Abstract

Gas sensor technology is widely utilized in various areas ranging from home security, environment and air pollution, to industrial production. It also hold great promise in non-invasive exhaled breath detection and an essential device in future internet of things. The past decade has witnessed giant advance in both fundamental research and industrial development of gas sensors, yet current efforts are being explored to achieve better selectivity, higher sensitivity and lower power consumption. The sensing layer in gas sensors have attracted dominant attention in the past research. In addition to the conventional metal oxide semiconductors, emerging nanocomposites and graphene-like two-dimensional materials also have drawn considerable research interest. This inspires us to organize this comprehensive 2020 gas sensing materials roadmap to discuss the current status, state-of-the-art progress, and present and future challenges in various materials that is potentially useful for gas sensors.

Export citation and abstract BibTeX RIS

1. Introduction

Huaping Wang1, Jianmin Ma1, Jun Zhang2, Yuezhan Feng3

1Hunan University, People's Republic of China

2Qingdao University, People's Republic of China

3Zhengzhou University, People's Republic of China

Environment quality and safety are of great importance to a sustainable human society [1, 2]. With the fast development of industries, transportation of vehicles and the worldwide use of chemicals, our environment has been suffering from some challenges such air pollution and depletion of the ozone layer, which has posed a great risk to the human health [3, 4].

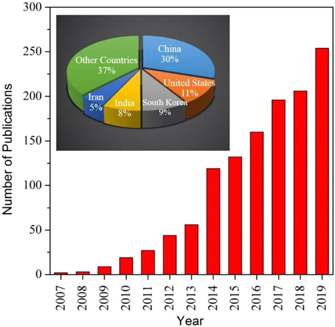

Gas sensor plays an irreplaceable role in the detection and monitoring of toxic and explosive substances for the sake of safety and has attracted increasing attention [5–10]. The research on gas sensors has expanded significantly during the past decades. Figure 1(a) presents the number of the papers & patents published each year, from 2010 to 2020, relevant to gas sensors. In the past ten years, more than 40 000 publications have been reported worldwide, with a peak value of 5961 publications in 2018. Most research has been done in some countries, such as China, USA, Japan, Germany, South Korea, India, and so on. It should be noted that the researchers from China have made a considerable contribution to the field, as shown in figure 1(b).

Figure 1. (a) The number of papers and patents published each year relevant to gas sensors from 2010 to 2020; (b) the number of papers and patents published in various countries relevant to gas sensors from 1964 to 2020; here, the papers and patents searched from the web of science refined by 'title = gas sensor' with all document types on March 15, 2020.

Download figure:

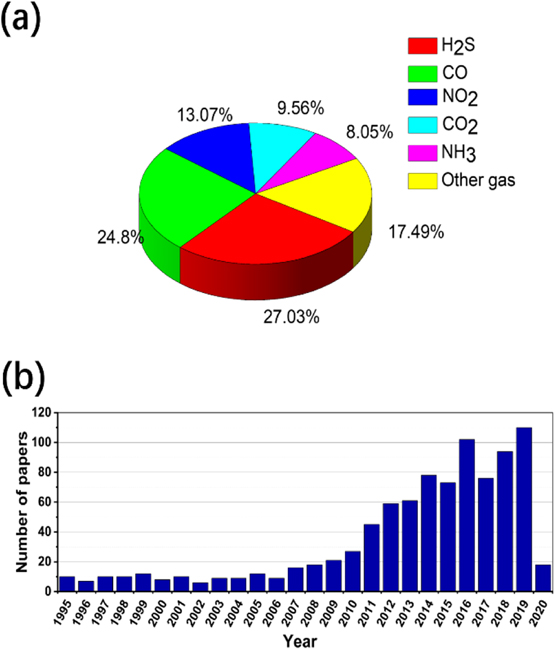

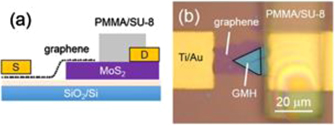

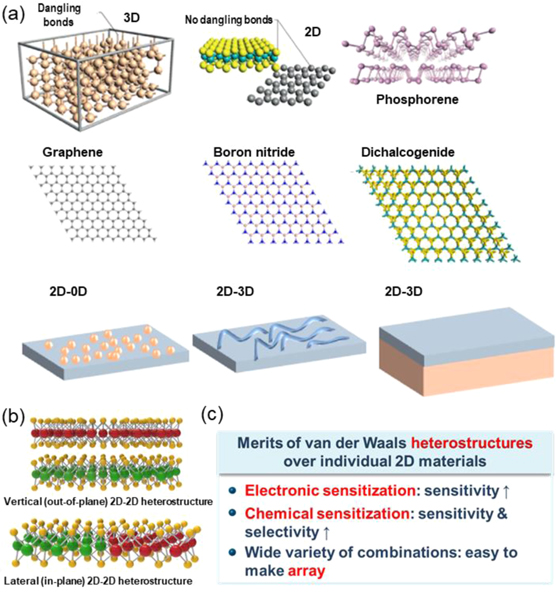

Standard image High-resolution imageThe field of gas sensors is very huge, and associated with many material systems and applications in detecting different gases [11, 12]. The present sensing materials have evolved from metal oxides (MOS), which play a dominant role in gas sensors, to emerging graphene and other two-dimensional (2D) materials, as well as various nanocomposites. Figure 2(a) presents the number of the papers & patents published on various gases or liquids, from 1964 to 2020, relevant to gas sensors. Many tested targets, such as H2S, HCHO, NH3, CO, NO, NO2, ethanol, acetone, and petroleum, have been intensively studied in the past decades. Nitrogen oxide (NO and NO2) sensors have drawn the most attention. Figure 2(b) shows the number of papers and patents published on various sensing materials relevant to gas sensors from 1964 to 2020. MOS have been utilized in both electrochemical and gas sensors due to their surface redox properties. SnO2 has been successfully developed into commercial sensors and attracted the most research interest. Other sensing materials, such as NiO, CuO, Fe2O3, SnO2, WO3, carbon nanotubes (CNTs), graphene and MoS2, have also been intensively reported [13–15]. Catalysts such as Pd and Pt have been applied as additives to MOS to improve the sensor sensitivity and stability.

Figure 2. (a) The number of papers and patents published on various gases or liquids relevant to gas sensors from 1964 to 2020; (b) the number of papers and patents published on various sensing materials relevant to gas sensors from 1964 to 2020; here, the papers and patents searched from the web of science refined by 'title = gas sensor' with all document types on March 15, 2020.

Download figure:

Standard image High-resolution imageThis roadmap demonstrates a comprehensive overview on various kinds of sensor materials, including MOS, sulfides, metal organic frameworks (MOFs), CNTs, graphene and noble metals-based composites. Although these materials also enable electrochemical detection of chemical molecules, this roadmap will only focus on the resistive and conductometric sensors for gas detection. Each subsection written by active researchers in this area covers a typical sensing material. The current status and the advantages/disadvantages of each sensing material are overviewed. In addition, current and future challenges in the development of this field are also discussed. We hope that this roadmap has help for the development of gas sensing materials and gas sensors in future.

2. ZnO gas sensors

Mani Teja Vijjapu, Saravanan Yuvaraja, Sandeep G Surya, Khaled N Salama

King Abdullah University of Science and Technology (KAUST), Saudi Arabia

2.1. Status

MOS (MOs)-type gas sensors revolutionized their commercialization for toxic gas monitoring and air quality monitoring owing to their intrinsic and remarkable material characteristics. ZnO is a wide bandgap semiconductor. Without any extrinsic doping, it exhibits the n-type semiconductor characteristics due to the presence of oxygen vacancies (Ov) arising from the non-stoichiometry of the oxide. Among existing MOs, ZnO is not only thermally/chemically stable, non-toxic and biocompatible, but also has a good affinity towards toxic analytes high charge carrier mobility. The stability and tuneable semiconducting, as well as chemical properties of ZnO, made it a favourable candidate to explore for the detection of chemicals [16], biomolecules [17], and gases [18], among the explored MO materials. Nonetheless, the bare ZnO-based sensor hinders the sensing performance; hence several strategies were adopted to make efficient use of ZnO materials for gas sensors [19].

2.2. Current and future challenges

Typically, ZnO-based gas sensors are chemi-resistive where the resistance of the material changes owing to targeted gas exposure. The change in resistance mainly depends on the availability of oxygen ions in either bulk or surface region of the material. The sensing mechanism in MO gas sensors to detect the oxidizing and reducing gases is dependent on the interaction of conduction band electrons with these targeted gas molecules, resulting in the change in conductivity of the active material. The operating temperature (T) profoundly influences the availability of the oxygen ionic species that are chemisorbed on the surface of oxide materials, as described in the equations (1)–(4) [18]. On applying thermal or light energy, the incoming gas molecules can effectively overcome the activation barrier to interact with the active sensing material to improve the sensing performance. This high operating temperature requirement is the biggest challenge in MO sensors. Another major challenge is the cross-sensitivity as the sensing mechanism in bare MO sensors mainly relies on the localized redox reactions. All these factors limit the sensing performance of bare ZnO thin film or nanomaterial in detecting toxic gases.

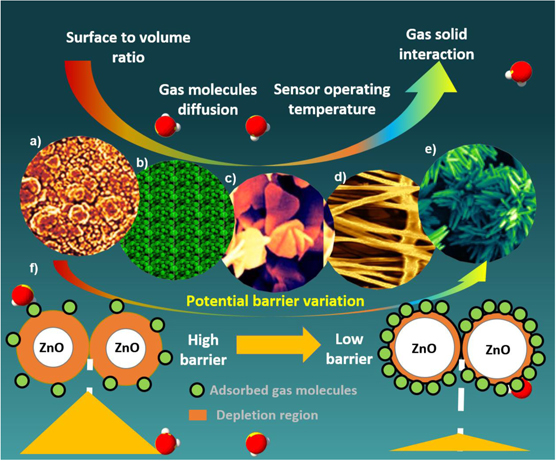

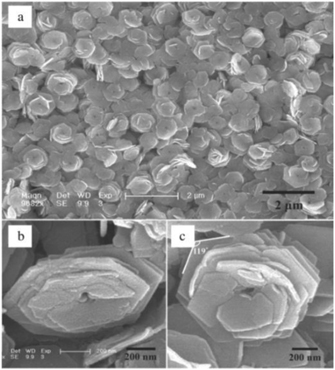

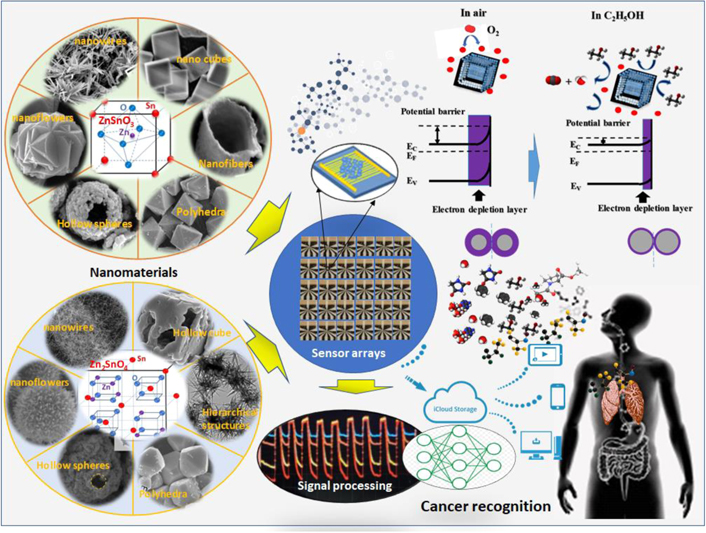

The transformation of sensors based on thin films to sensors with hierarchical nanostructures (NSs) is the general research trend in ZnO gas sensors to augment the sensing performance, as shown in figure 3. To date, many research groups have successfully fabricated a wide range of high aspect ratio ZnO nanomaterials from 0D quantum dots (QDs) to 3D core–shell nanostructures. Especially, reports focus on the synthesis of nanomaterials with different morphologies such as nanowires (NWs), nanotubes (NTs), nanorods (NRs), and nanosheets (NSHs) that modulate the potential barrier of the electrons in ZnO materials and increase the surface area to enhance the gas–solid interaction. Each of these morphologies has its advantages in providing more active sites and better electronic properties, facilitating more significant adsorption and diffusion of gas molecules. Commonly employed methods to obtain NSs are thermal evaporation, hydrothermal, electrochemical, and electrodeposition methods. The wide variety of the NSs reported to be efficient and effective are obtained by growing them directly on the sensor electrodes (in situ growth). The main challenge is the reproducibility in the growth and the mass production of these NSs.

Figure 3. Morphological transformation of ZnO active materials from thin-film to the hierarchical nanostructures. It depicts the qualitative improvement in the desired gas sensing properties and potential barrier variation with the transformation of nanostructures. SEM images of ZnO: (a) thin-film (reproduced from [20] with permission of The Royal Society of Chemistry), (b) NPs (reprinted with permission from [21]. Copyright (2016) American Chemical Society), (c) NSHs, (d) NRs, ((c) and (d) reprinted with permission from [22], Copyright (2009) American Chemical Society) (e) NFs (reprinted with permission from [21], Copyright (2016) American Chemical Society), (f) schematic illustration of potential barrier variation due to hierarchical nanostructures.

Download figure:

Standard image High-resolution imageFurthermore, performance enhancement is also determined by some of the fundamental material properties such as dangling bonds, active sites, and surface atomic arrangements. The key to deciding them is the formation of crystal facets with varying energy levels on the material surface. It is found that wurtzite ZnO crystal (0001) with the termination of Zn+ atoms is more energetic and possesses the best chemisorption capability to absorb oxygen ionic species [22]. However, the major challenge lies in the growth of ZnO NSs with precise control on the exposure of high energy surface crystal facets. In addition, the high-energy facets-based materials exhibit the agglomeration of NSs hence reducing the active area of material and poor air stability.

2.3. Advances in science and technology to meet challenges

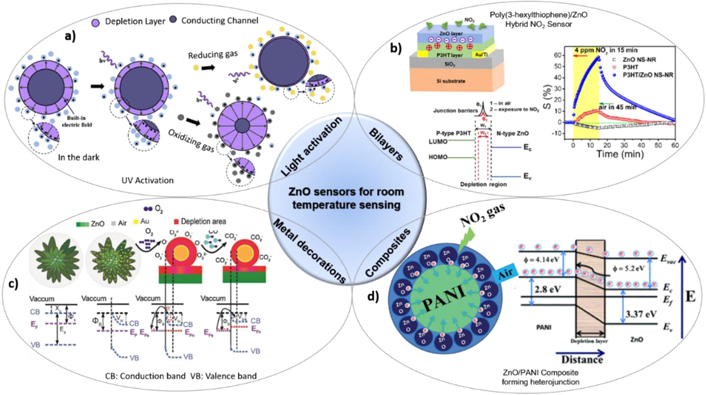

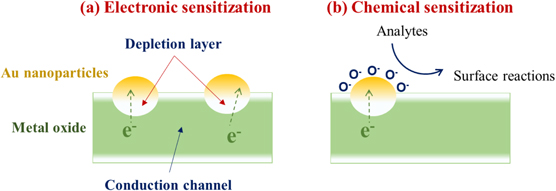

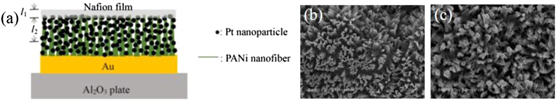

Higher operating temperatures in the gas sensors lead to more power-consumption and high-cost burden for real-time applications. Hence, significant research advanced towards ZnO hybrid sensors such as surface modification through additives/dopants with reduced operating temperature or light activation [23]. The noble metal (Pd, Pt, Ag, Au) decorations of ZnO materials [24], ZnO composites [20], bi-layers of polymers and inorganic materials on the ZnO NSs observed to be prominent in improving sensitivity and selectivity. The addition of noble metals induces chemical and electrical sensitization effects that aid the adsorption of the oxygen species. Chemically, the catalytic action of metal NPs results in dissociation of molecular oxygen into ionic oxygen species that get adsorbed on the oxide surface and reacts with targeted gas molecules. Whereas the electrical sensitization effect acts simultaneously and promotes the formation of the depletion region at the metal/ZnO nanostructure interface, which improves sensitivity. Arunkumar et al demonstrated Au coated ZnO nanoflowers (NFs) shown to have higher sensitivity towards CO2, as shown in figure 4(c). In the case of metals like Pd, which have a high affinity towards H2 also improves selectivity through catalytic action [18]. Followed by, the organic polymers as an additive bilayer on ZnO thin films is a novel way to make use of the best of both worlds, since polymers provide some of the distinguishable features such as intrinsic sensitivity towards toxic gases at room temperature (RT) and easy fabrication in large scale. Hence, researchers have strategically combined the polymers and ZnO materials as bilayers [21], and composites [20] to form the heterojunction interface. Due to the charge exchange between them, a strong depletion region will be formed at the interface, which acts as good active sites to adsorb gas molecules (figures 4(b) and (d)). Alternative to the usage of secondary materials, the light activation is a viable option to generate excess charge carriers (figure 4(a)) to achieve RT sensing with the bare ZnO based sensors with reasonable sensitivity. Primarily, UV LEDs employed to generate the excess electron–hole pairs into the ZnO material that enable the sensing and regeneration of the device at RT [23]. Whereas, visible light activation could be a cost-effective and safe approach without compromising the desired RM sensing performance.

Figure 4. Schematic illustrations of the ZnO sensors operating at room at temperature (a) sensing mechanism of the light-activated sensors (reprinted from [23] Copyright (2017), with permission from Elsevier), (b) device schematic and response of hybrid P3HT/ZnO bilayer sensor (reprinted from [21], Copyright (2016), with permission from Elsevier), (c) Au–metal decoration on ZnO NRs and its sensing mechanism (reprinted from [24], Copyright (2017), with permission from Elsevier) (d) PANI/ZnO composite forming multiple p–n heterojunctions for enhanced sensing performance (reproduced from [20] with permission of The Royal Society of Chemistry).

Download figure:

Standard image High-resolution imageFurther studies indicate that the sensing performance is limited not only by the surface morphology but also the intrinsic electronic and optical properties of ZnO materials. To augment the intrinsic properties of the material, the creation of intrinsic defects was carried out in recent years [18]. As a result, several electronic properties, such as charge transport and surface properties were improved. Such a material engineering technique paves the way to overcome the long-time challenges, mass production of sensors, and controlled synthesis of Ov dominant ZnO structures. High-temperature fabrication is another process challenge; numerous techniques were proposed to grow diverse ZnO NSs at low temperatures. For example, ZnO NRs with high aspect ratio and vertically aligned features [18], were fabricated using a simple vapour transfer approach, exhibited excellent sensing performance towards H2S at RT. In addition, ecofriendly and biocompatible ZnO chemical sensors have also been explored [25].

Selectivity is still an issue with bare ZnO NSs. For instance, bare ZnO NRs sensors were sensitive to both hydrogen and benzene. Through another bilayer approach of targeted molecular sieving, the selectivity was achieved. Khudiar et al employed ZIF-8 to restrict the interferon targeted molecules which have larger kinetic diameters to diffuse through the smaller pores of MOFs. In this report, they demonstrated the selective H2 sensing at RT by allowing its diffusion only through the MOFs over ZnO NRs. The optical sensors based on surface plasmon resonance (SPR) technique can offer high selectivity, as observed in the case of CO detection using ZnO NRs [26]. The major challenge in these optical sensors is the portability for commercial applications.

2.4. Concluding remarks

We have briefly discussed the potential of ZnO materials for gas sensing applications. Although ZnO is considered as the best candidate for gas sensors, the operating temperature that leads to high power consumption and the high cost was a hurdle of bare ZnO sensors. Tremendous efforts include synthesizing NSs, light activation, the use of additive/dopants, the hybridization with other inorganic materials, polymers, and MOFs can be witnessed to reduce the operating temperature without compromising the sensing performance. However, another major challenge to overcome in ZnO gas sensors is the interference of humidity at RM. The development trend of sensors is approaching towards wearable/flexible electronics, which needs the material synthesis procedures to be compatible. For commercialization purposes, advanced methods to enhance sensitivity and selectivity have to be feasible for mass production.

3. WO3 for gas sensors

Chengjun Dong and Yude Wang

Yunnan University, People's Republic of China

3.1. Status

WO3 is an n-type gas sensing material with a wide bandgap. Due to its outstanding semiconductor properties, WO3 has been widely employed for gas sensors in many fields including environment protection, healthcare, disease diagnosis, and food safety [27]. The basic working principles of gas sensors decisively determine their construction and applications. Based on WO3, resistive gas sensors are more popular compared with other types [e.g., microelectro mechanical systems (MEMS) sensor, optical sensors, surface acoustic sensors, and electrochemical sensors] [28], in which the concentrations of target. gas are reflected by the changes in conductivity. The chemical reaction of target. molecules is strongly influenced by the microstructures and surface states of sensing materials.

The morphology and microstructure of WO3 will determine the specific surface area, the amounts of active sites, and the gas diffusion channel, thus affects the sensing outcomes. Therefore, a wide range of synthesis methods have been carried out to prepare different WO3 in 0D, 1D, 2D, 3D and irregular shapes [29], as shown in figure 5. Especially, hierarchical structures with hollow or porous subunits are believed to exhibit superior sensing properties [30, 31]. To achieve morphologies control, templates (e.g., soft templates, hard templates, bio-templates) or additives are efficient strategies to tune the nucleation and growth of unique WO3.

Figure 5. WO3 with different morphologies and common strategies to enhance sensing properties of WO3 gas sensors.

Download figure:

Standard image High-resolution imageThe approaches to enhance the reaction of target. molecules or regulate the charge transfer can effectively enhance the sensing properties (figure 5) [27]. It is well reported that the exposed facet and elemental doping have an ability to regular the surface chemical states of WO3. The noble metal focalization will significantly favour the reaction of target. molecules by spillover effect and electronic sensitization (ES) due to their merits of catalytic characteristics. Essentially, the creation of heterojunctions is a good way to couple WO3 with other sensing materials to tune the electronic structures and interface configuration. 1D WO3 (i.e., NWs, NTs, NRs, etc) is a favourable backbone to support second phases to form a large number of heterojunctions at the interface [32]. Photon activated assisted by light is also a useful option to significantly reduce the operating temperature. Generally, synergistic effects including more than one reasons are fundamental for the outstanding performances.

3.2. Current and future challenges

Efforts to control WO3 morphologies to bring about superior sensing performance is the subject of a large number of concerns. The synthesis processes of WO3 are heavily restricted by the solubility of the available tungsten related precursors. For instance, because of the hydrolysis characteristics, only organic solvents are available to be selected for tungsten chloride. Sodium tungstate dehydrate is another common precursor, however, the solvent is confined to water. Attempts are ongoing to make full use of these precursors and try others as well.

Although diverse morphologies of WO3 in different dimensions for gas sensors have been found in the literature, the main current challenge is that these products are limited to laboratory preparation under severe experimental conditions. If massive production, the aggregation and uncontrollable growth is inevitable. On the other hand, thermal treatment is always mandatory to converse precursors into crystalline WO3. Thus, synthesizing WO3 by one-pot methods is very appealing to simplify the experimental process and reduce the cost.

Parallel challenges we faced must be the improvement in gas sensing performances to meet the requirements for practical applications [33]. The detection capability of low concentrations, high operating temperature, unsatisfactory selectivity and stability are the major bottlenecks. The most cited sensing mechanism is the resistance changes rooted in the reaction between target. molecules and the absorbed active oxygen species. Nevertheless, a big breakthrough is highly expected to provide more fundamental understanding. Admittedly, the sensing properties have been greatly enhanced through several strategies above. Currently, it is still a huge challenge to precisely control the modification, thus the enhancement in sensing properties could be adjustable. Additionally, more studies are needed to survey the specific reasons. Furthermore, integration WO3 with related base to fabricate wearable/flexible sensors to collect comprehensive information simultaneously is a high passionate research topic for personalized health monitoring or medicine in particular.

3.3. Advances in science and technology to meet challenges

Massive synthesis of WO3 with uniformly controllable morphologies to promote its commercial application in gas sensor seems to be unrealistic in short time. Regarding to the precursors, metal tungsten is an alternative source to prepare WO3. WO3 films were deposited from tungsten target as gas sensors by physical and chemical methods, but the microstructures of these prepared films were monotonous. As a soluble substance in polar solvents, amorphous peroxo-tungstic acid obtained by dissolving metal tungstate into hydrogen peroxide is a very promising way [34]. Thermal decomposition of tungsten salt in organic solvents at higher temperature or hydrothermal condition was utilized for one-pot WO3 synthesis [35]. External auxiliary such as microwave-assisted will be helpful to boost the synthesis. These as-prepared WO3 is beneficial to directly coat on textile or polymeric substrates to serve as flexible gas sensors. Moreover, time dependent experiments and controllable parameters should be conducted to reveal the growth mechanism of a certain microstructures and morphologies.

With respect to the gas sensors based on WO3, lower the detection of limitation and operating temperature as well as strengthen the selectivity and long-term stability is still the research topics to be devoted to. Centre on the working principle, any ways to increase the specific surface area and rich the porous structures, especially microporous structure, is worth to have a try to favour the gas molecule diffusion and reaction on the WO3 surface. More suitable additives will be added into to control the crystal plane and amounts of exposed high energy facets. Appropriate doping elements or their co-doping may be attempted to enhance the sensing properties. To fully use the catalytic activities of noble metal NPs, their distribution in WO3 matrix should be regulated. One-pot synthesis of WO3 NPs are easily to fabricate wearable/flexible sensors with/without the help of polymers. Combined with experimental findings, it would enable the gas adsorption/desorption process be investigated using developed computational models such as density functional theory (DFT) [36]. Based on the enhanced sensing strategies, the roles of exposed facets, doping, vacancies, noble metal fictionalization are theoretically simulated, thus the mechanism may be deeply excavated using interdisciplinary knowledge.

On the other hand, using WO3 as active material, MEMS sensor, optical sensor, optoelectronic sensor for various gas detection are less studied so far. These sensors are especially advantageous in selectivity and high-precision detection operated at room temperature.

3.4. Concluding remarks

Here, we have briefly discussed the microstructures and sensing properties of WO3. Although the progresses have been made in controlling the morphologies of WO3, it is still a challenge to expand these synthesis methods for massive production. A series of time-dependent and controllable process conditions will help to explore the growth mechanism in depth. Using metal tungsten as an option of starting material, novel WO3 could be prepared via physical or chemical methods. Hierarchical WO3 with hollow or porous structures are beneficial for the effective gas detection. One-pot synthesis of WO3 is believed to promote the wearable/flexible devices based on WO3. Several common strategies are summarized to enhance the sensing performances of WO3 based gas sensors. Neither the sensing mechanism or the enhanced reasons still need to be deeply understood through computational simulations. Compared to resistive type sensors, the inadequate development in other types of gas sensors based on WO3 requires more attention. As the continuous progresses, we believe that WO3 with desirable sensing properties for practical applications will be controllably synthesized in the upcoming years. Accordingly, future efforts will hopefully include full understanding the growth and sensing mechanism in great details.

Acknowledgments

This work was financially supported by National Natural Science Foundation of China with Grant No. 61761047 and 41876055).

4. Fe2O3-based gas sensors

Qin Kuang

Xiamen University, People's Republic of China

4.1. Status

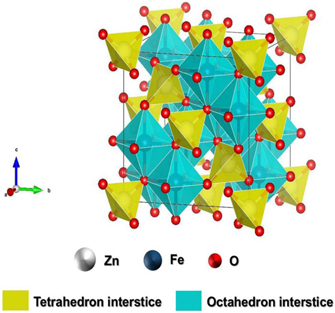

Fe2O3-based nanomaterials are widely used in gas sensors owing to their high sensitivity, good corrosion resistance, environmental friendliness, and low cost [37, 38]. To date, the existence of four crystalline polymorphs (α-Fe2O3, β-Fe2O3, γ-Fe2O3, and ε-Fe2O3) as well as amorphous Fe2O3 has been well recognized. Among these, α-Fe2O3 and γ-Fe2O3 exist in nature and have attracted much attention, while there have been few studies on the others as gas sensing materials. α-Fe2O3 is the most stable phase and has a rhombohedral corundum structure (space group: R

ch167), in which Fe3+ ions occupy two-thirds of the octahedral sites confined by the hexagonal close-packed O lattice. Metastable γ-Fe2O3 possesses a cubic, inverse spinel structure with Fd

ch167), in which Fe3+ ions occupy two-thirds of the octahedral sites confined by the hexagonal close-packed O lattice. Metastable γ-Fe2O3 possesses a cubic, inverse spinel structure with Fd

m space group. The vacant cation sites, usually located at octahedral sites, are a feature of γ-Fe2O3. Most of them are exposed on the surface, acting as strong adsorption sites [39, 40].

m space group. The vacant cation sites, usually located at octahedral sites, are a feature of γ-Fe2O3. Most of them are exposed on the surface, acting as strong adsorption sites [39, 40].

The gas-sensing mechanisms of α-Fe2O3 and γ-Fe2O3 are different due to their different crystal structures. α-Fe2O3 is the surface-resistance-control-type material, and the surface-depletion model is often used to explain its gas sensing mechanism. In contrast, γ-Fe2O3 is the bulk-resistance-control-type material, whose resistance change mainly arises from the conversion between γ-Fe2O3 and Fe3O4 [41]. Fe2O3-based gas sensors generally operate at relatively high temperatures. The phase transition temperature from γ-Fe2O3 to α-Fe2O3 is between 523 and 873 K [38]. This thermal stability problem greatly limits the application of γ-Fe2O3, although its operating temperature can be reduced below the phase transition temperature [42]. Therefore, α-Fe2O3 is potentially the most useful phase of iron(III) oxide for gas sensing applications, and the following discussions are focussed on α-Fe2O3-based materials.

In addition to phase, the morphology of sensing materials, including shape, size, and orientation, plays a crucial role in gas sensing performance. Excellent sensing materials usually possess a large specific surface area and an appropriate porous structure. The former contributes to providing abundant active sites, enhancing gas adsorption, and improving sensitivity, while the latter is favorable for reducing the response/recovery time because of rapid gas molecule diffusion. In the past few decades, great efforts have been devoted to synthesizing various types of nanostructured α-Fe2O3, such as NPs, NRs, NTs, and NFs [38]. The gas-sensing performance of these nanostructured α-Fe2O3 is improved to varying degrees in comparison to bulk α-Fe2O3. Recently, it has been recognized that a large specific surface area cannot ensure an improved gas sensing performance of α-Fe2O3. Other factors related to the surface are also important, such as surface energy, surface atomic arrangement, and dangling bond density. However, it is difficult to explore the specific roles of these factors in randomly oriented nanomaterials. Hence, shape-controlled α-Fe2O3 nanocrystals (NCs) with specific exposed facets have gradually attracted the interest of scientists.

4.2. Current and future challenges

α-Fe2O3-based gas sensors have been widely used in detecting various gases, such as H2, NO2, H2S, and volatile organic compounds (VOCs). However, there are still some obstacles to overcome in future research. Nanostructures usually contribute to enhanced gas-sensing performance. However, most nanostructures easily stack together spontaneously to reduce their overall surface energy. Such densely stacked structures decrease the specific surface area, obscure active sites, and influence gas diffusion, thereby weakening the intrinsic gas sensing performance [42]. There is therefore current interest in the rational design of large specific surface area NSs that can make full use of their sensing ability for developing high-performance α-Fe2O3-based gas sensors.

Exposing the surface of high-energy facets has proven to be an effective approach to improve the performance of gas sensing materials. As for α-Fe2O3, NCs with exposure to well-controlled surfaces, such as {012}, {104}, {113}, and {001}, have been investigated to date [43]. The facet-dependent gas sensing of α-Fe2O3 NCs strongly depends on the variation in atomic configurations and chemical composition of different facets. However, owing to the complicated crystal growth environments and uncertain roles of various influencing factors, the synthesis of α-Fe2O3 NCs with specific exposed facets mainly depends on trial and error at present [44]. It is still a great challenge to synthesize α-Fe2O3 NCs with a high percentage of exposed active facets without capping agents. On the other hand, the surface terminations, including atomic structures and chemical compositions, are quite complex in real environments when solvation reactions and/or surface reconstruction are considered. Thus, analyzing the surfaces of ideal crystals is unlikely to be sufficient to explain the facet-dependent sensing properties of α-Fe2O3 NCs.

Pure α-Fe2O3-based gas sensors are usually very cheap and exhibit good sensitivity, but most of them have higher operating temperatures and have limited selectivity and long-term stability [38]. The optimal operating temperatures of reported α-Fe2O3-based gas sensors are approximately 200 °C and higher, due to the need to balance the effect of activation energy and gas molecule adsorption. In consideration of energy costs, environmental protection, and safety, an excessively high operating temperature is not practical. Selectivity is an important consideration in α-Fe2O3-based gas sensors. It is often difficult to quantify the complex characteristics that determine selectivity. Many factors influence selectivity, such as the reaction process, adsorption capacity, bond dissociation energy, pore size, and consumed number of chemisorbed oxygen species [42]. Low stability and long-term signal drift will result in uncertain results and false alarms, and the need for the sensors to be recalibrated frequently. Thus, Fe2O3 gas sensors should have excellent long-term stability for up to 2–3 years to meet the demands of practical applications, including stability in high operating temperatures, humid environments, and corrosive media [38]. However, little attention is paid to stability in reported studies, with stability of α-Fe2O3 reported in literature only over a matter of weeks.

To address the challenges mentioned above, new strategies need to be developed. Assembling NRs, NWs, and NSHs into 3D hierarchical nanostructures of α-Fe2O3 with a large active surface and appropriate porous structures is an effective approach to solve the problem of easy stacking of nanomaterials. Many studies have proven the superiority of such structures [42]. Apart from exposing more active surfaces, the well-aligned porous structures among adjacent units serve as unimpeded passages, which facilitates rapid gas diffusion.

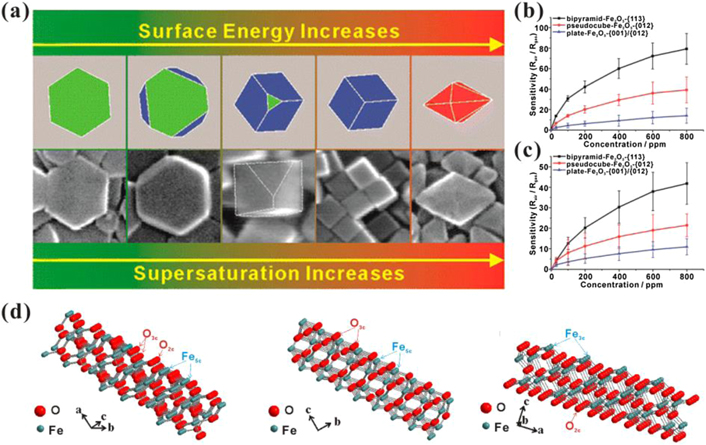

A recent study found that the surface energy of as-prepared micro- and nanocrystals is correlated with the supersaturation of growth units, and high supersaturation is conducive to forming high-energy surfaces [44]. As shown in figure 6(a), with the increase in supersaturation, the as-formed α-Fe2O3 NCs are gradually transformed from nanoplates with stable {001} facets to pseudocubes and hexagonal bipyramids with higher energy {012} and {113} facets, respectively [45]. For highly energetic facets, the loss of original singly coordinated O atoms produces coordinatively unsaturated Fe atoms with dangling bonds. The higher density of low-coordinated Fe atoms gives rise to an excellent ability to adsorb oxygen and other gas molecules, resulting in enhanced performance (figures 6(b)–(d)) [45]. The sensitivity and selectivity of α-Fe2O3-based gas sensors can be further improved with a deeper understanding of surface-enhanced gas sensing when combined with other modification strategies.

Figure 6. (a) Schematic of the supersaturation-controlled morphology evolution of α-Fe2O3 NCs from {001} to {012} and {113} facets. (b) and (c) Concentration-dependent sensing curves of different shaped α-Fe2O3 NCs towards acetone and methanol, respectively. (d) Surface terminations of {113}, {012}, and {001} of α-Fe2O3. Reprinted with permission from [45]. Copyright (2014) American Chemical Society.

Download figure:

Standard image High-resolution imageApart from morphology control, constructing heterojunctions is also a common method to overcome the inherent problems of pure α-Fe2O3 gas sensors. There are many studies in which metal/α-Fe2O3 and metal oxide/α-Fe2O3 gas sensors are conducive to reducing operating temperatures, shortening the response/recovery time, and improving selectivity [46]. In contrast, reports on polymer/α-Fe2O3 gas sensors are still rare. Low conductivity and poor stability of organic materials, high operating temperatures, and complicated processability of inorganic materials limit their development. Surprisingly, a hybrid of these two classes of materials can negate their individual disadvantages to some extent and lead to enhanced performance, especially resulting in greatly reduced operating temperatures. Thus, polymer/α-Fe2O3 is a promising material for gas sensors working at RM [38].

4.3. Concluding remarks

α-Fe2O3 is the most promising phase of ferric oxide in gas monitoring areas. Nanostructured α-Fe2O3 generally has greatly improved sensitivity and dynamic response. Therefore, proper design of nanostructures, especially hierarchical NSs with a large proportion of exposed high-energy facets, is an effective approach to enhance the performance of α-Fe2O3-based gas sensors. In addition, introducing other components (noble metals, MOS, or conducting polymers) can partly avoid or improve the inherent shortcomings of pure α-Fe2O3, such as high operating temperatures and low selectivity. Although α-Fe2O3-based gas sensors are already widely used, it is still important to develop higher performance sensors to meet future needs and improve the accuracy of measurements.

Acknowledgments

This work was supported by the National Key Research and Development Programme of China (2017YFA0206801), and the National Natural Science Foundation of China (No. 21671163).

5. Chemiresistive CeO2-based gas sensors

Zamaswazi P Tshabalala3, David E Motaung1,3

1University of the Free State, South Africa

3University of Limpopo, South Africa

5.1. Status

The necessity for detection and continuous monitoring of lethal and combustible gaseous substances has become more vital over the years for the drive of public and domestic welfare, industrial developments, and environmental monitoring for air pollution. Currently, chemiresistive gas sensors based on MOs are more appealing. Among the MOs, cerium oxide (CeO2) which is a rare-earth oxide compound vastly abundant on the Earth crust has gained attention in gas sensing field. CeO2 is a widely used catalyst with impressive physical and chemical properties such as, the unique electronic configuration in the 4f shells, ample amount of oxygen vacancies (Ov) and dual valence state Ce4+ and Ce3+ giving rise to its extraordinary redox properties [47–49]. Catalytic ability of CeO2 highly influences the chemisorption of the oxygen molecules and reactant gas during the sensing process. Currently, numerous works has been done using CeO2 based sensors, for detection of toxic and flammable gases, such as CO, H2S, formaldehyde, operating at temperature higher than 100 °C [47–50]. Few studies have been done on pristine CeO2 focussing on low operating sensing temperature (⩽100 °C) [51]. CeO2 NPs synthesized using chemical precipitation method showed high sensor response at RT towards H2S, CO, NO2 and isopropanol (IPA) gas (figure 7(d)) [51]. Hybrid materials formed by CeO2-heterostructures showed RT operation towards NH3, NO2 and CO, using CeO2 NPs coated by cross-linked polyaniline (PANI) hydrogel, CeO2/graphene heterostructure and Pt NCs on CeO2 nanowire, respectively [52, 53]. Gas sensing mechanism is surface dependent, thus, maximized sensitivity requires improved surface area and porosity, and surface functionalization. Pristine CeO2 nanospheres with surface area of 773.3 cm3 g−1 displayed enhanced sensitivity towards 30 ppm CO [47]. Motaung et al [49] reported on ultra-high sensitivity and selectivity to H2 induced by CeO2–SnO2 heterojunction. The {100} facet in CeO2 exhibited high surface energy, influencing the decomposition of analyte gas. Zhang et al achieved RM NO2 sensing driven by CeO2–graphene with exposed {100} polar facets. Besides, the CeO2–graphene nanocubes exhibited plentiful amount of Ov, which expedited the adsorption of NO2 on the surface, such that sensitivity increased with Ce3+ concentration [53]. Elger et al showed the potential of joint operando Raman-gas-phase FTIR spectroscopy to clarify the mode of operation of 0.5 wt% Au doped CeO2 during ethanol gas sensing, where the presence of Ov in CeO2 were directly monitored, in addition the surface species [54]. In terms of selectivity, by using heterostructures and surface loaded CeO2, improved selectivity was witnessed. Jayababu et al [55] reported on NiO decorated CeO2 nanostructures with superior sensitivity to 1–100 ppm IPA. Figure 7(a) shows improved selectivity towards IPA among other VOC's, by 11 folds increase in response from 139 to 1570 for NiO–CeO2 nanocomposite. With regards to response and recovery times, CeO2–SnO2 heterostructure showed fast response and recovery times to H2 at 300 °C [49]. Similar results were displayed by CeO2 decorated by NiO NPs exposed to IPA at RT (figures 7(b) and (c)) [55].

Figure 7. (a) IPA selectivity plot due to NiO-decoration on CeO2. Response and recovery times of (b) pure CeO2 and (c) NiO–CeO2. (d) 15 monthss stability test of pristine CeO2 towards 30 ppm CO at 400 °C. (e) Schematic diagram of various nanomaterials-based sensor array for medical diagnosis by analyzing human breath. (Reproduced from [55] with permission of The Royal Society of Chemistry, reprinted with permission from [47]. Copyright (2018) American Chemical Society.)

Download figure:

Standard image High-resolution image5.2. Current and future challenges

Despite the several positive properties that CeO2 possess, nonetheless, it is more prone to achieve optimum response at high operating temperatures of 200–700 °C, making it unattractive. Since it compromises the material's stability, adhesion to substrate, lifetime of the sensor, leads to high power consumption and may ignite in the presence of combustible gases. The current achievable response and recovery times on CeO2-based sensors need to be improved further as to reach ultra-fast (<1 s) response kinetics. This is justified by the toxicity of analyte gas and field of application (indoor air quality, process monitoring, medical diagnosis, food safety), there are time based limits, such as 10 ms threshold response time for O2 monitoring in order to control combustion in cylinders of two-wheeled vehicles engines [56]. A sensor needs to maintain its response and resist change whether in phase due to heat or segregation of dopants and chemical change due to poisoning during reactions, therefore long-term stability is of great importance for commercial applications as it guarantees a prolonged the sensor lifetime. While the CeO2 nanospheres presented by Majumder and Roy [47] displayed (figures 7(c) and (d)) great stability in baseline resistance and sensitivity with standard deviation less than 2 over 15 months under 30 ppm CO at 400 °C, however, the high operating temperature still indicate a limitation.

Furthermore, the cross-sensitivity to relative humidity (RH) also remains a significant challenge, more especially at low operating temperatures <100 °C. Since water from RH get physiosorbed and occupy the active sites of the sensing material, thus decreasing the sensor response. Additionally, the gas selectivity is a universal challenge even to other MOS based sensors, and this limit their commercialization, as a result, significant amount of work is required in order to accelerate the commercialization. Additionally, to accomplish accurate and reliable gases sensor outputs CeO2 based nanoarrays should be considered. Nanoarrays enable smart sensing by integrating multiple sensors each selective to a specific targeted gas and a GCMS to quantify the concentration of each parameter, such as analyte gas and RH (figure 7(e)). To properly achieve nanoarrays, further miniaturization is required for portable, light weight devices and this owes to achieving smaller particle sized morphologies (QD), large surface area exposed for analyte gas and stable sensor performance [57].

5.3. Concluding remarks

Owing to its chemical and physical properties, such as catalytic activity, dual valence state Ce4+ and Ce3+ and high concentration of Ov, CeO2 demonstrated potential and sustainability in gas sensing application. Further research still needs to be conducted to address the aforementioned challenges, such as improving operating temperature and selectivity, rapid response time and long-term stability and RH. RT gas sensing is attractive from the standpoint of low energy consumption, streamlined sensor fabrication without the requirement of a heating component, and thus low cost can be anticipated. Moreover, synthesis of nanostructures in a controlled way, particularly for commercial devices is tremendously important. The concept of exploiting metal additives, (e.g. Ni) to improve the moisture-resistant of the MO gas sensors is overbearing and is ought to be considered cautiously as well. This may advance to close the gap between the research and practical application.

Acknowledgments

The National Research Foundation is also acknowledged for financial support.

6. Tin dioxide-based gas sensors

Xianghong Liu1 and Junliang Yang2

1Qingdao University, People's Republic of China

2Central South University, People's Republic of China

6.1. Status

Among the many metal oxide semiconductors (MOS), SnO2 is the most broadly used material in chemiresistive gas sensors ever since the first development of the commercial sensor devices, i.e. TGS 109 utilizing a sintered SnO2 pellet with embedded electrodes and heaters as the sensing elements, by Naoyoshi Taguchi in the 1960s due to its high sensitivity, cost effectiveness, and good thermal stability compared with other MOS [58, 59]. Starting from the beginning of 20th century, the research in gas sensors expanded significantly with a fast-growing number of yearly publications. A survey from Web of Science reveals that publications of 'SnO2 gas sensors' during 2000–2020 accumulates to a total number of over 6500, followed by a number of 6100 from ZnO which is also extensively investigated for gas sensors.

Nanostructured materials can afford many advantages when applied as the sensing layers in compared to the conventional thick-films, due to the large surface area, high surface reactivity, tunable porosity and dimensionality. As a result, enormous effort has been explored to synthesize SnO2 nanomaterials, NPs, NWs, nanosheets, and other nanoarchitectures. The gas sensors based on these SnO2 nanostructures have displayed improved '4s' parameters [60], i.e., sensitivity, selectivity, response–recovery speed and stability, for detection of various gaseous molecules such as H2, NO2, CO, CH4 and VOCs. For instance, the nanorods or NWs are more resistant to thermal ripening and aggregation than NPs at the operating temperatures, usually higher than 300 °C, which would deteriorate the sensor performances due to the loss of surface area of sensing layers. The porous nanostructures have abundant internal channels to facilitate the mass transfer and gas diffusion [4], as well as increased accesses to external molecules, thereby leading to faster response speed and higher sensitivity.

In order to improve the sensor performances, noble metals such as Au, Pt, and Pd have been widely employed as a sensitizer for SnO2 materials either by electronic or chemical sensitization (CS) mechanism [61]. The fabrication of heterostructures from SnO2 and other MOS were also beneficial for better sensors due to a synergic effect [62], which has been demonstrated by numerous studies. Apart from the well-known grain size effect [61], the manipulation of the thickness of sensing layers comparable to the Debye length also results in a higher sensitivity.

6.2. Current and future challenges

Despite of the extensive research for over 50 years, the sensing mechanism of metal oxide sensors is still to be clarified. Although the trial-error approach can be useful in developing more sensitive materials, a thorough understanding of the fundamentals of sensors can lead to knowledge-based approaches. The widely accepted mechanism for SnO2 sensors is ascribed to the reaction of molecules with surface oxygen species (O2 −, O− and O2−), which alters the carrier density and the size of electron depleted layer or hole accumulation layer (HAL), hence modulating the conductivity of the sensing layers [63]. Since the ionized oxygen species are responsible for the sensing reactions, a clear knowledge of their generation and reaction pathway is very important. When noble metal catalysts are incorporated in sensing materials, their functions and how they contribute to the sensor reactions are still not clearly understood and more efforts are needed to clarify their roles.

Although SnO2 gas sensors have some merits such as high sensitivity and good thermal stability, as well as miniaturized size compared with analytic instruments such as gas/mass chromatography, they suffer from the lack of selectivity due to its sensing mechanism. Selectivity turns out to be very important when gas sensors are applied to exhaled breath diagnosis to screen potential diseases or disorders in human bodies [64]. An accurate detection of the VOCs biomarkers is thus of great significance, considering the exhaled breath normally consists of many interfering molecules such as CO2, O2, and H2O, as well as other molecules from metabolism.

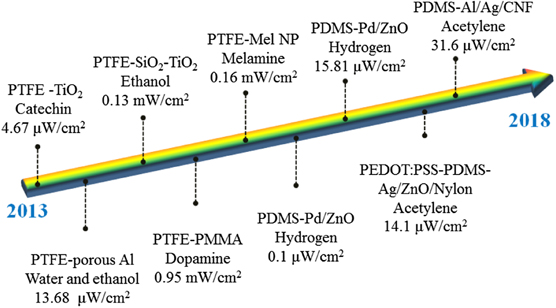

In order to activate the SnO2 sensors, a high temperature normally in the range of 300–500 °C is required. This indicates a high-power consumption considering the conventional gas sensors generally need a typical power of hundreds of mW. The demands for integration of gas sensors into smart electronics such as mobile phones requires a power low enough to be powered up by a battery or even by nanogenerators integrated in wearable devices [65].

6.3. Advances in science and technology to meet challenges

Noble metal catalysts are always needed in a real sensor (e.g. Pd has been essential in the SnO2 gas sensors from Figaro) to enhance the sensor performance, this has propelled enormous research effort to investigate other catalysts such as Au and Pt. Sensing mechanisms can be different and complex considering the diverse electronic structure, size and morphology of the catalyst, as well as the electronic or catalytic interaction with the host materials. This is why today many controversial results can be found in the literature. To better understand the structure–property correlations, experiments or test systems with in situ and operando techniques might be useful to rationalize the details behind sensing reactions.

Selectivity of MOS sensors can be improved by using a molecular sieve layer such as zeolites or MOFs and this has been demonstrated by many publications. Alternatively, by incorporating a gas sensor array with integrated circuits and data analysis system, the electronic nose (e-nose) can become very selective [66]. The independent and different response features of individual sensors are subject to logic analysis through a pattern recognition method. Based on the MEMS technology, the e-nose can be fabricated from various modified SnO2 sensors with different sensing characteristics. This will largely improve the detection accuracy in a very complicated situation such as the exhaled breath diagnosis [67].

Gas sensors are currently being developed to have more functions such as flexibility, deformation and compatibility for integration into smart electronics like mobile phones and watches. The MEMS technology makes it possible to produce sensor devices with very small size and easy integration into portable electronics or sensor networks (internet of things). Furthermore, the MEMS sensors generally have a much low power consumption. For example, the TGS 8100 sensor has a power consumption of 15 mW, which is significantly lower than the 210 mW of TGS 2600. With the advance of MEMS design or working under a pulse-heating mode, a power consumption of several mW or even lower is also possible.

Currently RT gas sensor has aroused much interest since it does not consume any power for heating. It also helps simplify the fabrication and lower the cost of sensors because heater is not needed at RT operation. There are already some reports showing the potential of SnO2 materials for RT gas sensors under the optical illumination or by incorporating carbon NTs or graphene, or by Ov engineering.

6.4. Concluding remarks and prospects

SnO2 has been the most popular materials in practical gas sensors, and probably it will continue to play a dominant role in future sensors due to its tunable structure and peculiar sensing properties. More efforts are needed to obtain a clear knowledge of the sensing mechanism with more powerful analysis techniques, as well as theoretical simulation. MEMS gas sensors based on SnO2 with low fabrication cost and low power consumption will be of great importance for artificial e-noses, portable electronic devices, and wireless sensor network. Considering the limited area of the sensing layers in an MEMS device and the important effects of materials microstructure on the receptor and transducer functions, new technology to deposit nanostructured SnO2 sensing layers rather than the conventional thick-films that is compatible with MEMS process or flexible substrates will be essential. With time, the application of SnO2 sensors to practical non-invasive diagnosis as well as other areas, which requires exclusive detection accuracy and selectivity, may can be realized through pattern recognition, machine learning, and optimized algorithm method, etc.

Acknowledgments

This work is supported by the National Natural Science Foundation of China (Nos. 51972182 and 61971252).

7. TiO2 for gas sensors

Haitao Fu1, Xiaohong Yang1,2, Xizhong An2

1Key Laboratory for Ecological Metallurgy of Multumetallic Mineral, Ministry of Education, Northeastern University, People's Republic of China

2School of Metallurgy, Northeastern University, People's Republic of China

7.1. Status

TiO2 is a typical n-type semiconductor and mainly exists in three crystal forms (e.g., rutile, anatase, and brookite phase). Among them, anatase and rutile TiO2 (bandgap of 3.2 and 3.02 eV) are regarded as promising functional materials (especially for nanomaterials) due to their excellent instinct properties (e.g., high stability, harsh environmental tolerance, and environment-friendly), which impart them diverse cutting-edge applications [68]. In the past decades, sensors are one of the most popular applications for TiO2, and have been widely investigated. Based on sensing principles, TiO2 is capable to be utilized as various types of sensors (biological sensors based on electrochemistry, gas sensors based on chemi-resistors, and COD sensors based on optical properties). For gas sensors, the vast majority of TiO2-based gas sensors are developed as resistance type metal oxide gas sensors (also called chemi-resistors), which achieve detection by the change of the resistance of sensing materials when exposed to the targeted gases. Such a gas sensor normally works in the temperature of 150–400 °C.

Similar to other semiconductor gas sensing materials, the sensing mechanism of TiO2 is described as a two-step process (receptor and transducer process, as illustrated in figure 8), which corresponds to surface reaction (adsorption and reaction) and electron transfer, respectively [69]. The electrons of TiO2 are excited by heat from the valence band (VB) to the conductive band (CB). Oxygen molecules in the air react with the electrons on the surface to form chemisorbed oxygen ion species (O−, O2 −, or O2−), which are related to the working temperature. In this chemical adsorption process, electrons of TiO2 are trapped on the surface, leading to high resistance compared to that in vacuum or inert gas atmospheres. At this stage, if reducing gases (H2, H2S, NH3, CO, and VOCs) are introduced, the resistance of TiO2 will decrease since the trapped electrons are released back to CB by the reaction between oxygen ion species and the reducing gases; on the contrary, the resistance will further increase if exposed to oxidizing gases (NO2, O2, and O3) because more electrons are captured on the surface. The amount of resistance change reflects the sensitivity/response of a sensor.

Figure 8. Schematic images of gas sensing at different modes, where L represents the depletion layer, R represents particle size, and DN corresponds to the diameter of the neck cross section. Reproduced from [69]. CC BY 4.0.

Download figure:

Standard image High-resolution imageThe transducer process, related to the electron transfer in the sensing materials, can be illustrated by three modes: surface-controlled mode, grain-controlled mode, and neck-controlled mode. Which mode plays the dominant role is dependent upon the particle size. Nowadays, the active sensing layers of TiO2-based sensors are basically manufactured by NPs, among which the neck resistance (neck-controlled mode) plays a key role in the contribution of whole resistance.

Based on the sensing mechanism, two-aspect efforts have been made for enhancing the sensing performance, i.e., (1) controlling the morphology of TiO2 NPs to pursue large surface area or expose large area of the certain lattice plane which strongly interacts with targeted gas molecules [70, 71]; (2) transferring more electrons to the surface of TiO2 NPs.

For morphology control, various novel TiO2 nanostructures, including 0D, 1D, 2D nanostructures, and 3D hierarchical microstructures, are prepared as gas sensing materials via various physical and chemical methods. A good example can be demonstrated via a butterfly wing structure of TiO2, which has been constructed by a biological template for fast detection of acetone at RM [72]. Furthermore, for practical use (in MEMS or wearable sensors), TiO2-based sensing materials are always packed or prepared in thin films [73].

To let electrons transfer to the surface, a variety of methods are introduced, including the formation of heterostructures, element lattice doping, and UV irradiation assistance [74]. Fabricating heterostructures are the most commonly used strategy to enhance sensing performance. Two types of TiO2-based heterojunction are widely reported, i.e., nanoparticle surface modification and core–shell structures [75]. The guest materials involve noble metal NPs (Au, Pt, Ag, Pd), transmit MOS (SnO2, ZnO, V2O5, Fe2O3 etc), carbon materials (CNTs, graphene oxides, and carbon QDs), and semi-conductive polymers. The main contribution of the heterostructures sensing mechanism can be attributed to electron sensation and chemical sensation. Generally, when the heterojunction forms, the Femi-level of two materials reaches equilibrium, leading to band bending. Electron transfer occurs from the materials with high work function to the other one, increasing depletion layers and improving sensing performances. The heterojunction can also improve gas diffusion in the structure, introduce more Ov of TiO2, and increase active surface area (spillover effect).

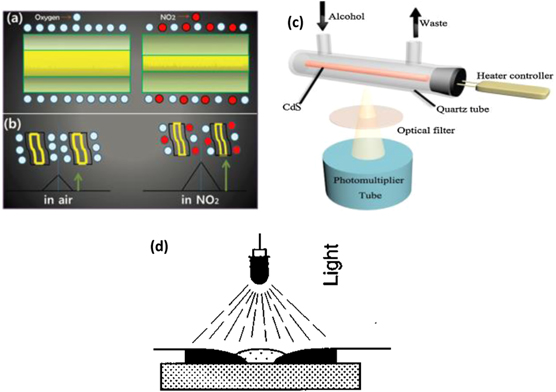

UV irradiation assistance is another way to increase charge transfer. The idea is inspired by the excellent photocatalytic properties of TiO2. UV irradiation can effectively excite electrons from the VB of TiO2 to CB at low temperature, further achieving transformation electrons to the TiO2 surface. This is also a physical assistant way to lower the working temperature of TiO2-based gas sensors. As above mentioned, combining these strategies into a product could be an effective way to improve sensing performance.

7.2. Current and future challenges

Of achieved so far, challenges still exist in TiO2-based gas sensors. High sensitivity (especially at low concentration) is the main pursue in the current and future research, particularly in medical diagnosis. The diagnosis by gas sensors is based on the analysis of the VOCs (ppb level) in human's exhaled gas [76].

Why TiO2-based sensing materials are sensitive to various targeted gases in different reports need to be well answered. For example, some articles demonstrate that TiO2 nanostructures or nanocomposites are sensitive to ammonia; while others report that TiO2 based materials show high sensitivity to acetone, even though ammonia exists.

For practical use (especially for wearable gas sensors by combining with 2D materials), the reliability of TiO2 nanocomposites is a key issue. Researchers try to keep the stability of high-performance TiO2 nanocomposites via purposed pre-treatments, such as UV irradiation treatment for firmly bonding TiO2 and guest materials, and high-temperature annealing [77]. But further investigations are still required.

Improving the sensitivity of TiO2-based sensors is the main vision for current research. To the view of materials, as aforementioned, morphology control and heterostructures are the main strategies used. It is noted that heterojunctions may improve not only sensitivity, but also response time, the limit of detection (LOD), and even lower working temperature.

The mechanisms of the selectivity and low-temperature detection of the TiO2 nanocomposites must be better investigated. Opinions are divided as to which gases show better sensitivity/response to certain TiO2-based materials. Besides, many articles demonstrate TiO2 sensing materials can detect targeted gases at low (room) temperature. However, the reasons are always missing. Two kinds of techniques may offer help: in situ techniques (in situ XPS, UV, FTIR) and first principle computational simulation.

7.3. Concluding remark

TiO2-based gas sensors have been intensively explored in the past decades. There are still challenges to be addressed, such as the development of novel nanostructures, detection at low temperature, ultra-high sensitivity, the stability of heterojunction, and the fundamental understanding for high-performance sensing behaviours.

Dependent upon the specific use of sensors, it is not necessary to combine all the excellent performances (high sensitivity, fast response and recovery, low LOD, wide dynamic range, etc) in a sensor. However, the high selectivity is always required for practical applications. Therefore, the fundamental understanding of selectivity is crucial for the TiO2-based gas sensors. In addition, the breakthrough of the fundamental mechanism will play a decisive role in the development of gas sensors' new applications (medical diagnosis) and wearable devices.

Acknowledgments

We acknowledge the support by National Natural Science Foundation of China (Nos. 51974086) and the Fundamental Reserch Funds for the Central Universities (N2125027).

8. CuO for gas sensors

Shiqiang Zhou, Baoye Zi and Qingju Liu

Yunnan University, People's Republic of China

8.1. Status

Various types of hazardous gases, such as NO2, NH3, H2S, H2, CO and VOCs, are routinely and daily released from industrial and agriculture processes, or emitted as vehicle exhaust emissions. Therefore, detection of hazardous gases and pollution of environment in situ and real time have motivated us to develop high-precision gas sensors devices with good selectivity, fast response, high sensitivity, low LOD. The first commercially available gas sensor device was introduced in the 1962s using metal oxide as the sensing layer [78]. The research in the field of gas sensors has grown rapidly in the latest years; CuO is one of the most representative p-type metal oxide semiconductors, which has been extensively studied in various fields especially as an effective and affordable material for gas sensor. Up to now, the p-type MOS CuO used in gas sensing have been mainly monitoring targeted gases, including H2S, CO, NO2, CO2 and NH3 (figure 9(a)). Generally, p-type CuO offers poor selectivity, low response, long response time, high working temperature to targeted gases, and they are not very popular for sensing applications especially in pristine form, which causes great concern on the gas sensing performance of CuO method. As of today, it has been realized that a good pathway for sensing enhancement is developed with p–p homojunction, n–n as well as n–p heterojunctions via loading semiconducting nanomaterials or modification of the semiconductor metal oxide with noble metals. Figure 9(b) shows the number papers concerning CuO-based gas sensors published from 1995 to now.

Figure 9. The copper oxides: (a) schematic view of the CuO-based gas sensors for detection of various hazardous gases and (b) the number of papers related to CuO-based gas sensors from 1995–2020 (data from web of knowledge.com) from 1995–2020; here, the papers searched from the web of science refined by 'title = gas sensor and CuO' with all document types on March 15, 2020.

Download figure:

Standard image High-resolution image8.2. Current and future challenges

Currently, a great progress has been made in understanding the mechanisms and designing of CuO gas-sensitive materials. New mechanistic studies that lead to potential solutions to overcome the existing issues of CuO. Oosthuizen et al [79] affirmed that CuO sensor response/sensitivity is dependent on the average crystallite size and specific surface area which resulting in a reduction of the charge carrier concentration, giving rise to a more pronounced change in CuO sensor resistance as validated by Hall effect analysis. Anisotropy is a basic property of single crystals. Dissimilar facets/surfaces have different geometric and electronic structure that results in dissimilar functional properties. Yin and Liu [80] studied that the enhanced ethanol sensing performance characteristics are obviously dependent on the low index (111) facet with high activity relative to high index (202) facet of CuO microstructures. Crystal quality and surface defect density also play important roles in gas sensing performance. Dhakshinamoorthy and Pullithadathil [81] reported a comprehensive H2S gas sensing property analysis of CuO nanocuboids to explore the sensing mechanism and gas/material interaction as a function of temperature. Strong catalytic activity of CuO (111) surface towards the dissociation of O2 and H2S molecules make the monoclinic CuO nanocuboid a highly selective material towards H2S gas sensing. Oosthuizen et al [82] unambiguously demonstrated that the gas sensing activity of CuO is determined by the nature of surfaces exposed to ambient gas. Accordingly, a control over crystal morphology, i.e. over the angular relationships, size and shape of faces in a crystal, is required for the development of better sensors with increased selectivity and sensitivity in the chemical determination of gases. It is mandatory to understand mechanisms and find out its kinetic pathway on different gas. However, the attention of mechanism research on specific gas species is still insufficient.

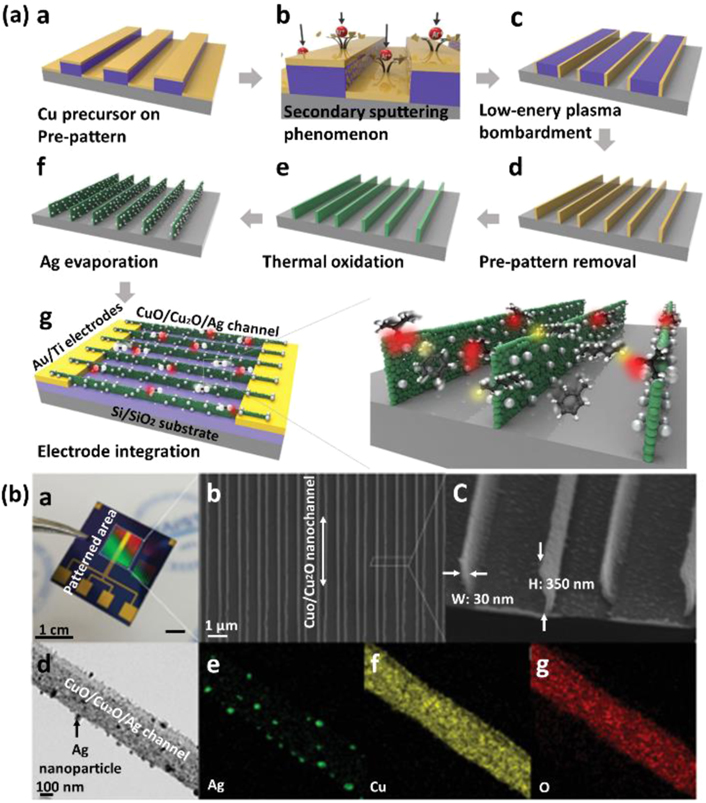

Several long-standing issues in gas sensor of CuO need to be overcome to develop a practical excellent performance CuO gas sensor, including long-term stability caused by gas poisoning and other factors, and temperature and humidity effects. For further improvement of sensing performance, they have been modified using noble metals, metal ions, and other materials. Composites of multi-phase CuO have also been frequently reported. Adamu et al [83] reported a sensor for NO2 detection based on a p–p heterojunction consisting of tertiary Cu3Mo2O9 micro/nanorods vertically aligned on a continuous CuO layer using a simple, cheap, and catalyst-free chemical vapour deposition (CVD) technique. The performances for NO2 gas are quite outstanding compared to those reported for the metal oxide-based semiconductor sensors. This study would further enrich the sensitive materials as a gas sensor and provide a simple and cheap way to fabricate micro/nanorod array-based gas sensors. Kim et al [84] reported H2S gas sensing characteristics of RGO loaded CuO NFs. Besides large surface area of RGO and plenty of dangling bonds, work function difference between RGO and CuO will results in formation of plenty RGO–CuO heterojunctions, where electrons from CuO will transfer to RGO and accordingly a HAL will develop on CuO. When exposed to H2S, conversion of CuO to CuS changes the conductivity from semiconducting to metallic type and destroys the established heterojunction, leading to a high response to H2S. Choi et al [85] fabricated high-resolution p-type CuO/Cu2O nanopattern channels decorated with Ag NPs using a low-energy argon ion bombardment process via a unique top-down lithographic approach for high-performance sensing of VOCs (figure 10). The high-resolution CuO/Cu2O/Ag nanopattern sensor showed improved sensitivity from minimum 2.9 to maximum 7.7 times for various VOCs compared with the pristine CuO/Cu2O nanopattern. This explains the key role of the noble metal dopant in inducing electronic and CS effects on the entire sensing channel and improving the performance of VOCs gas sensors.

Figure 10. (a) Schematic of the fabrication process for CuO/Cu2O/Ag nanopattern sensors. (b) Photographic image of a representative gas sensor and SEM images of the CuO/Cu2O/Ag nanopattern. [85] John Wiley & Sons. [Copyright © 2019 WILEY‐VCH Verlag GmbH & Co. KGaA, Weinheim].

Download figure:

Standard image High-resolution imageRecently, CuO thin film gas sensors have been studied to detect various gas. The most important feature of the CuO thin film gas sensors is their possibility to function at low or RMs for a long time. Recently published reports have shown that pure CuO, as well as modified/doped CuO films can be developed by various techniques, which also increases the possibility to develop gas sensors. Ponmudi et al [86] reported on the properties of thin Cr2O3:CuO films prepared by radio frequency magnetron sputtering technique, which suggests that the radio frequency magnetron sputtered Cr2O3:CuO thin films can perform efficiently as an ammonia gas sensor at RM. Choi et al [87] fabricated a CO gas sensor using CuO thin film deposition onto a flexible polyimide substrate using a kinetic spraying process. This work would play a pioneering role in disseminating knowledge in the field of CO gas sensors using a kinetic spraying method.

Although great progress has been made in improving CuO sensing performance by trying a mass of related various methods, which include using metal ion doping CuO, noble metal modifying, and composites with other materials, the bottleneck still exists in current gas sensing systems for further improving performance. Many gas sensing mechanisms of CuO based materials with various sizes and morphologies have been presented to explain their sensing properties. However, it is not clearly elucidated why the same CuO based materials with similar sizes and morphologies show markedly different sensing properties. Moreover, interfering gases often affect the sensing performance, resulting in a drastically reduced response, which causes great concern on the selectivity of gas sensors. As a result, it is of key importance for detection of multiple gases to construct reliable gas sensing devices with asymmetric structures and disparate sensing outputs, a goal that is yet to be achieved. In addition, long-term stability and durability studies are far from meeting the requirements of industrialization under varying environmental conditions, such as different temperatures and humidity levels.

8.3. Concluding remarks

From what have been discussed above, we can realize the CuO is a promising gas sensor for detecting various harmful gas. With the tremendous efforts of scientists and the development of in situ instruments characterizations and theory calculations, it is very possible to clearly reveal the complicated mechanism of gas sensing, design and prepare CuO gas sensor with low cost, good sensitivity, fast response/recovery time, long-term stability for fabrication of future gas sensing and other sensor-related devices.

Acknowledgments

This work was supported by National Natural Science Foundation of China (No. 51562038), Yunnan Key Project of Natural Science Foundation of Yunnan (2018FY001(-011)).

9. NiO for gas sensors

Mario Urso

Università di Catania, Italy

9.1. Status

Nickel oxide (NiO) is a wide bandgap (3.6–4.2 eV) p-type metal oxide semiconductor where holes are the majority carriers due to the presence of Ni vacancies in the cubic crystal structure. NiO has high chemical and thermal stability, low dependence on humidity, and unique optical, electrical and magnetic properties [88]. Moreover, NiO nanostructures with large surface area, porous structure and low amount of material can be prepared by calcination of precursor nanostructures grown by low-cost methods, among which chemical/co-precipitation, hydrothermal/solvothermal synthesis, sol–gel, etc. Owing to their exceptional properties, NiO nanostructures have been frequently used as sensing material for chemoresistive gas sensors, which are attracting enormous attention in a wide range of applications, including medical diagnosis, environmental monitoring, industrial processes, etc. Among the different targets of NiO-based gas sensors are VOCs such as ethanol, acetone, toluene and xylene, highly toxic gases such as CO, NO2 and H2S, and combustible gases such as H2 and methane. In particular, NiO nanostructures have shown remarkable performance as acetone sensors operated at high temperature for non-invasive diagnosis of diabetes by human breath analysis [89], and as NO2 sensors operating at RM for indoor and outdoor air quality monitoring [90].

As for all other gas sensors, researchers have developed several strategies to achieve as many as possible of the ideal characteristics of a sensor, i.e. high sensitivity, selectivity and stability, low LOD, short response and recovery time. Above all, the sensitivity has attracted great attentions since p-type semiconductors have a lower sensitivity than n-type [5]. The most effective strategies to obtain high performance with NiO-based gas sensors include:

- (a)Nanostructure morphological design: NPs, NWs, nanorods, nanosheets, porous thin film, etc with large surface area offer a higher number of adsorption sites for the gas molecules and thus higher sensitivity, in principle [88];

- (b)Doping with metals (Al, Cr, Fe, Co, Zn, In, W, etc) or rare metals (Ce): W-doped NiO showed enhanced sensitivity and selectivity to xylene with respect to bare NiO due to the electronic charge compensation caused by the substitution of Ni2+ with W6+ and the consequent hole concentration decrease and resistance increase [91];

- (c)p–n or p–p NiO-based heterostructures/nanocomposites with other metal oxide semiconductors (ZnO, WO3, SnO2, Fe2O3, CuO, etc): the band bending generated at the interface between the two semiconductors and their synergic effect can improve the sensitivity and selectivity [88];

- (d)Noble metals catalysts (Au, Pt, Pd, etc): Au@NiO core–shell NPs showed higher sensitivity to ethanol than pure NiO NPs due to the larger HAL and lower baseline resistance caused by the formation of a Schottky junction at the Au/NiO interface, and to the catalytic effect of Au NPs which promote O2 dissociation increasing the number of adsorbed oxygen species and thus surface reactivity [92].

Further advances in the gas sensing performance of NiO-based sensors are expected from new nanostructure designs and more fundamental studies on the gas–NiO interaction.

9.2. Current and future challenges

Today, the sensitivity of NiO-based sensors is not an issue of major concern, however the selectivity needs to be improved, especially for VOCs sensors operated at high temperatures. In fact, it has been often reported that the response of NiO nanostructures to acetone, ethanol and other VOCs can be similar, limiting their practical applications [89]. In principle, the selectivity can be improved by using specific dopants, heterostructures/nanocomposites and noble metals catalysts, or through an appropriate choice of the operating temperature. Nevertheless, these approaches often result in limited improvements and more complicate and expensive fabrication processes. A promising and alternative approach to achieve better selectivity with NiO-based sensors could be to investigate the effect of NiO exposed crystalline planes. In fact, each crystalline plane has different surface energy levels which control the interaction between gas molecules and the metal oxide, leading to a better selectivity as it has been already reported for a ZnO-based NH3 sensor [93].

Another major drawback of NiO-based gas sensors is the high operating temperature of 150–400 °C (except for those few sensors that can be operated at low temperature) due to the thermal energy required to activate the surface redox reactions between gas molecules and NiO surface. Indeed, high temperatures imply larger energy waste, higher cost, and safety issues upon exposure to flammable or explosive gases. Moreover, it has been assessed that the high operating temperatures worsen sensor stability due to the thermally induced growth of metal oxide grains, and it can also lead to a significant drift of the baseline resistance [94]. For these reasons, low temperature operated NiO-based sensors have attracted increasing attention. Still, one important problem with low temperature operated sensors is represented by the long recovery time, since the desorption of gas molecules from NiO surface at low temperatures is not favoured as at higher temperatures. As a consequence, in some cases the sensor is not able to recover the baseline at all, as it has been observed for the RM NO2 sensor based on CuInSn2 QDs decorated ring-like NiO [95].

UV-assisted gas sensing is a promising approach to reduce the operating temperature, improve the sensitivity and shorten the response and recovery time of NiO-based sensors. Figure 11 shows the schematic illustration of the photoactivated sensing mechanism under UV irradiation. UV photons with energy comparable or higher than the semiconductor bandgap generate electron–hole pairs which result in an increase of conductivity and adsorption of oxygen ions species, leading to an enhanced surface reactivity and sensitivity to targeted gases. Also, the photo-desorption of oxygen ions species facilitates the recovery process [74, 94].

Figure 11. Photo-activated sensing mechanism under UV irradiation. [74] [2017], reprinted by permission of the publisher (Taylor & Francis Ltd, http://www.tandfonline.com.

Download figure:

Standard image High-resolution imageAt low temperatures, humidity significantly influences the performance of NiO-based gas sensors. Since the gas sensing tests are typically performed in dry air atmosphere, the effect of humidity should be carefully investigated and minimized to enable their use in real applications. Furthermore, the effect of small temperature fluctuations on the performance of low temperature operated sensors should be also considered in future investigations.

Great efforts should also be devoted to reducing the LOD of highly toxic gases to the ppb level. This is particularly important for NO2 sensors where the challenge is to meet the USA air quality standards of 100 ppb for 1 h exposure and 53 ppb for 1 year exposure. Moreover, the sensitivity and selectivity of these sensors should be evaluated at these very low concentrations while, to the date, this has been done only for a few NiO-based NO2 sensors at RM [90].

The study of the gas sensing mechanism still offers great opportunities and challenges. In fact, despite the gas sensing mechanism of simple NiO nanostructures has been extensively investigated and comprehended, the picture could be much more complicate when more elaborate nanostructures are considered. Consequently, it is necessary to conduct more in-depth studies on the gas sensing mechanism by NiO-based nanostructures in order to further improve the sensing performance.