Abstract

This work presents a detailed comparison of our computer simulation study with our own experiment on coatings of aluminium wires for high-voltage lines and characterization of coatings. Computer modelling, using finite element method (FEM), has shown a significant dependence of a local electric field enhancement factor (β-factor) on the surface hydrophilicity (wettability). Modelling explained that the β-factor from a micro-tip on a high-voltage line can be decreased with dependence from contact angles. It has been shown that highly porous and hygroscopic properties of the modified surface reduce the contact angle of water droplets on the wire and the β-factor from the rough surface due to the dielectric shielding. Newly engineered surfaces allow for control of the contact angle of a water droplet on the wire and also reduce the β-factor, in comparison with an uncoated surface.

Export citation and abstract BibTeX RIS

Corrections were made to this article on 18 10 2019. An additional corresponding author was added.

1. Introduction

A crucial amount of the power grid is based on the overhead high voltage alternating current (HVAC) transmission lines, due to their large transmission capacity and economic feasibility. However, up to 30% of electrical power losses are associated with corona discharge (CD), especially under adverse weather conditions such as rain and snow [1–3]. Thus, a new approach is urgently needed to reduce the corona losses. Different approaches to anti-corona coating for rain conditions have been developed in several previous works, where the benefits of anti-corona coating, in terms of hydrophobicity or hydrophilic, have been shown. The principal aims of the anti-corona dielectrically coating proposals are using electrical insulation performance and good hydrophobic properties of the RTV (room temperature vulcanisation) or silicone rubber [4, 5]. In [6], the authors proposed to use hydrophilicity of the rolled fibrouse textile coatings for absorbing water and to minimize number of droplets.

In this present work, aluminium wires were coated by the high-temperature alumina alloys α-Al2O3 containing various modifications of silicon oxide SiO2 and silicon carbide SiC, reinforced with graphene oxide (GO) and carbon nanotubes (CNT) were designed [7, 8]. A compact ceramic coating using the MAO, also known as electrolytic plasma oxidation (EPO), is an attractive topic in the field of metal protection. In addition, it has advantageous characteristics, including their remarkable thickness, high microhardness, high porous, hygroscopicity, and good adhesion with substrates [9].

Similar investigations have been conducted on the influence of rainfall intensity with the radio interference level on AC CD, where the dependence of the dynamic characteristics of CD under rainfall conditions was shown [10]. Also, experiments were supported by the results of computer modelling of the CD formation in the positive phase of the electric field voltage frequency when the water film temporarily acts as the cathode, the plasma duration is remarkably long and shows a clear similarity with a resistive barrier discharge, which are attributed to the resistive nature of the water film and the formation of a cathode fall [11, 12]. They proposed several elementary mechanisms that might underlie the observed unique behavior, based on the specific features of a water electrode [12].

This paper demonstrates computer modelling results of experimental data for [8], for HV breakdown aluminium wires coated with thin film consisting of the alloys of high-temperature α-Al2O3 alumina allow and various modifications of silicon oxide SiO2, silicon carbide SiC, reinforced with graphene oxide and carbon nanotubes. The extent scale of experimental conditions for CD ignition on HVAC in a dry and rain weather conditions were provided by a special climate chamber [13].

2. Experimental

2.1. MAO coating

The initial samples (A0) of non-insulated (bare) industrial aluminium wires of AC300/39 type for 500 kV HVAC air transmission lines were exploited for this research paper. The results for three types of electrolytes have been indicated which were used for MAO coating (Samples A1, A4, and A5). Sample A1 used an electrolyte solution (NaOH (3 g l−1), Na4P2O7 (4 g l−1), Na2SiO3 (15 g l−1), C3H8O3 (10 ml l−1), Al2O3 (50 mg l−1) without particle additives. Sample A4 used an electrolyte solution from A1 with a suspension of Graphene oxide (2 mg GO/ml H2O) manufactured by Sigma Aldrich, USA. Sample A5 used an electrolyte solution from A1 with CNT suspension (50 g 0.01% by weight of CNT per 100 ml of C3H8O3) manufactured by TUBALL, Novosibirsk, Russia. Depositing thin films with 9–20 μm in thickness (figures 1(b)–(d)) by MAO on wire samples with a length of 1500 mm was carried out using a pulsed DC of up to 3 A passing through an electrolysis equipment consisting of a negative Al-electrode (cathode), an electrolyte, and a positive electrode the Al-wire sample (anode). A stepwise voltage in a range from 160 V to 320 V with steps of 20 V was applied for each wire sample for 4 h [8].

Figure 1. Spectra of x-ray energy-dispersive analysis of samples A0 (a), A1 (b), A4 (c) and A5 (d).

Download figure:

Standard image High-resolution image2.2. Characterisation

Morphology and elemental composition of the deposited thin film coatings were visualized with a scanning electron Crossbeam 540 with an energy dispersive analyser and an optical LSM 780, Carl Zeiss microscopes, and characterized by an XRD method (Smartlab, Rigaku, XRF Panalytical). Separate measurements were carried out using a scanning electron microscope LYRA3 GMH. The EDS spectra show that the main elements (with more than 10% by weight) in the deposited coatings of samples A1, A4 and A5 are Al, Si and O, (see table 1). Sample A0 contained the main element Al, 99.42%.The elemental composition of the coatings on the surface of wires was determined from the x-ray energy-dispersive EDS spectra, figure 1.

Table 1. Basic elements of the composition of coatings.

| EDS spectra | |||||

|---|---|---|---|---|---|

| Sample | Al (%) | O (%) | Si (%) | Cr (%) | Na (%) |

| A0 | 99.42 | — | — | 0.58 | |

| A1 | 21.84 | 48.27 | 23.90 | 4.20 | |

| A4 | 20.35 | 41.77 | 19.19 | 8.32 | 4.51 |

| A5 | 12.34 | 49.94 | 26.53 | 5.99 | 2.71 |

| XRF analyze | |||||

| Sample | Al2O3 (%) | SiO2 (%) | P2O5 (%) | ||

| A0 | — | — | — | ||

| A1 | 37.9 | 45.2 | 6.3 | ||

| A4 | 36.9 | 35.4 | 9.0 | ||

| A5 | 37.1 | 32.0 | 21.5 | ||

The results of x-ray fluorescence XRF analysis showed that the coatings consist mainly of aluminium oxides Al2O3 and silicon SiO2: sample A4 contains 36.9% Al2O3, 35.4% SiO2, 9.0% P2O5; sample A5 contains 37.1% Al2O3, 32.0% SiO2, 21.5% P2O5 (see table 1).

Carbon and carbon compounds, which were one of the main components of the coating composition, were not recorded by the XRF and EDS characterization methods.

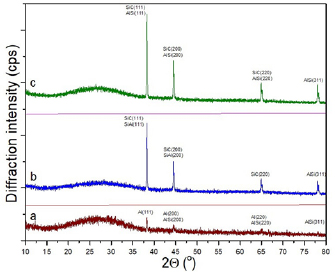

X-ray diffraction (XRD) spectra shows that the coating composition contained carbon compounds with silicon and aluminium, silicon carbide SiC and silumin AlSi (figure 2).

Figure 2. XRD-spectra of samples A1 (a), A4 (b) and A5 (c).

Download figure:

Standard image High-resolution imageThe XRD spectra of samples A1 (a), A4 (b) and A5 (c) shows that all XRD spectra exhibits peaks that are characteristic for contenting of Si. The Si content is due to the presence of sodium metasilicate Na2SiO3 in the composition of the three types of electrolyte for A1, A4, and A5.

The XRD spectra of the samples A4 (figure 2(b)) and A5 (figure 2(c)) contains SiC peaks that were not observed in sample A1. That is, silicon carbide in the coatings of the samples A4 and A5 obtained in electrolytes were produced by additives of GO and CNT. The XRD spectrum of sample A5 is characterized by a 25%–37% more intense signals of the SiC peak than that in the sample A4. XRD-peaks of SiC and AlSi were obtained in the deposited coatings for all test samples which can be explained due to the presence of Si in the sodium salt Na2SiO3 (sodium metasilicate) in the main electrolyte.

Analysis of EDS-, XRF- and XRD-spectra shows that the main compounds that makes up the coatings are Al2O3, SiO2, AlSi and SiC. The chemical analysis of the elemental coating content was based on the EDS microanalysis data. The results that were based on the stoichiometry of the main compounds Al2O3, SiO2, AlSi and SiC show the same carbon content in all coatings, of about 31.35%, with slight variations.

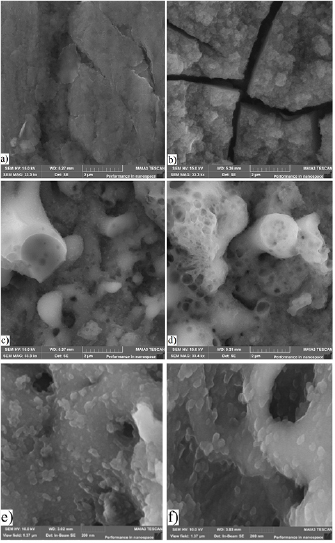

The highest porosity and wettability were provided by depositing coatings with additives of nanoparticles of GO (sample A4) and CNT (sample A5). The wettability of the deposited coatings was measured on the control wires, with a diameter of 4 mm and a length of 180 mm. The weight of samples A4 and A5 after wetting with water has increased by 13.5 mg and 8.5 mg, respectively, compared to the weight increase of the original sample A0 (1.1 mg increase). That is, the high wettability (table 2) of the coatings of samples A4 (figures 3(c) and (e)) and A5 (figures 3(d) and (f)) was related to the high porosity of the coating surface.

Table 2. Wettability and contact angle of samples.

| Wettability, amount of water before and after (mg) | α—contact angle (°) | |

|---|---|---|

| A0 | 5363.1/5364.1 (Δ1.1) | α ≈ 46°–56° |

| A1 | 6331.1/6336.4 (Δ5.3) | α < 24° |

| A4 | 5382.7/5396.2 (Δ13.5) | α ≈ 24° |

| A5 | 5675.7/5684.2 (Δ8.5) | α < 24° |

Figure 3. Electron microscopy of the surface of coatings for samples with 2 μm resolution: (a) A0, (b) A1 (c) A4, (d) A5 [8]; 200 nm resolution: (e) A4, (f) A5.

Download figure:

Standard image High-resolution image2.3. HVAC industrial scale test

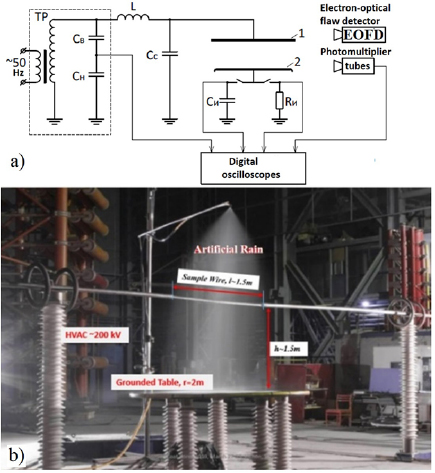

HVAC with industrial frequency (50 Hz) was carried out on a wire-plane electrode system reproduced with a scale of 1:2.38 by voltage, which corresponds to the 500 kV level with the same electric field in the real conditions. A series of experiments with the step of increasing and decreasing the voltage to 20 kV were carried out both for rain (50–170–50 kV) and dry climate conditions (100–200–100 kV). The voltage of the onset of CDs was determined by the optical method using the electron-optical flaw detector (EOFD) 'Filin-6', the discharge lightning including the invisible ultraviolet spectral region was recorded using a photomultiplier tube 'PMT-119', which is synchronized with a digital oscilloscope. The EOFD scheme and a photograph of the equipment are shown on figure 4.

Figure 4. (a) Industrial HVAC testing scheme (C-capacitors, R-resistance, L-inductance) for detecting the characteristics of CD on wire to plane; (b) front view of HV climate chamber with related sizes.

Download figure:

Standard image High-resolution imageSome measurement cases are provided in the table 3, where comparable visible differences of CD mitigation between coated and uncoated samples obtained with a highly sensitive fast multi-channel photodetector 'Filin-6' and the amount of losses (PL) at thes ame voltage level for rain and dry conditions, can be seen. Clearly observable, is the pack of CDa discharges due to rainfall occurring in the positive phase which well confirms the results in [11, 12] with analogical experimental statements (with different scale and frequency).

Table 3. Captured measurements for different voltages, wire samples and climate conditions.

| Dry |  |

|

| Sample:A0 | ||

| V = 180 kV | ||

| PL = 30.3 W | ||

| Dry |  |

|

| Sample:A5 | ||

| V = 180 kV | ||

| PL = 22.7 W | ||

| Rain |  |

|

| Sample:A0 | ||

| V = 140 kV | ||

| PL = 26.5 W | ||

| Rain |  |

|

| Sample:A5 | ||

| V = 140 kV | ||

| PL = 19.1 W | ||

These images show visible plasma spots of CDs initiated on water droplets. The fewer droplets of water formed on the wire, the fewer CD plasma spots were observed. The number of CD plasma spots on the coated samples A1, A4 and A5 is significantly lower than that on the sample A0 of the uncoated reference wire sample. A higher anti-corona resistance (a lower power loss) of the coated samples in rain conditions can be related with formation of a smaller number of water droplets on coated surfaces, where a local electric field enhancement triggers a CD.

The rainfall was simulated using a nozzle sprayer located above the wire at a height of 112 cm which covered the entire length of the sample (figure 4(b)). In each series of experiments, a preliminary exposure of the wire in the rain for at least 5 min was provided. The intensity of rain (~0.9 mm min−1) fixed for all samples. The power loss for the corona was determined by numerical integration of the volt-charging characteristics.

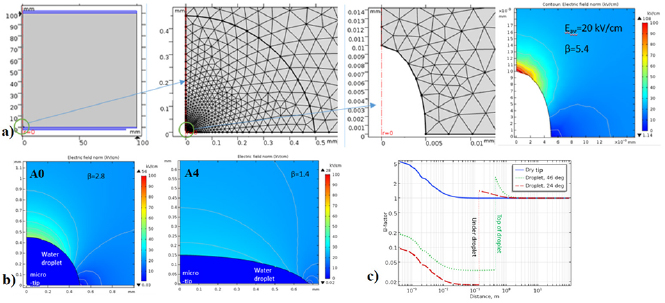

3. Computer modelling of dielectric shielding

Electric field enhancement factor (β-factor) on the micro-size tips, microcracks (T-junction), and surface roughness on the electrode can provide a good condition for arising CD [14, 15]. The finite element method (FEM) was used for modelling dry and wetted wire with a 10 μm tip on surface according to the contact angels from table 2. For dry conditions, a local electric field around a micro-size tip increased up to β = 5.4. This β-factor can be reduced by the dielectric shielding effect if water layer covers the surface with low contact angle. Figure 5(a) shows the calculated β-factor for samples of wires. If we consider the water droplet which covered tip, we will observe that the electric field strength decreased two times with β = 2.8. In the case for high wettability surface (wires A1, A4 and A5) we observe decreased electric field strength with β = 1.4 (figure 5(b)), it is close to average electric field strength.

Figure 5. (a) Problem statement, mesh, and electric field enhancement of electrode with 10 μm tip without water. (b) Calculated β-factors for droplets with different contact angles on samples A0 (α ≈ 46°) and A1, A4, A5 (α < 24°). (c) β-factor from micro-size tip versus distance from the wire.

Download figure:

Standard image High-resolution imageThe electrostatic model based on FEM shows that the β-factor can be shielded and decreased under water droplet due to the high dielectric permeability of water (figures 5(b) and (c)). During the rainfall the contact angle between wire surface and formatted droplet plays key electrostatically role for decreasing CD spots. The electric field intensity from a micro-tip on a high-voltage transmission line was modelled in the case when it is covered with a droplet of water with different contact angles and without water.

4. Results and discussions

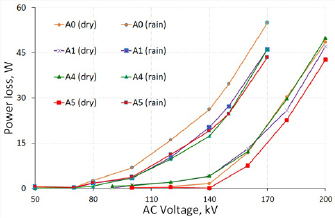

The results of the high-voltage breakdown tests of the samples in dry and rain climate conditions are shown in figure 6. As can be seen from the power of losses dependences for the CD on the values of triggering voltages, the highest anti-corona resistance was observed for both conditions on the sample A5.

Figure 6. Power losses due to CD versus the triggering voltage on the wires for rain and dry climate conditions.

Download figure:

Standard image High-resolution imageThe CD in dry conditions increase the CD triggering voltage for the sample A5 and reached up to 15%, as compared with the triggering voltage of the original sample A0, and the power losses for corona was much lower than that by approximately 30%–50%.

In the case of dry weather, the unipolar plasma model [14] can explain the occurrence of a CD on spatial microcracks (T-junction) and irregularities on the wire surface. MOA coating effectively eliminates T-junctions and carbon particle additions in the electrolyte play important role to minimise number of microcracks on the surface. The air is a good dielectric, but in the case of intense ionization at electric field close to 30 kV cm−1, as often in natural conditions, a CD can be observed with high probability. Overhead HVDC lines are not covered by insulating dielectric, CD is often observed during precipitation (high humidity) as the result of enhancement in charge carriers and areas (points) with an increased β-factor.

Considering the XRD spectra, a high anti-corona resistance of sample A5 in a dry condition can be related to a higher content of SiC in the coating composition, which is characterized by a high microhardness, the high electrical and thermal strength [16], high porous, hygroscopicity and good adhesion with substrates [8].

In the case of rainy weather all three coated samples have shown the corona mitigation effect. This means that impact of porosity properties of coating plays a weighted role on dielectric shielding with high relative dielectric constant. The power losses on CD in rain conditions are much lower for the A1, A4 and A5 coated samples than for the reference sample A0. As can be seen from figure 6 (see table 4), the power losses on the CD in rain conditions are much lower for the A1, A4 and A5 coated samples than for the reference sample A0 [8].

Table 4. Characteristics of CDs on wire samples in a dry and rain state.

| Name of the characteristic | Characteristic value for the sample: | ||||

|---|---|---|---|---|---|

| A0 | A1 | A4 | A5 | ||

| Ignition of CD (kV) |

Dry | 140/143 | 140/140 | 140/130 | 160/148 |

| Rain | 80/83 | 100/97 | 100/97 | 100/94 | |

| Voltage (V, kV): | Power losses for corona (P, W) |

||||

| 100 | Dry | 0.1 | 1.0 (0.2) | 0.9 (0.5) | 0.2 (0.1) |

| 120 | 0.6 (0.1) | 1.9 (0.6) | 2.0 (1.1) | 0.4 (0.2) | |

| 140 | 1.5 | 4.0 | 4.1 | <0.1 | |

| 160 | 11.8 (12.9) | 13.2 (9.8) | 12.2 | 7.5 | |

| 180 | 30.3 | 25.8 | 29.7 | 22.7 | |

| 200 | 48.5 | 47.1 | 49.9 | 42.7 | |

| 100 | Rain | 6.8 (5.8) | 3.3 | 3.5 (2.8) | 3.7 (3.1) |

| 120 | 16.0 | 10.2 | 9.7 | 11.2 | |

| 140 | 26.2 | 20.2 (19.3) | 17.3 | 19.1 (16.6) | |

| 150 | 34.6 | 27.2 | 24.8 | 24.6 | |

| 170 | 55.0 | 46.2 | 46.2 | 43.5 | |

aIn the numerator is given the voltage of the beginning of the CD, in the denominator—by the losses per crown with a loss power of 3 W. bIn parentheses—the loss values when the voltage drops are given.

Table 4 presents the data on the characteristics of CDs on wire samples in the dry state, determined by two methods, both by ejection and by losses on the corona at a loss of power of 3 W.

Results have shown that MAO coating is one of perspective ways for effective anti-corona coatings of aluminium wires. The formation of water droplets is related to the wettability of the surface of the coatings of the wire samples, which can be related to their porosity and different sticking probabilities of water molecules to the surface, depending on the contents of the deposited this film. The highest wettability was observed for samples A4 and A5, where coatings were deposited using electrolytes having additives of GO and CNT. A higher hydrophilicity of these samples can be partially related due to a high porosity of A4 coatings (figure 3(e)) and A5 (figure 3(f)). Consequently, a higher anti-corona resistance of aluminium wire samples in rain conditions was achieved using a higher hydrophilicity of the coatings. An increase of water wettability of the surface and changing contact angle would probably reduce (see section 3) the electrical field enhancement factor and therefore, reduce the power losses in measured samples.

Since it is believed that although solid dielectrics (insulating glass ~0.7 MV cm−1, polyvinyl chloride ~0.4 MV cm−1, polyethylene ~0.3 MV cm−1) have great electrical strength, they are heated during dielectric losses, and as the temperature rises, the number of charge carriers increases and the dielectric strength decreases, and solid dielectrics cannot recover after the breakdown (i.e. aging of silicone rubber composite insulators). In this regard, distilled water has a high impulse electrical strength; additionally, it has the ability to quickly restore the electrical strength after the breakdown. For high-voltage technology, it is possible to consider other liquid dielectrics [17].

5. Conclusions

The computer modelling study shows a higher anti-corona resistance of aluminium wire samples in rain conditions that was achieved using a higher hydrophilicity of the coatings. An increase of water wettability of the surface and changing contact angle would probably reduce the electrical field enhancement factor, and therefore reduce the power losses in measured samples. These results reveal the possibility for a new method to revise the potential of using liquid (probably liquid crystals, hydrogels) dielectrics with high dielectric permeability constant in high-voltage technology, accelerators, and other devices.

Significant dependence of the micro-tip's β-factor from contact angles for different hydrophilic surface were calculated and compared. Modelling explained that highly porous and hygroscopic properties of the modified surface reduces the β-factor from the rough surface through to the dielectric shielding effect.

A significant decrease in the power loss has been measured due to the 30%–40% of corona. At the same time, the voltage of the corona ignition increased for rain by 40% and for dry weather condition by 15%. Thus, a higher anti-corona resistance of aluminium wire samples in rain conditions was achieved using a higher hydrophilicity of the coatings. An increase of water wettability/hygroscopicity of the surface would reduce the electrical field enhancement factor and therefore, reduce the power losses in measured samples.

A new method of a high-corona discharge resistance coating on aluminium wires has been developed and investigated. High anti-corona resistance of wire samples was achieved by depositing MAO coatings based on the high-temperature α-Al2O3 alloys, SiO2, AlSi and SiC, reinforced with particle additions GO and CNT. Coating has high porosity, hydrophilicity, and hygroscopicity properties that reduces the number of local CD foci (up to 40% in rain).

The electrostatic model based on FEM has shown that the field enhancement factor can be decreased due to dielectric shielding by water. During rainfall, droplet formation geometry plays an important role in abatement of field-enhanced spots. Achieved experimental result illustrates that MAO with carbon particle additives is one of the perspectives for effective anti-corona coatings of overhead lines. The formation of water droplets is related to the wettability of the surface of the coatings of the wire samples, which can be related to their porosity and different sticking probabilities of water molecules to the surface, depending on the contents of the deposited thin film.

This study leads to the possibility of a new way of revising the potential of using liquid dielectrics (probably liquid crystals, hydrogels) with high dielectric permeability constant in high-voltage technology, accelerators, and other devices.

Acknowledgments

This work was supported in part by the Kazakhstan Electricity Grid Operating Company (KEGOC) (Agreement No. 192) and by the World Science Stars program of Nazarbayev University.