Export citation and abstract BibTeX RIS

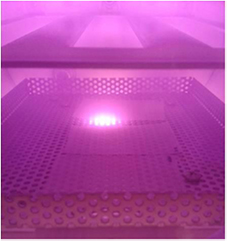

The first questions which arise when one looks at the title of this special issue are what are plasma-inspired biomaterials, and what is this Special Issue of Journal of Physics D: Applied Physics (JPhysD) all about? Peculiar as it may seem, from a philosophical point of view 'inspiration' is something that influences by idea or is a good idea that connects two at first glance opposite things—plasma and biomaterials. On the one hand, plasma as a discharge state of the gas is considered nowadays as a cutting edge tool which can manipulate objects at the atomic or molecular scale (figure 1). On the other hand, biomaterials are substances that are engineered to possess certain properties which can control the interactions with components of living systems, inducing favourable response from the biological entities, and as such can direct the course of a therapy or diagnostic procedure [1]. In this respect, plasmas can be used to initiating even more favourable or selective responses, making the biomaterials even more suitable for their interaction biological entities.

Figure 1. Low pressure RF plasma system for modification of biomedical polymers.

Download figure:

Standard image High-resolution imageThe most appropriate plasmas for initiation of these responses and modifications are so-called cold plasmas, which are generated either at reduced or atmospheric pressures. Cold plasmas are employed to tailor the surfaces of materials for decades. With the increasing relevance of biomaterials, which can augment or replace partially or totally any tissue, organ or function of the body, in order to maintain or improve the quality of life of the individuals, the potential of plasmas in the field is extraordinary and has seen some significant advances in last years.

This Special Issue on plasma-inspired biomaterials wishes to highlight the most recent developments in the area where plasmas are used directly or indirectly for preparation of biomaterials or biocompatible surfaces. The issue covers all aspects of research which connect plasma and biomaterials, ranging from plasma preparation of biomaterials for different applications (hard tissues such as bone, and soft tissues) including drug delivery applications, antibacterial coatings, and focuses also on biological interactions of the novel plasma-prepared surfaces with bacteria, cells and tissues. Novel developments for diagnostics and sensing are also included in this issue. All these contributions to the issue are briefly summarized in the four coming sections.

Novel biomaterials, implants and grafts

Bone is one of the most transplanted tissues, and as such, bone grafts and bone implants raise significant attention. Titanium is often the material of choice for bone implants given its excellent biocompatibility. An issue not so often taken into account is that temporary implants have to fulfil different requirements as permanent implants. For instance, the former should avoid osseointegration, as they need to act as support materials only until bone is healed. For this purpose, different plasma processes are investigated to produce fluorocarbon polymer films which are able to prevent osteoblast adhesion in vitro, with comparable in vivo inflammatory response with uncoated materials [2]. In general, the surface of Ti is oxidized and then this thin layer of TiO2 was exposed to the biological media. To ascertain its potential to enhance osteoblast-like cell response, oxygen plasmas are studied on TiO2 with promising results following cleaning and functionalisation of the surface [3]. An alternative way to enhance ossteointegration is by the precipitation of calcium phosphates onto titanium surfaces. To enhance the efficiency of the process was evaluated by Mahanti et al, who demonstrated that the parameters should be adjusted to induce surface heating and plasma-mediated surface reactions [4].

From bone implants to bone grafts, resorbable calcium phosphate bone grafts have excellent features, but controlling drug delivery from such matrices is a complicated issue. To address this aim, low pressure plasma processes are investigated with biocompatible plasma polymers, successfully reducing antibiotic release rates [5]. A similar approach is investigated for elution of another antibiotic from polymeric substrates by multilayer siloxane coatings generated by plasma, which extends the drug release duration after coating [6]. In both cases the antimicrobial activity of the drug is conserved after the plasma treatments. In view of antibiotic sensitivity tests, the atmospheric plasma jet as another technique of surface preparation is employed to modify cellulose [7].

Cold plasmas are also an excellent alternative to the still widely used wet chemistry to conjugate biomolecules onto biomaterials. For instance, electrospun PLLA fibers can be plasma-functionalized prior to antibody immobilisation with great success [8]. But plasma itself can be employed beyond functionalisation, and is used to build the scaffolds, including nanostructured surfaces like vertically interconnected carbon nanowalls with good biocompatibility with bone forming cells [9]. Orthesis are also of interest in this area, whereas the increased adhesion of polydimethylsiloxane for medical use is achieved by atmospheric pressure plasma. The increase demonstrated is significant though with the limitation of time-decay that could be controlled with the application of a further adhesive layer [10].

Tailoring surface-cell response

Tailoring cell response to surfaces is one of the most difficult tasks in surfaces engineering, since there are many parameters which can influence how cells will behave. In previous years, researchers have already found clues that functional groups, surface temperatures, surface charge, material properties and composition, stiffness, topography, etc. can influence the response of interacting biological cells. A relatively straightforward way to tailor cell response is by playing with the topography of biocompatible materials. Herein, plasmas present an inexhaustible source of options to design nanostructured surfaces and tailor their response. This can be achieved for various biological entities like proteins and enzymes as well as living cells and tissues [11]. Similarly, one can also mimic nature with nanostructured films that have been investigated by combining the gas aggregation of nanoparticles and coating over-deposition [12]. By adjusting plasma parameters the surface morphology can change as a function of roughness height, correlation length and fractal dimensions on polymer surfaces. Such surfaces can differently influence cell attachment and proliferation [13]. However, plasma-surface interactions can result also in change of surface-electric properties. Namely, electrical conductivity and surface energy are identified to play a key role in different time scales of the cell proliferation processes [14].

Antimicrobial surfaces

On the contrary to the expected favourable eucariotic cell responses of plasma treated surfaces, where proliferation, cell growth, attachment, etc. are desired, the focus in antimicrobial surfaces is repulsion and/or prokaryotic cell death. Plasma generated antimicrobial coatings include nanocomposite films, plasma engineered drug delivery coatings, etc. Compared to traditional wet chemistry, plasma deposition and polymerization are new promising approaches for synthesis of nanocomposite films with the advantage of dry phase processes, effective use of chemical and wide applicability, as reviewed by Nikiforov et al [15]. Alternatively to highly resistive antimicrobial coatings, enhanced effects of nanoparticles which account for antibacterial properties of textiles can be achieved also by plasma-enhanced binding of nanoparticles [16]. More complex systems can be further tailored by plasmas in various steps of the process. Therein, to obtain antimicrobial surfaces, plasma can be used first to synthesize and then functionalize nanoparticles as well as attaching biomolecules such as antibodies more efficiently [17]. Instead, plasma etching is another way of designing complex structures such as nanoscale surfaces like silicon nanograss with tuned hydrophilicity to regulate the antimicrobial activity [18]. However, one needs to look beyond pure bactericidal effects of surfaces, and antifungal activity is also a requirement for many applications. Plasma polymer coatings derived from chlorinated hydrocarbon molecules may therefore offer another promising solution to prevent yeast or mould biofilm formation [19].

Generation and detection of reactive oxygen and nitrogen species (RONS)

At the end of the line, to tailor the biological response of materials one has to first understand the underlying mechanisms and species created in the applied plasmas. Due to the lack of proper detection tools, this can be a pretty tricky task. These tools for detection can vary for low or atmospheric pressure plasmas as well as depend on the gas or liquid phase. A well-known technique typically used for gas phase diagnostics is optical emission spectroscopy, which is used to probe any plasma and help to understand the mechanisms of plasma interaction with biological materials. This technique is employed in this special issue to evaluate differences in blood coagulation behaviour during different plasma treatments [20]. Increasing complexity in measurements can occur when one measures a gas–liquid or only liquid phase in systems with biological materials. To overcome this complexity, the models are required such as the one described in the work of Oh et al, where the interactions of plasmas with biological tissues are simulated thorough an agarose target, reflecting the choice of process gas that can have a profound effect on concentration of RONS [21]. The effects on cells are even more complex. It is known that plasma induces cell membrane permeabilization [22] and liposomes can be successfully implemented and evaluated in a very interesting approach as membrane models for cell inactivation [23].

The path of cold plasmas for design and tailoring of biomaterials has only started, and there is a long way to the top of summit with exciting new horizons of research ahead. Furthermore, the bench models and lab experiments have to be transferred into biotechnological and medical practice. The editors of this issue hope that this issue will inspire the readers to undertake more research in this field to unravel yet unsolved challenges.