Abstract

Plasma catalysis is gaining increasing interest for various applications, but the underlying mechanisms are still far from understood. Hence, more fundamental research is needed to understand these mechanisms. This can be obtained by both modelling and experiments. This foundations paper describes the fundamental insights in plasma catalysis, as well as efforts to gain more insights by modelling and experiments. Furthermore, it discusses the state-of-the-art of the major plasma catalysis applications, as well as successes and challenges of technology transfer of these applications.

Export citation and abstract BibTeX RIS

1. Introduction

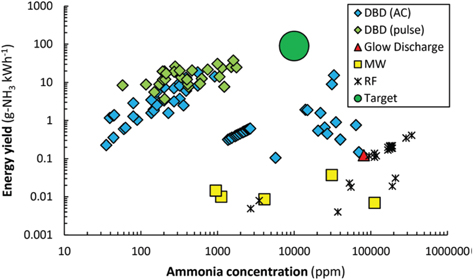

Plasma catalysis is gaining increasing interest for various environmental applications [1–10]. We can roughly distinguish two main application fields, i.e., gas cleaning and gas conversion. Gas cleaning refers to the removal of relatively low concentrations of unwanted components from a gas stream, such as volatile organic compounds (VOCs) and NOx . In gas conversion, the input gases are in high concentration and are typically converted to higher-value products. Examples include the splitting and hydrogenation of CO2, dry reforming or partial oxidation of methane to produce syngas, higher hydrocarbons or oxygenates, and the production of ammonia from nitrogen and hydrogen.

The gas cleaning applications are quite mature already, and this is especially true for the removal of VOCs, for which commercial devices have been available for many years. The technology readiness level (TRL) of gas conversion applications is much lower. Indeed, these applications are better described as emerging and still face several challenges, such as the need to improve energy efficiency and to design optimal catalysts tailored to the plasma conditions, as well as to improve the product yield and selectivity.

Hence, to make further progress, there is a crucial need for a better understanding of the underlying mechanisms. While plasma and catalysis on their own are already quite complex, their combination is even much more complicated. Indeed, the catalyst affects the plasma behaviour, and the plasma affects the catalytic process in multiple ways (see further). A better insight in these mechanisms can be obtained from experiments and modelling.

This foundations paper explains the current knowledge on the underlying mechanisms (section 2), followed by how modelling and diagnostic experiments of both the plasma and catalyst surface can help to elucidate these mechanisms. As explained in section 3, multi-scale modelling is being developed, combining models at various levels. The measurements carried out in plasma catalysis are mostly focused on determining performance parameters, for which it is important to be precise about their meaning in order to make relevant comparisons between reactors. Furthermore, the understanding of the microscopic mechanisms at the heart of the plasma–catalyst interaction requires the use of in situ measurement techniques of both the plasma phase in contact with the catalyst and the surface properties under direct exposure to the plasma, as will be discussed in section 4. Section 5 provides an overview of the various applications, and finally, section 6 describes the status, successes and challenges of technology transfer.

2. Fundamental insights

2.1. From thermal catalysis to plasma catalysis: the role of kinetics and thermodynamics

When asked to describe the fundamental laws governing the whole of chemistry, the likely answer would be quantum mechanics and thermodynamics. Quantum mechanics essentially dictates how molecules interact with each other at the most fundamental level, while thermodynamics tells us the end-point of the evolution of a macroscopic system, given a set of boundary conditions. As such, it defines the arrow of time. It also tells us, from a more chemical perspective, where the equilibrium state of the system is located along the reaction coordinates. The driving force to reach this equilibrium state, then, is the change in the free energy of the system. The free energy of the system, finally, is determined by what molecules the system is composed of under the given boundary conditions and how energy is partitioned over their various degrees of freedom, which are essentially solutions to the Schrödinger equation.

So, where does kinetics enter the equation? It could be argued that kinetics is nature's way of bringing thermodynamics into practice. Given enough time, the ratios of the reaction rates of all possible reactions in the system, given the imposed boundary conditions, eventually lead to an equilibrium state—or, in many open system cases, a steady-state. Alternatively, of course, one could say that thermodynamics is essentially the convoluted result of kinetics. Either way, both kinetics and thermodynamics are of fundamental importance for any chemical process and are intimately connected. Kinetics, furthermore, yield a wealth of data on the possible operative mechanisms and can thus be studied to elucidate these mechanisms. As plasma catalysis is nothing more than a—admittedly very complicated—chemical process, it is thus important to understand how thermodynamics and kinetics determine the processes occurring in plasma catalysis. This is further underlined by the intrinsic non-equilibrium nature of plasmas, which, incidentally, distinguishes plasma–catalytic systems from thermal-catalytic systems, which are most often characterized by thermal equilibrium. Indeed, this non-equilibrium nature turns out to be an essential feature determining many of their properties, and thereby their application potential in catalysis.

Let us illustrate the importance of both kinetics and thermodynamics by referring to a specific study by Rouwenhorst et al on plasma–catalytic NH3 synthesis. Although the discussion below focusses on the importance of vibrationally excited molecules, this is by no means the only route to an effective plasma–catalytic process or to synergy. Indeed, in other setups or other processes, other mechanisms may (and will) be at play.

In a theoretical calculation by Mehta et al [11], the plasma-induced vibrational excitation of N2 in the gas phase was put forward as the key mechanism in lowering the rate-limiting N2 dissociation barrier, and thus enhancing the overall rate of the NH3 synthesis reaction. In their experimental study, Rouwenhorst et al verified and confirmed this hypothesis [12]. Furthermore, they demonstrated that the apparent activation barrier for the process, which for the thermal-catalytic process is ∼60–115 kJ mol−1, is lowered to a range of ∼20–40 kJ mol−1 in their plasma–catalytic setup.

To distinguish the possible mechanisms in their discussion, they introduced the following nomenclature (see figure 1 ): (1) plasma-phase NH3 synthesis, where the entire synthesis proceeds through gas-phase reactions; (2) surface-enhanced plasma-driven NH3 synthesis, where plasma-generated radicals adsorb on the surface, which may subsequently diffuse and combine to form NH3; (3) plasma-enhanced semi-catalytic NH3 synthesis, where plasma-generated N* radicals adsorb on the catalyst surface, while H2 dissociates on the catalyst. Note that in this mechanism, the rate-limiting step, viz N2 dissociation, is not catalyzed. And (4) plasma-enhanced catalytic NH3 synthesis, where both N2 and H2 chemisorb dissociatively.

Figure 1. Reaction mechanisms of ammonia synthesis, after Rouwenhorst et al [12]: (a) plasma-phase mechanism; (b) surface-enhanced plasma-driven mechanism; (c) plasma-enhanced semicatalytic mechanism; (d) plasma-enhanced catalytic mechanism. Reactions directly relevant for the mechanisms are depicted with full arrows, while subsequent reactions to ammonia formation are depicted with dashed arrows. Blue spheres represent nitrogen atoms, grey spheres represent hydrogen atoms. For further details, see text.

Download figure:

Standard image High-resolution imageOnly the latter mechanism turns out to be consistent with the obtained kinetic data in their particular setup. We emphasize that the results and conclusions are indeed particular for this setup, as their conclusions were modified in a later work, which used a somewhat different setup [13]. In this more recent work, the authors impart an important role to the radicals as function of reaction temperature and plasma power [13]. Regardless, from their kinetic studies, Rouwenhorst et al demonstrate what the operative mechanism in their particular setup should be. The first observation is therefore that the study of chemical kinetics is essential in unravelling plasma–catalytic pathways.

The second important observation with respect to the kinetics of the process is that the plasma–catalytic operation—at least in this particular study—does not necessarily change the conceptual mechanism. Indeed, both the N2 and the H2 are still catalytically dissociated on the catalyst surface, as they are in thermal catalysis. The importance of the plasma, rather, is to efficiently pre-activate the key reactant, which in turn increases the rate of the overall process. Therefore, while different mechanisms may be operative in plasma catalysis compared to thermal catalysis, an actual change in mechanism does not seem to be a prerequisite.

A third important observation coming forward from this and similar studies is the role of thermodynamics in plasma catalysis. Recall that classical equilibrium thermodynamics in a closed system essentially determines where the equilibrium of a system is located along the global reaction coordinate, which in turn is determined by all possible reactions, subject to the boundary conditions of the process. This equilibrium is a direct result of the equalization of the chemical potentials of the various components in the reaction mixture and leads to the unambiguous definition of an equilibrium constant for the process as a function of the reaction conditions. The driving force to reach this equilibrium is, as mentioned, the change in free energy of the system: the system reaches an equilibrium state when the free energy attains its minimum value along the reaction coordinate.

However, plasma–catalytic systems are typically not closed but rather open systems, operating in a continuous manner, where reactants continuously flow into the reactor and products flow out. In this case, one typically strives to attain a steady-state, as this allows control to be maintained over the process on the one hand (e.g. a constant outflow of products) while at the same time allowing continuous operation. In any such system, equilibrium will, in general, not be reached.

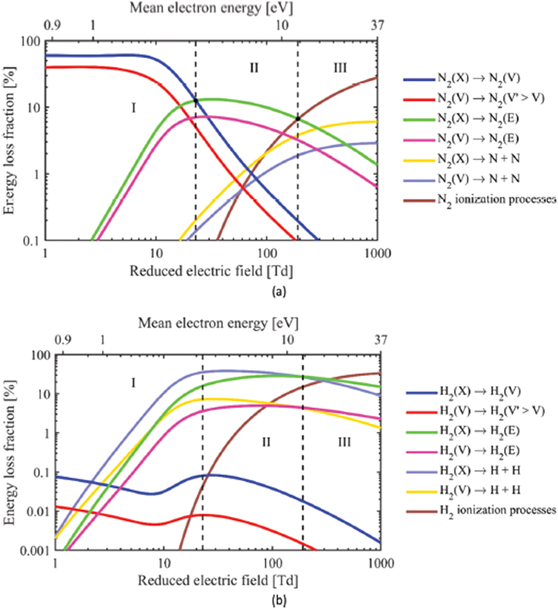

Second, technological plasmas are, by their very nature, strongly non-equilibrium systems. They are characterized by either a continuous or pulsed energy input (in the form of electricity), resulting in an electron temperature that is typically much higher than the neutral gas temperature. Moreover, depending on the mean energy of the electrons, different plasma phase reaction channels may be preferentially tapped. For instance, vibrational excitation, electronic excitation, dissociation, ionization, etc, are all important non-equilibrium features of many technological plasmas, not observed (to any substantial degree) in the gas phase of thermal catalytic processes. Thus, again depending on the precise nature of the plasma and the operating conditions, one could, and one typically does, define several temperature scales: an electronic temperature (or more elaborately, an electron energy distribution function (EEDF)), an ion temperature (or equivalently an ion energy distribution function), a neutral gas temperature, and also, for instance, a vibrational temperature characterizing the population of vibrationally excited states. Indeed, while under standard thermal catalytic operating conditions the vibrational levels of most molecules will be nearly frozen, i.e., not activated, they can be activated in plasma–catalytic systems, such that energy is also partitioned into these degrees of freedom.

In the study of Rouwenhorst et al mentioned above [12], the electrons indeed gave rise to a significant vibrational excitation of N2. This is very much a non-equilibrium feature of the plasma. This feature thus changes the nature of the reactants involved, and therefore the relevant chemical potentials, which strive to equalise to reach equilibrium. As a result, it can be expected that even when the global mechanism of a process does not change in a plasma–catalytic setup, the equilibrium constant will be modified. This, in turn, leads directly to the observed modified kinetics.

It is thus clear that the notion that the kinetics and the thermodynamics of a process are intimately connected still holds in plasma–catalytic processes. The boundary conditions of the process (e.g. the input of electrical energy) modify the process relative to thermal catalysis, thereby modifying the nature of the reactants, which alter the governing thermodynamics, resulting in different kinetics. In the case of the Rouwenhorst study, this led to a clear plasma–catalytic synergy.

This change in boundary conditions, however, is not a sufficient condition for synergy. Indeed, only when the key, rate-determining processes are affected by the plasma can synergy be expected.

Based on the above, it could be argued that only the fourth mechanism described above ('plasma-enhanced catalytic NH3 synthesis') is truly plasma–catalytic, where synergy is to be expected. Indeed, the plasma, in this case, serves to vibrationally excite the N2 molecules, which enhances the N–N bond-breaking process at the catalytic surface. Importantly, it was found that while this pathway still follows classical thermodynamics, it does show a change in equilibrium constant due to the plasma-induced vibrational excitation of the key reactant.

We reiterate that the discussion above does not imply that vibrational excitation of reactant molecules is the only mechanism towards some form of synergy in plasma catalysis. Indeed, other mechanisms may be operative in different setups and in different systems, as a function of the various elementary processes that may take place. We shall now describe these elementary processes.

2.2. Elementary processes in plasma–catalyst interactions

As argued in section 2.1 above, the key difference between non-thermal plasma and traditional thermal approaches is that much of the energy in the plasma is stored in a limited number of degrees of freedom, i.e., in free electrons, ions, radicals and (vibrationally or electronically) excited molecules. Energy can, therefore, at least in principle, be much more efficiently delivered to specific reaction channels, thereby selectively stimulating certain chemical processes beyond what would be achievable under local thermal equilibrium, with efficiencies exceeding 50% [6]. We do note, however, that this non-equilibrium character is easier to maintain at low pressures, while plasma chemistry for conversion processes generally requires atmospheric pressure to be efficient.

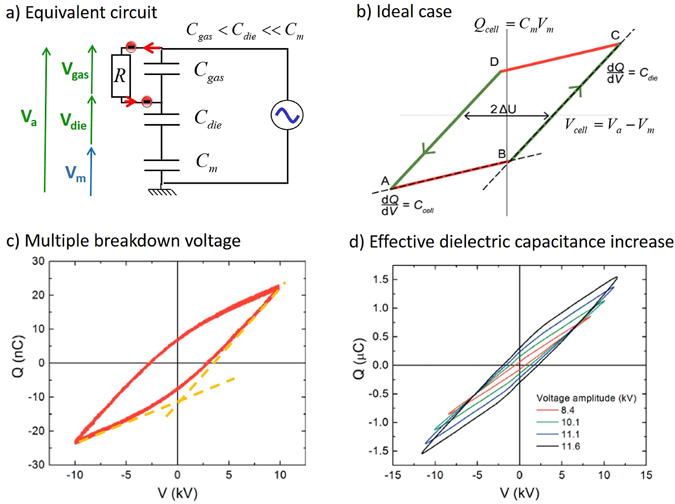

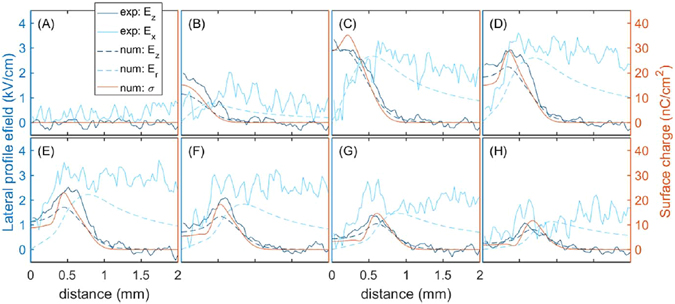

As is the case with gas-phase plasma chemistry, the physicochemical plasma-driven processes at the catalyst surface can be divided into electronic effects, arising from the charge separation in the plasma, and thermal effects, in the form of vibrationally or electronically excited molecules and localized heating. These can affect both the reactions at the catalyst as well as the chemical properties of the catalyst itself. A pictorial summary of possible interactions between plasma and catalyst is shown in figure 2.

Figure 2. Elementary plasma–catalyst interactions, leading to possible plasma–catalyst synergy. Reproduced from [9]. © IOP Publishing Ltd. CC BY 4.0.

Download figure:

Standard image High-resolution imageA zeroth-order approximation to plasma–catalyst interactions is the gas-catalyst interaction typical of thermal catalysis. As a result, all the typical elementary processes occurring in thermal catalysis can also be expected to be operative, at least to some degree, in plasma catalysis. These processes include adsorption of stable molecules, including reactants, but also readsorption of product molecules, surface diffusion, surface-mediated bond breaking and bond formation, and surface desorption. Adsorption may further be subdivided into physisorption and chemisorption, and chemisorption may occur either molecularly (i.e., without concurrent dissociation of the adsorbing molecule) or dissociatively (i.e., when the molecule dissociates while adsorbing on the surface). Moreover, all of the factors that contribute to the catalytic process in thermal catalysis are likely to be important in plasma catalysis as well. These factors include, for instance, the size distribution of the catalyst particles [14], the precise surface structure of the catalyst [15], and the support material [16]. All of these modify critical process parameters, including both thermodynamic properties such as the adsorption energy of the reactants [17], as well as kinetic properties, such as the reaction barriers and rate coefficients [18, 19]. The convoluted result is that the thermodynamics and kinetics of the catalytic process are strongly dependent on the chosen boundary conditions.

Plasma–surface interactions, then, can naively be thought of as a first-order perturbation of this zeroth-order approximation. While this may be a valid approach for post-plasma catalysis setups, where the catalytic stage is spatially separated from the plasma stage, experimental evidence seems to point out that the very effects that arise due to the presence of the plasma may be the leading term in in-plasma catalysis, where the catalysis takes place in the same spatial volume as the plasma. Thus, in in-plasma catalysis setups, effects such as surface charging, adsorption of (vibrationally or electronically) excited species or radicals, or the presence of an electric field in determining a plasma–catalytic process may significantly contribute to the thermal catalytic mechanisms. Thus, from a process point of view, also post-plasma catalysis may be advantageous with respect to thermal catalysis, as the plasma may generate species not available in thermal catalysis that can subsequently react more efficiently with the catalyst (as is e.g. the case in NOx reduction), but in in-plasma catalysis, the very nature of the catalytic step itself may be modified due to these plasma-induced processes. This may lead to plasma–catalyst synergy, as discussed in section 2.3.

Surface charging is inevitable in in-plasma catalysis setups. It arises due to the much higher mobility of electrons compared to ions, leading to an initially much higher electron flux than ion flux to any surface exposed to the plasma. This surface charge sets up a counteracting potential, such that ion and electron fluxes eventually become balanced on average. The resulting negative surface charge modifies the electronic structure of the surface. Considered from a more chemical perspective, this negative surface charge makes the surface less Lewis acidic and more Lewis basic, which therefore promotes the reactivity of incoming Lewis acids such as CO2. The overall effect of surface charge may or may not be important, depending on the surface charge density and the nature of the surface chemical reactions taking place.

Vice versa, the impinging species may also be charged—ions are an essential component of plasmas. Depending on the plasma source gas, both positive and negative ions may be present. Further, as ions are charged, their behaviour is determined by the electric field. The importance of ion impacts on plasma-enhanced chemical vapour deposition processes is well-known [20]. However, most technological plasmas are only weakly ionized, so the fraction of ions relative to the fractions of neutral molecules and radicals is small. In contrast to processes that are dominated by the energetic ion impacts on a surface, ion–surface interactions are not expected to be a process-dominating feature in plasma catalysis [21].

Plasmas are also characterized by the presence of electric fields. These fields not only determine the energy distributions of electrons and ions, and thus also the energy of the ions arriving at the surface, but also operate on the charge distribution at the surface. This effect is further enhanced on rough surfaces or on surfaces with distinct geometric surface features, such as surface protrusions where the field lines can concentrate. In such cases, the electric field will be quite strong locally, which is likely to affect the charge distribution and hence the chemical reactivity strongly.

The adsorption of (vibrationally or electronically) excited species is another factor that is characteristic of plasma–catalytic systems. Basically, if the mean energy of the plasma electrons is in a suitable range (typically around 1 eV for, e.g. CO2 or N2), they preferentially pump energy into the molecular vibrational levels. This, in turn, lowers the barrier for dissociation when the excited molecule impinges on the surface, as shown in figure 3(a). The condition for this typical plasma feature to have a significant effect on the catalyst reactions is that the vibrational energy can be channelled into the actual reaction coordinate. As argued above in section 2.1, this can be the case for plasma–catalytic NH3 synthesis under specific (very mild) plasma conditions. As argued below in section 2.3.2.1 for CH4 methane dissociation, this is not necessarily the case.

Figure 3. (a) Energy plot for plasma activation of vibrational levels of molecular reactants lower the reaction barrier. (b) Energy plot of plasma formation of radicals. Reproduced from [9]. © IOP Publishing Ltd. CC BY 4.0.

Download figure:

Standard image High-resolution imageA fifth process that is unique to plasma–catalyst interactions is the interaction of radicals with the surface. Indeed, while in thermal catalysis, the impinging particles are (thermally) stable molecules, a variety of radicals are generally also formed in a plasma. While their densities are often much lower than those of the parent molecules, their reactivity is much higher. For instance, many molecules show a barrier to adsorption on a surface; in contrast, radicals often do not show this barrier, thanks to their dangling bond(s), resulting in sticking coefficients close to 1. The corresponding energy plot is shown in figure 3(b). As discussed in section 2.3 below, this may also lead to plasma–catalyst synergy.

Therefore, all of these elementary phenomena (charging, electric fields, vibrational and electronic excitation of reactants, as well as radicals) may lead to a change in the overall process with respect to a thermal process, and possibly lead to plasma–catalyst synergy. In the following section, we describe this synergy.

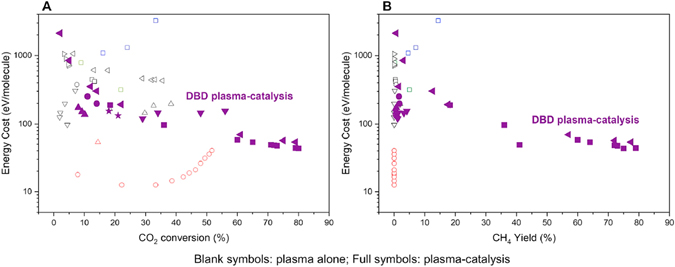

2.3. Plasma–catalyst synergy

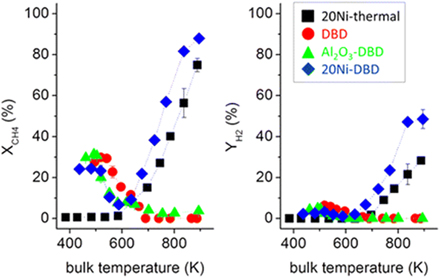

One of the main reasons why plasma catalysis continues to attract much interest is the so-called plasma–catalyst synergy. Synergy means that the combination of plasma with the catalyst yields results better than the sum of the separate plasma process and the thermal catalytic process [5, 21, 22]. A typical example is shown in figure 4 for CO2 and CH4 conversion [6, 23]. The improved result in this context is typically the conversion of the reactants, e.g. CO2 and CH4, the yield of the desired product, such as ammonia, or the VOC degradation efficiency. If synergy is observed, the questions of the origins of this synergy and how it could be maximized then arise. If synergy is not observed, it could be asked how it could be induced so as to improve over the thermal process and/or the pure plasma process.

Figure 4. Typical example of synergy in plasma catalysis: the conversion in the plasma–catalytic setup is larger than the sum of the conversions in the pure plasma and pure catalytic setups. Reproduced from [6]. CC BY 3.0.

Download figure:

Standard image High-resolution imageTo answer these questions, let us revisit the distinct advantages of plasma catalysis over conventional thermochemical approaches. The far-from-equilibrium state of technological plasmas at relatively low temperatures, typically in the range 300–1000 K, allows thermodynamically unfavourable conversions to occur under relatively mild conditions [6]. Also, it has been claimed that plasma catalysis can be used to overcome the omnipresent scaling relations in thermal catalysis [11], which normally impose strong limitations on the maximum achievable rate of many catalytic processes. Indeed, traditional catalysis research has been dominated by structure-activity relations, which imply that optimization of a catalytic process is a matter of finding the 'right' catalysts or engineering the perfect active site [24]. In contrast, plasma–catalyst interaction might allow tuning of the surface chemistry beyond structure-property relations, thanks to the strong synergies that can arise at the interface [5–7].

As mentioned above, synergy is not always observed in plasma catalysis. Indeed, while several groups have reported that plasma catalysis achieves higher yields or efficiencies than either pure plasma or pure catalytic processes [23, 25, 26], there are just as many studies that find little evidence of synergy [27, 28]. Similarly, the precise respective roles of catalyst and plasma, and the nature of their cross-interaction, are currently quite controversial: for example, of two recent studies of plasma–catalytic NH3 synthesis, one claims that the process is dominated by reactions at the catalyst surface [12], while in a different setup the catalyst is assumed to merely act as a surface on which plasma-generated species can recombine [29].

The origin of the apparent discrepancy lies essentially in the contribution of plasma-induced processes (either in the plasma phase or at the catalyst surface) to the overall process. For instance, Rouwenhorst et al demonstrated that the plasma induces vibrational excitation of the prime reactant, N2, the dissociation of which is the rate-limiting step of the process. As a result, synergy was observed: the catalyst still acts as a catalyst in effectively rupturing the N–N and H–H bonds and in bringing the N and H atoms together, while the plasma ensures that the N–N bond rupture requires less energy than in thermal catalysis. If, on the other hand, the electron energy were too high or too low, such that the plasma could not (efficiently) excite the vibrational levels of the N2 molecules, synergy would be unlikely to be observed in this particular process although it is still a plasma–catalytic setup.

Moreover, in general, not only vibrational excitation will be operative, but also other plasma-induced effects, as discussed above. It is thus clear that at least a basic understanding of all the possible interactions between plasma and catalyst is required. Moreover, also an understanding of how these interactions affect each other is crucial to induce new or maximize existing synergies. At present, we indeed have a basic understanding of individual interactions, although little is currently known about their interplay. We, therefore, have to conclude that it is currently impossible to design an optimal plasma–catalytic process systematically.

Below we list the various features known to have the potential to induce a synergistic effect. Note, however, that none of them guarantees a synergy.

2.3.1. Surface charge

As mentioned above in section 2.2, all surfaces exposed to a plasma naturally acquire a negative surface charge. This charge effectively changes the electronic structure of the surface, and thus also the electronic structure of the catalyst. As the catalytic action of a material is ultimately determined by its electronic structure [30], it is thus not unlikely that the catalytic efficiency of any given material would be different in a thermal catalytic setup and a plasma–catalytic setup.

Moreover, charging is a reversible process that does not directly change the morphology, structure or other physical properties of the catalyst. In a study by Kim et al [26], the synergistic effect was also found to be reversible, and surface charging could indeed be responsible for the experimental observations. However, there are currently no direct experimental works validating or falsifying this hypothesis. Recent atomistic simulations (discussed in section 3.1), however, clearly demonstrate the potential of surface charge to significantly alter the catalytic process and thus induce a synergetic effect [31].

Also, the importance of charge in determining the efficiency or yield of a plasma–catalytic process should depend on the magnitude of the charging, or more precisely, on the surface charge density, and on the distribution of that charge density. Peeters et al estimated the plasma-induced surface electron density on alumina to be of the order of 1015–1017 m−2 in their atmospheric-pressure dielectric barrier discharge (DBD) [32], in agreement with direct measurement of surface charges on dielectric targets exposed to ionization waves obtained by 'Pockels effect' based techniques (see section 4.3.1). While such significant charge densities can be expected to have at least some effect on the catalytic behaviour, it remains to be conclusively demonstrated that surface charge can be a dominant factor in inducing plasma–catalytic synergy.

2.3.2. Nature of the reactants

2.3.2.1. Excited species.

In the above (section 2.1), we already described the theoretical (and conceptual) study of Mehta et al and the experimental study of Rouwenhorst et al on the importance of a specific plasma-induced phenomenon—in this particular case vibrationally excited species, but it could in principle also be e.g. electronic excitation—in inducing a possible synergy in plasma catalysis. Similarly, it has been shown before that vibrational excitation of CH4 can lead to a three-order of magnitude higher adsorption probability on a Ni surface compared to CH4 in its vibrational ground state [33]. Moreover, it has also been shown that the crucial parameter is actually the precise vibrational mode which is excited. In the case of methane, the ν3 stretch mode was found to be more effective in enhancing the adsorption than the ν4 bending mode [34]. On the other hand, simulation studies combining molecular dynamics (MD), free energy methods and machine learning techniques demonstrated that at temperatures relevant to plasma catalysis, the importance of vibrational excitation on catalytic CH4 dissociation may be limited [35]. In section 5.2.3, however, we shall also discuss how vibrational excitation of CH4 in dry reforming of methane may be important.

2.3.2.2. Radicals.

In contrast to thermal systems operating at typical catalysis temperatures, plasmas often generate a wealth of radical species initiated through electron-impact dissociation reactions and subsequent gas-phase reactions. As radicals are characterized by one or more dangling bonds, they are extremely reactive. Therefore, their sticking probability on any surface can often be expected to be close to one, although this is not always the case—H, for instance, shows a sticking coefficient of a few 10% at most. This effect has two immediate consequences, both of which may affect the catalytic process: (1) if key reactants are generated through dissociation in the plasma, there is less or no need for the dissociative adsorption of their parent molecules on the catalyst surface for subsequent Langmuir–Hinshelwood (L–H) reactions; (2) the presence of radicals may also increase the contribution of Eley–Rideal (E–R) reactions. An additional effect of radicals is that they may contribute to catalyst re-activation, by removal of poisoning species (see section 2.3.4).

These consequences, however, are only likely to be of importance if the plasma can effectively couple the input power into the dissociation channel of the key reactants. Moreover, the density of these radicals must be high enough to allow for the radicals to play a significant role. The criterion for this process to become on par with the thermal catalytic mechanism is then that the ratio of radical-to-molecule adsorption probability per impinging particle is equal to or higher than the molecule-to-radical density near the surface.

Very recently, a computational study by Engelmann et al [36] clearly demonstrated the effect of increasing fractions of radicals in plasma–catalytic NH3 synthesis. The authors show that E–R reactions indeed quickly become dominant if high enough densities are present, albeit under the assumption that E–R reactions present no enthalpic but only an entropic barrier to adsorption. Interestingly, their results show that in that case, the turnover frequency (TOF) becomes (nearly) independent of catalyst material. The calculated TOFs are in line with several experimental studies [37], indicating that E–R reactions might indeed be dominant in plasma catalysis, instead of the dissociative adsorption of vibrationally excited N2 molecules.

2.3.3. Photons, electrons and electric fields

Both electrons and electromagnetic fields are known to induce or modify chemical processes. Indeed, they are the root cause for the existence of technological plasmas in the first place. Also, at a surface, they may induce or modify reactions. Electron-induced desorption, either due to electron-impact induced thermal heating or by direct interaction of the electron with the bonding and antibonding orbitals, has been well-known for a long time [38]. A typical example relevant to plasma catalysis is the desorption of CO from a TiO2 surface through electron-impact induced CO2 dissociation. Additionally, electrons may also ionize surface-adsorbed species to form anions, which subsequently desorb from the surface [39].

Electric fields are also known to impact surface processes. This may be of particular importance on rough surfaces and when field lines concentrate near local surface irregularities. Although it is difficult to investigate this effect separately from other factors, and in particular from charges, a recent computational study (see section 3.1.2) indeed showed that the application of an electric field might change the adsorption energy of CO2 at a Cu surface [40]. Therefore, the existence of the electric field changes the thermodynamics of the process, which in turn may modify the plasma–catalytic process relative to the thermal-catalytic process if the effect is sufficiently large.

Finally, while photons have been considered to be of possible importance in contributing to a synergetic effect, in particular when using photocatalytic materials as the catalyst, there is at present no clear evidence supporting this.

2.3.4. Plasma-modification, activation and regeneration of the catalyst

Any (heterogeneous) catalytic process requires the adsorption and desorption of reactants and products on and from the catalyst surface. If the plasma, therefore, changes the surface morphology, structure, or any of its other physical or electronic properties, the catalytic process is likely to be influenced. Such catalyst modifications are indeed quite often observed in plasma–catalytic setups. Stere et al [41] provided a nice example of plasma modification of catalyst activity. They observed that the Ag/Al2O3 catalyst in their atmospheric-pressure DBD was active towards NOx reduction at temperatures at which the catalyst should be inactive in a thermal-catalytic setup. This, therefore, clearly demonstrates a synergistic plasma–catalytic effect.

In situ catalyst regeneration was reviewed recently by Lee et al [42]. In particular, two direct pathways to in situ catalyst regeneration are reduction of (partially) oxidized catalyst material to the metallic structure and the removal of carbon deposit to de-passivate the catalyst.

Of course, one could argue that plasma-induced catalyst modification, activation or regeneration is not a fundamental process but rather the convoluted result of possibly many, more elementary, plasma–surface interactions, ultimately leading to the observed catalyst activity. Regardless, if such plasma-induced catalyst modification may be controlled or tuned, it does provide a reliable means to induce or enhance synergy in plasma catalysis.

Another effect that may be important in plasma catalysis, is catalyst heating. Indeed, the catalyst temperature determines its 'thermal' activity, and also determines the rate of many elementary processes such as surface diffusion and desorption. Moreover, spatially and temporally localized heating of the catalyst surface may affect the surface processes. This catalyst heating, however, is again rather a net result of a variety of surface processes rather than a separate fundamental process. For a more thorough discussion in the context of plasma catalysis, we refer the reader to [43].

2.3.5. Microdischarge in mesoscopic pores of the catalyst

Finally, highly reactive plasma-generated species such as radicals may be stabilized on the inner surfaces of voids in the catalyst material [44]. This, in turn, leads to increased surface retention times and, therefore, to possible higher catalyst activity. Below a certain limit, defined by the Debye length, the discharge cannot penetrate into the pores, as discussed in more detail in section 3.3 below. Larger pore sizes, however, can have a distinct effect on the plasma chemistry [45].

Similar to the plasma modification and activation of a catalyst, the occurrence of microdischarges in the pores of a catalyst is not in itself a truly fundamental plasma–surface interaction but may effectively contribute to the overall plasma–catalytic process.

3. Multi-scale modelling

3.1. Atomic-scale at the catalyst surface

The overall coupling between the plasma nonequilibrium and gas-phase plasma-induced chemistry can be studied in kinetic models, as will be described in section 3.2. Such models are based on a mixture of empirical data and simplified models to describe the interaction of electrons and excited species with other molecules, see, e.g. [46]. However, no such extensive information, be it experimental or theoretical, is available for much of the specific plasma-induced chemistry that arises at the catalyst–plasma interface. Within the realm of plasma-based materials processing, the effects of plasma-derived radicals and ions are quite well-studied [47], but the role of many of the more physically complicated effects remain largely unknown. To understand such effects, a more detail-oriented approach is needed.

Indeed, understanding the mechanisms underpinning plasma catalysis in any of its many incarnations relies on a thorough understanding of the various interactions between the plasma and the catalyst surface. By their very nature, these interactions are operative on a molecular scale. It is only the final convolution of these interactions that eventually yields the typical macroscopic observations such as reactant conversion or energy efficiency.

Modelling is in that perspective a tool par excellence to study these interactions: models can be constructed as needed so as to shed light on particular aspects, leaving other aspects as parameters. This stands in stark contrast to experiments, which by necessity always encompass all processes that effectively take place. Modelling therefore allows one to unravel the mechanisms of individual processes; its main challenge is essentially how to couple all of these different aspects. In other words, atomic scale modelling may be well suited to provide information on individual parts, but not necessarily on the whole. In a sense, this is the opposite of the main challenge of experiments, which are well suited to yield information on the whole, but not on the individual parts.

As a result, there is—at least at present—an inevitable gap between atomic-scale models and experiments. This gap, however, can be filled with larger-scale modelling studies, as described in sections 3.2 to 3.5. We shall now describe some essential features of atomic-scale modelling, and subsequently highlight our current understanding on plasma–catalyst interactions coming from recent atomistic simulation studies, focusing on surface charging and vibrational excitation.

3.1.1. Density functional theory and classical atomistic approaches to simulating molecule–surface interactions

Atomic-scale simulations provide a representation of the system to be studied with atomistic resolution. A variety of techniques exist to gain information from this atomic-scale representation: static calculations may optimize the critical points (energy minima and barriers) in a process, MD simulations provide the trajectories of the atoms through space and time, and enhanced sampling techniques, such as metadynamics or replica exchange MD, allow the calculation of free energy profiles along the (often reduced) reaction coordinate.

The critical factor in all of such calculations is how the interactions, viz the energies and forces, between the atoms, molecules and surface, are accounted for. These interactions can either be described classically or quantum mechanically.

In the classical approach, a so-called force field is constructed that yields the potential energy of the system as a function of the positions of the atoms. Forces between the atoms are obtained as the negative gradient of the potential energy function. The complexity of such force fields may vary from very simple, such as the Lennard-Jones potentials, to much more complex, such as the Reax family of force fields. In general, fairly complex expressions are needed to enable the force field to accurately represent the near-infinite number of possible atomic configurations and the corresponding energies and thus yield sensible chemistry. The main advantage of this approach is that it does not require the solution of the electronic structure problem and is therefore computationally fast.

Alternatively, one may resort to a quantum-based approach to attain a higher level of accuracy. This, of course, comes at the price of a higher computational cost. In quantum-based simulations, the electronic structure of the system is solved, subject to a number of assumptions and approximations. Due to its computational efficiency, the approach taken in the (plasma) catalysis community is invariably so-called density functional theory (DFT) calculations, in which all physical and chemical properties of the system are derived from the electron density instead of from the much more complex electronic wavefunction. The most important choice to make in any DFT calculation is, in essence, the same as in classical simulations: how to represent the energy? In DFT, the energy is expressed as a functional of the electron density, which itself is a function of space. As a rule of thumb, the higher the level of theory of the functional, the more accurate the calculation will be, but also the higher the computational cost will be.

If one wishes to calculate atomic trajectories, the equations of motion need to be integrated, requiring a discretization of time. To maintain a stable trajectory for this time integration, the time step must be sufficiently small, typically of the order of a femtosecond. The simulated period is inevitably very short—at most of the order of microseconds in the case of classical force fields, and of the order of nanoseconds in the case of DFT-based MD, depending, of course, on the system size and complexity of the force description (classical force field or DFT energy functional). Still, as the atomic connectivity may be reevaluated at each step, this indeed allows the study of the actual dynamic trajectories in a chemical reaction. Importantly, if the force field or functional is indeed suitable for the process to be studied, no assumptions regarding possible mechanisms need in principle to be made.

The main limitation of MD simulations is the very short time scale that can be accessed in the simulation. Indeed, thermal processes typically occur on μs—ms timescales, which is beyond the reach of atomistic simulations. Solutions to the time scale problem exist, viz accelerated MD, such as, e.g. temperature accelerated dynamics [48] or collective variable-driven hyperdynamics [49]. Alternatively, enhanced sampling of the free energy profile of a process may be both more efficient and yield more information. An example of this approach is presented in section 3.1.2.2 below.

Besides explicitly and deterministically calculating atomic trajectories, it is also possible to follow the system evolution stochastically, based on a set of probabilities for transitions between states, in a so-called kinetic Monte Carlo approach. Various implementations exist and were evaluated in the context of plasma catalysis by Marinov and Guerra [50, 51]. A major advantage of these models is that the coupling between the surface chemistry and gas-phase chemistry is relatively straightforward. The timescale that can be handled is the nanoseconds-to-minutes range, while the calculations are still very fast compared to MD simulations. A major disadvantage is that the simulations require a list of possible species as well as events that can take place, with appropriate rate coefficients. This limits what can (and cannot) happen in the simulation. So far, the application of this type of modelling to plasma catalysis has been limited.

3.1.2. Simulation of plasma–surface interactions

In contrast to the extensive body of computational (mainly DFT) studies of thermal catalysis, the number of works on plasma catalysis using atomic-scale simulations remains very limited. This is partly due to the computational cost of (reliable) DFT calculations and the unpredictable suitability of force fields, which are generally not optimized for plasma–catalytic processes. An additional reason is the non-existence of methodologies capable of modelling certain aspects of plasma catalysis, such as surface charging. Only recently have methods been developed that allow such aspects of plasma–catalyst interactions to be described.

Moreover, the stochastic nature of many surface processes, such as simple surface diffusion required for L–H kinetics, leads to an exponential distribution in reaction times. To dynamically simulate surface reactions thus seems a near-impossible task, which is further complicated by the wide range of flux ratios of species reaching the surface. For instance, for every ion reaching the surface, perhaps 106 neutrals would need to be accounted for. It is clear that this cannot be accomplished in a single dynamic simulation effort.

Instead, atomic-scale simulations typically approach the problem by one of two options. The first option is to statically calculate system properties of interest, such as, e.g. the reaction energy as a function of the progress of a reaction. This can be accomplished using sampling techniques such as metadynamics or alternatively by barrier finding techniques such as nudged elastic band calculations. This information can subsequently be used as input in, e.g. microkinetic models as described in section 3.2. The second option is to dynamically simulate reactions focusing on, e.g. a single reaction or a single parameter such as surface charge.

In the remainder of section 3.1.2, we shall describe what is currently known from atomistic calculations about fundamental factors of influence specific to plasma catalysis, viz surface charge, electric fields and vibrational excitation.

3.1.2.1. Surface charge and electric fields.

As discussed above (sections 2.2 and 2.3.1), a solid in contact with plasma accumulates a negative surface charge due to the influx of free electrons. Excess surface electrons can reach densities of the order of 1017 m−2 and may remain trapped for long times, up to days [32, 52]. Since excess charge at the surface may modify the electronic structure of the material, capturing charge-induced changes in surface reactions requires a quantum chemical approach. Bal et al developed a DFT-based technique to add charges to a periodic surface slab [31]. Divergence of the energy is avoided by inserting a counter charge in the gas phase above the charged slab. This setup effectively corresponds to a negatively charged surface with a positive space charge next to it. The surface charge density can be tuned by varying the lateral dimensions of the surface. Note that this approach is valid only for DFT-codes based on an atom-centred basis set (such as, e.g. CP2K), and would not be suitable for plane-wave based codes (such as, e.g. VASP).

Using this methodology, Bal et al investigated how charging a dielectric Al2O3 surface loaded with a single metal atom (Ti, Ni or Cu) as the catalyst would affect its chemical reactivity [31]. It was found that the metal atom adsorbed less strongly on the surface, with a decrease in adsorption energy of about 1 eV. This was explained by the charge-induced change in the support electron affinity: the metal was found to adsorb as an M2+ species, thus reducing the surface upon adsorption. Upon adding a negative surface charge, the support is already reduced and therefore becomes more resistant against further reduction by adsorption of the metal. This, in turn, leads to lowered adsorption energies.

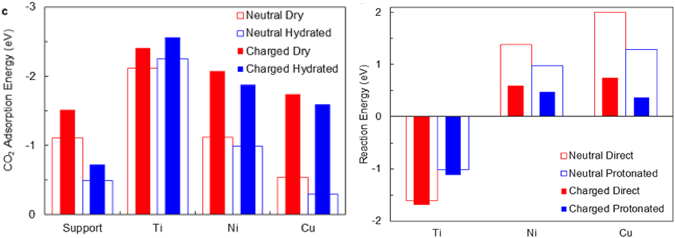

When allowing CO2 to adsorb on the charged surface, Bal et al observed that the adsorption energy changes significantly, in particular on Ni and Cu: whereas the CO2 adsorption energy on the neutral Cu/Al2O3 surface is about 0.5 eV, it increases to about 1.5 eV on the charged surface. This adsorption energy is similar to that for CO2 adsorption on neutral Ni/Al2O3. This is shown in figure 5(a). Moreover, when CO2 was considered, it was found that the overall reaction energy was also significantly influenced by surface charge. In particular, CO2 dissociation was found to be much less endothermic on the charged surface, as shown in figure 5(b).

Figure 5. Effect of charging the adsorbent (bare dry and hydrated Al2O3 support, as well as Ti-atom, Ni-atom and Cu-atom adsorbed on the Al2O3 support) on (a) the CO2 adsorption energy and (b) the CO2 dissociation energy. Reproduced from [31]. © IOP Publishing Ltd. All rights reserved.

Download figure:

Standard image High-resolution imageThese observations can be rationalized by inspecting the partial density of states. Essentially, the M–CO2 bond is formed by the overlap of the metal d-orbitals with the CO2 antibonding π* orbitals. The resulting bonding states are lowered in energy relative to the neutral systems due to the increased overlap between the d-orbitals and the CO2 antibonding π* orbitals. This effectively strengthens the M–CO2 bond and weakens the C–O bonds in CO2. Thus, surface charging activates the CO2 molecule upon adsorption. From a chemical perspective, charging makes the surface more basic and thus more prone to react with the Lewis acid CO2. Similarly, and also using DFT calculations, Jafarzadeh et al found that adsorption energies of CO2 on TiO2-supported Ni5 and Cu5 catalyst clusters substantially increase upon charging, by up to 2 eV [53].

Large electric fields are also found in common plasma–catalytic setups [54], which can polarize the surface. The electronic and thus chemical properties of a catalyst can hence be significantly altered through plasma exposure without changing its actual chemical composition. Recently, Jafarzadeh developed the (as yet) only model specific to plasma catalysis, incorporating both charging and electric fields [40]. The authors investigated the effect of charge, electric fields and the combination of both on the adsorption and activation of CO2 on various Cu-surfaces. When only an electric field was applied, the partial charges on the adsorbed CO2 and the adsorption energy were predicted to increase. Concurrently, C–O bond lengths were observed to increase, thus activating the molecule towards dissociation. When combining the electric field with excess surface electrons, this effect is enhanced, leading to binding and reaction energies shifted by up to 1 eV. It was thus concluded that the presence of both surface charge and an electric field might be a key factor in enhancing CO2 conversion in plasma catalysis.

Whether or not this effect is indeed dominant, or at least can be dominant in plasma catalysis, remains to be validated. Indeed, the surface charges investigated in these studies (about 0.09 C m−2), as well as the values of the electric field strength (up to 250 V nm−1), are rather high. Regardless, simulations like these demonstrate the crucial importance of methodological developments in elucidating specific mechanisms operative in plasma catalysis.

3.1.2.2. Vibrational excitation.

As discussed in section 2, the presence of vibrationally excited molecules has also been presumed and, for some processes, demonstrated to be important in plasma catalysis [55]. Indeed, the average vibrational temperature of specific chemically active normal modes can be well above 1000 K in plasmas that are otherwise at room temperature [46]. The effect of vibrational excitation of gas-surface reactions is usually studied through explicit quasi-classical trajectory studies, which can only model molecular beams at fixed translational and vibrational energies.

However, such state-resolved molecular beams are a poor representation of the broad energy distributions found in a plasma. Moreover, these simulations are highly demanding and time-consuming: up to 106 trajectories have to be calculated for a single condition, which is only feasible when an efficient classical interatomic potential is parametrized for the system a priori and precludes more wide-ranging studies over several catalysts, reactions, or conditions. Nevertheless, a recent preliminary study used a simplified analytical model, the so-called Fridman–Macheret model (which was, however, untested for surface reactions) to include the effect of vibrational excitation in a kinetic model of catalytic NH3 synthesis. The model predicted a rate increase by up to five orders of magnitude and a shift in relative catalyst activities, analogous to the charging effects mentioned above [11].

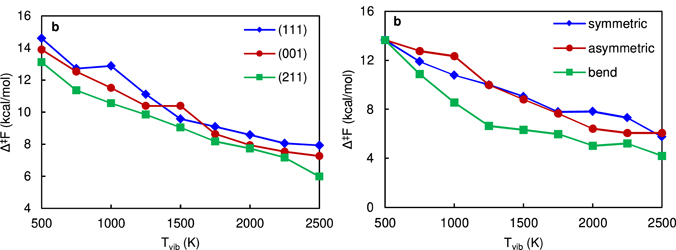

Employing an ensemble-based approach to investigate the effect of vibrational non-equilibrium on chemical reactivity [56], Bal et al attempted to quantify the importance of this vibrational non-equilibrium on dissociative chemisorption of H2 and CH4 on Ni catalysts [35]. These authors found that vibrational excitation can indeed very efficiently lower the apparent free energy barrier to dissociation at the surface. The free energy barrier for dissociative chemisorption is shown in figure 6 for H2 and CH4 on Ni in figure 6.

Figure 6. Lowering of the free energy barrier for dissociation as a function of the vibrational temperature for (a) H2 on different surface facets, and (b) CH4 for different vibrational modes. Reproduced from [35]. © IOP Publishing Ltd. All rights reserved.

Download figure:

Standard image High-resolution imageFurther, it is observed that the rate enhancement is not captured well by the Fridman–Macheret model and that an accurate assessment of the importance of vibrational excitation requires consideration of the vibrational temperature, the specific modes that are excited, the degeneracy of these modes, and the presence of steps and terraces, which also affects the impact of vibrational excitation. Although this study shows that significant rate enhancements can be expected at low temperatures, the lowering of the apparent free energy barrier is limited at more realistic temperatures (Tvib ∼ 1500 K), so the rate enhancement will also be limited. The authors, therefore, concluded that the potential impact of vibrationally excited CH4 on the overall catalytic process may be minor.

3.2. Zero-dimensional (0D) scale: chemical kinetics modelling

Zero-dimensional (0D) chemical kinetics models provide insight into chemical kinetics, both in the plasma and at the catalyst surface. They are based on the same general principles, i.e., solving continuity equations for the various species (either in the plasma or their surface coverages) based on production and loss rates, as defined by the chemical reactions. They can describe a detailed (plasma or surface) chemistry without too much computational effort. For plasma chemistry modelling, some codes are available within the plasma community, such as ZDPlasKin, developed by Pancheshnyi et al [57], GlobalKin, developed by Kushner and co-workers [58, 59], for which also a commercial application with a graphical user interface has been developed, Quantemol-P [60], and PLASIMO, which includes among others a global model, developed by van Dijk and co-workers [61]. Modelling the chemical reactions of plasma species with a catalyst surface has only recently begun to attract significant interest, and to our knowledge, codes are only being developed within individual research groups.

The characteristics of the models for either the plasma or surface chemistry will be explained in the following two sections, after which some examples will be given of what type of information they can provide.

3.2.1. Plasma chemistry modelling

The continuity equations for the species densities in 0D plasma chemistry models are written in their simplest form as:

with aij (1) and aij (2) the stoichiometric coefficients of species i, at the left and right-hand side of a reaction j, respectively, nl is the species density at the left-hand side of the reaction, and kj is the rate coefficient of reaction j.

The rate coefficients of chemical reactions between neutral species or ions are usually adopted from literature and are typically calculated from Arrhenius equations, expressing the dependence on gas temperature. The rate coefficients of electron impact reactions are usually obtained from energy-dependent cross-sections integrated over the EEDF. The latter is then calculated with a Boltzmann solver, which is commonly incorporated in plasma chemistry models.

Besides the species densities, the electron and gas temperatures can also be calculated from similar (energy-balance) equations, again based on production and loss terms, as defined by the power deposition or by the electric field, and by chemical reactions. For more details, we refer to an interesting tutorial review paper by Hurlbatt et al [62].

The balance equations yield the time-evolution of the species densities, electron and gas temperature, averaged over the plasma reactor volume; spatial variations due to transport in the plasma are typically not considered, although 1D fluid models describing detailed plasma chemistry and accounting for diffusion, migration and convection, have also been developed for plasma catalysis (gas-conversion) applications (e.g. [63]). In addition, several methods exist to account for spatial variations in 0D chemical kinetics models, for instance, the so-called hl factor, which describes the relationship between the central ion density and the ion density at the sheath edge; see details in [62]. Moreover, the effect of diffusion and losses due to chemical reactions at the catalytic surface is typically considered by an additional loss term in the balance equations [64].

Finally, spatial variations can also be accounted for by translating the time-variation of the balance equations into a spatial variation, i.e., as a function of distance travelled through the plasma reactor, based on the gas flow rate, hence considering the plasma reactor as a plug flow reactor. This also allows spatial variations of input parameters, such as applied power or gas temperature, to be considered. Note that this feature is particularly useful in accounting for the filamentary behaviour of a DBD, which is the reactor type primarily used in plasma catalysis, as illustrated for instance in [65, 66]. This method is computationally much more manageable than accounting for filament formation in 1D, 2D or 3D fluid models.

Typically about 100 different species, including the electrons, various types of molecules, radicals, ions and (electronically and vibrationally) excited species, are included in such plasma chemistry models, which react in (above) 1000 reactions. As shown by Hurlbatt et al [62], the number of chemical reactions to be considered typically rises more or less linearly with the number of species included.

The possibility of describing detailed plasma chemistry is the main advantage of this type of model, but at the same time also their main weakness, i.e., the need for accurate rate coefficients or cross-sections for all reactions. Indeed, the latter are subject to uncertainties, which limits the accuracy and predictive power of chemical kinetics models. Hence, there is a strong need for model validation. The effect of the uncertainties can be evaluated by Monte-Carlo simulations, which use a large number of combinations of rate coefficients randomly generated within their reported uncertainties, hence providing information on the uncertainty of the model output results attributable to the rate coefficients. This method was first developed by Turner for an He/O2 plasma [67–69] and later also illustrated for a CO2 plasma [70] and a CO2/CH4 mixture [71]. Although reliable rate coefficients and cross-sections are needed for all kinds of plasma models, this is especially true for chemical kinetics models, which focus precisely on studying complex chemistries.

Obviously, the more reactions included in such models, the more complicated it is to evaluate the model uncertainty. Hence, while it is tempting to include all possible reactions for all species, this complexity may also limit the predictive power. Turner [67, 68] demonstrated that reaction schemes could be drastically reduced, even up to 85%, without significantly affecting the output [68].

Plasma chemistry models are very popular for plasma catalysis applications because they can handle many different plasma species and chemical reactions. Some examples for CO2 splitting, CH4 conversion, as well as for CO2/CH4, CO2/H2, CO2/N2, CO2/H2O, CH4/O2 and N2/H2, and their combinations can be found in, e.g. [72–77].

3.2.2. Plasma–surface chemistry modelling

Surface kinetics models solve the continuity equations for the fractional coverage of all surface species as a function of time, again based on production and loss terms:

where θx is the fractional coverage of species x, cx,i is the stoichiometric coefficient of this species in the production and loss reactions i and ri are the rates of the corresponding reactions. These rates are calculated as the difference between the rates of the forward and reverse reactions:

where ki,f and ki,r are the rate constants of the forward and reverse reactions, respectively, and axf and axr are the activities of the reactant species xf and the product species xr , respectively. The activities are assumed equal to the fractional coverages for surface species and to the partial pressures (in bar) for gas-phase species. While in plasma chemistry models, the rate coefficients are typically adopted from literature (or databases), in surface chemistry models, the rate constants are usually calculated from transition state theory:

where kB is the Boltzmann constant, T is the temperature, h is Planck's constant, R is the ideal gas constant and ΔG‡, ΔH‡ and ΔS‡ are the Gibbs free energy, enthalpy and entropy of activation, respectively. The latter are typically obtained by DFT calculations, and are also available for many catalyst materials in databases, such as the CatApp database [78].

By solving the differential equations to steady-state  for all species, and inserting the steady-state coverages back into the rate equations, the steady-state reaction rates can be obtained, which provide the product formation TOFs, a common term in catalysis. More information about such models can be found in [79].

for all species, and inserting the steady-state coverages back into the rate equations, the steady-state reaction rates can be obtained, which provide the product formation TOFs, a common term in catalysis. More information about such models can be found in [79].

3.2.3. Some illustrations in plasma catalysis

Chemical kinetics models are very useful for chemical reaction pathway analysis, to study the most important production and loss processes for various species, both in the plasma and at the catalyst surface. In this way, they can pinpoint limitations for the production of some species, and thus also propose solutions on how to overcome these limitations.

Hong et al developed a chemical kinetics model for NH3 synthesis by plasma catalysis, accounting for surface reactions at the catalyst surface [64]. The loss and production rates due to the surface reactions were included as additional loss or source terms, consisting of the rate coefficients multiplied by the free surface site density. The model revealed that the surface-adsorbed N atoms, N(s), were mainly formed by dissociative adsorption of ground-state N2 molecules, as well as by N2 molecules in the first vibrational level, and by direct adsorption of N atoms. H(s) were also mainly formed by dissociative adsorption from ground-state H2 molecules, but also by direct adsorption of H atoms, while dissociative adsorption from vibrationally excited H2 molecules seemed less important. In addition, the rate of H(s) formation was calculated to be four orders of magnitude higher than the rate of N(s) formation. The model did not only account for stepwise hydrogenation on the surface, which is the dominant pathway in conventional catalysis, but also for reactions between plasma radicals and surface-adsorbed species, i.e., E–R reactions, and the E–R reaction of NH2 radicals with H(s) was indeed reported to be more important for the NH3 synthesis [64].

van't Veer et al developed a similar model for plasma–catalytic NH3 synthesis, again for a simple catalyst metal and paying most attention to the plasma chemistry [80]. This model focused on the role of the filamentary microdischarges (FMs) and their afterglows, typical of DBD plasmas. The model revealed that most of the NH3 production occurs in the afterglows, while during the microdischarges, the NH3 is actually decomposed upon electron impact dissociation. However, during the microdischarges, electron-impact dissociation of N2 and H2 also creates N and H atoms, which form NH radicals. These species adsorb onto the surface and are subject to hydrogenation, leading to the formation and desorption of NH3.

Electron-impact dissociation of N2 followed by adsorption of N atoms was identified as the rate-limiting step, rather than dissociative adsorption of N2 at the catalyst surface, like in thermal catalysis. In addition, despite the fact that vibrational excitation is stated to be of minor importance in DBD plasmas, electron-impact dissociation from vibrationally excited N2 levels was predicted to contribute ca. 8% to the overall N2 dissociation in the plasma. The larger this contribution, the more energy-efficient the overall NH3 synthesis, as the required dissociation energy is reduced by vibrational excitation. Overall, just like the model of Hong et al, this model revealed that both E–R and L–H reactions play a role in plasma–catalytic NH3 synthesis. The pathways predicted by the model during the microdischarges (a) and subsequent afterglows (b) are illustrated in figure 7.

Figure 7. Reaction pathways predicted by plasma and surface chemical kinetics modelling, leading to NH3 synthesis in a DBD plasma with catalyst, during the microdischarges (a) and their afterglows (b). E–R and L–H reaction steps are drawn with red and blue arrows, respectively. (a) During the micro-discharges, reactive species are created by electron-impact collisions with the feed gas, and they react further to form NH3, but at the same time, NH3 is also destroyed by electron-impact collisions. (b) In the subsequent afterglows, the reactive species created during the microdischarges react further to form NH3 via several E–R and L–H reactions. Reprinted with permission from [80]. Copyright (2020) American Chemical Society.

Download figure:

Standard image High-resolution imageMehta et al developed a more detailed surface microkinetics model for plasma–catalytic NH3 synthesis, but without a plasma chemistry model, thus not accounting for plasma radicals and only considering vibrational excitation [11]. They reported that vibrationally excited N2, as produced by the plasma, can drastically enhance the NH3 synthesis rates on catalyst materials that are kinetically limited by N2 dissociation, and thus, that the optimal catalytic material in plasma catalysis would be different from thermal conditions [11]. In addition, the model revealed that due to the non-thermal plasma excitation, the NH3 yields could exceed equilibrium limits [81]. Engelmann et al studied the impact of different vibrational distribution functions on the catalytic dissociation of N2 and the subsequent production of NH3, and also included radical reactions, to illustrate the contribution of these species and their corresponding reaction pathways. Their model was applied to a large range of catalyst materials and revealed that when radical adsorption and E–R reactions determine the reaction pathways, the NH3 synthesis becomes virtually independent of the catalyst material [36]. These model predictions are confirmed by various experimental data [37], indicating that in most common (DBD) plasma–catalytic conditions, radical adsorption and E–R reactions indeed dictate the plasma–catalytic NH3 synthesis mechanisms.

Engelmann et al [82] also developed a similar surface microkinetics model for plasma–catalytic non-oxidative coupling of CH4 for a range of different metal catalyst surfaces, and the overall conclusion was that the optimal catalyst material depends on (i) the desired products and (ii) the plasma conditions. Indeed, plasma conditions that favour vibrational excitation of CH4 could significantly enhance C2H4 formation on most catalysts, like Pt, Rh, Pd and Cu, while C2H6 formation was promoted on the more noble catalysts, like Ag. On the other hand, plasma conditions that give rise to many radicals, such as CH3, CH2, C2H5 and C2H3, cause a high selectivity towards C2H4 on all catalysts, hence including noble catalysts as well [82].

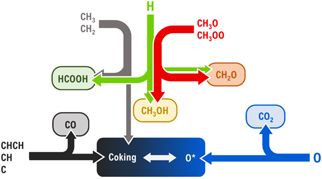

Finally, microkinetics models were also developed for plasma–catalytic CO2 hydrogenation into CH3OH [83] and oxidative coupling of CH4 [84]. Plasma-generated radicals and intermediates were found to increase the calculated CH3OH production rate by 6–7 orders of magnitude compared to thermal catalysis on a Cu(111) surface, showing the potential of plasma–catalytic CO2 hydrogenation into CH3OH [83]. Also, in the case of plasma–catalytic oxidative coupling of CH4, the plasma-generated radicals and intermediates largely enhance the oxygenated product yields [84]. In addition, the model revealed the role of individual radicals in the surface processes, as summarized in figure 8.

- Strongly dehydrogenated carbonaceous species (CHCH, CH, C) strongly induce coking, and their formation should be avoided.

- O radicals counteract coking, so their partial pressure should be tuned against that of the carbonaceous radicals, but they also lead to deep oxidation to CO2.

- The more hydrogenated carbonaceous radicals (CH3, CH2) are in general beneficial, as they bind less strongly to the catalyst and lead to H* formation on the surface, yet they also cause coking at high partial pressures.

- H radicals appear beneficial by promoting hydrogenation of CH3O* and HCOO*, yielding CH3OH and HCOOH, respectively. Moreover, high H partial pressures can potentially form more free surface sites by removing excess O* via H2O formation.

- CH3O and CH3OO radicals are important precursors to both CH3OH and CH2O. Increasing their partial pressures thus also strongly enhances CH3OH and CH2O formation.

Figure 8. Schematic overview of the influence of various plasma species on the formation of oxygenates and COx in the plasma–catalytic partial oxidation of CH4 on Pt(111). Reprinted with permission from [84]. Copyright (2021) American Chemical Society.

Download figure:

Standard image High-resolution imageIn general, these chemical kinetics models can reveal how various plasma species affect the catalyst surface chemistry. This can guide alterations of the plasma composition to improve the formation of desired products.

3.3. Micro-scale: behaviour of plasma (species) inside catalyst pores

An important question in plasma catalysis is whether plasma (streamers) can penetrate into catalyst pores and what is the minimum pore size needed for this. To answer this question, both fluid modelling and particle-in-cell-Monte-Carlo collision (PIC-MCC) simulations have been carried out, as will be briefly explained in the remainder of this section.

3.3.1. Fluid modelling

A fluid model is based on solving conservation equations for the densities of the various plasma species, similar to equation (1) in section 3.2.1 above, but in addition also account for spatial gradients. Moreover, transport of the species is described by migration in the electric field (for the charged species), diffusion due to concentration gradients, and convection. In addition, Poisson's equation is usually solved, for a self-consistent calculation of the electric field distribution, based on the charged species densities. Finally, gas heating can be calculated by a heat transfer model, and the gas flow dynamics by the Navier–Stokes equations, although static gas conditions are also often assumed, depending on the application and the research question under study.

Zhang et al developed a 2D fluid model to study the plasma behaviour in inter-particle macro (10–400 μm) pores for a DBD plasma operating in a homogeneous mode in helium [85, 86]. The model revealed that the plasma species can only be generated inside pores with diameter ⩾30 μm. This can be correlated with the Debye length, which is in this order for the typical conditions of a helium plasma in glow discharge mode (i.e., electron temperature and density of 3 eV and 1017 m−3).

In general, modelling predicted that plasma formation inside pores occurs more easily at larger pore size and applied voltage [85], which was also observed experimentally [87, 88]. In addition, the dielectric constant of the catalyst support also plays a role [86]. Modelling revealed that for small dielectric constants, ionization inside the pores appears to occur more easily. The reason is that for large dielectric constants, the polarization of the left sidewall of the pore counteracts that of the right sidewall, reducing the net electric field, and thus the electron temperature and electron-impact ionization inside the pore are lower. To our knowledge, no experiments have investigated the plasma behaviour inside catalyst pores with different dielectric constants. Hence, these model predictions still have to be validated by experiments, but they suggest that the most common catalyst supports, i.e., Al2O3 and SiO2, with dielectric constants around 8–11 and 4, respectively, can more easily promote plasma formation inside catalyst pores than, e.g. ferroelectric materials with dielectric constants above 300. Finally, also the pore shape determines how easily plasma can be formed inside catalyst pores because it greatly affects the electric field enhancement. Indeed, modelling predicted that the electric field is significantly enhanced near tip-like structures, which affects the electron-impact ionization and thus plasma formation [89].

3.3.2. Particle-in-cell—Monte Carlo collision modelling

While μm-sized pore sizes are of interest for structured catalysts, catalytic supports typically have pores in the nm range. Fluid modelling, however, cannot be applied to nm-sized pores because the mesh size would be too small for a fluid description. To gain insight into whether plasma can penetrate into such small pores, PIC-MCC simulations must be applied. They are based on calculating the trajectory of a large number of individual particles (so-called super-particles, typically various types of ions, and the electrons) using Newton's laws, while the collisions of these super-particles are treated with random numbers, which are compared with the collision probabilities, defined by the collision cross-sections. The electric field distribution is calculated self-consistently from the positions of the charged super-particles. For this purpose, the positions of the super-particles are projected onto a grid to obtain a charge density distribution, from which the electric field distribution can be calculated with Poisson's equation.

Most applications of plasma catalysis use reactive gases, like air, CO2, hydrocarbons and their mixtures, rather than helium. The reactive gas plasmas are typically filamentary, and the plasma density inside the filaments can be much higher than in a homogeneous plasma in glow discharge mode. This can induce a much smaller Debye length and enable the plasma to penetrate into smaller catalyst pores.

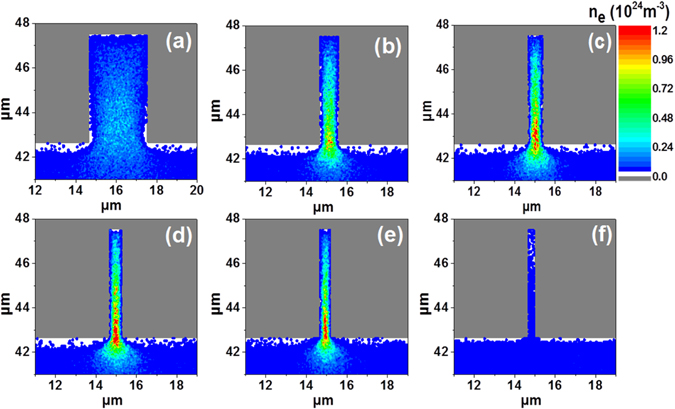

Figure 9 illustrates the calculated electron number density profile inside pores with different diameters, obtained from PIC-MCC simulations in dry air, for an applied voltage of −8 kV [90]. The electron density inside the pore is negligible for a pore diameter of 400 nm, while it reaches a maximum inside pores with diameter of 600 nm and above. Hence, these PIC-MCC simulations predict that plasma streamer formation can occur in pores of 600 nm and above but not in smaller pores. This behaviour is again correlated with the Debye length, which is calculated to be 415 nm for this case (dry air, atmospheric pressure and applied voltage of −8 kV). In general, we can conclude that the Debye length is an important criterion for plasma streamer penetration into catalyst pores, i.e., plasma streamers can only penetrate into pores with diameter larger than the Debye length.

Figure 9. Calculated electron density profiles, near and inside a pore, with diameter of (a) 3 μm, (b) 1 μm, (c) 800 nm, (d) 700 nm, (e) 600 nm, (f) 400 nm, as obtained from PIC-MCC simulations in dry air, for an applied voltage of −8 kV. Reproduced from [90]. © IOP Publishing Ltd. All rights reserved.

Download figure: