Highlights

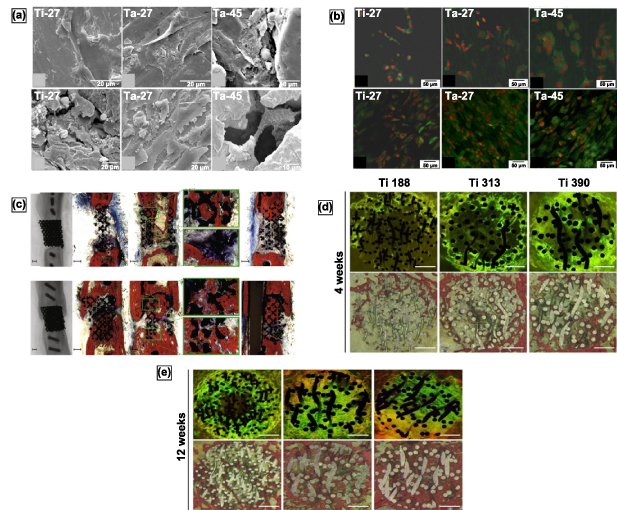

Porous metals are extensively used in load-bearing implants to improve osseointegration.

Different processing approaches for porous metals are discussed here.

Static and dynamic mechanical properties are critically reviewed for porous metal implants.

In vitro and in vivo biological properties of porous metal implants are critically reviewed.

Current challenges and future directions for porous metal implants are discussed.

Abstract

Porous and functionally graded materials have seen extensive applications in modern biomedical devices—allowing for improved site-specific performance; their appreciable mechanical, corrosive, and biocompatible properties are highly sought after for lightweight and high-strength load-bearing orthopedic and dental implants. Examples of such porous materials are metals, ceramics, and polymers. Although, easy to manufacture and lightweight, porous polymers do not inherently exhibit the required mechanical strength for hard tissue repair or replacement. Alternatively, porous ceramics are brittle and do not possess the required fatigue resistance. On the other hand, porous biocompatible metals have shown tailorable strength, fatigue resistance, and toughness. Thereby, a significant interest in investigating the manufacturing challenges of porous metals has taken place in recent years. Past research has shown that once the advantages of porous metallic structures in the orthopedic implant industry have been realized, their biological and biomechanical compatibility—with the host bone—has been followed up with extensive methodical research. Various manufacturing methods for porous or functionally graded metals are discussed and compared in this review, specifically, how the manufacturing process influences microstructure, graded composition, porosity, biocompatibility, and mechanical properties. Most of the studies discussed in this review are related to porous structures for bone implant applications; however, the understanding of these investigations may also be extended to other devices beyond the biomedical field.

Export citation and abstract BibTeX RIS

Original content from this work may be used under the terms of the Creative Commons Attribution 4.0 license. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

1. Introduction

Porous metals were first introduced in 77 AD when goldsmiths used a newly discovered granulation process to prepare aesthetically pleasing jewelry [1]. To this day, derivations of this approach are used when processing porous metals or metallic foams. Modern derivations began in the early 20th century when powderized metals were sintered to form first-of-a-kind porous metals for various engineering applications. Since then, this method has been used successfully to prepare filters, batteries, self-lubricating bearings, etc. [2, 3]. Although the commercial investigation into porous metals began in 1925, the progress was slow until the 1980s [4]. Since then, the widespread commercial availability of varying porous metallic materials for various applications has steadily increased. Porous metals are often the best option in structural engineering, where lightweight and high mechanical properties, high surface area, and/or interconnected porosity are needed. Although porous ceramic [5, 6] and porous polymeric materials [7–11] are also available, porous metallic materials offer unique properties that are often difficult to accomplish with other material systems. For example, porous polymeric materials lack in both sufficient mechanical strength and high-temperature stability. Alternatively, porous ceramic materials possess inherent brittleness, which limits their use in applications requiring high toughness and fatigue resistance [12, 13].

Using porous metals for orthopedic implants began with osseointegration devices [14]. Early on, many disadvantages with the use of dense metals as orthopedic implants were observed; specifically, the main disadvantage was the mismatch in effective Young's modulus of the bulk implant structure (110 GPa for titanium (Ti); 193 GPa for stainless steel (SS316L); 220–230 GPa for cobalt-chrome alloys) and the surrounding bone, which ranges from 10–30 GPa. Compared to the host tissue, the difference in effective stiffness of the implant inherently allowed for the physical phenomena known as stress shielding. When the effective stiffness of the implant is significantly greater than that of the surrounding hard tissue, the implant shields the host tissue from applied loads; this promotes uneven localized loading events and limits bone compliance during mechanical loading. The stress shielding event may cause premature failure by aseptic loosening, where the host tissue becomes idle from insufficient use, also known as bone resorption. The second is the separation and fracture at the host tissue–implant interface due to insufficient tissue anchorage [15]; bulk non-porous implant materials tend to exhibit weaker interfacial bonding with the surrounding bone tissue. Surface texturing, such as surface roughening or lattice-designed surface porosity, may remedy this issue and thus lead us to the topic at hand.

The typical lifetime for total hip replacement (THR) remained nearly unchanged for the last fifty years, averaging 10–15 years of operational use [16]. This was particularly so because most THR surgical procedures were performed in patients age 65 or greater, thus, creating a lack of impetus for an implant of a greater operational lifetime. However, a general trend of these procedures being performed on much younger patients has been observed in recent years. With improving medical care and medication, patient self-heath awareness, and the ability to catch early-stage illnesses, the average lifespan of society has increased, and demand for an increase in the operational life of load-bearing articulating implants has also increased. Alternatively, for the younger members of society, greater trust in medical care has allowed for more reparative surgeries, which return normal biomechanical motion of a limb or joint. One challenge associated with implantation into a more youthful society is that the implants will most commonly undergo more significant mechanical stresses with an increased exposure rate. Therefore, a push for improved implant performance and lifespan is imperative; investigating and innovating porous metallic implant structures with stiffness closer to bone and interconnected porosity is deemed highly significant. These implants should promote metabolite and nutrient exchange and allow bone ingrowth leading to improved implant-tissue anchorage and interfacial strength [16]. Furthermore, a porous implant surface allows for the introduction of a compliant layer; this layer should mimic the natural bone joint, such as the hip joint, and reduce wear-related issues [17]. The consolidation of these requirements when considering implant material design will allow for the reduction in revisional surgeries and increase operational life. A significant reason behind the lack of interest in porous metallic materials until recently was the lack of substantial mechanical strength and lower fatigue resistance [13]. However, recent manufacturing techniques have improved the properties of porous metals, and the drive to develop improved and longer-lasting implant structures have reinvigorated interest in the area.

Mechanical properties and the applicability of porous structures for load-bearing implantation sites depend highly on factors such as pore interconnectivity, open porosity, pore size, phases present, compositional variations, grain size, etc. Naturally, most studies investigating porous metal applicability for biomedical implants. Therefore, studying a novel fabrication technique focus on and evaluate the mechanical properties, corrosion resistance, fatigue resistance, and biological compatibility, of biomaterials; all of which are directly linked to the cell morphology and factors of which have an influence on cell attachment and integration into the host tissue.

Material structure cell morphologies, to an extent, tend to depend on the fabrication techniques and, in some cases, the parameters used in the fabrication process. For instance, random foaming processes form closed-cell porosity, where the pore morphology depends on the fabrication process parameters. Similarly, open-cell porous structures may be fabricated by solid-state fusion of metal powder, fibers, decomposition of foaming agents in liquid metals, or vapor deposition. While the solid-state fusion of powdered metals and the vapor deposition methods can produce controlled and higher open-cell porosities, using foaming agents in molten metal matrices usually produces lower and less predictable porosities in closed-cell [18]. Thus, some of the fabrication techniques, based on the type of pore morphology produced, are discussed and tabulated in table 1 [13], and some of the commercially available fully porous and porous-coated implants, their applications and description are reported in table 2 [19].

Table 1. Porous metal fabrication techniques categorized based on the pore morphology.

| Porosity type | Fabrication methods | Pore distribution |

|---|---|---|

| Closed-Cell | Gas Foaming Method | Random |

| Decomposition of Foaming agents | ||

| Plasma Spraying Method | Graded | |

| Open-Cell | Metal powder sintering | Non-homogeneous |

| Metal fiber sintering | ||

| Plasma-spraying | ||

| Replication | ||

| Combustion synthesis | ||

| Space-holder technique | ||

| Wire mesh oriented orderly | Homogeneous | |

| Vapor deposition | ||

| Additive manufacturing |

Table 2. Commercially available porous metal structures or porous coatings and their applications.

| Fabrication methods | Commercial name | Description | Application |

|---|---|---|---|

| Sintering | CSTiTM | Powder Sintering with pressure. | Hip and Knee Surgeries |

| Porous Ti coating | |||

| Porosity: 50%–60% | |||

| Pore Size: 400 μm–600 μm | |||

| Stiffness: 106–115 GPa | |||

| CoCr beads | Powder Sintering | Hip Surgery | |

| Porous CoCrMo coating | |||

| Porosity: 30%–50% | |||

| Pore Size: 100 μm–400 μm | |||

| Stiffness: 206 GPa | |||

| Fiber Metal | Sintering | ||

| Porous Ti coating | |||

| Porosity: 40%–50% | |||

| Pore Size: 100 μm–400 μm | |||

| Stiffness: 106–115 GPa | |||

| Vapor Deposition | TritaniumTM | Low-temperature arc vapor deposition of the polyurethane foam shell | |

| Porous Ti coating | |||

| Porosity: 60% | |||

| Pore Size: 616 μm | |||

| Stiffness: 106–115 GPa | |||

| Chemical Vapor Deposition infiltrating Carbon skeleton. | |||

| Trabecular MetalTM | Open cell | Hip and Knee Surgeries | |

| Porous Ta | |||

| Porosity: 75%–85% | |||

| Pore Size: 550 μm | |||

| Stiffness: 2.5–3.9 GPa | |||

| Porous Ti | |||

| Porous Plasma Processing | RegenerexTM | Porosity: 67% | Hip and Shoulder Surgeries |

| Pore Size: 300 μm | |||

| Stiffness: 1.6 GPa | |||

| Porous Ti coating | |||

| StiktiteTM | Porosity: 60% | Hip and Knee Surgeries | |

| Pore Size: 500 μm | |||

| Stiffness: 106–115 GPa |

With each technique, challenges may arise, but porous implants have inherent challenges that need to be resolved. Porous structures display lower mechanical strength, which is disadvantageous for load-bearing and load-bearing articulating applications. The fatigue life of porous structures is significantly reduced due to stress concentration sites at the neck region of each pore. The increased surface area of porous structures tends to increase corrosion rates. Moreover, as mentioned before, surface porosity affects implant anchoring by influencing bone ingrowth. Porous metal structures' corrosion and wear properties depend on the structure's porosity, hardness, and resistance to plastic deformation. It is necessary to understand a porous structure's physical, mechanical, and biological properties based on its porosity, microstructure, and composition, some of which vary drastically depending on the fabrication process. Therefore, in this review article, different fabrication processes for manufacturing porous metal structures have been discussed; microstructural and compositional influences of these processes have been elaborated on. Additionally, an effort has been made to compare porous implant structures' physical, mechanical, and biological properties based on their fabrication process. In summary, a knowledge-based discussion of the challenges and possible future direction for the fabrication and application of porous metallic implants is presented; some currently produced implants have been summarized in figure 1.

Figure 1. AM-produced porous-metal structures by the research and industrial sector. (a) Porous Nitinol cage for anterior intervertebral fusion produced by combustion synthesis, higher magnification image displaying the irregular pore morphology. Reproduced from [20]. CC BY 4.0. (b) Fabricated TiO2 nanotubes on the surface of porous Ti implant. Reproduced from [21], with permission from Springer Nature. (c) Porous hip stems produced with varying porosity. Reprinted from [22], Copyright (2010), with permission from Elsevier. (d) DED-LENSTM in vivo cylindrical samples with 25% porosity. Reproduced from [21], with permission from Springer Nature. (e) Micro CT imaging of DED produced porous Ti samples and (f) the respective 3D reconstruction [23], 2010, reprinted by permission of the publisher (Taylor & Francis Ltd, www.tandfonline.com.) (g) Porous tantalum trabecular metal (PTTM) dental implant displaying the Ti body and Ta porous surface [24], John Wiley & Sons. © 2013 Wiley Periodicals, Inc. (h) 3D systems powder bed fusion produced samples with varying cell-size and strut-size. Reprinted from [25], Copyright (2022), with permission from Elsevier and (i) powder bed fusion produced porous acetabular cup.

Download figure:

Standard image High-resolution image2. Fabrication methods for porous metals

Porous metal structures can be classified into closed-cell and open-cell porous structures, as listed in table 1. Considering that the type of porosity is dependent, to an extent, on the fabrication process, several fabrication methods have been discussed in this section.

2.1. Fabrication methods for closed-cell porous metals

While closed-cell porous metal structures might be helpful in various industrial applications, their use in orthopedic implants has certain limitations. Closed porosity reduces a porous structure's effective modulus and density, reducing the susceptibility for the occurrence of stress shielding. However, bone ingrowth would be compromised due to the lack of interconnected open porosity and surface wettability, thus limiting protein adhesion and subsequent cell attachment. Therefore, bone cement or another fixation means must hold the implant for osseointegration. Again, depending on the fabrication method used, the closed-cell pores can be either random or graded in distribution. The method for producing metal foams from molten metal due to gas introduction can be categorized into gas foaming and in situ gas generation by decomposition of foaming agents [26]. While gas injection into molten metal and decomposition of foaming agents would produce randomly distributed porosity, plasma spraying would produce graded pore distribution [13].

2.1.1. Gas foaming method.

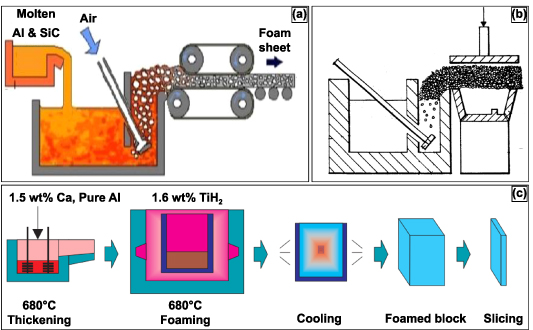

The method of self-formation of metal foams has been considered one of the most economical methods. The porosity in the metal foams generated by such methods is produced via self-evolution based on physical principles. Thereby, the stochastic nature and unpredictability of the cell structure are inevitable. Moreover, since the metal melt has high surface energy and low viscosity, certain additives and surfactants would be required to stabilize the cell walls by lowering surface energy and increasing the viscosity, thereby increasing the bubbles' stability [19]. A specific method of the gas foaming process is melt gas injection (MGI), as displayed in figure 2; this method involves using conventional foundry procedures to prepare a metal matrix composite consisting of additives and surfactants. In previous work, the additives have been ceramic particles such as SiC or Al2O3 and are added into the melt. In its molten state, gas is injected as small bubbles throughout the melt; the additives trap the gas bubbles, delay their coalescence due to their higher interfacial energies, and stabilize the cell walls. Moreover, the presence of the additives increases the viscosity, decreasing the velocity of the rising bubbles [26–28]. Then, using a conveyor belt system, the generated foam is carried away, cooled, and solidified. In this process, it was observed that the size of the bubbles was controlled by changing the gas flow rate, the propeller's design, and the propeller's speed. The metal foam produced by this method offered a density gradient and elongated or distorted cell morphology with corrugations in the cell wall. Additionally, the produced unit displayed anisotropy, heterogeneity, and lower mechanical properties [29–31]. It was later observed that these metal foam features could be improved by pulling the foam vertically [32]. For more complex part fabrication, numerous attempts were made by casting the semiliquid foam into melds or shaping it using rolls, as displayed in figure 2(b) [33, 34].

Figure 2. Two established processes for producing metal foam structures. (a) Schematic diagram of the melt gas injected (MGI) process. Reproduced from [35]. CC BY 4.0. (b) Sectional view of an alternate MGI process for manufacturing complex shapes. Reproduced from [34]. CC BY 2.0. (c) Manufacturing process of ALPORAS for metal foam production. [36] John Wiley & Sons. © 2000 WILEY-VCH Verlag GmbH, Weinheim, Fed. Rep. of Germany.

Download figure:

Standard image High-resolution image2.1.2. Decomposition of foaming agents in a melt.

An alternative method for producing metal foams is by producing gas within the melt itself; this is typically done by adding foaming or blowing agents to the melt and not by gas injection from an external source. The foaming agent decomposes within the melt, generating gas in situ, thus producing metal foams [37–39]. Once the desired viscosity is obtained, the melt and the foaming agent are added to the casting mold. The foamed metal expands gradually at a constant pressure conforming to the mold, illustrated in figure 2(c) [40]. The metal foams produced by this technique have displayed a high degree of homogeneity [40, 41]. Typical foaming agents observed in the field have been TiH2 and ZrH2 [41]. Porous aluminum slabs or cast Al alloys with 10–20 vol. % SiC or Al2O3 particles have been produced by the decomposition of the foaming agent method [40, 41].

2.1.3. Plasma spraying method.

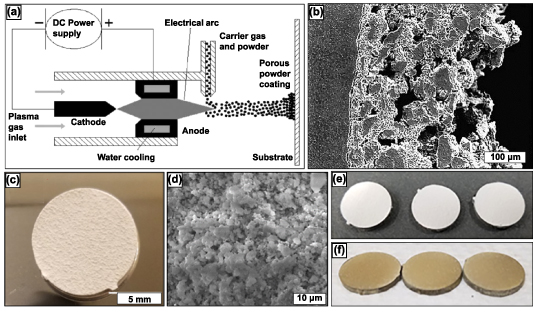

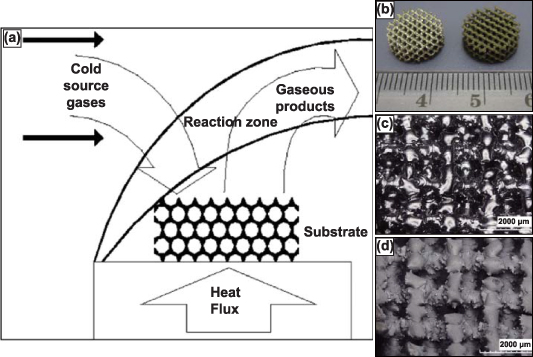

Plasma spraying primarily produces functionally graded porous coatings or completely porous parts [42]. Functionally graded porous structures offer a rough and porous surface for the bone tissue to grow within and anchor to the implant. The versatility of this method is such that it can produce porous coatings on dense substrates with porosity >50% [43]. The metal powder is added to the carrier gas, which is injected into the hot plasma jet stream, where the metal powder is brought to its melting point, accelerated, and impinged onto the substrate with high kinetic energy. The plasma spraying process can be done in a controlled environment to avoid the influences of the surrounding atmosphere [42]. The schematic representation of the process is shown in figure 3(a) [13]. The porosity of the coating produced by this method is altered by varying the spray parameters. The porous coating deposited on the substrate comprises of the starting material matrix with some spontaneously generated phases owing to the short reaction time. The porosity of these coatings varied largely in 3 layers: a very dense inner layer that enabled desirable mechanical, metallurgical, and physical bonding properties, a middle layer consisting of a combination of micro and macro pores, and an outer layer that largely contained macro pores [44, 45]. The porosity of these coatings is irregular and has low interconnectivity, figure 3(b) [42], however current research in this field has shown that these coatings can be doped with anti-inflammatory, antibacterial, recovery period and with natural medicinal compounds to promote cell attachment and phenomena such as angiogenesis, as displayed in figures 3(c)–(f) [46, 47]. A. Vu reported that thymol and carvacrol-loaded hydroxyapatite displayed bacterial inhibition of Staphylococcus epidermidis and reduced osteoclast resorption pit formation [46]. The objective was to derive a natural medicinal system that would prompt bone healing with antibiotic infection prevention.

Figure 3. The plasma spray technique along with research produced samples. (a) Schematic representation of plasma spraying process. The porosity of the coating may be varied by altering spraying parameters (b) Cross-sectional view of plasma sprayed coating on a substrate. Reprinted from [13], Copyright (2006), with permission from Elsevier. (c) Induction plasma-sprayed carvacrol/thymol-loaded hydroxyapatite (HA) on Ti64 substrate and (d) high magnification SEM micrographs of after-release study. Reprinted with permission from [46]. Copyright (2020) American Chemical Society. (e) Displays HA-coated and (f) ZnSiAg-HA doped coatings on Ti64 substrate. Reprinted from [47], Copyright (2019), with permission from Elsevier.

Download figure:

Standard image High-resolution image2.2. Fabrication methods for open-cell porous metals

Most commonly, implants are fixed in place with the help of bone cement or metal screws. However, the major drawback to bone cement is fragmentation which can result in foreign body response to the released debris; this mode of implant fixation usually leads to periprosthetic osteolysis, early aseptic loosening, and failure of the implant [48]. For quicker healing after implantation, osseointegration is critical. Osseointegration, meaning, bone tissue ingrowth into the implant surface. The correlation between the morphology and size of the porous surface and the strength of fixation with the surrounding tissue has also been determined [49]. Many studies have concluded that open porosity improves implant wettability and aids bodily fluids flow, thus improving osseointegration when >100 μm pore size is present [50]. The porosity is either homogeneously or non-homogeneously distributed based on the processing method. Discussed are several fabrication methods for producing open-cell porous implants or coatings.

2.2.1. Sintering.

Sintering is one of the oldest and most evolved techniques in powder metallurgy for producing density-controlled materials. The basic concept of the process is to prepare powder (metal/ceramics) by compacting and binding powdered raw material and providing thermal energy for the compacted powder for densification and grain growth. In this process, the powder particles bond at high temperatures with minor changes to the initial powder particle shape. Binders hold the powder particles together, providing enough area for mass transport during solid-state diffusion. Due to this technique's highly evolved nature, many studies on porous orthopedic implant structures have employed sintering or modified versions of sintering for preparing porous metal structures.

The porosity of the sintered structures can be controlled by tailoring the shape and size of the metal powder, the compaction pressure, and the temperature and time of sintering. It was observed that the compaction pressure and the sintering temperature significantly impact the microstructural and mechanical properties of the porous sintered metals. In general, it was observed that sintered Ti compacts at 1173 K, 1373 K, and 1573 K at no applied pressure; as the temperature increased, the porosity decreased. However, the porosity remained more significant than 30% for each temperature, and almost 100% was observed to be open porosity. Moreover, the effect of different applied pressures at different sintering temperatures has also been studied, and it was observed that the porosity decreases considerably (∼19%). However, most of the porosity still was found to be open porosity. The scanning electron microscope (SEM) images of the microstructure of Ti compacts sintered at 1173 K, 1373 K, and 1573 K with an applied pressure of 10 MPa can be seen in figures 4(a)–(c), respectively [51].

Figure 4. SEM micrographs of the fracture surface microstructure of porous Ti compacts sintered at (a) 1173 K, (b) 1373 K, and (c) 1573 K. Reprinted from [51], Copyright (2003), with permission from Elsevier. Figure (d) displays the cross-sectional microstructure of functionally graded Ti produced by stacked sintering. Reproduced from [45], with permission from Springer Nature. Displayed is a (e) schematic of processing Ag-based foams with hierarchical pore structures: (e1) packing NaCl particles (hard template) to obtain a porous preform, (e2) infiltrating the porous preform in (e1) with Al25Ag, (e3) dissolving the NaCl particles in water to generate a foam structure with coarse pores, and (e4) selectively dissolving in acidic or alkaline media to generate micro/meso/macropores in the initial foam struts in (e3). Various three-dimensional zoom drawing views of hierarchical porous foams produced in the present work: (f1) general view, (f2) zoomed view showing coarse pores and pore-connecting windows, and (f3) zoomed view showing micro/meso/macropores developed in struts. Reprinted with permission from [52]. Copyright (2021) American Chemical Society.

Download figure:

Standard image High-resolution imageAdditional investigations produced porous functionally graded Ti using the sintering method by stacking layers of powders with varying particle sizes and the volume fraction of the additive (silicon), i.e. the low volume fraction of additive with finer powder (20% with 45 μm) to the high-volume fraction of additive with coarser powder (45% with 200 μm). The cross-sectional microstructure of a functionally graded porous Ti structure prepared in this manner is shown in figure 4(d) [45].

Another alternative form of porous surface characteristics to implant the structure's dense core via sintering is metal fibers instead of metal powder. This method has been investigated for both stainless steel and Ti fibers, and the procedure used to make such porous coatings is similar to the powder metal sintering process [53–56]. The metal fibers are laid complying with the form of the implant structure, compacted, and then sintered at high temperatures. The solid-state diffusion process forms a fully interconnected porous coating at each point of contact of the fibers [57]. However, the main drawback of this process is that compacting the metal fibers to the form of the implant structure is challenging and time-consuming. Moreover, the interfacial bond between the dense implant core and the fiber mesh coating depends on the complexity of the contours of the implant structure [53]. Even though the sintering method of building porous structures is relatively mature, several limitations exist. A most relevant limitation is that particle oxidation could inhibit the proper bonding of the particles because it is a high-temperature operation. Further, solid-state diffusion bonding of particles usually results in the neck formation comprised of brittle phases and might result in lower mechanical toughness and fatigue resistance. Moreover, the pore size and morphology are usually irregular and largely dependent on the particle size and shape. However, these limitations could be substantially improved upon by using appropriate sintering techniques [13].

Many modified sintering techniques have been investigated to produce porous metallic structures with improved porosity and controlled pore morphology, including the space holder, the spark plasma sintering (SPS), and the replication methods. In the space holder method, several investigations have used carbamide particles as the space holder in preparing porous Ti and porous Ti6Al4V alloys. Carbamide has been chosen in the space holder method because of its ideal spherical particle geometry and chemical properties, such as ease of removal before sintering [58, 59]. A properly sieved and sized mixture of Ti or Ti6Al4V with carbamide was weighed and compacted under pressure. The compaction was then heat treated so that the carbamide particles dissociated at lower temperatures (∼193 °C), and the dissociated by-products were expelled by either using a vacuum furnace or by the continued flow of argon. Thereby, the heat treatment cycle was typically followed where the compact was first heated up to 100 °C, and then slower heating rates were used up to 500 °C to ensure enough time for most of the carbamide particles to dissociate, and the consequent by-products were expelled. Following this, much faster heating rates could be used up to the sintering temperature at which the compaction was held for a considerable time, depending on the size of the compaction being sintered [58]. In this method, the size, shape of the pores, and porosity could be controlled primarily by controlling the volume fraction and the shape of the space holder particles. Other parameters that determine the porosity and the pore morphology are the compaction pressure and the holding time during sintering. While the compaction pressure applied to prepare the pre-sintered compact varied between investigations, the dependence on the mean porosity and mechanical properties (such as yield strength) and the compaction pressure seemed similar, i.e. as the compaction pressure increased, the mean porosity decreased. Also, it was observed among several investigations that the porosities that could be produced by this method ranged between 55% and 75%. It was observed that most of the pores were considered to possess consecutive and open cell morphology, with the sizes of the majority of these pores (<700 μm) being less than the largest space holder particle size (∼700 μm). The pores with larger sizes were observed to be the consequence of pore coalescence. Furthermore, the pore walls' thickness is believed to significantly impact the porous structure's mechanical strength. Thereby, it has been observed that, while the pore wall thickness of the structure produced by this method is in the same range as any other powder metallurgy process (i.e. ∼100–200 μm; compared with Berger's report), interconnected angular-shaped micropores were observed along the pore walls suggesting that the sintering process was incomplete because of low diffusivity. While these micropores were considered beneficial in improving the interconnectivity of the pores, they might significantly deteriorate the structure's mechanical properties. Different space holders or compaction techniques investigated other variants of this process [60, 61].

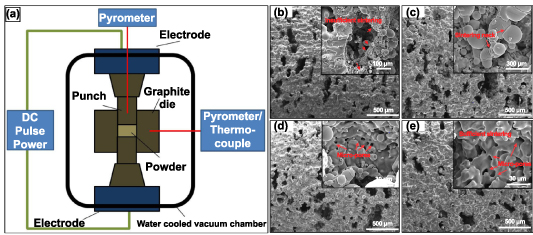

Another variant of the sintering technique is the SPS method. SPS or field assisted sintering technique (FAST) is a process similar to hot pressing where the heat required to sinter the powder particles in a compact is provided by joule heating due to the current flowing within the compact [62]. The general working principle of SPS, as indicated by figure 5(a), is that the sintering powder is compacted within a graphite die and DC voltage pulses pass through the die, and the compact (in the case of conductive sintering powder) produces joule heating, with heating rates up to 1000 °C·min−1, cooling rates of up to 400 °C·min−1 and maximum temperature of 2400 °C, sintering conditions could be facilitated by appropriately controlling the pulse voltages and durations [63]. Furthermore, this process could be controlled by controlling the die's measured temperature, power, or current. The rapid heating and cooling rates make this one of the fastest sintering processes, thereby ensuring limited grain growth in the sintered metal [64].

Figure 5. Field-assisted sintering technology/spark plasma sintering (FAST/SPS) technique and the produced porous structures. (a) A FAST/SPS apparatus displaying the working principle. [62] John Wiley & Sons. © 2014 The Authors. Advanced Engineering Materials Published by WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. Additionally, SEM images of pores walls of porous Ti produced at pressureless conditions with varying SPS sintering temperatures: (b) 1000 °C, (c) 1050 °C, (d) 1100 °C and (e) 1200 °C. Reprinted from [65], Copyright (2015), with permission from Elsevier.

Download figure:

Standard image High-resolution imageThe powder mixture is produced similarly to the space holder technique to produce porous metal structures using the SPS technique. The metal or alloy powder is mixed with varying volume fractions of space holder constituents such as NaCl or NH4HCO3. Then, the powder mixture is cold compacted under pressure to produce green compacts, sintered using SPS in a specially designed graphite die, as shown in figure 5(b) [65]. In the case of the study, where NaCl was used as an additive, post-sintering dissolution of NaCl in deionized water produced porous Ti6Al4V structures [66]. And in the case of the study where NH4HCO3 was used as an additive, it dissociates into NH3, H2O, and CO2 and is expelled during the sintering process and thus produces porous Ti structures [65]. In both studies, the x-ray diffraction (XRD) analysis of the porous structure showed negligible impurity content indicating that the space holders used were eliminated during the process. Also, it was observed that the majority phase appears to be α-Ti in the post-sintered structure, and the grains developed in the sintered porous structure are mostly fine. This indicates that the SPS process offers extremely fast heating and cooling rates.

The porosity, pore size, and morphology of the porous structures produced by the SPS method showed similarity with the previously discussed space holder method. In general, two types of pores were observed: Macro pores caused due to the dissociation of the space holder, and the micropores, within the pore walls of the macro pores, caused because of the incomplete sintering between adjacent metal particles (as shown in figures 5(c) and (e) in both the studies). Both studies also observed that as the sintering temperature was increased or by heat treatment post-sintering, the pore walls became thicker, and the porosity reduced (as shown in figures 5(d) and (f) in both studies). Also, both studies produced 40%–70% porosities; most pores were well interconnected.

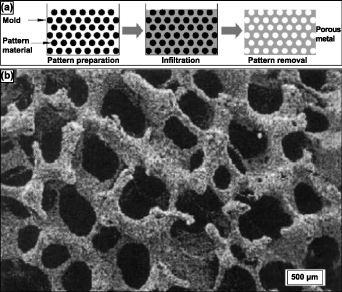

Finally, the replication method's third variant of the sintering method is discussed here. This process is typically three-step and has traditionally been used to prepare porous ceramics [13]. However, some investigations have used this method to produce porous Ti and Ti alloys. This method immersed polyurethane foams in a slurry and then rapidly dried for the metal powder to positively maintain the polyurethane foam replica. The slurry comprises 70% by weight Ti6Al4V and 20% by weight H2O and ammonia solution, where the ammonia solution has been added to improve the flow properties of the slurry. After repeating this process multiple times till the polyurethane foam struts were coated entirely with the Ti6Al4V powder, the polyurethane foam and binder were removed thermally, and the remaining Ti6Al4V powder arrangement was sintered, forming an open-cell reticulated Ti6Al4V foam [67]. This three-step process's schematic is shown in figure 6(a) [13].

Figure 6. Schematic representation of the (a) 3-step replication sintering process, (b) SEM micrograph of reticulated Ti-6Al-4V foam pore morphology of 88% porous Ti alloys. Reprinted from [13], Copyright (2006), with permission from Elsevier.

Download figure:

Standard image High-resolution imageAs expected, in this process, the flowability of the slurry, controlled via particle size distribution, binder chemistry, the pH of the slurry, air bubble quantity, and the solid–liquid ratio, determines the quality of foam produced by this process [68]. By this process, Ti alloy foams of 88% primarily open porosity have been attained, and the pore morphology could be observed in the SEM image shown in figure 6(b) [67]. The pores formed are chiefly found to be of three types: the primary porosity, comprising of smaller pores on the strut surface; secondary porosity, medium-sized pores formed at the core of the hollow strut formed by previously occupied polyurethane foam; and the tertiary porosity, larger open pores between the struts. A subsequent study observed that a second coating of the powder slurry and second sintering on a previously sintered foam enhanced the density and mechanical properties of the Ti or Ti alloy foams [69].

Even though sintering is a very mature metallurgical process, up to 80% of porosities could be achieved with slight modification. However, the process has inherent limitations. Sintered porous metallic structures are susceptible to brittle fracture and low fatigue resistance. Since, in this process, the metal particles bond via a solid-state diffusion process, the neck formed between metal particles after sintering is usually quite brittle. Also, the sintering process usually produces non-homogeneous pore distribution and pore morphology.

2.2.2. Combustion synthesis.

Combustion synthesis (CS) or self-propagating high-temperature synthesis (SHS) are commonly used with oxide-based materials. Typically, in conventional SHS, condensed-phase combustion takes place using solid-state reactants. A derivation to SHS would be solution-CS (SCS), where the initial reaction medium required is aqueous-based [70]. Additionally, if nanoparticle synthesis occurs in a flame, it is called gas-phase combustion. Most commonly, the techniques are used to produce various oxide materials, a wide range of highly pure and homogenous nanocrystalline powders [71]. CS can be accomplished in two differing modes. The first would require preheating by an external source up to the ignition temperature. Once the reaction is initiated, the reacting layer becomes the igniting heat source for the subsequent layer. The second mode is volume CS, in which the entire reactive body is uniformly brought up to the ignition temperature, and the reaction commences homogenously in the reactive body. The process is considered energy efficient as some thermodynamic systems reach temperatures of 500–4000 K with temperature rates of 103–106K·s−1 [72]. This process can form alloys Nitinol (NiTi), NiAl, TiSi, etc [73, 74]. Among those alloys, most literature concerning porous metallic orthopedic implants primarily focused on porous NiTi alloy. Thus, in this review, emphasis has been placed on the fabrication of porous NiTi alloy via CS.

The development of porous NiTi alloys via the SHS method requires an equimolar mixture of Ni and Ti powders with comparable particle size distribution to be prepared. The exothermic reaction between Ni and Ti when producing NiTi alloy is a low exothermic reaction (Ni + Ti → NiTi + 67 kJ·mol−1). Therefore, to produce a self-sustaining combustion wave to propagate throughout the initial powder compact, preheating to the ignition temperature is required, as previously mentioned [13]. Once the activation energy barrier is overcome, the combustion wave propagates throughout the green compact and is self-sustained [75]. In this case, a preheating temperature of approximately 450 °C produced a combustion temperature of 1260 °C. It has also been observed that finer powder particles tend to produce higher combustion temperatures for a specific preheating temperature. Important and contrasting observations made on the pore distribution and the combustion temperatures between two similar investigations were that by altering the preheating or ignition technique of the green compact, much higher combustion temperatures were obtained, and the pore distribution was observed to be more isotropic compared to the anisotropic porosity of the conventional preheating method [76].

This method's resulting crystallographic phases most commonly produced were B2 (NiTi) and B19' (NiTi). Li et al observed that up to 57% porosity with about 86% open porosity could be achieved with this method [77]. These results corroborate with Aihara et al reported 60vol% porosity for improved cell response. The correlation between vol% and cell size and interconnectivity will be briefly discussed here but more so in the biological properties section of the review. Pore morphology in the NiTi alloy may be tailored by varying the particle size distribution, binder use, compaction pressure, and preheating temperature of the green compact. Porosity due to unforeseen events may be present due to differences in molar volume and Ni and Ti diffusion flux. Gas bubble formation at high-temperature during the combustion phase is another reason [77].

Aihara et al work displayed the practicality and advantages associated with the low-cost CS method. Expanding on the fundamental knowledge and research associated with the CS of Nitinol, Aihara et al work attained a successful three-dimensional anisotropic structure with open-cell interconnectivity. The produced structure exhibited comparable effective stiffness of cancellous bone at 1 GPa, achieved by producing 60vol% porosity and pore size of 100–500 μm. A homogenous composition comprising cubic and monoclinic NiTi was achieved without observing pure Ni or Ni-rich phases. The results showed increased corrosion resistance, rapid osseointegration within two weeks, and complete bone growth in six weeks.

2.2.3. Vapor deposition.

Vapor deposition is a relatively new metallurgical process for producing high-porosity metal structures with homogeneous porosity. The method involves using medical-grade polyurethane foam to produce a low-density reticulated vitreous carbon skeleton (RVC) by reticulation and pyrolyzing. These RVC skeletal structures are then machined and shaped into preforms, determining the pore morphology of the final porous structure. Then, using a specialized chemical vapor deposition/infiltration (CVD/CVI) technique, tantalum (commercially pure) is deposited throughout the RVC preforms [78]. In CVD/CVI process, generally, reactants in the gaseous phase are activated such that they chemically react, and solid material is deposited on a substrate. The process is schematically illustrated in figure 7(a). The reactant gases and carrier gas enter the reaction chamber at room temperature and are then heated via radiation close to the deposition surface or a heated substrate [78]. The heated reactant gases homogeneously undergo a chemical reaction in their vapor phase before striking the substrate and being deposited. However, this reaction and the products of this reaction are strongly dependent on the process and operating conditions. Ultimately, the reaction products are deposited on the substrate, and the gaseous by-products are eliminated from the chamber [13].

Figure 7. The chemical vapor deposition (CVD) process and produced porous structures. (a) Schematic of the vapor deposition process. Reprinted from [13], Copyright (2006), with permission from Elsevier. (b) Porous Ti6Al4V scaffolds without tantalum coating (left) and with CVD tantalum coating (right). Optical high magnification micrographs depicting the porous Ti6Al4V structure (c) before coating and (d) after CVD tantalum coating. Reprinted from [82], Copyright (2013), with permission from Elsevier.

Download figure:

Standard image High-resolution imageThe porosity and the mechanical properties of the structure produced by this method depend primarily on the duration of the CVD process. Typically porosities produced by this method are in the range of 75%–85% (as in Trabecular metal) with an average pore diameter of 550 μm [79]. The scaffold-like Ta structure obtained via this method is comparable to that of the cancellous bone in open interconnected porosity and strut thickness, observable in figures 7(b) and (c). The porous structure obtained by this method displayed a 99% Ta and 1% vitreous carbon by weight presence [79]. Further investigations of the mechanical properties of porous Ta produced via this method indicated that the material's strength, stiffness, and flexural rigidity increased with increasing density [80]. Ta has been under continual investigation as numerous studies have reported that the mechanical properties of porous Ta far exceed those of other biocompatible metals. Moreover, the porous Ta structure showed superior ductility to other porous materials [81].

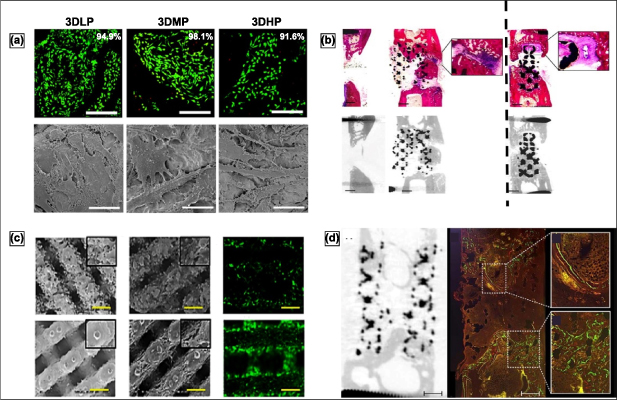

2.2.4. Additive manufacturing.

Rapid prototyping or 3D printing is a relatively novel manufacturing process that has proven to produce porous implants of varying sizes, shapes, and porosity—all tailorable directly from the computer-aided design (CAD) to the machine with minimal to no tooling requirement [83, 84]. Additive manufacturing (AM) techniques used to produce porous biomaterials are displayed in table 3, along with details associated with the most common vendor, process, and material details [85, 86]. In the case of porous metallic orthopedic implants and scaffolds, AM-based processes lead the recent advances. Various AM processes are currently being used to manufacture metallic implants, figure 1 [13, 86]. The AM technologies have significantly contributed to porous scaffolds to enhance biocompatibility [87–89].

Table 3. Various additive manufacturing methods, commercially available techniques, processing details, and materials.

| 3D printing techniques | Commercial technologies/vendors | Process details | Processing materials | Advantages/disadvantages [90] |

|---|---|---|---|---|

| Vat Polymerization | Stereolithography by 3D systems | Layer-by-layer fabrication by curing thermoset photopolymer via exposure. | Mostly photocurable, thermoset polymers | High level of accuracy and finish, relatively quick, relatively large build areas and model weights (200 kg)/relatively expensive, time-consuming post-processing of resin removal, limited photo-resins, requires support structures and post-curing |

| Bioplotters by Envisiontec | ||||

| Large Area Maskless Photopolymerization by DDM Systems | ||||

| Lithography-based ceramic manufacturing—Lithoz | ||||

| Material Extrusion | Fused Deposition Modeling by Stratasys | Layer-by-layer deposition via extrusion of usually thermoplastic polymers or polymer-ceramic composite. | Various polymers and ceramics include Polycaprolactone, Hydroxy Apatite (HA), Polylactic Acid, Bioglass, Polyethylene Glycol (PEG), etc. | Very common process and inexpensive, suitable for prototyping/nozzle radius limits the part quality, accuracy, and production speed are low for larger parts |

| Powder bed fusion | Selective laser sintering by 3D Systems | Layer-by-layer selective sintering or melting of powder particles on a powder bed system via laser- or electron-beam-based heat source. | Many metals or alloys such as Ti/T alloys, Stainless Steel, Ni-Ti, etc. Ceramics were also reportedly used. | The powder acts as a support structure for intricate part fabrication, a variety of material options/ |

| Electron Beam Melting by Arcam | ||||

| Direct Metal Laser Sintering by EOS | ||||

| Selective Laser Melting from SLM solutions | ||||

| Directed energy deposition | Laser Engineered Net Shaping by Optmec Inc. | Powder particles are simultaneously flowed through a nozzle and fused using a heat source (Laser, wire arc, and Electron Beam) | Many metals or alloys such as Ti/T alloys, Stainless Steel, Ni-Ti, etc. Ceramics were also reportedly used. | Ability to control grain structure, low raw material loss/may require post-processing for desired surface finish, warping with larger/taller structures |

| Direct Metal Deposition by DM3D | ||||

| Electron Beam Welding by Sciaky Inc. | ||||

| Material Jetting | Objet by Stratasys | Material is jetted through an ink jet type nozzle, continuously or Drop on Demand (DOD), and solidifies on a substrate, building the part layer-by-layer. | A wide variety of polymers and ceramics can be used. | High accuracy and low material waste, multi-material and varying color capabilities/support material required; only polymers and waxes may be used |

| Solidscape 3D printers from Solidscape | ||||

| Multi-Jet Fusion Technology by HP | ||||

| Binder Jetting | ZCorp | Like material jetting, a binder is jetted selectively onto a powder bed, fusing the desired powder particles, which lowers to accommodate the next layer of powder. | A wide variety of polymers and ceramics can be used. | Varying color capabilities, metals, polymers, and ceramics may be used, large binder-powder combinations for varying mechanical properties/high porosity in metals, post-processing time can be significant |

| ExOne | ||||

| Voxeljet | ||||

| Sheet Lamination | MCor Technologies | Thin sheets of material are bound together and ultrasonically welded together. This process continues layer by layer. | Metallic sheets could be used to build simple geometries. | Low cost and fast, ease of material handling/strength and integrity rely on adhesive, limited material usage |

The general advantage of using rapid prototyping processes over conventional powder metallurgy processes in fabricating porous metal structures is that powder metallurgy, particularly sintering, produces brittle structures with limited control over pore size and shape, volume fraction, and distribution. Moreover, some conventional processes using foaming agents or molten metal generally result in contaminants and impurity phases [91]. Thus, 3D printing or AM has shown to be the future for producing patient-specific implant structures with controlled shape and porosity. Studies investigating porous metal-based rapid prototyping will be elaborated for some of the more common methods.

2.2.4.1. Powder-bed-based metal AM methods.

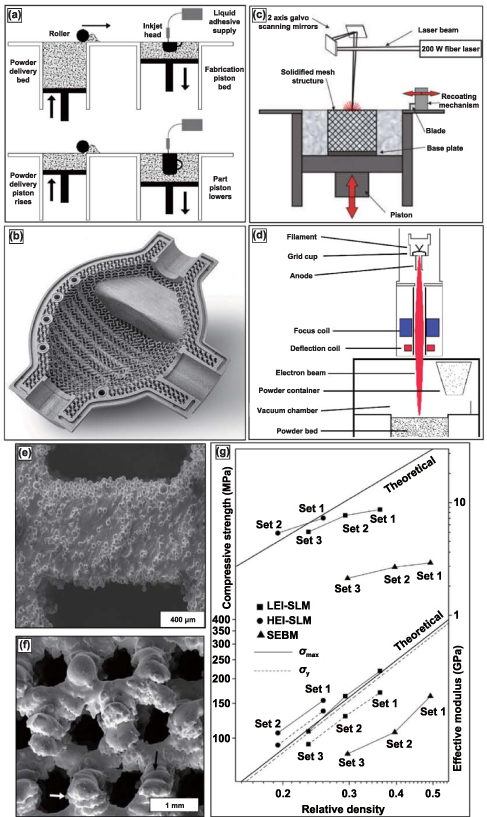

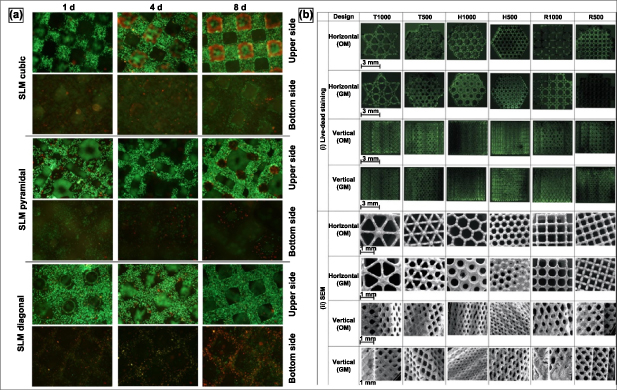

Several variations of powder-bed AM exist—binder jetting, selective laser melting (SLM), and electron beam melting (EBM). Binder jetting, displayed in figure 8(a), uses print head technology similar to ink-jet printing; the binder selectively prints the part layer-by-layer with a binder. This process is repeated until the entire part is completed, commonly called the green part. The green part is then pulled from the print bed, de-powdered, and fired for binder burnout and densification. The binder gives the green part sufficient structural rigidity for de-powdering and firing. Porous surface metal implants with extremely controlled surface porosity and texture, as shown in figure 8(b), can be obtained [13]. SLM and EBM, displayed in figures 8(c) and (d), respectively—unlike binder jetting—rely on thermal energy input during layer-by-layer production for part fabrication. SLM utilizes a laser source to selectively melt and bond the metal powder particles, whereas the EBM method uses an electron beam source—most commonly from a tungsten filament. SLM is usually performed in an inert Argon atmosphere, while EBM is conducted under high vacuum conditions. The benefit of fabricating under a vacuum in the EBM method is a significant reduction in oxidation products and impurities, in general. The three variations of powder bed AM produced porous metal structures of complex geometries with controlled internal architectures.

Figure 8. Binder jetting, selective laser melting (SLM), and electron-beam melting (EBM) process with produced structures and compressive testing data. (a) Schematic of the binder jetting process for manufacturing porous metallic structures. Reprinted from [13], Copyright (2006), with permission from Elsevier. (b) Typical surface resolution of a part built using the binder jetting process. Reproduced with permission from [98]. (c) Schematic representation of SLM and EBM setups for [92] John Wiley & Sons. Copyright © 2008 Wiley Periodicals, Inc. and (d) Reprinted from [99], Copyright (2016), with permission from Elsevier respectively. (e) Reprinted from [96], Copyright (2013), with permission from Elsevier and (f) display microstructures of porous Ti6Al4V samples prepared via SLM and EBM, respectively. [97] John Wiley & Sons. Copyright © 2011 Wiley Periodicals, Inc. and, (g) comparative mechanical properties of porous Ti6Al4V samples prepared via SLM and EBM processes. Reprinted from [96], Copyright (2013), with permission from Elsevier.

Download figure:

Standard image High-resolution imageThe schematic of the SLM method has been indicated in figure 8(c), and it should be noted that this method is suitable for any processable powder, either elemental or alloy, with ideal flowability [92]. The parts could be built layer-wise on a substrate that could be moved vertically downwards using a scanning laser source in an argon environment (<0.2% O2 levels). The powder exposed to the scanning laser is fully melted, and depending on how high the laser energy density is, either fully dense or porous metallic structures could be manufactured. Furthermore, it should be realized that the best results of this process could be obtained from powders with better laser absorbability and lower thermal conductivity. Higher laser absorbability of the powder ensures lower laser energy density required to melt the powder, and lower thermal conductivity implies that the melt pool remains small and concentrated in the region where the laser is directed [92].

In the case of the EBM method, as shown in the schematic in figure 8(d), the tungsten filament housed in an electron beam head reacts with excited electrons resulting in an electron beam [93]. Then, using two different magnetic fields, the electron beam is first organized into the desired shape and then focussed towards the target position on the metal powder on a powder bed that is retractable, and the part is built layer by layer as per the sliced information of the CAD model. The entire part-building process usually occurs under a high vacuum, ensuring low oxidation and low impurity phases. SLM and EBM processes require post-processing to blow or clean the excess unbonded metal powder particles [94, 95].

SLM and EBM processes can produce structures with up to 80% volume porosities. The mechanical properties can be tailored by varying the process parameters, including energy input and part orientation to the main loading direction. The SEM images of the microstructure of the porous Ti alloy structures built using SLM and EBM are shown in figures 8(e) and (f), respectively. These images show partially melted metal particles sintered at the surface [96, 97]. In one of the studies, which compares the mechanical properties of SLM-made and EBM (or also SEBM) made porous Ti structures, it was observed that there is a considerable difference in the mechanical properties of structures of similar porosity. SLM-produced porous structures were observed to have much thinner struts than the designed dimensions, whereas EBM produced much thicker struts than the intended design thickness. This implies that the SLM-made structures have higher relative porosity for the same designed structure than the EBM-made structure [93]. Also, the microstructural comparison showed that the SLM-based structures comprise α' phase (martensitic), whereas the EBM-based structure comprises α + β equilibrium phases [96].

A comparison of the effective stiffness and the ultimate compressive strength between SLM and EBM-made and also theoretical stiffness and strength of porous Ti structures of similar relative density (as shown in figure 8(g)) shows that SLM-made Ti structures have improved mechanical properties compared to the EBM-made porous Ti structures and similar (or slightly lower) than the theoretical values [80, 93, 96]. A similar conclusion has been obtained for the comparative investigation conducted for porous Ti6Al4V structures made from SLM and EBM methods. EBM-processed structures tend to show higher ductility despite lower stiffness and strength properties. These mechanical property differences between SLM and EBM-made porous structures could be attributed to the difference in the microstructural phases induced by each process.

2.2.4.2. Directed energy deposition (DED) of porous metallic materials.

The DED technique eliminates the need for a powder bed; the raw material—metal powder or metal-wire filament—is fed into the melt pool created by a focused energy source. The energy source can be a laser, electron beam, or a current-discharge induced electrical arc, which is the case with wire-based DED. Currently, there are many variants of the DED technique that are commercially available, which largely depend on raw material (powder-based or filament-based), energy source (laser or electron beam-based), or CNC control (substrate controlled or source controlled) [100].

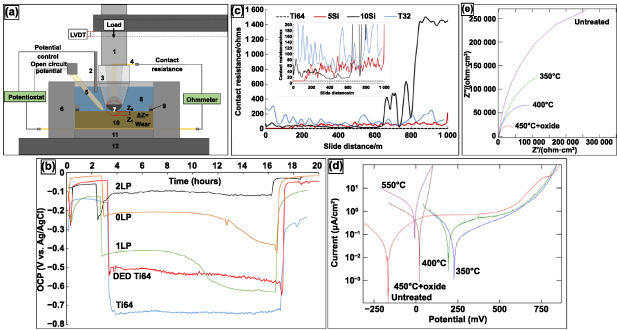

Sandia National Lab first developed the blown-powder DED technique to manufacture a metal part directly from a CAD file. The part deposition begins with directing a focussed laser beam, usually Nd-YAG, on the metal substrate to produce the melt pool; at the same time, metal powder is injected directly into the melt pool through a coaxial deposition head by the use of carrier gas, as displayed in figure 9(a) [101]. Compared to conventional sintering methods, one advantage of the DED technique is the ability to either entirely melt or sinter fuse the metal particles at a fraction of the time and thermal energy requirement. Bonding between metal particles is formed in the molten state in contrast to the solid-state diffusion-based bonding observed in the sintering process. Furthermore, from the deposition methodology, it has been reported that the cooling rates for this process are extremely high—in the range of 103–105K·s−1. The high cooling rates promote solid-state phase transformation and the formation of a supersaturated solution with non-equilibrium phases. Very fine microstructures are formed, having extremely low elemental segregation and fine second-phase particles. Moreover, by altering the process parameters such as the laser power, layer thickness, powder flow rate, scan speed, scan pattern, etc, the effective modulus, porosity, and several other mechanical properties can be altered. Additionally, considering the fabrication process occurs in an inert atmosphere, compositional purity is unaltered [101].

Figure 9. Directed energy deposition (DED) technique displaying the porosity variability. (a) Schematic of DED-based metal additive manufacturing setup; (b) schematic for fabrication of porous structures using DED. Reproduced from [101], with permission from Springer Nature. (c) Design concept to fabricate complex or functionally graded structures using DED by (i) partial melting, (ii) designed porosity, (iii) combination approach, and (d) transverse and longitudinal micrographs of LENSTM made porous Ti compacts. Reprinted from [16], Copyright (2007), with permission from Elsevier.

Download figure:

Standard image High-resolution imageControlling the porosity can be done in two ways—(1) by introducing inter-particle porosity or (2) by varying scanning strategy. By altering the process parameters, the total energy input—energy density—into the melt pool may be controlled; lower thermal energy density facilitates partial melting of the metal particles, allowing for inter-particle porosity. On the other hand, the toolpath porosity is scanning strategy-based, most commonly allowing for physical separation of independent beads of deposited material, i.e. hatch spacing. The scanning strategy allows for fabricating functionally graded porosity or precise internal porosity architecture. Illustrations for the fabrication of porous parts using a commercial DED process, known as laser-engineered net shaping or LENSTM are displayed in figure 9(b) [101], and a design concept for building complex or functionally-graded porosity is shown in figure 9(c) [16]. Such fabrication feats have allowed for the advancement of metallic biomaterials for patient-specific implantation sites.

A high volume of published literature investigates LENSTM-based porous metal structures' mechanical, biomedical, physical, and chemical properties. For instance, LENSTM-made porous Ti or Ti6Al4V structures were studied to understand the dependence of the stiffness and the strength of the material on the porosity and the pore morphology. As discussed above, the material's porosity depends chiefly on the process parameters and scanning strategy. It was observed that about 20%–70% highly interconnected porosity, with >90% open porosity, could be achieved using lower laser power, higher scan speed, higher hatch distance, and higher powder feed rate—equating to low powder mass flow rate and low thermal energy density. Micrographs of LENSTM transverse and longitudinal sections made of porous Ti parts are displayed in figure 9(d). The micrographs displayed preferential pore connectivity in the longitudinal build direction than in the transverse orientation for parts with lower porosity. However, as the porosity increases, pore interconnectivity becomes more uniform [16]. Another critical relation between the various process parameters of the LENSTM method and the porosity is that while the laser power, scan speed, or the powder feed rate affect the porosity, the pore size remains unaffected by these parameters and is singularly influenced by the hatch distance; that is, as the hatch distance increases, an increase in mean pore diameter occurred [42].

2.2.5. Fiber mesh-based porous implants.

An additional AM method for fabricating porous coatings on implant surfaces for enhanced cementless implant fixation is via sintering fiber meshes, comparable to the sintering of powder metals. The advantage of using fiber meshes instead of metal powders is that the porosity of the coatings obtained through this method is almost always interconnected, enhancing bone ingrowth and implant fixation [13]. In this method, the metal fibers are usually compacted onto the implant surface, requiring a biocompatible coating, while the sintering process follows. During the sintering process, metallurgical bonds are formed at points of physical contact between the fibers and the implant surface—attaining sufficient mechanical strength. However, the major disadvantage of using fiber mesh is that it is unfeasible to prepare fiber mesh compact on the implant surface using sufficient compaction forces for complex implant shapes. Furthermore, fiber mesh loss of contact with the substrate due to relaxation post-compaction is quite common, leading to regions of poor bonding with the implant surface. Regarding mechanical stability, the literature suggests that fiber mesh coatings show improved stability than powder-sintered coatings; however, if the failure mode is observed, fiber mesh coatings fail via tearing instead of crack propagation [53]. Also, the porosities of these fiber mesh coatings are usually limited between 30%–50%, which influences the maximum possible strength of the implant fixation via bone ingrowth and is usually attained by non-homogeneous porosity. Although the literature on sintered fiber mesh coatings is available for both stainless steel and Ti, only Ti fiber mesh coatings are available clinically [53–57, 102].

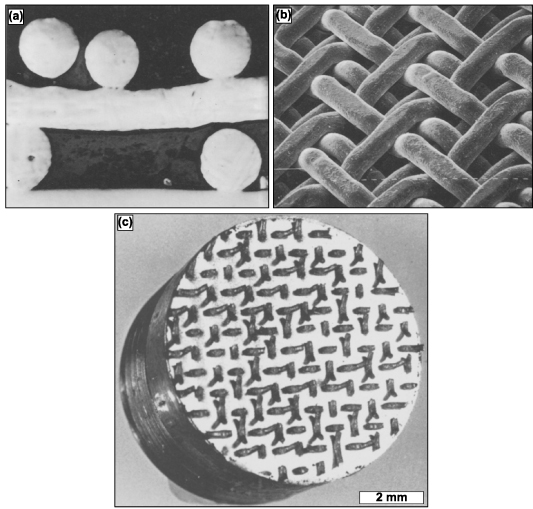

A variant of fiber mesh sintering for producing homogenously distributed porous coatings is orderly-oriented wire mesh (OOWM). This method uses woven continuous long metal small-diameter fibers instead of short fibers for compaction to form an orderly meshwork. The woven fiber mesh is pre-compacted to improve contact with the implant surface and then pressure sintered, analogous to hot isostatic pressing (HIP). The advantage of the OOWM method over the fiber mesh sintering method is that the issues, such as fiber detachment from the implant surface, are avoided. Moreover, twill weaves have been used instead of the regular weaved mesh. These are formed by consecutively passing the metal wires above and below two crossing wires, and any two neighboring wires running parallel pass a crossing wire from above to below, as displayed in figures 10(a) and (b). The advantage of using a twill weave lies in the ease of mesh fabrication, and the following coating procedures also become more accessible because of the improved flexibility and formability of the twill-woven fiber meshwork [103]. Additionally, their performance under tensional testing displayed no failure along the interface, as displayed in figure 10(c).

Figure 10. Twill-weaved triple orderly-oriented wire mesh (OOWM) process for porous coating production. (a) Cross-sectional micrograph and (b) SEM image of twill-weaved triple OOWM coating, in which the mesh size is 16 and wire diameter is 500 μm. Reprinted from [103], Copyright (1986), with permission from Elsevier. Displayed in (c) is a Ti OOWM-coated sintered sample post-tension testing revealing that failure did not occur at the interface. Reprinted from [104], Copyright (1986), with permission from Elsevier.

Download figure:

Standard image High-resolution imageA final method known as ferromagnetic fiber arrays use ferromagnetic metal fibers to fabricate porous coatings; these use a magneto-mechanical mechanism to induce slight deflection into the porous coatings via an applied external magnetic field. These magnetic field-induced strains and deformations are believed to stimulate bone ingrowth into the pores—as reported, a minimum of 0.1% strain is necessary to stimulate bone growth into the porous coating. Thus, metal implants coated with highly porous, bonded ferromagnetic fibers under an external magnetic field enhance implant-host tissue fixation. In this method, the porous coatings were produced by spraying fibers with slow-setting aerosol glue, surface dispersed brazing powder, and then placed in a long quartz tube at 1200 °C [105]. The coating thus produced high porosities ranging from 70%–90%, with pore size ranging from 100–300 μm. Moreover, ferromagnetic materials also tend to have better corrosion resistance in a biological environment than non-ferromagnetic materials [106–108]. Such properties are highly sought in porous metal implants as corrosion by-products can adversely affect the physiological environment.

3. Properties of porous metallic materials

When considering all the fabrication methods for the production of porous metallic structures, porous coatings, or functionally graded porous structures (discussed in the previous section), it can be understood that different pore shapes, sizes, and interconnectivity could be obtained. However, the type and volume fraction of porosity governs several inherent characteristics of the porous structure and its applicability as an implant material. It was discussed in the earlier parts of this review that one of the significant advantages of porosity in metallic implant structures is that it allows bodily fluids to flow through and hence facilitates bone ingrowth which would provide proper anchorage to the implant with the host tissue, thereby increasing the lifetime of the implant. However, this bone tissue ingrowth mainly depends on the pore size and morphology.

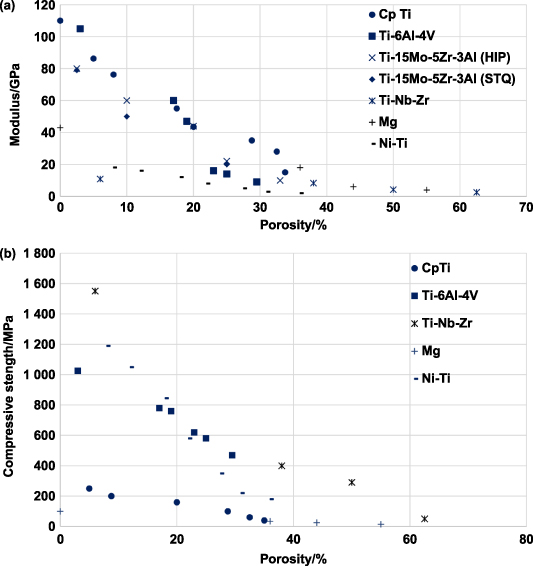

It was generally observed that the pore shape had limited biological response [101], whereas pore size and interconnectivity primarily affect the bone tissue ingrowth capability [50, 109–116]. It was accepted that interconnected pore sizes in the 100–400 μm were required for optimal bone ingrowth [50]; however, some bone ingrowth was also observed with pore sizes as small as 50 μm [115, 116]. In the case of substantial pore sizes (>1 mm), there seemed to be a higher possibility of forming fibrous tissue, which is detrimental to the implant's lifetime as it would eventually cause aseptic loosening of the implant. Another advantage of using porous metallic structures as orthopedic implants are the reduced structure stiffness. As discussed earlier, a much stiffer implant material induces stress shielding, weakening the surrounding host tissue and causing implant loosening. Thereby, a porous metallic implant would have a lower stiffness than a dense implant, and its stiffness could be modeled by altering the porosity and pore morphology such that the implant stiffness is in the same range as the surrounding bone stiffness.

Porosity in a metallic implant structure also introduces inherent limitations in the mechanical behavior of the load-bearing implant structures. The implant's mechanical strength, dynamic load-bearing capabilities, and corrosive properties are expected to be negatively affected due to porosity. Also, the porosity predominantly affects the implant structure's biological compatibility. Thus, numerous investigations have been conducted to understand and quantify the effect of porosity on the mechanical behavior of porous metallic orthopedic implants, and in this section, the results, findings, and inferences of various studies investigating the physical, mechanical and biological properties of the porous metallic structures would be discussed.

3.1. Physical properties

Porous metallic structures' physical properties include porosity, density, and hardness. The methods of measuring these properties and the reported values for these physical characteristics will be discussed in detail in this section.

3.1.1. Porosity and density.

The porosity and density of a structure can be used interchangeably, in most cases, depending on engineering vernacular. This is because as a structure's porosity increases, the structure's density decreases and vice versa. Moreover, as discussed previously, porosity has two types: open- and closed-cell porosity. If the pores are interconnected and allow for the free flow of fluids, they are called open pores; if the pores are isolated and negate fluid flow, they are called closed pores. One commonly used method for measuring the total porosity is gravimetry. First, the apparent density of the porous structure is calculated by measuring its total volume and weight [65]. Then, the total porosity (PT ) is calculated using the following equation:

where,  is the apparent density of the porous structure.

is the apparent density of the porous structure.  is the bulk density.

is the bulk density.

The total porosity of the structure combines open- and closed-cell porosity. For orthopedic implants, open and interconnected porosity is desired to facilitate bone tissue growth and improve implant anchorage; it is necessary to know what fraction of total porosity is open porosity. One method used to measure the fraction of open porosity is the infiltration of paraffin into the open pores of the structure by boiling the sample in paraffin in a vacuum chamber. Subsequently, the weight and volume of paraffin penetrating the porous structure are measured. The fabrication method and the processing parameters usually determine the total porosity that can be achieved and the open porosity fraction. However, depending on the metal or alloy being investigated, an optimal porosity could be achieved, making the mechanical properties, such as effective stiffness and strength, comparable to that of the target bone structure. Previously reported, it was observed that a porous Ti structure with a three-dimensionally interconnected open-cell network achieved porosity in the range of 35%–42% and a porous Ti6Al4V structure with porosity in the range of 23%–32%. Both result in mechanical properties similar to human cortical bone [93, 117].

3.2. Mechanical properties

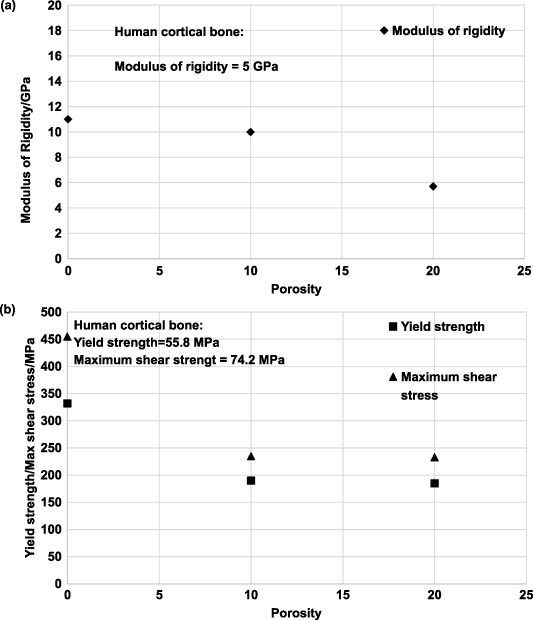

Similar to the physical properties desired by orthopedic implants, a load-bearing implant must meet specific mechanical property criteria appropriate for the implantation site. Therefore, it is critical to understand the biomechanics of the host bone site for a proper match with the porous metallic implant for hard tissue replacement or implantation. The skeletal system sustains mechanical loading of several modes with continuously changing loading vectors; such force examples can be simple reaction forces at the hip joint to bending moments and torsional strain along bone segmental bodies. Several investigative studies were conducted on the bone structures to understand the different loading mechanisms endured and the capacity of the load that the skeletal system can endure. Generally, it was observed that the skeletal system experiences loading in uniaxial compressive, flexural, multiaxial, and dynamic loading, such as fatigue or high strain rate [118–121]. Thus, general knowledge of the mechanical properties desired by the porous metallic orthopedic implant has been surmised in literature, which will be discussed.

3.2.1. Hardness.

The hardness of a material is defined as its resistance to localized penetration, scratching, bending, and/or plastic deformation. A material's hardness is usually measured using an indentation tester under a load. Varying names for the differing methods of hardness exist. Among the most common examples are Mohs, Shore, Brinell, Rockwell, Vickers, and Knoop. The application of each type of hardness testing varies for use in minerals, polymers, and metals and even for thin materials. The hardness number is based on the applied force divided by the surface area of the indent and sometimes assesses the microstructural phase changes of the material [122]. The resulting units are in force per area, but it is not to be mistaken for pressure.

AM-based literature typically uses the microhardness characteristic to quantify the degree of hard phase presence resulting from the fabrication process. DED-processed porous CpTi will typically not display an increase in hardness when processed in this fashion; however, the hardness will increase for LENSTM Ti6Al4V. The presence of aluminum (Al) and vanadium (V) in the Ti matrix influence the stability of crystallographic phase presence at room temperature. Al is an α-phase stabilizer in Ti, while V is a β-phase stabilizer [123]. The β-phase is only present in pure Ti when heated to a temperature above 880 °C; upon cooling, the β-phase undergoes a diffusion-less solid-phase change to α-phase. Suppose phase stabilizing constituents are present in the diffusion-less transformation from β-phase to α-phase. In that case, the resulting crystal structure may result in an interstitial atomic-induced strained configuration and thus result in an increase in hardness at room temperature compared to conventionally prepared samples [124]. Therefore, the increase in microhardness of LENSTM processed samples is directly correlated to the fine needle-like α'-phase and β-phase [125]. Without in-depth materials characterization, hardness testing will provide insight or validation into the crystallographic phase presence.

Although the correlation of hardness increase of Ti6Al4V with LENS TM treatment was discussed, it does not say that varying laser parameters will affect hardness. The contributing factor appears to be simply treatment vs. no treatment. CpTi and Ti6Al4V do not exhibit a change in hardness with the change in laser parameters, even when porosity changes. This indicates that the laser parameters do not influence phase presence, thus allowing biocompatible phases to remain present in structures with varying porosities [124, 126]. Additionally, the hardness of a metallic material decreases as the microstructure becomes coarser, following the Hall–Petch effect; this is because finer grain microstructures tend to create lower stress concentration sites due to dislocation pile up at the grain boundary and thus would require higher stress to deform plastically [127]. Furthermore, it was observed in several studies that the composition of the alloy and the processing temperature influence the hardness of the structure. In the case of processing parameters that influence the phase stability of a material, the hardness value also depends on these parameters. However, in the case of laser-prepared Ti alloys, the process parameters tend to have a negligible effect on the varying phase composition; thereby, the material's hardness remained unchanged [128]. Microhardness, values of different materials processed via different methods, are reported in table 4 for comparison.

Table 4. Microhardness values of various materials investigated by several studies.

| Material | Fabrication process | Porosity | Hardness | References |

|---|---|---|---|---|

| Ta | LENS | — | 395 ± 30 | [19] |

| EDM | — | 240–393 | [81] | |

| CpTi | Space holder method | — | 258–263 | [60] |

| SPS | — | 163 | [118] | |

| Ti-6Al-4V | SLM | — | 483 | [119] |

| EBM | — | 410–442 | [120] | |

| EBM-High Energy | — | 364 | [121] | |

| EBM-Low energy | — | 372 | ||

| LENS | 10% | 251 | [23] | |

| 20% | 259 | |||

| Ti-Mn alloys | SPS | — | [118] | |

| Ti5Mn | — | 372 | ||

| Ti2Mn | — | 245 | ||

| Ti12Mn | — | 538 | ||

| Ti-Nb-Zr alloys | NH4HCO3 spacer | — | [128] | |

| 2-step foaming process | — | |||

| Ti20Nb15Zr | 0% NH4HCO3 | 5% | 290 | |

| 20% NH4HCO3 | 36% | 260 | ||

| 35% NH4HCO3 | 48% | 155 | ||

| 50% NH4HCO3 | 63% | 110 | ||

| Ti | 50% NH4HCO3 | 63% | 254 | |

| Ti20Nb15Zr | 63% | 110 | ||

| Ti35Nb15Zr | 63% | 56 | ||

| Ti20Nb15Zr | 1473 | 290 | ||

| 1673 | 256 |

3.2.2. Static mechanical properties.

Static mechanical properties of any material generally include stiffness, creep, yield criterion, uniaxial strength properties, and multiaxial strength properties. Since load-bearing implants are likely to be subjected to compressive loads, ample literature has reported the compressive behavior of different porous metals. Considering that the primary reason for using porous metals in orthopedic implants is to alleviate stress shielding, the effects of porosity and stiffness of the porous structure on the compression strength have been investigated extensively. Furthermore, research has also examined the tensile strength properties and the multiaxial behavior of porous metals. Most of the static mechanical properties reported in the literature and discussed in this section have been enlisted in table 5.

Table 5. Critical mechanical performance values for porous metallic biomaterials.

| Material | Fabrication process | Porosity (%) | Young's modulus (GPa) | Compressive yield strength (MPa) | Compressive ultimate strength (MPa) | Flexural yield strength (MPa) | Torsional properties | ||

|---|---|---|---|---|---|---|---|---|---|