corresponding points was estimated. At this level, BIM was used to select the images containing the sensitive components, and GrabCut was used for component identification.

3.2.2. Physics-based modeling approaches.

Wagg et al (2020) used a small-scale three-story structure to show a DT's construction as a case study. The authors argued that the DT is considered from the simulation stage, then learning and management follow for a higher-level DT. Using a case study, they applied system identification to find the model parameters of a non-linearly behaved model. After training, the users predicted where no bumper contact was present based on standard deviation. The DT was thus able to detect the presence of uncertainty. Gardner et al (2020) explored the ability of a DT to target predictive maintenance using physics-based and data-based models. The study's main objectives were better estimating model parameters, adding/updating a data-based component to model unknown physics, and adding additional physics-based modeling to the DT. To study harsh linearity behavior, a GP regressor was coupled with the physics-based model to improve predictive maintenance. An active learning approach was used, along with the measured uncertainty, to update the data-based components based on observations from stream-based active learning. Hybrid testing isolated a component or sub-assembly of interest to test the physical component under real dynamic conditions, and to identify new physics. Chiachío et al (2022) proposed a methodology for implementing DTs for structural engineering. The authors aimed to update the virtual asset based on the measured physical interactions using a connection system. The framework included a mathematical idealization of structural performance, a Bayesian approach for model learning where a physics-based approach was used for updating the virtual asset, and a high-level petri net (HLPN) structure for management modeling. The DT was divided into smart devices, network connections, and an integration platform (front-end and back-end). The front end was used for user visualization, while the back end was used for data storage, analytics, and IoT apps.

Other studies specifically utilized FEM approaches. Angjeliu et al (2020) focused on studying a DT application on a historic masonry building. Using photogrammetric measuring, parametric modeling, retrieving material properties, and carefully studying the various construction phases, the FEM was built. After calibrating and validating the model using structural response tests, the correct use of mass and relative rigidity between components was confirmed. The study monitored the effect of iron ties and the effects of their substitution on the system. Funari et al (2021) introduced a scan-to-FEM approach for creating a DT for historic masonry structures. The users transformed the input point clouds of sub-entities visualized in Grasshopper into Python script files for generating the FEM in Abaqus. The FEM was then calibrated until the model was closely correlated with experimental frequencies. The final DT was able to simulate the damage present on the real structure. Gattulli et al (2022) explored the use of DT models for SHM subjected to earthquake-induced damage. The study used 5G technology with sensory networks. The modal frequencies were updated to correlate the FEM built to the actual model based on experimental data. The time series simulated by the FEM were fed into an ML application for SHM. After identifying the structure as damaged, the application deployed a low latency alarm to the damaged building to identify seismic movement.

3.2.3. Hybrid modeling approaches.

Valinejadshoubi et al (2018) further explored the potential of BIM for SHM applications. The study consisted of a five-story concrete building built with Revit. The analysis in the powerful software program, Extended Three-Dimensional Analysis of Building Systems (ETABS), facilitated the identification of sensor placement on the real building. Using the user-defined IFC property sets such as position, ID, manufacturer, etc, the sensors were created in the BIM model. MySQL database was used to store the structural engineer's data until Dynamo linked the data between the database and the virtual sensors created in the IFC model. Angulo et al (2020) followed a BIM-integrated approach to evaluating the performance of buildings under seismic activity. IDA curves were generated from non-linear static FE-generated models to determine whether the structure had reached collapse. The authors were able to categorize the buildings based on damage vulnerability. This led to the leverage of decision-making and preventing the occurrence of catastrophic losses. Tahmasebinia et al (2019) focused on the numerical analysis of creep and shrinkage using an FEM. QuasiStatic solver calculated the creep and shrinkage values from the FEM to be later integrated with BIM to create the DT.

3.2.4. Surrogate-based modeling approach.

Wang et al (2017) explored IoT technology integration for SHM and early warning using a semantic description modeling approach. The authors introduced multifunctional systems that include sensors, signal processing, and communication facilities to promote IoT technology. Their framework consisted of an intelligent data box to connect various sensors and collect and preprocess data, a unified data parsing framework to tackle heterogeneous data sources, and two warning models. Warning levels were generated based on monitoring points and abnormal descriptions. Zhu et al (2020) proposed a methodology for a real-time data updating strategy for an SHM DT. They followed a Bayesian identification approach that accounts for identification uncertainty while applying modal analysis. Divergence analysis, based on modal information of the model was conducted to check if the system model needs updating after every SHM stream. Using a three-degree-of-freedom laboratory test model, dynamic data was collected for different excitation signals and different temperatures. If the identified modal parameters changed at a discrepancy larger than the threshold, the system model needed to be updated. In another study, Kita et al (2021) focused on extending the operational modal analysis approach for SHM into two DTs using SM and IDA. The SM-based damage identification followed linear numerical modeling and long-term vibration data, while the IDA-based followed non-linear modeling. The SM-based procedure utilized monitoring data to generate an FEM of San Pietro Bell, while the IDA investigated damage versus intensity measures. Both linear and non-linear DTs proved effective and localized damage in the structure.

3.2.5. 3D representation modeling approach.

Tran et al (2021) utilized a DT process and laser scanning technology to generate the as-built point clouds into a 3D semantic model for prefabricated construction. The users were able to link the physical structure with its digital model by supplying decision-making and localizing discrepancies between as-built and as-designed models during construction. The quantitative assessment of both models measured accuracy, completeness, and correctness. The proposed approach aligns perfectly with interest in DT creation by integrating rich geometric and semantic BIM models. Pan et al (2022) focused on integrating small objects into a rich DT for buildings. The authors focused on the geometric data of the DT application. The inputs of point clouds from laser scanning and image capture output labeled mesh models for each small-scale element found. The process included transfer learning for object detection in images, creating photogrammetric point clouds, point cloud alignment, extracting visible points, mapping 2D data into 3D space, finding best-fitting labels, fitting shapes to point clusters, and detecting text. The results showed significant improvement in detecting small objects compared to point cloud networks. Pantoja-Rosero et al (2023) developed an autonomous framework for generating a compact geometric damage-augmented DT model for buildings. A LOD2 model was first generated using multiple view images from point clouds and camera poses. Crack segmentation detected by trained CNNs and crack kinematics characterized by a least-squares-based 2D algorithm build the final LOD3 damage augmented DT. Table 3 summarizes the specific applications and tools of data collection and data analysis that have been explored in building applications.

Table 3. Summary of DT-based SHM studies involving buildings.

| Authors | Data collection types | Data analysis types |

|---|---|---|

| Anil et al (2016) | Visual assessment of damage records | Strength analysis |

| Valinejadshoubi et al (2017) | Accelerometers, strain, thermocouple sensors | Fast Fourier transform analysis |

| Valinejadshoubi et al (2018) | Strain gauge | Threshold value analysis |

| Wang et al (2017) | Steel stress gauges, earth pressure cells | Threshold value analysis |

| Theiler et al (2017) | Accelerometers, strain gauges | Frequency analysis |

| Bruno et al (2018) | Historical records, 3D laser scanning, photogrammetry | Point cloud tracing, non-uniform rational B-splines, neural network, DL |

| Valinejadshoubi et al (2019) | Strain sensor | Threshold value analysis |

| Tahmasebinia et al (2019) | Dead load and wind load information | Numerical analysis |

| Angulo et al (2020) | Structural information | IDA |

| Jouan and Hallot (2020) | On-site sensors, weather forecasts | Threshold value analysis |

| Wagg et al (2020) | Piezoelectric accelerometers | Self-adaptive differential evolution algorithm, Bayesian calibration, Gaussian process |

| Gardner et al (2020) | Acceleration responses | Gaussian process regression, active learning |

| Angjeliu et al (2020) | NDT, photogrammetry | Structural analysis |

| Zhu et al (2020) | Uniaxial accelerometer | Divergence analysis, Bayesian system identification |

| Musella et al (2021) | Images | CNN |

| Kita et al (2021) | Seismic responses and records | SSI, IDA |

| Hou et al (2021) | Strain gauges fiber optics | Data querying |

| Angelosanti et al (2021) | Stereocamera vision system | DIC, phase-based motion magnification |

| Funari et al (2021) | Laser scanning, point clouds | Scan-to-FEM, SSI |

| Tran et al (2021) | Laser scanning | Coarse registration, iterative closest point |

| Chiachío et al (2022) | Ultrasonic sensor | High-level Petri Net, probabilistic Bayesian model updating |

| Gattulli et al (2022) | Sensor boards, MEMS accelerometers | Power spectral density, ML-based model refining |

| Levine and Spencer (2022) | UAV imagery | CloudCompare, GrabCut |

| Pan et al (2022) | Laser scanning, image captures | Transfer learning, region-based CNN |

| Pantoja-Rosero et al (2023) | Images, camera | Structure from motion, CNN, least-squares-based algorithm |

3.3. DT applications involving offshore marine structures and wind turbines

3.3.1. BIM approaches.

O'Shea and Murphy (2020) proposed a framework to integrate BIM and sensors for the SHM of an offshore lighthouse. The authors tackled the gaps present in periodic maintenance evaluations. Vibration modes were identified to measure modes of reported swaying using a geophone system with an extra set of accelerometers. The pressure was measured by a pressure sensor and a logger system. A Raspberry Pi GSM transferred vibration and pressure data. Environmental data were obtained from wind speeds captured by LiDAR and anemometers, while external sensors captured tidal properties. All data were converted to a remote database to be integrated into BIM. Dynamo was also used to read the Excel sensor data into Revit, transforming the static model into a dynamic SHM tool.

3.3.2. Physics-based modeling approaches.

Studies in this section specifically utilized FEM. Tygesen et al (2018), for example, introduced a DT concept for fatigue prediction of marine structures. After building the structure fingerprint using a simple measurement setup, customized software generated the model parameters and compared them with the DT parameters. Acceleration and strain data were analyzed, followed by a calibration of the DT. Calibration significantly reduced the uncertainty of the DT, and its update enabled continuous fatigue monitoring. Tao et al (2018) proposed a DT for a case study of a wind turbine that deals with prognostics and health management. The authors used extreme ML to build the fault cause–prediction model. They introduced a 5D model that contained the physical information, the virtual information, the DT data, the services model, and the connection between all models. If the deviation of the inconsistency between virtual and physical models was within the threshold, the degradation would be detected and its cause would be predicted. If not within the threshold, the model would return to calibration. Grosse (2019) explored the creation of a DT for a wind turbine. Data from video capture systems were stored in the camera's memory and analyzed by DIC. Based on the analyzed measured data, the stiffness and the mass of the FEM were updated to replicate the design life of the physical structure more accurately. The study proposed the benefits of combining FE data with sensing data. No automation of data transfer or data collection was proposed in the study for updating the FEM.

Mahmoodian et al (2022) built a DT for intelligent maintenance of civil infrastructure. The real-time data collected from sensors were stored in a database until merged with FEM to create the DT. A reduced order model generated from CSV files was connected with the input data through an IoT platform using sequel codes to continuously monitor the structural behavior. Table 4 summarizes the specific applications and tools of data collection and data analysis that have been explored in marine structures and wind turbines.

Table 4. Summary of DT-based SHM studies involving offshore structures and wind turbines.

| Authors | Data collection types | Data analysis types |

|---|---|---|

| Tygesen et al (2018) | Accelerometers, strain gauge | SSI, Bayesian-based model updating |

| Tao et al (2018) | Acceleration/temperature sensors, speed transducers, torque/voltage/hydraulic sensors | Threshold value analysis, consistency judgment |

| Grosse (2019) | Video capture systems, wired/wireless accelerometers | DIC, covariance-driven SSI |

| O'Shea and Murphy (2020) | Geophone system, accelerometer, pressure sensor, LiDAR, anemometers | Threshold value analysis |

| Mahmoodian et al (2022) | Strain/tilt/vibration sensors | FE analysis |

3.4. DT applications involving other civil engineering elements and assets

Extending outside the scope of specific infrastructure's uses of DTs, there exist case implementations on other structural or non-structural civil engineering components in the literature. This section covers case studies on elements such as structural beams, cable domes, steel structures, bar structures, plate specimens, non-structural civil engineering utilities, and single-degree-of-freedom systems. For example, D'Amico et al (2019) focused on introducing a framework of a DT for a general complex engineering system. A central unit bonded all the modules via a common language through an attached interface, and no particular modeling approach was represented. A materials degradation assessment DT contained a CAD model to retrieve geometry and material data; it relied on ThermoStudio to process images. The results were analyzed in the degradation characterization module and transformed into JSON files to be sent to the learning module for predicting degradation.

3.4.1. BIM approaches.

Other studies such as Yin et al (2020), explored a BIM-based framework for the health maintenance of utility tunnels. The physical layer dealt with the collection of physical data from various sensors. The data was then sent to the network layer and managed under an SQL database. BIM also incorporated fundamental data of pipes and elements in the utility tunnel that can be exported to the database using open database connectivity. The application layer was responsible for the visualization of data such as safety information, basic element information, maintenance, cost, and contract management using a user-friendly interface. The system supplied an automatic safety monitoring system whenever the equipment's health was threatened. Cheng et al (2020) proposed a framework for applying predictive maintenance on non-structural components, incorporating BIM and IoT technology. Using an information layer, data was collected and organized using BIM with an IFC extension, an FM system, and an IoT system. The users developed a plugin using Revit API to transfer the sensor data to the BIM model where the data was synchronized with a corresponding condition Microsoft SQL database. Using an application layer, ANN and SVM algorithms predicted the future conditions of the elements. The study was able to predict the future of four chillers along with their health status and needs for rapid maintenance or inspection routines.