Abstract

Ring-shaped REBa2Cu3Oy melt-textured bulks have been successfully grown by the single-direction melt growth (SDMG) method. Three homogeneous DyBa2Cu3Oy ring-bulks were directly grown in this study, which exhibited concentrically cone-shaped trapped field distribution on the surface and a high trapped field of 1.84 T at 77 K inside the ring, the highest ever value among reported ring-shaped bulks to date. Furthermore, superconducting properties such as superconducting transitions and critical current densities are highly uniform throughout the bulk, confirming the effectiveness of the SDMG approach. Our findings represent a significant advancement in the fabrication of high-quality bulks suitable for various magnetic applications.

Export citation and abstract BibTeX RIS

Content from this work may be used under the terms of the Creative Commons Attribution 4.0 license. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

REBa2Cu3Oy (REBCO, RE: rare Earth element) is a high-temperature superconductor showing high critical temperature (Tc) of ∼90 K, which is higher than the boiling point of liquid nitrogen, 77 K. Therefore, REBCO textured materials have been intensively developed owing to their high critical current density (Jc), particularly under high magnetic fields. There are two types of nuclear magnetic resonance (NMR) systems being developed utilizing REBCO materials. The first aims to create a flagship model using high-temperature superconducting tapes, including REBCO-coated conductors, capable of generating a uniform and ultra-high magnetic field of ∼30 T. 1) The second involves the development of compact and cryogen-free NMR systems using stacked ring-shaped REBCO melt-textured bulks, which can trap magnetic field as high as ∼17 T. 2–4) In principle, these bulk NMR systems can be achieved with high-performance levels equivalent to those of conventional large and stationary 200–400 MHz, i.e. 5–10 T, NMR systems. This approach offers substantial advantages, including significant miniaturization, improved portability, and the elimination of the need for liquid helium, making it an attractive and promising alternative for various applications. However, to utilize REBCO bulks for NMR applications, two critical requirements must be resolved: the growth of highly homogeneous REBCO bulks with high reproducibility and the realization of large-scale ring-shaped bulks without mechanical damages. The conventional crystal growth methods, such as the top-seeded melt growth (TSMG) and the top-seeded infiltration growth (TSIG) have been energetically developed for decades. 5–10) Still, it is challenging to grow homogeneous ring-bulks as the crystal growth initiates from a small seed crystal placed on top of the REBCO pellet. To create ring-shaped bulks suitable for NMR, mechanical processing on disk-shaped bulks to make a hole along the central axis is necessary as schematically shown in Fig. 1(a). This process involves a risk of crack generation as well as results in significant material loss. For example, Sakai et al. have reported that mechanical processing on large bulks sometimes leads to the formation of cracks. 11) This is a serious issue particularly for applications in bulk NMR, as it deteriorates the uniformity of the trapped magnetic field. A few instances of direct growth of ring-shaped bulks using the top-seed method have been reported, such as employing a multi-seed approach or placing a buffer disk on a ring-shaped pellet. 12–15) Nevertheless, achieving a concentric trapped field in the ring-shaped REBCO bulk using the top-seeded method has been a significant challenge. Despite these hurdles, Nakamura et al. have developed the world's first compact 200 MHz NMR systems using stacked EuBCO ring-shaped bulks fabricated by the top-seeded method. NMR signal linewidths of less than 1 ppm were obtained using this bulk NMR system, demonstrating its potential for portable NMR applications. 16) Given the promising applications of ring-bulks such as magnetic resonance imaging (MRI), high gradient trapped field magnets (HG-TFM), and magnetic shielding, in addition to desktop NMR, there is an increasing amount of research aiming to better understand their theoretical magnetization processes and mechanical characteristics. 17–27)

Fig. 1. Schematic illustrations comparing the fabrication processes of a ring-shaped REBCO bulk via the top-seeded melt growth (TSMG) or the single-direction melt growth (SDMG) method (a) and appearance of the directly prepared DyBCO ring-bulks, #Dy1–3, using the SDMG method in this study (b).

Download figure:

Standard image High-resolution imageIn recent years, we have developed and reported on a novel bulk growth technique, the single-direction melt growth (SDMG) method, to address the challenges of scalability, homogeneity, and flexibility in shapes in the conventional top-seeded method. 28,29) In this SDMG approach, large bulk plates cut from commercially available TSMG-processed REBCO bulks, which exhibit relatively high peritectic temperature (Tp) such as EuBCO, are utilized as seed plates. REBCO bulks with lower Tp than the seed plate, such as YBCO, DyBCO and GdBCO, are grown vertically from the seed plate. This strategy simplifies the conventional three-dimensional crystal growth into one-dimensional growth process confined to the vertical direction, making it easier to fabricate bulks with larger sizes and enabling the direct growth of complex shapes including ring-shaped structures. Figure 1(a) presents a schematic illustration of growth of ring-bulks using the SDMG method compared to the typical TSMG method. The SDMG method enables the direct growth of ring-bulks, and they are separated simply by cutting from the seed plate, which can be reused multiple times. In the above discussed paper on the bulk NMR, 16) ring-shaped bulks with an outer diameter of 60 mm and an inner diameter of either 28 mm or 36 mm are stacked, which have been machined from TSMG-processed disk-bulks. However, this mechanical processing accompanies a substantial material loss of 21–36 vol% as well as the possibility of potential damages. We are confident that the SDMG method is well-suited for the preparation of REBCO ring-bulks for NMR applications, as it can eliminate the risk of crack generation and reduce material loss to very low level through the direct fabrication of ring-bulks with designed shapes. In the previous study, we successfully fabricated homogeneous REBCO bulks (RE of Y, Dy and Gd) using the SDMG method, which demonstrated superior concentrically cone-shaped trapped field (BT) distributions compared to those of TSMG-processed bulks. 29) In the present study, we attempt the direct growth of ring-shaped bulks with varying diameters and thicknesses using the SDMG method and report on their BT characteristics and superconducting properties.

We selected DyBCO and EuBCO for the ring-shaped bulks and seed plates, respectively. The EuBCO seed plates with (001) plane on the surface were extracted from TSMG bulks (Eu-QMG®) with a diameter of ∼64 mm provided by Nippon Steel Co. The precursor powders consisting of DyBCO, Dy2BaCuO5 (Dy211) with DyBCO: Dy211 = 7:3 in molar ratio, 10 wt% Ag2O, and 0.5 wt% CeO2 were provided from TEP Co. The Ag2O and CeO2 were incorporated into the precursor to lower the Tp and suppress the grain growth of Dy211, respectively. The precursor powder was then pressed into ring shapes using metallic dies under a uniaxial pressure of ∼100 MPa. Subsequently, "mmOD," "mmID," and "mmt" will refer to the outer diameter, inner diameter, and thickness, respectively. We utilized two types of metallic dies with (25 mmOD, 10 mmID) and (35 mmOD, 10 mmID) in this study. The precursor DyBCO rings underwent heat treatment above the peritectic temperature in the air for a short time to ensure densification, followed by surface polishing. A viscous paste, created by combining the precursor powder and several organic constituents, was coated at the interface between the bulk and the seed plate to ensure uniform contact. All ring-shaped DyBCO bulks in this study were directly grown using the SDMG method in air, where the highest holding temperature must be between the Tps of DyBCO (∼990 °C) and EuBCO (∼1030 °C) considering that the addition of Ag lowers the Tps by approximately 20 °C. For detailed SDMG profiles, please refer to our previous study. 29) In total, three Ag-added DyBCO bulks (numbered #Dy1–3, hereinafter) were fabricated in this study. The appearance of the prepared bulks is shown in Fig. 1(b) and their characteristics, such as the size and trapped fields at 77 K, are summarized in Table I. After separating the grown bulks from the seed plate using a diamond saw, post-annealing under the moderately reductive condition, i.e. 1% O2/Ar flow at 900 °C for 24 h, was carried out for the bulks, followed by oxygen annealing under flowing oxygen gas at 425 °C for more than 200 h to control carrier doping state being optimal. Post-annealing conditions were decided based on our recent study on the effects of reductive annealing on REBCO melt-grown bulks. 30) Using the SDMG method, approximately 1 mm of randomly oriented regions remains in the uppermost part, i.e. growth front, of the bulks due to the accumulation of extruded RE211 grains. Therefore, 1–2 mm from the growth front was removed for all prepared bulks. Notably, all the SDMG-processed bulks exhibit a slightly truncated cone shape. Despite the diameters listed in Table I referring to the seed side's outer and inner dimensions, the diameters on the growth front side are 1%–3% smaller. BT distributions ∼1 mm above the bulk surfaces and BT changes in the depth direction within the center of the ring were evaluated at 77 K using a Hall probe (Lake Shore Cryotronics Inc. HGCA-3020) after field cooling magnetization up to 2 T. The BT,max represents the highest BT value inside the ring. Zero-field cooled magnetization under 10 Oe and magnetization hysteresis loops at 77 and 60 K under dc fields up to 5 T were measured for small rectangular pieces cut from various positions of the #Dy2 bulk using a SQUID magnetometer (Quantum Design MPMS XL-5s). Magnetic fields were always applied parallel to the c-axis of the samples. Jc values were calculated from the widths of magnetization hysteresis based on the extended Bean model. 31,32) Based on our current understanding, the highest BT,max values at 77 K achieved inside a ring to date are 1.13 T for a single ring-bulk, and 2.59 T for an assembly of 10 stacked ring-bulks, respectively. 33,34)

Table I. Summary of the size of die and grown bulks, BT,max at 77 K, circularity, and ellipticity for the prepared ring-shaped DyBCO bulks in this study. mmOD, mmID, and mmt represent the outer, inner diameters, and thickness, respectively.

| No. | Die-size (mmOD, mmID) | Grown bulk-size (mmOD, mmID, mmt) | BT,max (77 K)/T | Circularity, c | Ellipticity, e |

|---|---|---|---|---|---|

| #Dy1 | (35OD, 10ID) | (29.0OD, 8.3ID, 7.4t) | 1.29 | 0.989 | 0.022 |

| #Dy2 | (25OD, 10ID) | (20.1OD, 7.5ID , 15.4t) | 1.24 | 0.991 | 0.031 |

| #Dy3 | (35OD, 10ID) | (28.7OD, 7.9ID, 11.5t) | 1.84 | 0.987 | 0.040 |

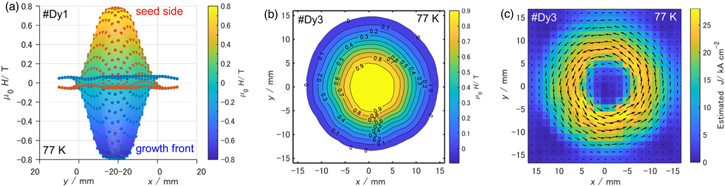

For all samples, #Dy1–#Dy3, we successfully grew crack-free ring-shaped REBCO bulks as shown in Fig. 1(b), which exhibited the glossy appearance characteristic of melt-textured bulks. Figure 2(a) shows the BT distribution at 77 K above seed side and growth front surfaces of the #Dy1 bulk. Both surfaces demonstrate high BT distributions in the shape of a concentrical cone with almost equivalent values of ∼0.8 T, indicating that a uniform bulk material has been obtained in both the radial and height directions. Figures 2(b) and 2(c) depict the two-dimensional BT distribution above the seed side surface of the #Dy3 bulk and the estimated in-plane current density (J) distribution, respectively. A homogeneous cone-shaped distribution, along with high BT value of more than 0.9 T, is also observed. Yang et al. have reported a maximum surface trapped field of 0.32 T at 77 K for a GdBCO ring-bulk directly grown by the buffer-aided TSIG method, whose size, (32 mmOD, 10 mmID, 13 mmt), is almost comparable to our SDMG ring-bulks. 13) The highest surface trapped field is reported by M. Tomita et al., who reported the maximum surface trapped field value of 0.9–1.0 T at 77 K observed in a very large GdBCO bulk (80 mmOD, 50 mmID, 20 mmt). 34) Compared with these reports, it is evident that the SDMG ring-bulks grown in this study exhibit a remarkably high surface trapped field considering their sizes. J distributions were calculated by resolving the inverse Biot–Savart problem using the previously proposed inverse matrix method. 35,36) In this calculation, we only adopted two assumptions: currents flowing only in the ab plane and a constant J along the thickness direction. Without any boundary conditions, we obtained a circulation of J reflecting the ring shape of the bulk. In addition, to quantitatively evaluate the homogeneity of the prepared bulks, we computed the circularity and ellipticity for the BT distribution above the seed side, as shown in Table I. Circularity (c) and ellipticity (e) were calculated for isomagnetic field lines at 0.02 T intervals using the following equations: c = 4πS/L2 and e = 1−b/a, where L, S, a and b represent the perimeter, area, major axis, and minor axis of each closed isomagnetic field line, respectively. The mean values were then calculated. The closer c is to 1 and e is to 0, the closer the obtained BT distribution approximates a perfect circle. A more detailed explanation of these parameters can be found in Refs. 28, 29. All ring-shaped bulks exhibited c and e values remarkably close to a perfect circle, with c > 0.98 and e < 0.05, whose values are equivalent to, or even surpass those of homogeneous disk-shaped SDMG bulks reported thus far. 29) For desktop NMR applications, where a larger sample space is desired, further scaling-up is expected. The SDMG method is advantageous for enlargement since the crystallization process progresses only in the vertical direction and the crystallization time is independent of the size in the radial direction in principle. In fact, we have successfully grown homogeneous ring-shaped bulks up to (50 mmOD, 25 mmID) under the short crystal growth time of ∼100 h, details of which will be provided in an upcoming publication.

Fig. 2. Three-dimensional trapped magnetic field distributions at 77 K above the seed side and growth front surfaces of the #Dy1 bulk (a), where both surfaces exhibit concentrically cone-shaped trapped magnetic fields, indicating a uniform bulk material in radial and height directions. Two-dimensional trapped magnetic field distribution at 77 K above the seed side surface of the #Dy3 bulk (b) and computed in-plane current density distribution obtained by solving the inverse Biot–Savart problem (c).

Download figure:

Standard image High-resolution imageFigure 3 shows the BT distribution at 77 K in the height direction along the center of rings for the #Dy1–3 bulks. An arrow in the figure marks the center in the height direction for each bulk. Notably, for #Dy3, there is a slight offset between the physical center of the ring and the position of BT,max, which could suggest that the bulk has superior crystallinity and/or Jc characteristics on the seed side. From the figure, all these samples demonstrated extremely high BT,max exceeding 1 T at 77 K. Especially, #Dy3 exhibited a BT,max surpassing 1.8 T. This BT,max value of 1.84 T at 77 K is the highest ever achieved in single, i.e. not-stacked, ring-bulks across all reported sizes. O. Vakaliuk et al. reported a BT value of 1.13 T at 77 K inside a YBCO ring-bulk similar in size to the #Dy3, (28.1 mmOD, 6.0 mmID, 17.3 mmt), and this ring-bulk trapped up to 9.78 T when cooled to 25 K. 33) We anticipate that cooling our bulk to low temperatures will enable the realization of an internal magnetic field exceeding 10 T.

Fig. 3. Trapped magnetic field distribution at 77 K along the height direction inside the center of the rings of the #Dy1–#Dy3 bulks. An arrow marks the center in the height direction for each bulk. Samples exhibit extremely high trapped magnetic fields exceeding 1 T, with #Dy3 in particular showing a central magnetic field surpassing 1.8 T.

Download figure:

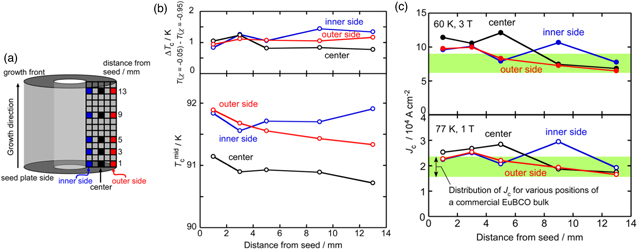

Standard image High-resolution imageFinally, superconducting properties were evaluated in detail for the #Dy2 bulks. As schematically shown in Fig. 4(a), small pieces were cut from different positions, namely varying radial positions (inner side, center, and outer side) and different heights, within the #Dy2 sample, and their superconducting properties were evaluated. Figures 4(b) and 4(c) summarize the sample position dependences of transition widths (ΔTc), Tc mid, and Jc at 77 K, 1 T and 60 K, 3 T, respectively. ΔTc is defined as the temperature difference between T(χ = −0.05) and T(χ = −0.95), while Tc mid is defined as the temperature at which χ = −0.5, where χ is zero-field-cooled magnetization normalized at 80 K. Despite slight variation in Tc mid between 90.8–91.9 K in the radial direction, all samples exhibited very sharp superconducting transitions with the transition widths less than 1.5 K, even at the positions distant from the seed. This suggests that the RE/Ba substitution, which deteriorates both Tc and ΔTc, is suppressed and the carrier doping state is almost uniform throughout the bulk. In Fig. 4(c), the distribution of Jc measured from various positions in the commercial EuBCO bulk is also indicated by bands. Although this sample is not identical to the seed plate used in this study, it was produced using the same growth method and is a homogeneous product also used in the compact bulk NMR that Nakamura et al. have reported. 16) From the Jc characteristics of the SDMG bulks, the overall performance in magnetic fields is the same or higher with an equivalent level of uniformity as the commercial bulk. It should be noted that there is a strong correlation between Jc at 77 K, 1 T and that at 60 K, 3 T, suggesting that the Jc characteristics at middle to low temperatures, where desktop NMR applications are expected to operate, can be inferred from the in-field Jc properties at 77 K.

Fig. 4. Schematic illustration of the measured sample positions (a), sample position dependences of ΔTc and Tc mid (b), and of Jc at 77 K, 1 T (open) and 60 K, 3 T (closed) (c). ΔTc is defined as the temperature difference between T(χ = −0.05) and T(χ = −0.95), while Tc mid is defined as the temperature at which χ = −0.5, where χ is a zero-field cooled magnetization under 10 Oe normalized at 80 K. Distribution of Jc measured at various positions in the commercial EuBCO bulk is also indicated in the figure (c) by green bands.

Download figure:

Standard image High-resolution imageIn conclusion, we have succeeded in the direct fabrication of high-quality ring-shaped DyBCO melt-textured bulks using the SDMG method, which overcomes the shape limitations posed by conventional top-seeded crystal growth methods. The prepared bulks demonstrated concentrically cone-shaped trapped field distributions on the surface and impressively high trapped fields exceeding 1.8 T at 77 K inside the center of the ring, which is the highest record among single ring-shaped bulks to date. Moreover, these bulks exhibited highly uniform superconducting properties across both radial and height dimensions. These results strongly highlight the promising potential of REBCO ring-shaped bulks fabricated using the SDMG method, which opens up innovative magnetic applications, particularly in the development of compact and cryogen-free bulk NMR systems. Continued enhancement of the SDMG method, combined with scaling-up of bulk sizes will facilitate the realization of these promising applications.

Acknowledgments

This research was supported by the NEDO Uncharted Territory Challenge 2050 (22M1C01Y) and by a research grant program of the Nippon Sheet Glass Foundation for Materials Science and Engineering.