Abstract

L10-FeCo has attracted attention as a new, rare-metal-free magnetic material due to its large uniaxial magnetic anisotropy. However, the low stability of the L10 phase hampers its practical application. We here intend to prepare FeCo alloy thin films by utilizing the nitrogen surfactant effect. The enhancement of the out-of-plane magnetization of this thin film was observed by stacking cobalt single atomic layer on bilayer iron nitride and subsequent annealing at 470 K. This study provides an insight into the relationship between structural changes and magnetic properties of the FeCo interface on the atomic scale, and paves the way for the development of rare metal-free magnetic materials.

Export citation and abstract BibTeX RIS

1. Introduction

Large magnetic anisotropy, large magnetic moment, and high Curie temperature are essential for the development of practical magnetic materials. 1) Permanent magnetic materials currently used in devices are mainly made from rare earth elements and other rare metal materials, which are required to substitute with rare metal-free materials for the sake of environmental impacts. 2) 3d transition metal ordered alloys with L10 type crystal structure have attracted much attention as promising candidates for rare earth-free permanent magnet material due to large magnetic anisotropy, large magnetic moment, and high Curie temperature. Among them, L10 FeCo is predicted to have extraordinary high uniaxial magnetic anisotropy of Ku up to 1.0 × 107 J m−3, 3) and many efforts have been devoted to fabricate the L10 FeCo phase with uniaxial magnetic anisotropy. Using pulsed laser deposition, the growth of FeCo thin films with alternating Fe and Co atomic layers was investigated. 4) However, the formation of the L10 FeCo phase was not confirmed and Ku showed the low value of 3.0 × 105 J m−3. Thus, the method for achieving the out-of-plane magnetization has not been established due to the non-equilibrium state of the L10 structure in the FeCo phase. The main bottleneck for the fabrication of L10 FeCo is the atomic-scale disorder at the Fe/Co interface during the growth process, which highlights the importance of microscopic characterizations of the structural, electronic, and magnetic properties of L10 FeCo. However, detailed investigations on the structural properties of the Fe/Co interface have rarely done so far. In this work, we focus on fabricating high-quality Fe/Co interface in FeCo alloy thin films on Cu (001) by utilizing the nitrogen surfactant effect of monatomic layer nitride. 5–7) Due to the high surface lattice stability of monatomic layer nitride and the nitrogen surfactant effect, the interdiffusion at the Fe/Co interface can be effectively suppressed during deposition and annealing processes. The important role of the nitrogen surfactant effect in the preparation of high-quality L10 type alloy thin films has been demonstrated for FeNi alloy thin films by realizing the high Ku of 1.3 × 106 J m−3 and the resulting out-of-plane magnetization for the first time. 8,9)

2. Experiment

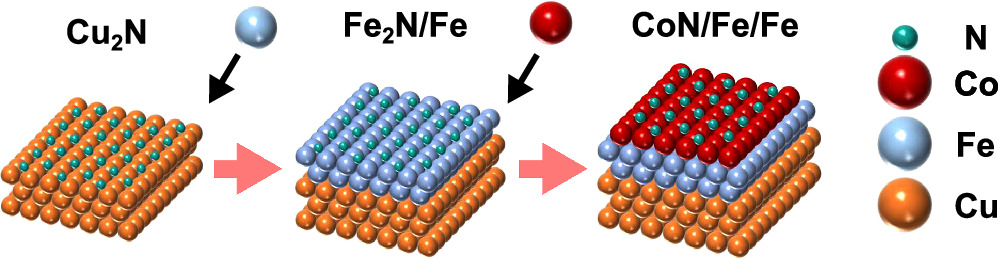

In this study, FeCo ordered alloy thin films in the initial growth stage were prepared on Cu(001) using the nitrogen surfactant effect in ultra-high vacuum (<2.0 × 10−10 Torr). Cu(001) is chosen as a supporting substrate to fabricate FeCo ordered alloy thin films due to the small lattice mismatch of ∼1% between L10 FeCo and fcc Fe (Co) thin films on Cu(001). 10,11) First, the Cu(001) surface was cleaned by a cycle of Ar+ sputtering and annealing at 720 K. Next, N+ ion bombardment was conducted with an incident energy of 500 eV onto the Cu substrate and 2 mono layer (ML) of Fe were deposited at 300 K. Subsequently, a bilayer iron nitride, Fe2N/Fe, was grown on Cu (001) by annealing at 570 K. One atomic layer of Co was thereafter deposited on Fe2N/Fe at low temperature (∼150 K), which results in the formation of CoN/Fe/Fe on Cu(001) via the nitrogen surfactant effect [see Fig. 1]. CoN/Fe/Fe/Cu(001) was then annealed at 300, 320, 420, and 470 K. The correlation between the structural changes at the surface and interface of CoN/Fe/Fe/Cu(001) and electronic/magnetic properties of the system upon sample annealing treatment was investigated using low energy electron diffraction (LEED), scanning tunneling microscopy (STM) and X-ray absorption spectroscopy/X-ray magnetic circular dichroism (XAS/XMCD). STM measurements were performed using Omicron LT-STM at 80 K in a constant current mode in ultra-high vacuum (<4.0 × 10−11 Torr). Electrochemically etched W tips were used in the STM measurements. XAS/XMCD measurements were performed at BL4B in UVSOR 12) by total electron yield mode with circularly polarized light at B = 0 to ±5 T and T = 7.9 K. The circular polarization of the incident X-rays was set to about 65 %, and the XMCD spectra are obtained at the normal (NI: θ = 0°) and the grazing (GI: θ = 55°) geometries. Note that θ is the angle between the sample normal and the incident X-ray. Element specific magnetization curves were also recorded by plotting the L3/L2 Fe and Co XAS intensities as a function of the magnetic field. 13) The coverages of Fe2N/Fe and Co overlayer were determined by the quartz-crystal micro-balance (QCM) and XAS edge jump. 14,15)

Fig. 1. Schematic model of the fabrication processes of CoN/Fe/Fe/Cu(001) via the nitrogen surfactant effect.

Download figure:

Standard image High-resolution image3. Results and discussion

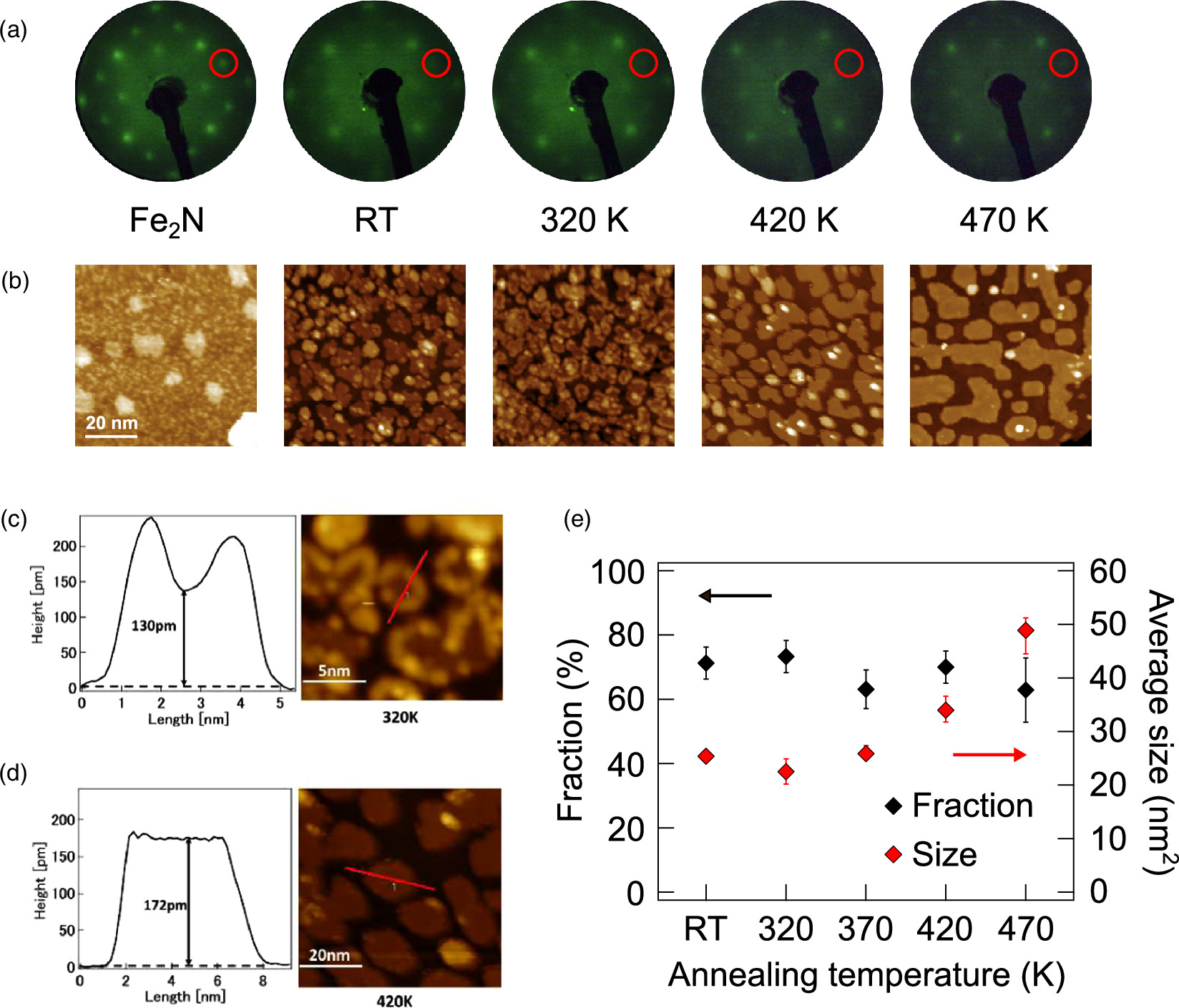

Macroscopic structural properties of the system are first characterized by LEED. Figure 2(a) shows LEED patterns of bare Fe2N/Fe/Cu(001) and CoN/Fe/Fe/Cu(001) with annealing at various temperatures. The high-quality surface of Fe2N/Fe is confirmed from sharp a p4gm(2×2) LEED pattern as previously reported. 14–17) After the deposition of Co at low temperature, the intensity of the p4gm(2×2) LEED spot gradually becomes weaker accompanied by the relative increase in the c(2×2) LEED intensity. This suggests the decreased fraction of the Fe2N p4gm(2×2) lattice and corresponding increased fraction of CoN c(2×2) lattice on the surface. Furthermore, upon annealing at 470 K, the p4gm(2×2) LEED spot further weakens, and the c(2×2) LEED spot becomes more prominent. Thus, it is reasonable to consider that the nitrogen surfactant suppresses the interdiffusion at the Fe/Co interface and promotes the formation of the CoN lattice in CoN/Fe/Fe/Cu(001) at least up to an annealing temperature of ∼470 K.

Fig. 2. (a) LEED patterns of Fe2N/Fe/Cu(001) and CoN/Fe/Fe/Cu(001) annealed at 300, 320, 420 and 470 K, respectively (from left to right). Red circles point LEED spots specific to the p4gm(2×2) lattice. (b) STM images of Fe2N/Fe/Cu(001) and CoN/Fe/Fe/Cu(001) annealed at 300, 320, 420 and 470 K, respectively (from left to right). The height profiles of Co islands at annealing temperatures of (c) 320 and (d) 420 K, respectively. (e) Fraction and average size of Co islands as a function of annealing temperature.

Download figure:

Standard image High-resolution imageWe investigate microscopic surface and interface structures of Co on Fe2N/Fe/Cu(001) by STM. In STM measurements, we set the amount of deposited Co to ∼0.8 ML to investigate the impacts of annealing on surface structures of both Fe2N (∼20%) and CoN (∼80%) regions. Figure 2(b) shows a series of STM images of bare Fe2N/Fe/Cu(001) and CoN/Fe/Fe/Cu(001) with annealing at various temperatures. The surface of bare Fe2N/Fe/Cu(001) is similar with the one previously reported, 15) which suggests the proper sample preparation in this work. At low annealing temperatures up to 320 K, we find that the height of rim and core regions in Co islands is different. As shown in Fig. 2(c), the height of the rim region is about 70 pm higher than that of the core region. The height modulation inside Co islands disappears at an annealing temperature of 420 K, which is clearly recognizable from the height profile along a Co island [see Fig. 2(d)]. The observed structural change could be associated with the diffusion of surfactant N atoms. Annealing at low temperatures is insufficient to diffuse N atoms overall Co islands, leading to sticking N atoms at the rim regions. Inc.reasing annealing temperature adequately activates the surface diffusion of N atoms and improves the surface ordering of CoN lattice with atomically flat Fe/Co interface underneath. To investigate details of annealing temperature dependence of the Fe/Co interface, we evaluate the fraction and average size of Co islands as a function of annealing temperatures between 300 and 470 K [see Fig. 2(e)]. We find the average size of Co islands increases from 420 K, while the fraction of Co islands remains nearly constant. These results indicate that lateral diffusion of Co islands on the surface and ordering of CoN lattice (Fe/Co interface) via the nitrogen surfactant effect are facilitated, but the interdiffusion at the Fe/Co interface is still suppressed up to an annealing temperature of 470 K. Indeed, atomically resolved STM observations of CoN/Fe/Fe/Cu(001) reveals the highest quality of Fe2N-p4gm(2×2) and CoN-c(2×2) lattices in this work at an annealing temperature of 470 K.

The axial ratio, c/a, is an important parameter to characterize L10-FeCo. Previous studies report that the lattice expansion along c axis is the signature of the emergence of the L10 FeCo phase, leading to c/a of up to ∼1.2. 3,18–20) Utilizing high spatial resolution of STM, we discuss c/a of N-surfactant assisted FeCo ordered alloy thin films. Since STM detects the projected local density of state on the surface, the height in the STM image, which gives the information on c axis, does not always correspond to the real height especially at the heterointerface. Thus, we here evaluate a lateral lattice constant, i.e. a axis of the Co layer on Fe/Fe/Cu(001) with surfactant nitrogen atoms and compare experimentally obtained a with c = 358 pm of L10 FeCo for c/a = 1.00. 10) We find from atomically resolved STM observations of CoN/Fe/Fe/Cu(001) annealed 470 K that a axis of the Co layer is 345 pm on average. This gives c/a of 1.04 at the Fe/Co interface in this work, which is in line with the lattice expansion along c axis characteristic for the L10-FeCo phase. Note that a axis of the Co layer is compressed relative to the lattice constant of Cu(001) substrate of ∼360 pm. Thus, the lattice strain is induced to the Fe/Co interface and the lattice tends to expand along c axis, possibly leading to greater c axis than 358 pm (c/a = 1.00).

For XAS/XMCD measurements, we first focus on XAS edge jumps of the system to evaluate coverages of Fe and Co layers. Figure 3(b) shows XAS spectra of Fe, Co, and Cu L edges for bare Fe2N/Fe/Cu(001) and CoN/Fe/Fe/Cu(001) annealed at 300, 470 K. Previous studies have demonstrated that the intensity of Fe (Co) L edges relative to Cu L edge, i.e. FeL(CoL)/CuL, of ∼0.10 corresponds to Fe (Co) coverage of ∼1 ML. 8,14,15) Thus, FeL/CuL of ∼0.20 and CoL/CuL of ∼0.10 evaluated for bare Fe2N/Fe/Cu(001) and CoN/Fe/Fe/Cu(001) annealed at 300 K reveal controlled deposition of Fe and Co. Furthermore, the values of FeL/CuL and CoL/CuL are almost unchanged even after annealing at 470 K, which indicates N surfactant assisted robust surface/interface lattices in this system.

Fig. 3. (a) Fe, Co and Cu L2,3 XAS for Fe2N/Fe/Cu(001) and CoN/Fe/Fe/Cu(001) annealed at 300 and 470 K. All the spectra are normalized by the intensity of the Cu edge jump. (b) Fe L2,3 XAS (μ+, μ−) and XMCD (μ+–μ−) for Fe2N/Fe/Cu(001) recorded under B = ±5 T in the GI geometry.

Download figure:

Standard image High-resolution imageNext, electronic and magnetic properties of bare Fe2N/Fe/Cu(001) are investigated by XAS/XMCD. Figure 3(b) shows Fe L-edge XAS (μ+, μ−) and XMCD (μ+−μ−) spectra under B = ±5 T in the GI geometry. Note that the magnetic easy direction of Fe2N/Fe/Cu(001) is toward in-plane direction. 15) Spin (mspin) and orbital (morb) magnetic moments are quantitatively evaluated by applying XMCD sum rules 21,22) to the XAS and XMCD spectra. For the sum rule analyses, the average number of Fe 3d electrons of 6.61 is used. 22) The mspin is evaluated to be 1.5 ± 0.1 μB /atom, which is in good agreement with previous studies. 15,17) We further discuss impacts of Co deposition and subsequent annealing on mspin and morb of the Fe layer. Figure 4 shows the evaluated mspin and morb of the Fe layer in Fe2N/Fe/Cu(001) and CoN/Fe/Fe/Cu(001) annealed at 300 and 470 K. The value of mspin is not affected by the existence of Co overlayer and annealing within the error by XMCD sum rules. In contrast, changes appear in morb especially in the GI geometry. We find that adding Co overlayer and annealing significantly decrease morb in the GI geometry, while morb is almost constant in the NI geometry. Since the difference of morb recorded between NI and GI geometries, morb NI–morb GI, is proportional to the magnetic anisotropy, 23) the observed changes in morb suggests the relative enhancement of the out-of-plane magnetic anisotropy of the Fe layer.

Fig. 4. Evaluated spin (top) and orbital (bottom) magnetic moments by XMCD sum rules for Fe2N/Fe/Cu(001) and CoN/Fe/Fe/Cu(001) annealed at 300 (RT) and 470 K. The horizontal error bars represent the standard deviations of evaluated magnetic moments.

Download figure:

Standard image High-resolution imageTo understand the origin of changes in morb in more detail, we investigate the magnetization curve of the Fe layer. Figure 5 shows magnetization curves of the Fe layer recorded in the NI and GI geometries. Overall, the magnetization curve shows the hysteresis loop in the GI geometry, but no remanence in the NI geometry, possibly reflecting the strong in-plane magnetic anisotropy of Fe2N/Fe/Cu(001). 15,17) Notable changes after Co deposition and annealing are observed in the magnetization curve recorded in the NI geometry. We find that the magnetization curve becomes steeper by adding 1 ML Co and subsequent annealing at 300 K. This is a clear signature of the enhanced out-of-plane magnetic anisotropy as seen in the values of morb [see Fig. 4]. The out-of-plane magnetization is further reinforced by annealing at 470 K.

Fig. 5. Magnetization curves of the Fe layer in Fe2N/Fe/Cu(001) and CoN/Fe/Fe/Cu(001) annealed at 300 and 470 K recorded in the NI (left) and GI (right) geometries. The Fe L3 XAS peak intensity normalized by the Fe L2 one is plotted one as a function of magnetic field.

Download figure:

Standard image High-resolution imageFinally, we discuss the correlation between structural, electronic and magnetic properties of Co on Fe2N/Fe/Cu(001). The results of STM and LEED observations reveal that the quality of CoN-c(2×2) lattice and hence underlying Fe/Co interface is improved via the nitrogen surfactant effect up to an annealing temperature of 470 K. Thus, the enhancement of the out-of-plane magnetic anisotropy observed by XAS/XMCD can be linked with the formation of atomically flat Fe/Co interface as well as larger c/a than 1.00, which would reflect characteristics of L10 FeCo. It should be noted that we extract the perpendicular magnetic anisotropy Ku of CoN/Fe/Fe/Cu(001) annealed at 470 K with the highest quality Fe/Co interface in this work using the equation described in Ref. 8. Although the evaluated Ku of 7.4 × 105 J m−3 is still smaller than the theoretical value of 1.0 × 107 J m−3, it is expected that the value of Ku can be improved by increasing the thickness of FeCo ordered alloy thin films. 8,9)

4. Summary

We investigated structural, electronic and magnetic properties of FeCo ordered alloy thin films grown via the nitrogen surfactant effect by STM LEED, and XAS/XMCD. We successfully link the enhancement of the out-of-plane magnetic anisotropy in CoN/Fe/Fe/Cu(001) annealed up to 470 K with the formation of the Fe/Co interface via the nitrogen surfactant effect. We here demonstrate the importance of atomically-resolved structural observations, which are inaccessible by conventional macroscopic structural characterization techniques, in the development of functional magnetic materials.

Acknowledgments

This work was partly supported by JSPS KAKENHI Grants (JP20H05179, JP20K21119, JP21H05016, JP22H01957, and JP23H01849), the Murata Science Foundation, the TEPCO Memorial Foundation, the Naito Science and Engineering Foundation, and Design and Engineering by Joint Inverse Innovation for Materials Architecture (DEJI2MA), MEXT. A part of this work was conducted at the BL4B of the UVSOR Synchrotron Facility, Institute for Molecular Science, and was supported by the Nanotechnology Platform Program "Molecule and Material Synthesis" (JPMXP09S19MS2001b, JPMXP09S19MS2001, JPMXP09S20MS2001, JPMXP09S21MS2001, and JPMXP09S21MS2002) and by the Advanced Research Infra- structure for Materials and Nanotechnology in Japan (JPMXP1222MS2001 and JPMXP1222MS2003), which is part of the Ministry of Education, Culture, Sport, Science and Technology (MEXT), Japan.