Abstract

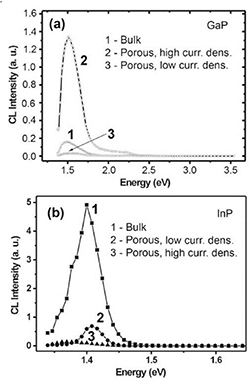

In this review paper, we present a comparative analysis of the electrochemical dissolution of III–V (InP, GaAs, GaN), II–VI (ZnSe, CdSe) and SiC semiconductor compounds. The resulting morphologies are discussed, including those of porous layers and networks of low-dimensional structures such as nanowires, nanobelts, and nanomembranes. Self-organized phenomena in anodic etching are disclosed, leading to the formation of controlled porous patterns and quasi-ordered distribution of pores. Results of templated electrochemical deposition of metal nanowires, nanotubes and nanodots are summarized. Porosification of some compounds is shown to improve luminescence characteristics as well as to enhance photoconductivity, second harmonic generation and Terahertz emission. Possible applications of porous semiconductor compounds in various areas are discussed.

Export citation and abstract BibTeX RIS

Original content from this work may be used under the terms of the Creative Commons Attribution 4.0 license. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

1. Introduction

The wide class of porous materials includes both organic and inorganic materials such as porous metals, porous semiconductor and dielectrics, porous ceramics, polymer foams, and metal-organic frameworks [1–3]. Porous solids often serve as structural bodies in nature, including in wood, bones and other biological objects. Depending on their nature, porous materials are prepared by specific technologies involving a lot of fundamental concepts, and specific fields of applications are determined by their properties.

Among semiconductor materials, considerable interest has been triggered by the discovery of luminescent porous Si three decades ago [4]. The efficiency of porous silicon LED's has risen by 5 orders of magnitude over the years and is currently approaching commercial viability for some integrated display applications [5]. During this time, it was shown at the laboratory research level that porous Si is suitable for many applications, including optic and optoelectronic applications (light emitting devices, optical waveguides, photonic crystals, optical resonators, distributed Bragg reflectors and diffraction gratings), electronic applications (gas sensing, gettering, lithium-ion batteries, and solar cells antireflection coatings), microfluidics, medical applications, etc [6–10].

Recently, it was proposed to produce size-controlled nanocrystalline (nc-Si) dot colloids by exposing porous silicon (PSi) in solvents to pulse laser, which results in fragmentation of the PSi layer with a considerably higher yield than the conventional techniques [11]. This was shown to pave the way for emerging functions of nanostructured PSi related to strong visible photoluminescence of about 40% in quantum efficiency in the red band, efficient quasi-ballistic hot electron emission from an nc-Si diode due to multiple-tunneling transport mode through nc-Si dot chain, and enhanced to a practical level thermo-acoustic conversion due to an extremely low thermal conductivity and volumetric heat capacity of the nc-Si layer. Applications of the quasi-ballistic electron source in flat panel display, multibeam parallel lithography, high-sensitivity image sensor and reductive deposition of thin films have been demonstrated.

Meanwhile, the transition of the porous silicon from academic studies to industry is in progress. Prototype devices on large area wafers taking advantages of the isolating properties of PSi, including power AC switches, radio-frequency (RF) devices and energy micro-sources, have been demonstrated through collaboration between GREMAN and ST Microlectronics [12]. Nevertheless, wide implementation of PSi in the field of electronic component manufacturing still needs significant investment, development, optimization and validation of reliable equipment and processes in terms of throughput. BOSCH GmbH uses PSi in high-volume industrial production of micro-electro-mechanical (MEMS) devices, particularly in the manufacturing of monolithically integrated pressure sensors [13]. SOLEXEL, in collaboration with SCREEN, is particularly active in the field of photovoltaic cells manufacturing with the design and the development of high throughput production equipment [12].

On the other hand, the development of technological methods for the preparation of porous alumina templates, including the ones with periodically ordered pore arrangement, triggered extensive activities in research for template synthesis of various nanoscale materials, with it being an elegant, inexpensive, and technologically simple approach [14].

Porous anodic aluminum oxide (AAO) attracted a huge interest due to the pioneering works of Martin [15] and Masuda and Fukuda [16]. Self-organized nanoporous structures with hexagonal ordered distribution of pores were obtained on a highly pure Al surface via electrochemical anodization in acidic medium [17, 18]. AAO templates have many advantages over the polycarbonate membranes, such as high pore density, thermal stability, cost effectiveness and versatility. Pore diameter, length, inter-pore spacing, and pore ordering can be easily tailored by tuning the anodizing parameters such as voltage, time, electrolytes, pH value, and temperature [18].

Both of these materials are prepared by electrochemical etching of Si wafers in the case of porous Si, and Al wafers in the case of porous alumina templates. Electrochemistry offers an accessible and cost-effective approach for the preparation of porous templates with tailored architecture on the submicrometer scale. However, Si is a material with indirect energy band gap corresponding to the infrared spectral range, which strongly restricts the area of applications for porous Si. On the other hand, porous alumina templates exhibit high resistivity and therefore they often play a passive role in nanofabrication processes, since they are used mostly for the templated synthesis of nanowire arrays which are prospective for several applications [19]. The templated growth of nanowires via electroplating is provided usually by the metal contact deposited on the back side of the high-resistivity membranes. To produce electroplating of metal nanodots and nanotubes into alumina templates, additional technological steps are required, e.g. chemical modification of the inner surface of the pores prior to electrodeposition, which leads to the incorporation of spurious phases in the nanotube walls [20].

Semiconductor nanotemplates, the properties of which can be easily controlled by external illumination, applied electric fields, etc, provide wider possibilities for nanofabrication. The production of nanodots, nanotubes and 2D metallo-semiconductor interpenetrating networks are promising for various nanoelectronic, optoelectronic, plasmonic, and nanophotonic applications. Metal nanodots are obtained routinely in solutions, but positioning them on a chip remains a significant challenge. Conventional controlled patterning approaches like electron beam lithography [21], stencil lithography [22, 23], and extreme ultraviolet interference are very expensive. In spite of the fact that low-cost alternatives such as nanoimprint [24] and nanosphere techniques [25] exist, they are limited because they imply complicated resists, lift-off processes, and cannot be accurately controlled as to their positioning, size, and shape.

The optoelectronic applications of metallic nanotubes are based on the extended dielectric/metal interface that can sustain the propagation of electromagnetic waves coupled to collective oscillations of the conduction electrons in the metal, the so called surface plasmon polaritons, allowing the manipulation and transmission of light on the nanoscale [26, 27]. 2D metallo-semiconductor networks may find potential applications in photonic integrated devices and circuits [26].

Since semiconductor compounds provide more space for tailored nanofabrication in terms of compositions, bandgaps, mechanisms of the pore growth and new properties with large potential for applications, their porosification was widely explored over the last two decades. This review will focus on the different aspects of pore growing, including self-organized pore formation which results in the production of ordered arrangements of pores; on properties of the produced semiconductor compound porous materials and nanocomposites on their basis; and on various actual applications and future prospects.

The paper is organized as follows. Section 2 introduces the electrochemical dissolution mechanisms for the porosification of various semiconductor materials with a main focus on III–V and II–VI compounds, followed by the description of approaches for obtaining morphologies related to networks of nanowires, nanobelts and nanomembranes as well as technologies for electrochemical deposition of metal nanostructures into porous semiconductor templates. Section 3 describes self-organized phenomena occurring under special conditions of electrochemical etching, which open possibilities for the formation of single crystals of pores, multilayer porous structures and nanocomposite materials. Section 4 is dedicated to the review of basic properties of porous materials as compared to their bulk counterparts with a main focus on luminescence, photoconductivity, optical phonon engineering and nonlinear optical properties. Section 5 analyses the state of the art and prospects for use of the advantageous properties generated by the electrochemical porosification in various applications. Finally, conclusions and outlooks are formulated.

2. Electrochemical dissolution mechanisms: comparative analysis of III–V compounds (InP, GaAs, GaN), II–VI compounds (CdSe, ZnSe, ZnxCd1-xS), and SiC

2.1. Dissolution mechanisms and types of pores: crystallographically oriented, current line oriented, and fractal pores

Over the last few decades, it was demonstrated that electrochemistry is one of the most accessible and cost-effective approaches for tailoring the architecture of semiconductor materials at the nanoscale level by introducing porosity. One of the key problems with electrochemical (EC) methods introducing porosity in semiconductor materials is the appropriate choice of the electrolyte composition. This problem is solved individually for each material. Due to the narrow band gap of InAs, it is relatively difficult to reach nanostructuring in this compound via electrochemical etching techniques. Nevertheless, the formation of InAs micro- and nano-pencils was reported [28]. However, the obtained structures are inhomogeneous. More recently, it was shown that the morphology of the porous InAs layers can be controlled by the composition of the electrolyte and the applied electrochemical parameters [29]. It is difficult to control the mechanism of pore growth in InAs, since in narrow bandgap semiconductors uniform electrochemical etching proves to occur simultaneously with the pore growth, thus resulting in the limitation of the achieved depth of the produced porous layer.

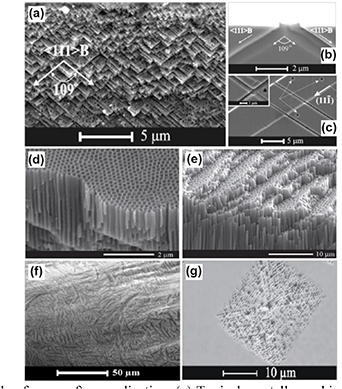

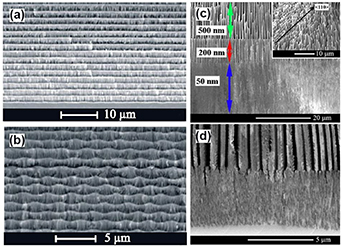

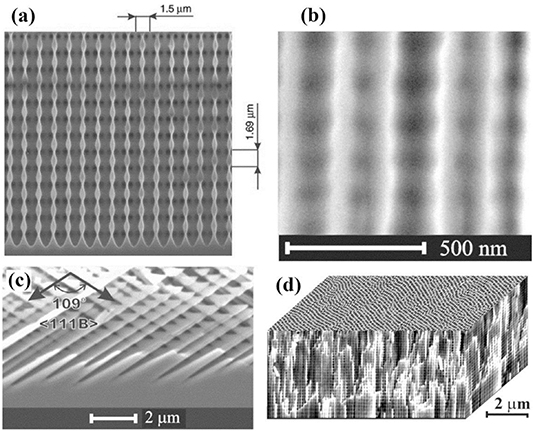

Usually, three types of pores can be generated in semiconductor compounds: current line oriented (CLO or curro pores), crystallographically oriented (CO or crysto pores), and fractal pores. The characteristics of the pores (shape, velocity of growth, etc) depend on the specific anodization conditions [30]. It was established that CO pores grow at current densities lower than a certain threshold value, whereas CLO pores grow at current densities higher than the threshold value. The threshold values depend strongly on the free carrier density in semiconductor crystal, electrolyte concentration, and temperature. The main feature of the CO pores is that they grow along definite crystallographic directions. In case of sphalerite crystal structures, they grow along <111> B crystallographic directions, independent of the initial surface orientation, the angle between pores being approximately 109° as shown in figures 1(a) and (b). They tend to have a triangular cross-section, with the pore walls and tips showing a pronounced crystallographic anisotropy as well [31]. A very important property of the crysto pores is their ability to intersect each other, thus opening a new way for semiconductor 3D structuring, seen in figure 1(c). Crysto pores are inherent to Si, GaP, InP and GaAs, however no crysto pores have been observed up to now in II–VI semiconductor compounds such as ZnSe and CdSe. On the other hand, curro pores are inherent to Si, GaP, InP and ZnSe, as shown in figures 1(d) and (e), however no curro pores have been observed so far in GaAs. No intersection of curro pores was demonstrated experimentally up to now.

Figure 1. Example of pores after anodization. (a) Typical crystallographically oriented pores in (100)-oriented n-InP; Crysto pores in GaAs: (b) pore growth along <111> B directions in GaAs and triangular cross-section shape as well as intersection of pores in (c). Current line oriented pores in InP (d) and ZnSe (e). (f) Fractal pores in ZnSe, cross-section. (g) Fractal like pores in GaAs, top view. [31] © John Wiley & Sons. Copyright © 2003 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim.

Download figure:

Standard image High-resolution imageFractal pores are the third type of pores observed in Si, III–V and II–VI semiconductor compounds. A fractal is normally defined as an object that can be divided into parts, and each of these parts will be similar to the original object. The structures presented in figures 1(f) and (g) are not perfect fractals, but the pores are called fractal due to their fractal-like way of growth, i.e. each point of a pore in such a structure can be a source for one or more similar pores growing in totally different directions. The existence of fractal pores not only opens new insides regarding the mechanism of pore formation in semiconductors, but it is also interesting for optical applications, for example nonlinear optical effects.

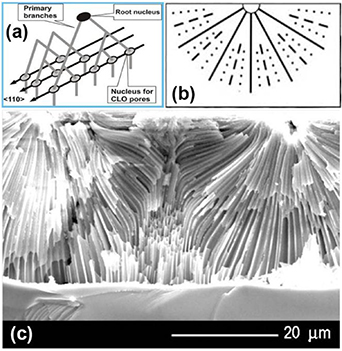

In the case of InP, at the beginning of the anodization process, multiple branching of a primary pore in the nucleation layer results in a whole set of secondary pores oriented along crystallographic directions <111> B. The end points of the set of pores originating from the same root nucleus form a linear domain and serve as the nuclei for a corresponding domain of CLO pores, as shown in figure 2(a). Thus, in case the nucleation layer is well developed, there is a general tendency of current line oriented pores to form rows oriented along the <110> direction. This tendency, accompanied by the repulsive pore–pore interaction due to overlapping space charge regions surrounding neighboring pores, leads to the observed ordered close packed 2D distribution of CLO pores, which will be described in section 3.

Figure 2. Schematic outline of the development of the porous structure in (a) III–V and II–VI (b) during anodic etching (see text for details). (c) Development of the porous structure in CdSe after neighboring domains meet. Reproduced from [32]. © IOP Publishing Ltd. All rights reserved.

Download figure:

Standard image High-resolution imageThings are different in the case of CdSe. At the beginning of anodization, the etching starts at surface imperfections. After the initial pitting of the surface, further etching proceeds in all directions, i.e. in the first approximation radially away from the surface imperfections, leaving the top surface of the sample practically intact. As a result, a porous domain forms around each etching pit. After neighboring porous domains meet, a continuous porous network emerges with parallel pores that continue to grow, under the applied voltage, in the direction perpendicular to the initial surface of the sample. The extension of a porous domain in CdSe until it joins the continuous porous network is illustrated in figure 2(c). The pores obviously grow perpendicular to the equipotential lines of the electric field in the anodized sample. The total number of pores is actually defined at the very beginning of anodization when an interesting process of pore multiplication occurs that is based on the doubling principle [32]. Namely, in the first instants of the pore etching, the number of pores progressively doubles until an equilibrium value of the ratio between pore diameter and wall thickness is reached. Figure 2(b) shows schematically the essence of the doubling principle in pore growth.

Figure 3 presents SEM images of electrochemically etched InP, ZnSe and Zn0.4Cd0.6S crystals [28, 30] with the anodization potential intentionally changed during the pore growth. It is evident from figure 3(a) that the change of the applied potential during anodization of InP crystals from high to low values leads to a switch in the pore growth mechanism from current-line oriented pores to crystallographically oriented pores, which will be discussed in more details in section 3. In contrast to this, the change in the applied potential for ZnSe and Zn0.4Cd0.6S single crystals, as seen in figures 3(b) and (c), does not change the pore growth mechanism, current-line oriented pores being produced under both high and low values of the applied potential. Switching from 18 V to 16 V during the etching of Zn0.4Cd0.6S just leads to the decrease in the pore diameter from 30 nm to around 15 nm, rather than to the commutation from current-line oriented pores to crystallographically oriented pores.

Figure 3. SEM image of porous InP (a), ZnSe (b), and Zn0.4Cd0.6S (c) layers anodized with changing the applied potential [from 7 V to 1 V in (a); from 15 V to 13 V in (b); and from 18 V to 16 V in (c). [31] John Wiley & Sons. Copyright © 2003 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim.

Download figure:

Standard image High-resolution imageThe lack of crystallographically oriented pores in II–VI semiconductors looks curious since, e.g., ZnSe has the same zinc-blend crystal structure as GaAs, GaP and InP. This can be explained taking into account the nature of chemical bonds between constituent atoms. Covalent tetrahedral bonds due to sp3 hybrid orbitals are inherent to elemental semiconductors such as Si and Ge. Tetrahedral bonds are also inherent to compound semiconductors. However, in this case the chemical bonds can be both covalent and ionic, since the semiconductor compounds consist of atoms with different electronegativities. Table 1 presents the atom electronegativity difference for some semiconductor compounds calculated using Pauling's law [33]. The electronegativity is an indicative of the strength with which atoms attract electrons. The difference in electronegativities of the constituent elements is therefore indicative of the ionicity, as shown in table 1 [34]. The higher the ionicity, the stronger the attraction between the atoms. It can be seen from table 1 that the degree of ionicity in III–V semiconductor compounds is lower compared to the II–VI compounds. As a result, crystallographically oriented pores can be obtained in III–V compounds, in contrast to II–VI compounds.

Table 1. Values of electronegativity difference and degree of ionicity in II–VI and III–V semiconductor compounds.

| II–VI | III–V | |||||||

|---|---|---|---|---|---|---|---|---|

| Compound | ZnO | ZnS | ZnSe | CdSe | InP | InAs | GaAs | GaP |

| Electro-negativity difference | 2 | 1 | 0.9 | 0.9 | 0.6 | 0.5 | 0.5 | 0.32 |

| Ionicity (%) | 63 | 22 | 19 | 19 | 11 | 9 | 9 | 2 |

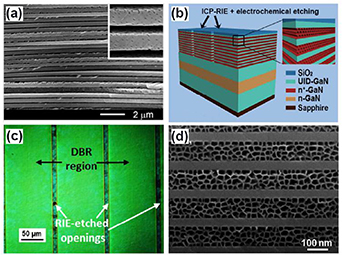

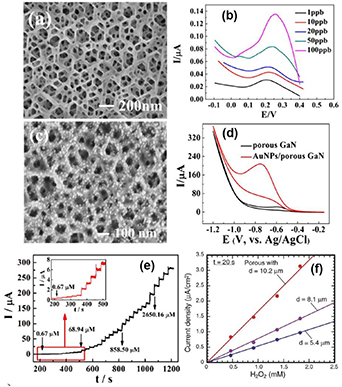

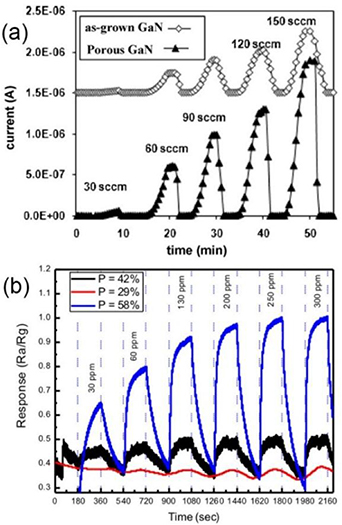

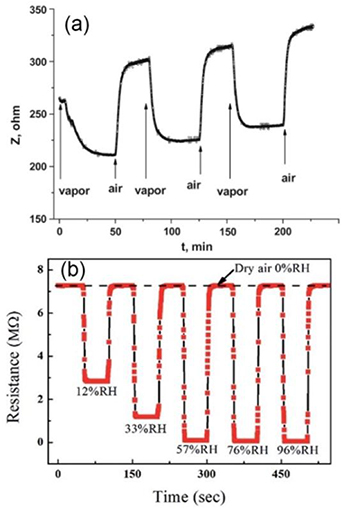

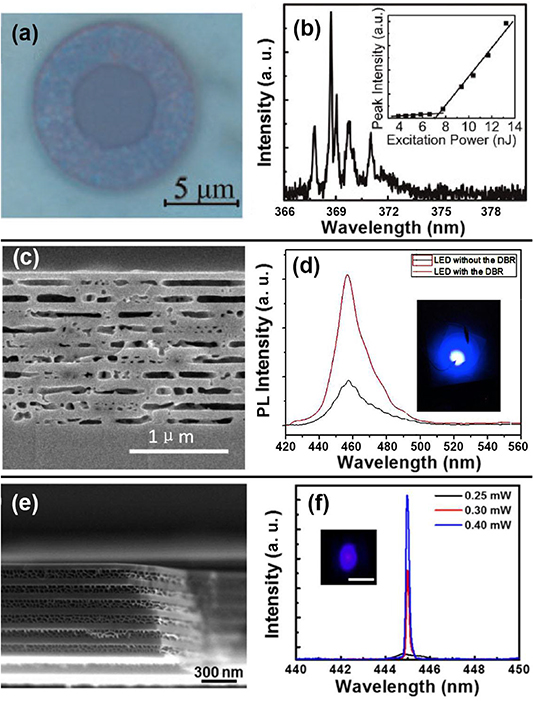

Let's move on to GaN, which represents a class of wide-bandgap III–V semiconductor compounds. Earlier investigations demonstrated that photoelectrochemical etching results mainly in the fabrication of nanowires or pyramidal structures consisting of nanowires, which represent threading dislocations [35]. It was recently shown that porous GaN can be produced in metal organic chemical vapor deposition (MOCVD) grown GaN layers by electrochemical etching, and the degree of porosity can be controlled by both the anodic voltage and sample doping [36, 37]. Aligned and exposed mesopores in single crystalline GaN formed in nitric acid were reported [38]. It was shown that, like in the case of InP, a nucleation layer is formed on the top surface which can be removed via UV-assisted anodic etching at low voltages. Moreover, combining electrochemistry with thermal treatment of porous substrates offers the possibility to release the free-standing porous membrane [39].

On the other hand, to assure further progress in the development of III-nitride-based power electronics and high brightness light emitting devices, high quality single crystalline GaN substrates are needed, since the thickness of MOCVD-grown layers is usually limited to 2–3 µm, and these layers suffer from internal strains and defects due to significant mismatches of crystal lattices and thermal expansion coefficients with the sapphire, Si or SiC usually used substrate material.

Hydride vapor phase epitaxy (HVPE) has been identified during the last decade as one of the most relevant techniques for the growth of bulk GaN for substrates. HVPE ensures the highest growth rates (up to 500 μm per hour) and favors the growth of thick GaN layers which are subsequently detached from the sapphire or other foreign substrates [40]. In recent years, many teams have focused their research on porosification of HVPE grown free-standing GaN substrates and fabrication of high aspect ratio GaN nanostructures [41, 42]. According to Ref. [43], the surface morphology of the photo-etched GaN consists of islands dispersed amongst concentric rings of alternating small and large pores. Further research using photoelectrochemical and electrochemical etching techniques brought to light self-organized three dimensional nanostructured architectures which were attributed to the spatial modulation of the electrical conductivity generated during HVPE growth of GaN [44]. The specific features of self-organized 3D nanostructured architectures including quasi-ordered concentric hexagonal structures have been disclosed due to the fact that electrochemical and photoelectrochemical etching techniques are highly sensitive to local doping. Recently, different porous morphologies produced by anodization in the depth of a HVPE-grown GaN substrates with respect to the N- or Ga-face were reported [45]. Complex porous pyramidal-type structures are formed at a depth of several tens of micrometers from the N-face, while homogenous porous matrices with pores oriented perpendicular to the wafer surface are generated at a depth of up to 50 μm at the Ga-face.

The features of SiC porosification will now be discussed. The pioneer work on the electrochemical porosification of 3C-SiC was reported by Takazawa et al [46]. According to recent publications [47, 48], electrochemical etching of low resistivity n-type SiC wafers results in the formation of two nanostructured products: porous SiC with a well-ordered crystalline structure and oligomeric compound named carbon fluorooxide (CFO). It has been established that the increase in HF concentration, presence of ethanol in the etchant, increase in SiC electrical conductivity and decrease in etching current density leads to an increase in CFO/SiC ratio in the etching product and an increase in the degree of porosity. As a result, the SiC morphology changes from macroporous tubular through mesoporous hierarchical to a mesoporous filamentary one. Note that porous SiC has found applications in electronic devices and has promising applications in sensing [49].

The results of a comparative analysis of the pore growth in II–VI and III–V compounds during electrochemical etching are summarized in table 2. Difficulties with controlled pore formation are evidenced in narrow badgap semiconductors. The absence of crysto pores in II–VI compounds and their growth in III–V compounds are explained in terms of bonds iconicity. Curro pores grow practically in all compounds with the exception of GaAs. However, in II–VI compounds, curro pores grow in a large diapason of potentials applied during electrochemical etching, while in III–V compounds they grow only at high values of the applied voltage. The issue with the absence of curro pores in GaAs needs additional investigation.

Table 2. Types of pores in semiconductor compounds.

| Type of pores, Determining factor | II–VI | III–V | ||||||

|---|---|---|---|---|---|---|---|---|

| ZnSe [29] | CdSe [32] | ZnCdS [29] | InP [31] | GaAs [30, 31] | GaP [31] | GaN [37, 38, 45] | InAs [28, 29] | |

| Crysto pores | No | No | No | Yes, low volt. | Yes | Yes, low volt. | Yes, low volt. | No |

| Determining factor | High ionicity | Low ionicity | Narrow bandgap | |||||

| Curro pores | Yes | Yes | Yes | Yes, high volt. | No | Yes, high volt. | Yes, high volt. | No |

| Determining factor | Not influenced by ionicity | Not influenced by ionicity | Narrow bandgap | |||||

| Fractal pores | Yes | No | No | No | Yes | No | No | No |

| Determining factor | Not identified | Not identified | ||||||

2.2. The choice of electrolytes. Porosification in neutral electrolytes

Usually, the pores in semiconductors are introduced via electrochemical dissolution of materials in electrolytes containing acids such as HF, HCl, H2SO4, HNO3, etc, or in alkaline electrolytes. The nature of the electrolyte and its concentration strongly influences the morphology of porous layers produced via the anodization process.

In the last decade, to make the process of nanofabrication based on anodic etching broadly accessible and environmentally friendly, a part of research was focused on nanostructuring in neutral electrolytes. Tiginyanu et al [50] proposed to use a neutral electrolyte based on an aqueous solution of NaCl instead of commonly used aggressive acids or alkaline electrolytes for the purpose of electrochemical nanostructuring of semiconductor substrates. The possibilities for controllable porosification of GaAs and CdSe substrates by anodic etching in an environmentally-friendly neutral electrolyte based on aqueous solution of NaCl have been demonstrated. Moreover, the photoluminescence investigation of the prepared porous structures showed no decrease in the near-bandgap emission intensity, in spite of the huge surface inherent to the porous skeleton. This implies that the surface recombination rate does not increase in porous samples, which is indicative of an effective passivation of the huge internal surface of the porous samples during anodization in the NaCl-based electrolyte. Later on, formation of uniform porous layers and porous InP membranes was realized for various applications, e.g. nonlithographic manufacturing of semiconductor nanotemplates for the deposition of metal nanotubes [51], and the development of gas sensors was demonstrated [52].

Anodization in salty water proves to be a powerful tool for manufacturing 3D ordered porous structures in InP [53]. Depending on anodization conditions, a spatial nanostructuring can be easily realized. For the fabrication of 2D porous structures, the anodic etching is carried out under constant applied voltage (5 V), while for 3D structures the value of the applied voltage between the reference electrode and working electrode is periodically modulated in three steps (2 V, 4 V and 6 V) for a duration as long as 10 s each. Spectacular wavy entities can be fabricated using switches from crysto pores to curro pores and vice versa, as shown in section 3.

Electrochemical nanostructuring in neutral electrolyte proves to be feasible for nanostructuring narrow band gap III–V semiconductor compounds. InAs is a direct band gap semiconductor compound with zinc blende structure and a narrowest energy gap among the III–V binary compounds, except for InSb. As mentioned above, due to the narrow band gap of InAs, it is relatively difficult to reach nanostructuring in this compound using electrochemical etching techniques. Nevertheless, a comparative anodization in acids and NaCl was investigated and the formation of InAs micro- and nano-pencils was reported by Sirbu et al [54].

The electronic band gaps of InAs, InP, GaAs and CdSe are respectively 0.35; 1.3; 1.4 and 1.7 eV at 300 K, which means that the nanotemplates based on these materials are opaque in the visible region of the spectrum. At the same time, GaN with the bandgap as high as 3.4 eV at 300 K is a perspective candidate for the fabrication of conductive nanotemplates transparent in the whole visible region of the spectrum.

Schwab et al reported results of MOCVD grown n-GaN nanostructuring in 0.3 M NaNO3 and 3 M NaCl neutral electrolytes [55]. It was demonstrated that the etching behaviors in NaNO3 and HNO3 electrolytes are very similar and etching has a minimal impact upon the produced morphologies characterized by propagation of pores parallel to the current flow, with the exception of a thin nucleation layer at the surface. At the same time, the use of NaCl implies the formation of crystallographically oriented pores exhibiting characteristic triangular cross-section at applied voltage of 6 V for 30 min. Even at increased applied anodization voltages of up to 30 V, the pores exhibit preferential growth along crystallographic directions. Note that the entire 2 μm thick MOCVD grown GaN layer can be fully etched in 1 s and 2 s at 30 V and 20 V, respectively, due to the high etch rate in NaCl electrolyte.

Growth of crystallographically oriented pores in highly doped GaN layers looks curious because the formation of such kind of pores is characteristic for low doped samples or low applied voltages [31]. A comparative study of HVPE-grown GaN etching in HNO3, HCl, and NaCl solutions performed recently on Ga- and N-faces of crystalline substrates demonstrated that GaN can be efficiently porosified in 3.5 M NaCl electrolyte [45].

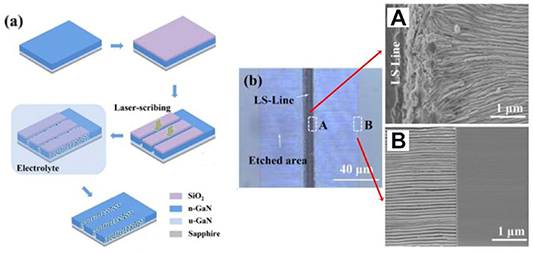

The increase of the anodization potential in the electrochemical etching process leads to the increase of the pores diameters [36] with the simultaneous reduction of the pore wall thickness which comprises two space charge regions. At some critical values of the potential an electro-polishing process can be initiated [55]. Based on these considerations, Gao et al [56] reported on the fabrication of self-standing GaN-based film with multiple quantum well (MQW) structure via an electrochemical etching technique in neutral electrolyte by switching the etching potential from 20 to 40 V at the end of anodization. The schematic representation of the electrochemical etching approach to produce free-standing GaN-based porous membranes is presented in figure 4(a).

Figure 4. (a) Schematic illustration of the electrochemical etching approach to produce free-standing GaN-based membranes and (b) transferred large-area nanoporous GaN-based membrane on a target substrate (a tape was used as an example). Reprinted from [56], Copyright (2017), with permission from Elsevier.

Download figure:

Standard image High-resolution imageThe analysis shows that, in spite of the fact that the etching behavior is mainly pertinent to anions, the cations also determine the peculiarities of GaN anodic etching [58]. The gallium-related intermediate product of photo-assisted anodic etching is generally believed to be gallium oxide Ga2O3. Since this oxide is not soluble at a neutral pH, there is an indication that another etching mechanism exists for neutral electrolytes. The analysis of data in table 3 also shows that, while electrochemical porosification of III–V semiconductor compounds in environment-friendly electrolytes was well explored, less attention has been paid to II–VI compounds. This issue needs further investigation and technological development.

Table 3. Semiconductor compounds suitable for nanostructuring in neutral electrolytes.

| Semiconductor compound | Typical electrolyte for anodization | Possibilities of anodization in environment-friendly electrolytes | ||

|---|---|---|---|---|

| III–V | InP | HCl [29, 31] | NaCl [51–53, 57] | |

| GaAs | HCl; H2SO4 [30, 31] | NaCl [50] | ||

| GaN | KOH [37]; HCl [37, 45]; H3PO4 [37] HNO3[37, 45, 58] | NaCl [45, 54]; NaNO3 [55, 56] KNO3 [58] (BMIM)ClO4 ionic liquid [59] (EMIM)(OTF) ionic liquid [42] (EDTA-2Na) [60] | ||

| InAs | H3PO4:HNO3 [28] KOH [29] | NaCl [54] | ||

| GaP | HCl; HNO3; H3PO4; HBr [31, 61, 62] | Not reported yet | ||

| II–VI | CdSe | HCl [32] | NaCl [50] | |

| ZnSe | K2Cr2O7:H2SO4 [29, 57] | Not reported yet | ||

| ZnCdS | HCl [29]; HNO3 [63] | Not reported yet | ||

According to the data presented in table 3, among III–V compounds the main interest was focused on gallium nitride, taking into account its prospects for various microelectronics, optoelectronic and photonic applications. Some peculiarities of GaN porosification in a neutral aqueous NaCl electrolyte are summarized in table 4.

Table 4. Some features of electrochemical porosification of GaN with doping density of around 1019 cm−3 in acid HNO3 and neutral NaCl electrolytes.

| Electrolyte used | Acid HNO3 | Neutral NaCl |

| Anodic potential for crysto pore growth | Up to 5 V | Up to 20–30 V |

| Pore growth mechanism | Neighboring pore interaction | Avalanche breakdown |

| Rate of pore penetration | 0.05 µm s−1 | 1 µm s−1 |

| Ref. | [45] | [55] |

As seen in table 4, crysto-pores grow in GaN up to much higher anodic potentials when anodization is performed in a neutral NaCl electrolyte as compared to anodization in an acid electrolyte, where no crysto-pores were observed at respective potentials, exclusively curro-pores being formed. The pore growth mechanisms are also different for anodic etching in neutral and acidic electrolytes. At the same time, the rate of pore growth in GaN is by more than an order of magnitude higher upon anodization in the neutral electrolyte.

2.3. From porous structures to networks of nanowires, nanobelts and nanomembranes. Metal-assisted photochemical etching

In the last few years, considerable research efforts have been focused on one-dimensional (1D) nanostructures, such as nanorods, nanowires, nanobelts, and nanotubes with well-controlled sizes, morphologies, and geometries, due to the quantum size effects which resulted in fascinating properties and novel applications in nanooptoelectronic and nanosensor devices. In particular, semiconductor nanowires are predicted to drive new generations of compact, ultrafast, and high efficiency electronic and optoelectronic devices.

At the same time, two-dimensional (2D) nanomaterials which are characterized by a thickness of the order of nanometers and a lateral scale much bigger than that of nanobelts, including nanosheets and nanoplates, receive much less research attention than 0-D (nanoparticles and quantum dots) and 1D materials. A small number of reports on 2D semiconductor nanosheets and related devices have been published. The main reason is related to the difficulty to obtain high-quality 2D semiconductor nanosheets with appropriate electron or hole concentrations required for device applications.

Semiconductor nanowires of different compositions have been prepared by a variety of methods, including laser ablation [64–66], template-assisted electrochemistry [67–69], chemical transportation [70], chemical vapor deposition [71] and solvothermal methods [72, 73]. However, the nanowires obtained by using these techniques have crystallographic defects due to impurities from electrolytes, precursors and different transport gases in the growth process. It was shown that the mobility in InP nanowires is significantly degraded by the presence of planar crystallographic defects [74]. These defects are also responsible for the spatial separation of electrons and holes which rapidly quench nanowire PL. Future nanowire-based devices require very high crystal quality of constituent InP nanowires. According to the literature data, the growth of defect-free nanowires with high crystalline quality is still a technological challenge.

All of the mentioned above technologies represent bottom-up approaches. An alternative and cost-effective technology for the fabrication of low-dimensional nanostructures proves to be anodic etching of bulk semiconductor crystals. By choosing the optimal electrochemical conditions, it is possible to obtain a huge amount of semiconductor nanowires connected to the bulk substrate. Usually, the wire formation procedure passes through the pore formation in the anodization process, but it is relatively difficult to identify the time when the electropolishing process starts.

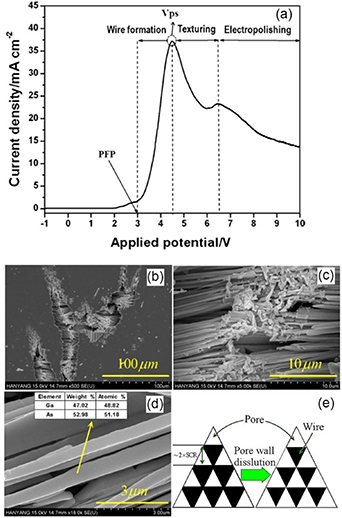

Li et al studied the I–V curves of the anodic etching of GaAs crystals and showed that the anodization can be divided into three regions, depending on the formation potential: pore/wire formation (3–4.5 V), texturing (4.5–6.6 V), and electropolishing (above 6.6 V) [75]. The electrochemical dissolution behaviors of the investigated n-type (100) GaAs crystals doped with Si (2.67–8.63 × 1017 cm−3) in a 5% KOH electrolyte was found to be characterized by the I–V curve shown in figure 5(a). It can be seen that a very low current level was registered when the applied potential was lower than the breakdown potential or pore formation potential (PFP) equaling 3 V. Further increase in the potential leads to the current rise due to the avalanche breakdown mechanism. Under such conditions pores and wires are obtained. Above the peak value Vps at 4.5 V a decrease in the current density was recorded. SEM investigation of samples in this region disclosed a surface texture without generated pores, while at higher applied potential electropolishing occurs.

Figure 5. (a) I–V plot of the n-GaAs (001) smooth surface swept in 5% KOH at a scan rate of 5 mV s−1. (b–d) Different magnification plan-view SEM images of GaAs wires etched at 3 V. The inset in (d) shows EDX data extracted from the nanowires. (e) Illustration showing the wire formation procedure. Reprinted from [75], Copyright (2011), with permission from Elsevier.

Download figure:

Standard image High-resolution imageAs mentioned above, due to the fact that As is more easily oxidized than Ga, pores were always found to grow along the <111> B directions [31]. Figures 5(b)–(d) illustrates GaAs wires, tilted to the surface along <111> B directions, with diameters ranging from 400 to 700 nm.

Normally, it is considered that the thickness of the pore walls is determined by the space charge region (SCR) effect. Langa et al reported that the distance between the centers of two pores must be at least one pore diameter plus twice the width of the SCR around a pore [76]. Namely, a wall with the thickness of two space charge regions remains between the two neighboring pores due to the two semiconductor/electrolyte junctions. So, Li et al calculated the width of the SCR to be approximately 150 nm when the voltage drop across the SCR was 3 V. Taking into account that the nanowire formation requires higher applied potential, this value is roughly in accordance with the obtained diameter of the GaAs nanowires.

The authors proposed and explained the formation of the GaAs nanowires, as seen in figure 5(e). In the case when the pore walls become thin enough to approach twice the space charge region width, holes cannot diffuse further into the interface region since hole diffusion is required to pass through the carrier depleted SCR. This behavior finally terminates the pore wall dissolution reactions, which stabilizes the wall morphology. Note that due to the fact that pores in GaAs possess a triangular cross-sectional shape, the resulted nanowires also have a triangular shape.

For some applications, it is necessary to prepare nanowires aligned vertically to the substrate surface. In 2014, Asoh et al succeeded to fabricate high-aspect-ratio GaAs nanowire arrays self-aligned perpendicular to the surface via anodization of n-type (111)B GaAs substrates [77]. In previous works, the authors optimized the electrochemical parameters of the GaAs etching process [78, 79]. It was found that during the anodization process, the nanopores grow in the vertical direction along the <111> crystallographic direction due to the use of (111)B substrates and, at the same time, new etch pits are nucleated. It is important to note that when a (100) oriented GaAs substrate was used, no formation of vertically aligned GaAs nanowires was found because the pores grew obliquely and intersected each other [75, 76]. The approach proposed by Asoh et al has some noteworthy features: (i) during the anodization, the pore diameter is homogenized by a self-regulating process; (ii) when three adjacent pores became interconnected following the dissolution of GaAs pore walls, the GaAs surrounded by the three adjacent pores formed a nanowire with a high aspect ratio; (iii) eventually, self-aligned GaAs nanowires with a uniformly sized triangular cross section formed spontaneously [77]. Free-standing nanowires with uniform diameters of approximately 200 nm and a length of 100 μm were obtained after 30 min of anodization of GaAs substrates with the electron density of (0.9–2.4) × 1018 cm−3. It was shown that the diameter of nanowires can be reduced from 200 nm to 150 nm by combining the anodic etching with post-chemical etching in an etchant consisting of ammonium hydroxide and hydrogen peroxide. Besides, the nanowires were joined tightly together at the surface forming bundle structures. The obtained arrays of bundles were used by authors as an electron field emitter exhibiting a low turn-on voltage and high field-emission current stability.

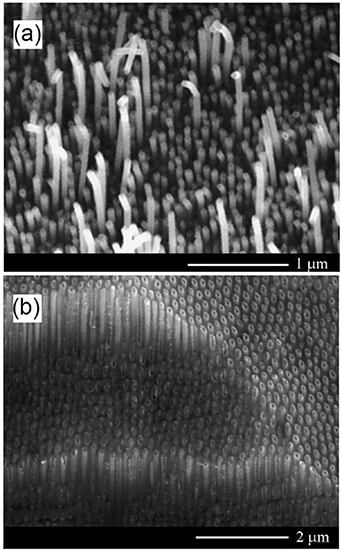

Litovchenko et al [28] also demonstrated the applicability of electrochemical technologies for nanostructuring of narrow band gap InAs semiconductor surfaces in view of preparing morphologies promising for electron field emission applications. They proposed a new technological approach for the preparation InAs rod-like micro- and nanostructures by applying the anodization voltage in pulses with the amplitude of 6 V and the duration of 1 ms at a pulse repetition frequency of 1 Hz. As a result, a homogeneous cone-like texture with the height of the cones h = 0.5–1 μm and sharp tops of ~100–200 nm was prepared. The obtained InAs nanostructures, as seen in figure 6(a), proved to be efficient electron field emission cathodes with rather high current emission (up to 1 × 10−5 A cm−2) and good stability in the range of applied voltages of 400–500 V, shown in figure 6(b).

Figure 6. (a) SEM image of InAs nanostructured surface. (b) Current–voltage characteristic of the electron field emission from the nanostructured InAs surface (arrows indicate the change in the slope). Reproduced from [28]. © IOP Publishing Ltd. All rights reserved.

Download figure:

Standard image High-resolution imageTo date, there are a small number of articles regarding electrochemical etching to fabricate p-type semiconductor nanowires. Formation of porous network in a p-type II–VI material, namely, in p-CdZnTe, was demonstrated by Erne et al [80, 81]. At the same time, Zenia et al subjected p-ZnTe crystals to electrochemical etching and illustrated the formation of needle-like structures exhibiting a blueshift of the excitonic transition energies [82]. The authors found that efficient etching occurs in the potential range 0.5 < U < 1.2 V SCE−1, corresponding to current densities of 200 mA cm−2, and established that the etching process is more homogeneous along the surface when the anodization process is performed under galvanostatic conditions at current densities of 200 mA cm−2. Even after prolonged etching, the length of the needle-like structures did not exceed 2 µm. Pulsed electrochemical etching, however, proved to be efficient for anodization of p-type ZnTe, resulting in the formation of 10 μm long nanowires with the diameter of 50 nm [83]. As in the study of Zenia et al, the authors used an electrolyte based on HNO3:HCl:H2O with the ratio 5:20:100, but under the application of 0.3 s voltage pulses with the frequency of 1 Hz and amplitude of 5 V (the pause between pulses was of 1 s). In this approach, the formation of nanowires required about 30 min of anodization. The dynamics from the etch pits formation up to fabrication of nanowires is presented in figures 7(a) and (b), respectively. The high quality of the produced ZnTe nanowires was demonstrated by photoluminescence investigations since the emission intensity and spectral distribution of PL are practically identical to those of the initial bulk material.

Figure 7. SEM view of a ZnTe sample after 15 min (a), and 30 min (b) of electrochemical treatment. Inset is the magnified view of an etch pit. Reproduced with permission from [83].

Download figure:

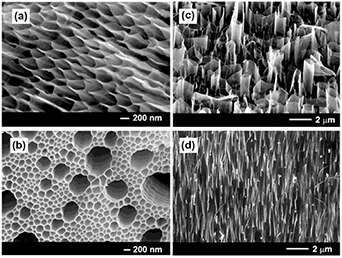

Standard image High-resolution imageThe preparation of nanowires described above requires at least half an hour of anodization duration. It is possible, however, to fabricate InP nanomembranes and nanowires in a cost-effective way, e.g. using fast anodic etching of n-InP single crystalline substrates under potentiostatic conditions [84]. The authors of [84] used the term 'fast anodic etching' because 2 μm long nanowires are obtained in just 3 s of anodization, which means that the rate of etching in depth direction is about 40 μm min−1 [84]. Applying anodization under 5 V potential to samples with the carrier density of 1 × 1018 cm−3, one can fabricate porous layers with pore diameter and wall thickness about 80 nm and 40 nm, respectively, as shown in figure 8(a). An increase in the applied potential up to 7 V gives rise to pronounced fluctuations in the pore diameter and leads to the formation of highly porous layers, the porous skeleton being characterized by percolation, as presented in figure 8(b). Furthermore, by applying a high-voltage pulse during the anodization, it is possible to detach the obtained porous layer from the substrate, i.e. to fabricate a highly porous membrane. In [84], conventional photolithography was used to open rectangular windows with a breadth of 35 μm in the photoresist covering the top surface of the samples. In this way, porous membranes with predefined width can be easily obtained. Moreover, applying a high-voltage short pulse via photolithographically defined windows before the anodization process leads to the formation of InP nanowalls and nanowires. It was established that the morphology depends drastically upon the value of the applied voltage pulse. As can be seen from figure 8(c), the etching results in the formation of mosaic structures consisting of ultrathin semiconductor walls. At the same time, a relatively large number of nanowires form with diameters of about 50 nm (figure 8(c)). The formation of nanowires starts to predominate with a further increase of the applied voltage. Figure 8(d) illustrates a uniform network of parallel nanowires fabricated by applying pulse voltage of 15 V.

Figure 8. SEM images taken from porous layers fabricated by anodization of bulk n-InP (a) at U = 5 V, (b) U = 7 V, (c) U = 10 V and (d) at U = 15 V. Reprinted from [84], Copyright (2014), with permission from Elsevier.

Download figure:

Standard image High-resolution imageAmong top-down methods, metal-assisted chemical etching (MacEtch), which was proposed by Li and Bohn in 2000, has attracted increasing attention in recent years as a novel micro-nanomachining approach [85]. In contrast to the electrochemical and photo-electrochemical (PEC) etching, MacEtch does not require an electrical contact to be made to the sample. The presence of noble metals accelerates the etching rate underneath them with a 'sinking' effect of the catalytic metal in the semiconductor substrate, acting as a negative resist etch mask. When the semiconductor substrate with deposited metal is immersed in the electrolyte, the surface of the catalytic metal serves as a local cathode and the reduction reaction of H2O2 with electron consumption, i.e. hole (h+) production, is initiated. At the same time, the interface of catalytic metal and semiconductor works as anode leading to the oxidation with the release of electrons. As a result, a local current flow occurs due to the difference of potential. Finally, the formed oxide is soluble in etching solution, causing partial removal of semiconductor without net consumption of the metal.

Based on these considerations, MacEtch proved to be a simple and low-cost method for fabricating various nanostructures, with the ability to control cross-sectional shape, diameter and length, depending on the type and pattern of the catalytic metal thin films or nanoparticles [86, 87]. Patterning of the catalytic metal can be carried out using lithographic and non-lithographic methods. For the preparation by design of a desirable catalytic metal pattern, lithographic methods are used [88, 89]. In the case of non-lithographic methods, various approaches for catalytic metal deposition in the form of a discontinuous layer, islands [90–94] or particles from a colloidal suspension are used [95–98]. Varying the density of particles, islands and cracks of the deposited metal layer determines whether the obtained structures represent porous-like material or nanowires. Another important parameter is the aspect ratio. Based on the mechanism of MacEtch, metal structure can drill through the bulk semiconductor as long as catalytic metal is in contact with the semiconductor surface.

DeJarld et al [99] demonstrated that MacEtch can produce high aspect ratio semiconductor nanoscale structures beyond Si. Using n-type (100) GaAs substrates and Au catalyst films patterned with soft lithography, the authors succeeded to fabricate periodic high-aspect-ratio GaAs nanopillars with widths in the range of 500–1000 nm. Controlling the electrolyte concentration and temperature, GaAs nanowires with either vertical or undulating sidewalls were formed at the etch rate of 1–2 μm min−1. Previous investigations of the influence of Cu, Ag, and Pd as catalytic metal and hydrogen peroxide (H2O2) as oxidizing agent showed the possibility to produce sporadic minor crevices [100] and protrusions [101].

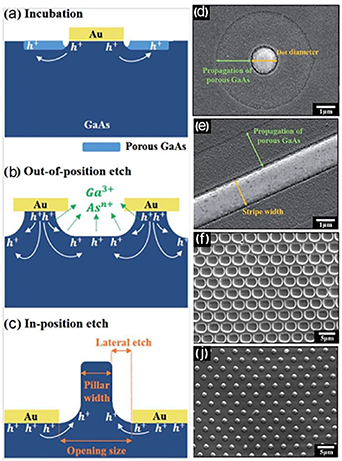

In contrast to MacEtch of Si, GaAs is more sensitive to the rate of oxidation with and without Au catalyst as well as to the rate of dissolution for etching product removal and to changes in the local concentration during etching. Song and Oh in their study [102] defined three characteristic stages of etching schematically illustrated in figure 9: incubation (a), out-of-position (b) and in-position (c) during metal-assisted chemical etching of GaAs using electronic hole and thermally driven chemical reactions. The authors used an etching solution based on potassium permanganate (KMnO4) dissolved with DI water and mixed with sulfuric acid (H2SO4), and changed the electrolyte temperature from 40 to 50 °C. According to their study, at relatively low temperatures, in the incubation stage as seen figure 9(a), the production of holes is suppressed. As a result of weak catalytic reaction, a small amount of holes is concentrated in the GaAs underneath the metal, leading to a slow mass transport of reactants and products at the Au/GaAs interface. In this case, no chemical reaction occurs underneath the metal and the produced holes diffuse in the bulk GaAs. The presence of the H2SO4 acid in the electrolyte causes the etching of the oxidized GaAs, resulting in slightly deep etch region of the surface which is in direct contact with the etching electrolyte.

Figure 9. Schematic illustration of the three stages of metal-assisted chemical etching of GaAs: (a) incubation, (b) out-of-position, and (c) in-position of the metal catalyst. SEM images of GaAs surface topologies with Au catalysts in the form of: (d) dots (1.4 µm in diameter), (e) stripes (1.5 µm wide), after metal-assisted chemical etching and mesh pattern with metal catalyst (2 µm diameters and 2 µm space) at 45 °C (f) and 50 °C (j) for 5 min. Reproduced from [102] with permission of The Royal Society of Chemistry.

Download figure:

Standard image High-resolution imageAt a slightly increased temperature (out-of-position stage in figure 9(b)), a higher amount of holes is produced by the Au catalytic reaction. The thermal activation energy for the chemical reaction seems to remain low enough to allow mass transport of the reactants and products at the Au/GaAs interface. The created conditions lead to a faster chemical etch out-of-position of the metal catalyst, resulting in craters in the bulk GaAs with a lateral etching intrusion on the edge of the Au/GaAs interface (see figure 9(e)). At higher temperatures (in-position stage figure 9(c)), a sufficient amount of holes is generated as a result of the reaction between the metal catalyst and KMnO4 oxidant. Under these conditions, immediate metal-assisted chemical etching occurs in-position of the metal catalyst due to the rice of thermally activated chemical reactions and mass transport at the Au/GaAs interface, as shown in figure 9(d). Note that some holes may diffuse towards the bulk of GaAs leading to lateral etching out-of-position of catalytic metal. In spite of this, the authors experimentally demonstrated that the length of the lateral etch is not dependent on the opening diameters. After optimization of the etch parameters and catalyst features, high aspect ratio nano-scale pillars were fabricated.

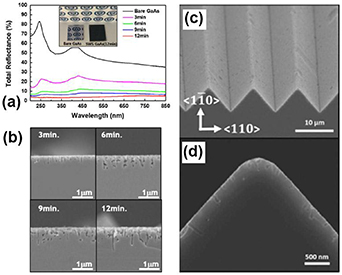

Afterwards, the same group of authors used MacEtch for the fabrication of antireflective GaAs subwavelength structures (SWSs) [103]. The fabricated GaAs structures drastically reduced the total reflectance up to 4.5% in the wavelength range of 200–850 nm and up to the incident angle of 50° (see figures 10(a) and (b)). In their study, they demonstrated that the reflectance strongly depended on the three-dimensional features of the GaAs SWSs, which can be controlled by Au agglomeration and chemical etching. To enhance their antireflective characteristics, two wet-based etching processes, orientation dependent etching and MacEtch, were used to fabricate GaAs nano/micro dual-scale textured antireflective structures [104]. The fabricated antireflective structures presented in figures 10(c) and (d) suppressed the reflectance by the combination of the increased light absorption path in the microscale triangular structure and the increased absorption of the incident light by the continuously changed refractive index between air and GaAs in the nanohole structure.

Figure 10. (a) Reflectance spectra of produced GaAs SWSs etched for 3, 6, 9, or 12 min as a function of the wavelength. Inset shows images of bare GaAs (left) and SWSs etched for 12 min (right). Reproduced from [103], Copyright (2016) with permission from Elsevier. The SEM images in cross-sectional view of GaAs SWSs for different durations of Au MacEtch are shown in (b). Reproduced from [103], Copyright (2016) with permission from Elsevier. SEM image showing tilted (c), and (d) cross-sectional views of nano/micro dual-scale textured (triangle and nanohole) GaAs fabricated by orientation-dependent etching for 25 s and MacEtch for 5 min. Reprinted with permission from [104] © The Optical Society.

Download figure:

Standard image High-resolution imageHowever, MacEtch of III–V semiconductor compounds for the fabrication of periodic nanostructures, especially in high aspect ratios, has been hardly explored in the last decade. Small microbump arrays of InP have been formed using MacEtch coupled with UV irradiation [105]. The authors described the effect of etchant concentration and catalyst species (Pt, Pd, or Au) on the resulted morphology of etched InP microstructures. They established that in the case of metal-assisted photodissolution, an exposed InP surface around a metal-coated area was etched remarkably. In addition, the etching rate of the InP substrate was affected by the difference in noble-metal species and increased in the order of Au < Pd < Pt, corresponding to the order of the magnitude of the work function of metals.

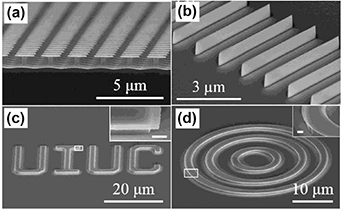

Kim et al reported fabrication of a wide variety of InP nanostructures with smooth sidewalls, lateral dimensions as low as sub-20 nm, and aspect ratio greater than 35 by a systematic inverse MacEtch (I-MacEtch) method and even without UV irradiation [106]. The term I-MacEtch is coined to describe the etching mechanism whereby a patterned metal layer acts as a catalyst as well as a mask for the formation of features in an inverse arrangement to that expected of traditional MacEtch. In this way, the I-MacEtch mechanism causes the semiconductor regions not in contact with the catalyst layer (i.e. between the metal covered areas) to be preferentially etched. In addition, the areas directly underneath the metal catalyst/mask can be etched (laterally) simultaneously at a fixed ratio relative to the vertical etch rate determined by I-MacEtch conditions. The effects of metal catalysts, nature of etching solution, etching duration, areal coverage and separation of the metal patterns, and metal pattern orientation as related to the crystallographic orientation of the substrate, on the etch rate and morphology of the resultant InP nanostructures were investigated. The SEM images of low dimensional structures (20 nm) are summarized in figure 11.

Figure 11. InP nanostructures produced via I-MacEtch: (a) arrays of nanopillars generated from Pt square pads, (b) arrays of nanoscale fins from Au lines after Au removal, (c) the letters 'UIUC' from Au pads with inset showing a high-magnification view of the outlined region (white box) corresponding to the letter 'I', and (d) concentric InP microstructures generated from a set of Au rings, with inset showing the high-magnification view of the outlined region. The inset scale bars are 500 nm. Reprinted with permission from [106]. Copyright (2015) American Chemical Society.

Download figure:

Standard image High-resolution imageThe study of MacEtch of GaN is still in the primary stage. The reported morphologies disclose mainly the pore structure [107–110]. More recently, by varying the solution composition, concentration and etch time under UV illumination, different GaN nanostructures including nanowires were reported [111–114].

Table 5 summarizes a variety of semiconductor nanostructures produced by electrochemical etching and MacEtch technologies.

Table 5. Technologies applied and parameters of the produced semiconductor nanostructures.

| Type of nano-structure | Material used | Technology applied | Parameters of the structure | Proposed application | Ref. |

|---|---|---|---|---|---|

| Triangular nanowires | Si-doped GaAs (2.7–8.6) × 1017 cm−3 | Anodization in KOH:H2O | D: 400–700 nm L: >10 µm | — | [75] |

| Nanowires | n-GaAs (0.9–2.4) × 1018 cm−3 | Anodization in HCl:H2O | D: 150–200 nm L: 100 µm | Field emission | [77] |

| Nanowires | p-ZnTe Na-doped 3 × 1018 cm−3 | Pulsed anodization in HNO3:HCl:H2O | D: 50 nm L: 10 µm | High light emission intensity | [83] |

| Nanowires | n-InP 1.3 × 1018 cm−3 | Anodization in HCl:H2O at 15 V | D: 50 nm L: 2 µm | Plasmonics | [84] |

| Nanobelts | n-InP 1.3 × 1018 cm−3 | Anodization in HCl:H2O at 13 V | Thick.: 2–5 nm Width: 50 nm Length: 2 µm | Plasmonics | [115] |

| Cone like structures | n-InAs | Pulsed anodization in H3PO4:HNO3:H2O | Height: 1 µm Top diameter: 100–200 nm | Field emission | [28] |

| Nano/micro dual scale SWS | Si-doped n-GaAs | MacEtch | Triangular- height: 8.5 µm, nanoholes: 60 nm | Anti-reflection | [104] |

| Nanowals | S-doped n-InP (0.8–8.0) × 1018 cm−3 | MacEtch | Thick.: 20 nm Height: 500 nm Length: 5 µm | Nano-electronics, opto-electronics | [106] |

2.4. Templated electrochemical deposition of metal nanowires, nanotubes and nanodots

As mentioned above, in the last decade extensive attention was paid to one-dimensional objects such as nanowires, nanotubes, and integrated arrays based on them, as they represent an emerging class of advanced multifunctional materials which are promising for wide applications in microelectronics, photonics, medicine, chemical and biological sensing. For many concrete applications, it is necessary to integrate a large amount of nanowires in one bundle or array to achieve the required functionalities.

As mentioned in the Introduction, porous semiconductors have attracted considerable interest from the point of view of manufacturing conductive nanotemplates which properties can be easily controlled by external illumination, applied electric fields, etc.

Several kinds of electrochemical deposition methods are applied for filling the pores, such as direct current electrodeposition, pulsed electrodeposition, and alternating current electrodeposition. Pulsed electrodeposition appears to be the most appropriate method for the preparation of metallic nanotubes embedded in porous semiconductor templates. It was demonstrated experimentally that in the case of macroporous Si electrochemical deposition of Cu can be realized via potentiostatic/galvanostatic electrodeposition in continuous mode, while filling the nanoscale pores in InP, GaAs or Ge require pulsed electrodeposition [116]. The possibility to deposit galvanically Ni [117] or Co [118] nanowires arrays in ultra-high aspect ratio porous InP membranes was demonstrated by coating the internal surface of the nanotemplates with a very thin dielectric interlayer prior to deposition. This dielectric layer electrically passivates the pore walls so that nucleation of metal clusters on the pore walls is prevented. At the same, time uniform distribution of Co nanodots over pore sidewall surface in the as-etched InP template was reported by Zhou et al [119].

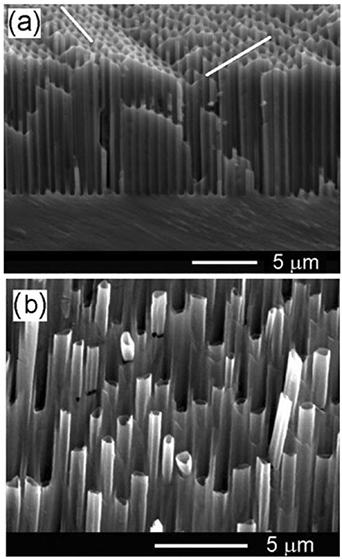

The deposition of Pt nanotubes in InP nanotemplates (see figure 1(d)) without any passivation layer [51] was realized by electroctrochemical pulsed deposition of Pt at 40 °C for 2 h in a common two-electrode plating cell where the porous sample served as working electrode, while a platinum wire was used as counter electrode. For nanotemplates with different pore diameters, the authors used different lengths of pulses: 100 μs and 300 μs for pore diameters of 70 nm and 140 nm, respectively. A cathodic potential of −12 V was applied between the electrodes to electrochemically reduce the metal species on the surface of the porous matrix in contact with the electrolyte. To assure a uniform deposition along the depth, after each pulse a delay time as long as 1 s was used, allowing ions to diffuse into pore regions depleted during the deposition pulse. Pt electroplating in nanotemplates with pore diameters of 70 nm and 140 nm leads to uniform metal deposition on inner surface of pores along the pores (figures 12(a) and (b)). As shown in figure 12(a), many of the Pt nanotubes get out from pores and are suspended in air indicating high uniformity and strength of deposited metal nanotube in spite of the nanoscale thickness of the walls. According to [51], under a pulsed voltage regime, it is possible to control the metal deposition within limited regions in depth of the porous structures by changing the ratio between the pulse duration and delay time between pulses.

Figure 12. SEM image taken from a cleaved porous template with pore diameter 70 nm (a) and 140 nm in (b) after pulsed electrodeposition of Pt. Reprinted from [51], Copyright (2008), with permission from Elsevier.

Download figure:

Standard image High-resolution imageAn interesting issue observed is that on SEM images, the Pt nanotubes look bright in comparison with the porous n-InP skeleton walls. The metal nanotubes possess higher conductivity than semiconductor template and normally no charging phenomenon must be observed. Indeed, taking into account that pulsed electrochemical deposition of Pt on n-InP leads to the formation of Schottky barrier with the height up to 0.65 eV [120], it is obvious that the negative charge accumulates in metal nanotubes during morphology study by SEM. Using pulsed electroplating, Sato et al demonstrated uniform deposition of Pt dots with the diameters ranging from 20 to 30 nm on n-GaAs and n-InP substrates with the free electron concentrations of 2 × 1016 and 5 × 1016 cm−3, respectively [121, 122]. The authors found the Fermi-level pinning at the metal-semiconductor interface to be greatly reduced, resulting in a strong dependence of the Schottky barrier height on the metal work function.

The electronic band gap of InP is 1.3 eV at 300 K, which means that the nanotemplates based on InP are opaque in the visible region of the spectrum. Porous ZnSe templates present even more interest, since they are transparent for the visible light due to the larger bandgap of the semiconductor compound (for ZnSe e.g. = 2.7 eV at 300 K).

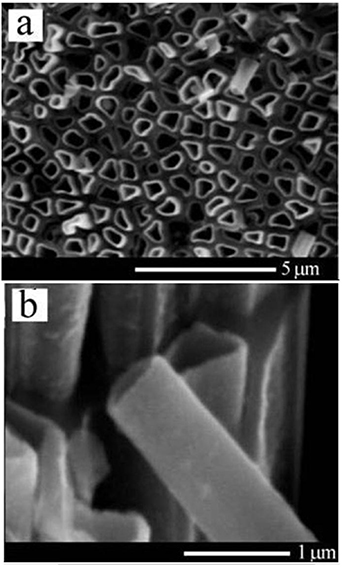

The electrical conductivity of ZnSe crystals can be controlled by doping and post-growth thermal treatments [123] which in turn determines the diameter of the produced pores by anodization. Figure 13(e) illustrates a porous template fabricated on 1 mm thick n-ZnSe substrate with free electron concentration of 7 × 1016 cm–3. The anodic etching was carried out in the dark at room temperature in a K2Cr2O7:H2SO4:H2O electrolyte with the ratio 5:100:10 [57]. Although the formation of uniformly distributed pores exhibiting features of short-range order is inherent to anodic etching of n-ZnSe, long-range order in pore distribution was not reached. The reason could be the absence of crystallographically oriented pores in ZnSe. As mentioned above, the long-range order in pore distribution illustrated in n-InP is favored by the network of crystallographically oriented pores initially formed in the nucleation layer [31]. In case this network is well developed, there is a general tendency of current-line oriented pores to form rows oriented along <110> direction.

Figure 13. SEM images taken from a cleaved ZnSe template with pore diameter 400 nm (a) and 40 nm (b) after pulsed electrodeposition of Pt. The insert in (a) illustrates a top view after the sample was additionally cleaved along a plane nearly perpendicular to the pores. [124] John Wiley & Sons. Copyright © 2009 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim.

Download figure:

Standard image High-resolution imagePt electroplating in pulsed voltage regime in 20 µm thick porous ZnSe layer with diameters of pores of about 400 nm and 40 nm was carried out at 40 °C for 8 h in a common two-electrode plating cell containing 2 g l−1 Pt where the porous sample served as a working electrode, while a platinum wire was used as a counter electrode. It was established that the cathodic potential depends upon the conductivity of the semiconductor template. This potential is −12 V for the used InP templates with free electron concentration of 1.3 × 1018 cm−3, −40 V for ZnSe with free electron concentration of 8 × 1016 cm−3, and −10 V for ZnSe with free electron concentration of 2 × 1018 cm−3 [57, 124]. Like in InP, after each pulse, the authors used a delay time as long as 1 sec at zero external voltage applied to allow ions to diffuse into pore regions depleted during the deposition pulse. As can be seen from figure 13(a), electrochemical deposition of Pt resulted in the formation of metal nanotubes with the wall thickness of about 50 nm. Pieces of Pt nanotubes getting out from pores are clearly seen in the cross-sectional view taken from a cleaved sample, as seen in the insert in figure 13(a). The quality of nanotubes is indicative of good uniformity of metal deposition on the inner surface of pores. The possibility of obtaining Pt nanotubes was also demonstrated for ZnSe nanotemplates with the diameters of pores of about 40 nm (figure 13(b)). Due to the small thickness of the metal wall (about 10 nm), the nanotubes can be easily destroyed – even through a simple cleavage. The high conductivity of the semiconductor nanotemplate skeleton provides conditions for uniform electrochemical deposition of metal species on the inner surface of pores, resulting in the formation of arrays of metal nanotubes embedded in semiconductor matrices.

The possibility to fabricate two-dimensional metallo-semiconductor quasi-periodic structures has also been demonstrated on porous GaP templates [125, 126]. Templates with parallel pores possessing diameters in the micrometer and sub-micrometer ranges have been fabricated by electrochemical etching of commercially available n-GaP substrates with (100) orientations and electron concentration of about 1017 cm−3 in H2SO4 aqueous electrolyte. Figure 14(a) illustrates the morphology of a porous GaP template. Similarly to InP templates, ordered arrays of pores are produced due to self-organization phenomena occurring during the pore growth. The white lines in figure 14(a) mark several directions of pore alignment in a porous GaP template. Uniform electroplating of Pt on inner surface of pores was realized in an acid platinum bath under a pulsed voltage regime, the deposition being performed at 40 °C in a common two-electrode cell where the porous sample served as a working electrode and a platinum wire was used as a counter electrode. It was found that under the pulsed voltage regime, it is possible to deposit metal within limited regions in depth of the porous structures, the depth of these regions being mainly dependent on the ratio between the pulse duration and the delay time between pulses. Electroplating starts with the deposition of metal dots, their density increasing with time. The overlapping of neighboring dots leads to the formation of tubular structures, as illustrated in figure 14(b). It was found that the application of short pulses (less than 0.3 ms) during electroplating results in a predominant deposition of Pt near the bottom of the pores, while longer pulses lead to the predominant deposition near the mouth of the pores. So, the pulse length of 0.3 ms was found to be optimal for a uniform metal deposition inside the pores of the template. As a result, arrays of metal nanotubes with the length reaching 200 μm, smooth walls and rather good mechanical strength were routinely fabricated.

Figure 14. SEM image of a porous GaP template with ordered arrays of pores indicated by white lines (a) and an image illustrating the formation of Pt tubular structures (b). Reproduced from [125]. © IOP Publishing Ltd. All rights reserved.

Download figure:

Standard image High-resolution imageSince the GaP template is characterized by ordered arrays of pores, it was found that packs of rows of Pt nanotubes in a semiconductor envelope can be easily cleaved from the sample. In fact, the semiconductor nanotemplate with the embedded array of metal nanotubes behaves like a layered crystal, the role of individual layers being played by the rows of Pt nanotubes in n-GaP envelopes. The possibility of such a cleavage is important from the point of view of photonic applications of the fabricated metalized porous GaP templates, as discussed in section 5.

Arrays of metal nanowires and nanotubes embedded in semiconductor nanotemplates, with uniform deposition of Pt on the inner surface of pores without any activation of the pore's wall was demonstrated, regardless of the pore shape (e.g. circular, triangular-prism-like pores, etc) as shown in figure 15 [125]. Moreover, the shape of nanopores can be controlled using semiconductor crystals with different crystallographic orientations. The influence of the (100) and (111) crystallographic orientations of the n-GaP substrates upon the shape of the produced pores was reported by Schmuki et al [61, 62].

Figure 15. SEM images demonstrating formation of Pt tubular structures in GaP template with complex shapes (a) and the image of an individual Pt nanotube (b). Reproduced from [125]. © IOP Publishing Ltd. All rights reserved.

Download figure:

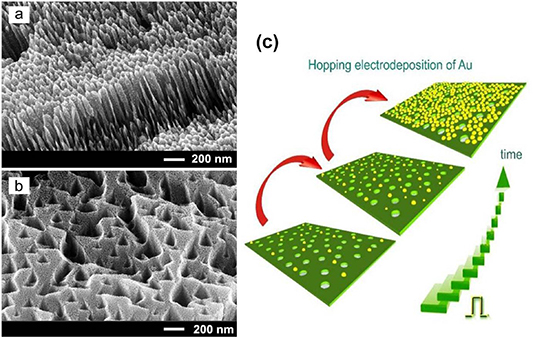

Standard image High-resolution imageThe electrochemical deposition of metal dots proves to be one of the most cost-effective and efficient means, especially when the dots are to be created on semiconductor substrates or matrices exhibiting electrical conductivity. The possibility to cover a huge surface inherent to GaP and InP porous structures by a self-assembled monolayer of electrochemically deposited Au nanodots was demonstrated [127]. The so-called 'hopping electrodeposition' mechanism was proposed by the authors to explain the electroplating of one monolayer of gold nanodots on porous semiconductor structures. In [125], the authors used pulsed electrochemical deposition of gold and established that after nucleation, each dot increased in size up to a critical transverse dimension of about 20 nm, the process of electrodeposition of gold being continuously supported by the formation of new nanodots. This value corroborates with the previously published data for Pt electrodeposition on n-InP, demonstrating that the value of the Schottky barrier height depends on the size of the Pt dots [121]. As the Pt dot diameter increases, the surface barrier height rapidly increases toward the value of the Mott-Schottky limit of 1.1 eV which is reached at the dot diameter of approx. 23 nm. Supposing that similar tendencies are obeyed in n-InP and n-GaP, one can expect enhanced values of Schottky barriers occurring at the interface between semiconductors involved and sub 20-nm diameter Au dots. The deposition process continues until the entire surface exposed to the electrolyte is covered by a monolayer of self-assembled gold nanodots (see figures 16(a) and (b)).

Figure 16. SEM images taken from fragments of porous GaP after electrochemical deposition of Au dots for 5 s (a) and 100 s (b). Reproduced from [127]. © IOP Publishing Ltd. All rights reserved. Schematic illustration of the 'hopping electrodeposition' mechanism is presented in (c).

Download figure:

Standard image High-resolution imageThe schematic illustration of the 'hopping electrodeposition' mechanism is presented in figure 16(c). At the beginning of electroplating the process of nucleation of gold dots takes place along with their gradual growth in size. As the transverse dimension of the dot reaches the threshold value, a Schottky barrier emerges, the barrier potential being oriented in the opposite direction relative to the applied cathodic voltage. It can be assumed that the modified local potential 'switches off' the electrodeposition within the area of this dot. To keep the process running, the system initiates the nucleation of new dots. In other words, one can imagine electrodeposition as a hopping process: Au deposition 'jumps' to other local areas as soon as one or more dots reach the threshold value of the diameter. The processes of 'switching off' and 'hopping' continue until the entire surface exposed to the electrolyte is covered by a monolayer of self-assembled Au dots. It is interesting to note that after the self-assembled monolayer is formed, further electroplating of gold is spatially non-uniform and leads to the deposition of particles with relatively large diameters.

Deposition of metal nanodots has also been investigated in porous templates with pores oriented parallel to the sample surface prepared according to a specially developed technology described in more details in section 3 [128]. A pulsed electrochemical deposition method was applied for this purpose. Figure 17(a) illustrates an InP template with pores buried underneath a thin surface layer. It was found that metal deposition takes place simultaneously both inside the buried pores and on the top template surface. On the template surface the metal is deposited in the form of nanodot lines as illustrated in figure 17(b), the thickness of such lines being determined by the number of applied pulses, while nanotubes are formed from metal nanodots inside the pores of the template as shown in figure 17(c). This uniformity of metal deposition inside the pores is ensured by the good electrical conductivity of the porous skeleton. A mechanism was discussed behind the mode of depositing nanodot lines on the top template surface and nanotubes inside the pores, on the basis of a recent work demonstrating that electroplating represents a simple and effective tool for assessing the conductivity of InP nanostructures fabricated by electrochemical etching of InP wafers [115]. The proposed approach could widen the area of potential applications of metal nanodots and nanotubes. They might be used to make plasmonic photonic crystals, optoelectronic on-chip interconnections, and chemical and biological sensors based on surface enhanced Raman scattering.

Figure 17. (a) SEM cross-sectional view of an InP template with pores parallel to the sample surface. (b) SEM view of the Au dots arrays deposited on the surface of the template after applying 100 pulses. (c) SEM image of the template with Au nanotubes deposited inside the pores, taken after removal of the surface layer of the template. The right side of the template in images (b) and (c) was protected against electrochemical deposition with the purpose of comparison.

Download figure:

Standard image High-resolution imageIt is important to note that the pulse duration and pause between pulses are the key parameters for the deposition of metal inside the porous semiconductor skeleton and for obtaining of metal nanostructures with desired shape (nanowires, nanotubes). The analysis of experimental data reveals that the pulse duration varies from 10 to 50 μs for metal nanodots formation, while the formation of metal nanotubes requires pulse duration from 100 to 300 μs and longer deposition time. At the same time, the manipulation with the amplitude of the applied pulses provides possibilities for metal deposition in a controlled fashion enabling one to reach specific designs of the semiconductor/metal porous architectures.

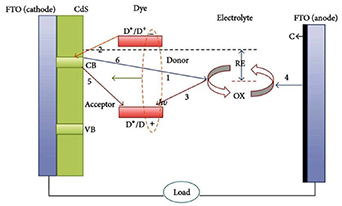

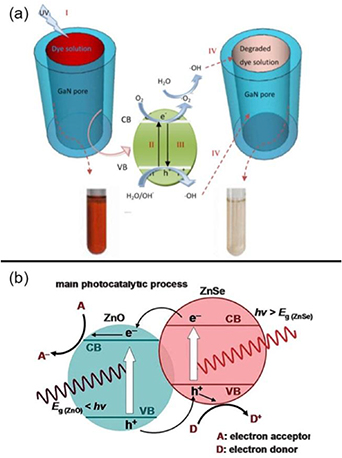

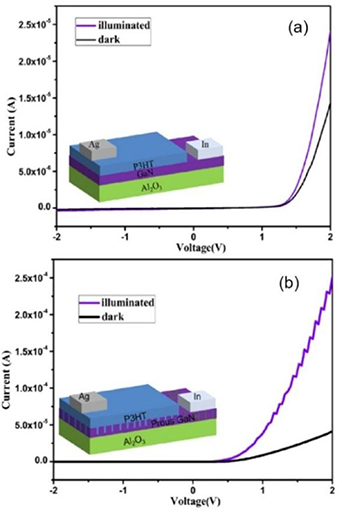

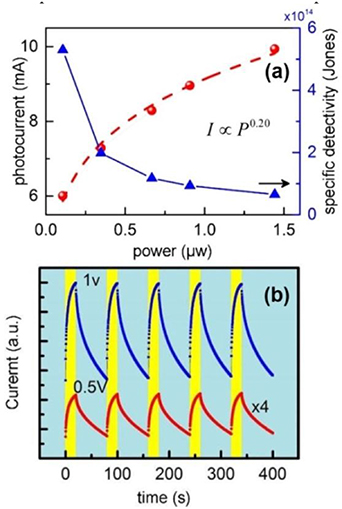

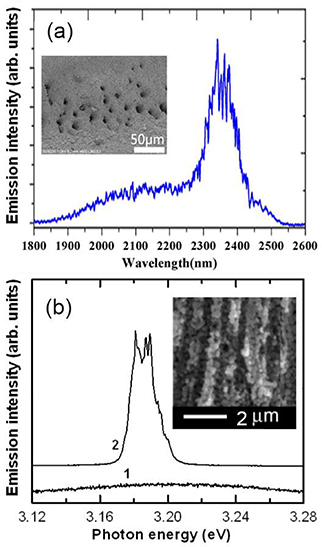

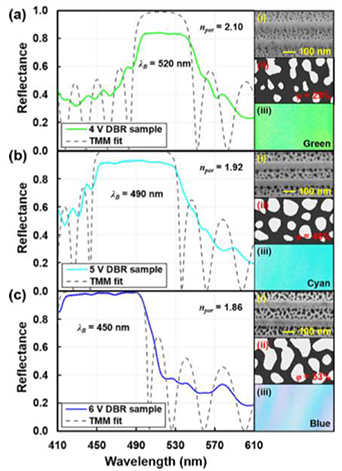

3. Self-organized phenomena in porous etching and formation of nanocomposite materials

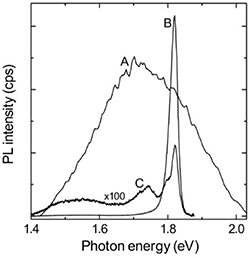

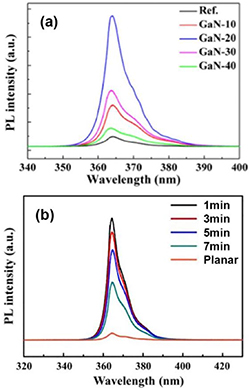

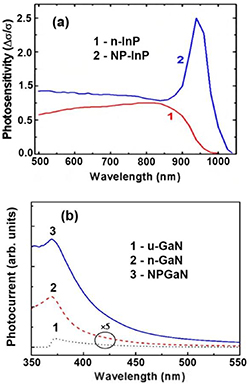

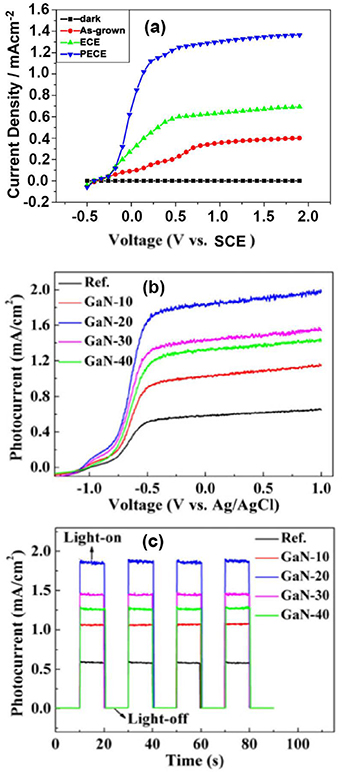

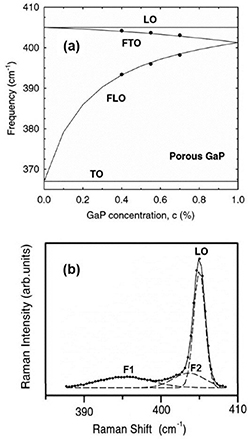

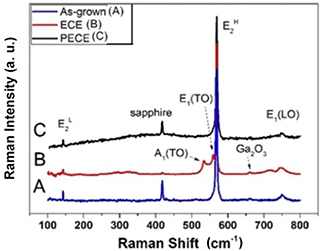

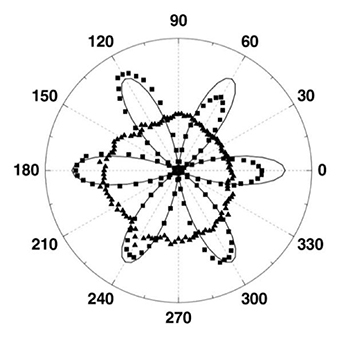

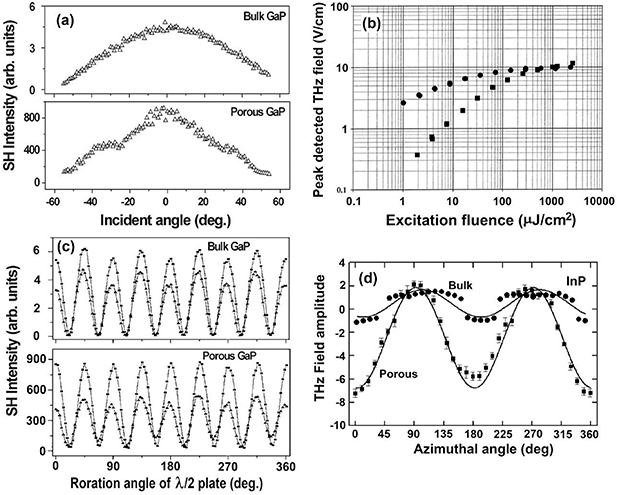

3.1. Material nanostructuring by controlling the porous pattern. Pores oriented parallel to the top surface of substrates