Abstract

The development of armour is as old as the dawn of civilization. Early man looked to natural structures to harvest or replicate for protection, leaning on millennia of evolutionary developments in natural protection. Since the advent of more modern weaponry, Armor development has seemingly been driven more by materials research than bio-inspiration. However, parallels can still be drawn between modern bullet-protective armours and natural defensive structures. Soft armour for handgun and fragmentation threats can be likened to mammalian skin, and similarly, hard armour can be compared with exoskeletons and turtle shells. Via bio-inspiration, it may be possible to develop structures previously un-researched for ballistic protection. This review will cover current modern ballistic protective structures focusing on energy dissipation and absorption methods, and their natural analogues. As all armour is a compromise between weight, flexibility and protection, the imbricated structure of scaled skin will be presented as a better balance between these factors.

Export citation and abstract BibTeX RIS

1. Introduction

Man has been creating protective armour since the very dawn of combat. From the practice of wearing animal skins as a means of protection, to medieval metallic armours, analogies to biological protective structures can be made throughout its development. By necessity, armour has evolved due to the threats encountered on the battlefield in order to increase survivability. Similarly, natural selection has weeded out the less effective defensive mechanisms and therefore, something can be learned from what has survived. Biomimetics, the study of biological materials and structures to inspire design, is one of the new frontiers in engineering allowing researchers to tap into millennia of evolutionary development [1, 2]. Biological armour systems have been developed in nature to defeat penetrating injuries and crushing blows from predators while maintaining mobility for daily activities and food scavenging. Man-made protective equipment followed an analogous development in keeping with the technology of the time, shown below in figure 1. Shields and other monolithic structures have been around for millennia but one of the first known armours to show a clearly bio-inspired structure was the lorica segmenta developed by the Romans; an early imbricated armour design [3, 4]. The use of metal bands that encircled the body overlapping each other in similar to shell design of an armadillo or the segmented body of many arthropods. Other implementations of imbricated armours included jazeraint, lamellar, and the armour worn by samurai [5, 6]. Chain mail was another common structure of overlapping metal rings similar to scales that became more common due to the lower cost of construction [6]. However, the proliferation of bows—especially higher velocity crossbows—rendered these armours ineffective which led knights to employ the prototypical plate armour [3]. This armour was more reminiscent of arthropods use of solid exoskeletal systems with articulations at the joints. However, all of these systems were heavy—especially plate armour—due to the materials and technology of the times. With the advent of firearms, most of these types of armour became obsolete or even a liability due to the encumberment [5]. Therefore, the preference was to forego armour for the sake of agility until materials and technology could catch up to the new, high velocity, ballistic threats. These armours developed more with materials advancement than with the bioinspired structures of early armours.

Figure 1. Biological armours, historical armour analogues, and modern ballistic incarnations. As will be shown, skin is a nature analogue for soft armour, turtle shells and arthropod exoskeletons are analogues of hard armour but there is no modern ballistic intermediary that could correspond with scales.

Download figure:

Standard image High-resolution imageSome of the first ballistic armour systems ever developed were flexible, soft armour packages made from layers of cotton or silk fibres [7]. Soft armour is characterized by utilizing layers of ballistic fabric to arrest projectile impact while maintaining a flexible armour package. With the dawn of the industrial revolution in the 20th century, these natural fibres gave way to high modulus synthetic materials with greater performance at a lower weight. The most notable was the invention of Kevlar® by the chemical company DuPont. Kevlar® and similar para-aramid fibres are still some of the most commonly used in armour to this day. Soft armour is the most regularly used type of armour on the market today due to its relatively light weight and low bulk for easier concealment. Law enforcement officers rely on this level of protection and soldiers utilize soft armour protection where harder armours are impractical. However, the relative light weight and ease of use of soft armours is offset by its ballistic limitations. To date, soft armour has only been employed commercially to defeat relatively low velocity threats such as handgun rounds and fragmentation threats. In order to attain higher levels of ballistic protection, hard armour designs must be used. One of the first manifestations of hard armour was seen in Australia in 1879 when members of Ned Kelly's bushranger gang devised armour from plough blades to protect against the firearms of law enforcement personnel. The 'Kelly Armour', however, was estimated at weighing close to 96lbs making it impractical for modern combat [7]. The United States started designing body armour systems including the 'Brewster Body Shield' made of chrome nickel steel which saw action in WWI [8]. At close to 40 lbs, this system was heavy and clumsy. As armour development continued, the transition was eventually made to ceramic replacements for metal for weight reduction. Hard armour is utilized today when it is necessary to defeat rifle threats or hardened penetrating threats such as armour piercing (AP) rounds. Depending on the intended threat class, designers may employ plates made from solely polymer matrix composites or may use hard ceramic cores.

What is not seen in modern ballistic armours, are the bio-inspired structures that look to balance weight, flexibility, and protection. While man-made armours have been in development for centuries, nature has been developing protective systems for millennia. It was with good reason that early civilizations looked for inspiration from natural systems around them. From the thickened hides of large mammals, to the imbricated structures of scales, nature has developed methods to balance protection with practically and mobility. While man-made weaponry has developed past any kind of threat seen in nature, parallels can still be drawn between the respective armours. It is important to note that natural protective structures have obviously never evolved to handle the high-velocity penetration of ballistics threats so this review focuses on the mechanisms employed in nature to distribute and mitigate force. Many works have already been undertaken to evaluate potential benefits from the hierarchical materials developed over millennia of evolution [1, 9–12]. As further study is undertaken on biological armour, it is increasing apparent that there is still lots of inspiration that can be drawn for modern man-made protection. Trade-offs will always be made for weight, flexibility, and protection and they must be taken into account with an understanding of the battlefield. Areal density and stiffness equate to encumberment which must be balanced with the potential for the defensive structure to absorb impact energy. For example, smaller, faster animals have developed less armour-like protection as they derive greater survival rates with their ability to evade without these structures to weigh them down. With ballistic armours, the relative velocity of the user to the threat is quite low and therefore, the analogues examined below come from larger or slower animals that have had to develop physical methods of protection as their primary form of defence. This review will focus on three types of natural armour: mammalian dermal shields as an analogue to soft armour, turtle shells and arthropod exoskeletons for hard armour, and scales which combine flexibility and protection in a way that has yet to be successfully mimicked in a modern man-made armour systems. The selection of natural analogues was completed by comparing methods for energy dissipation in form factors that allowed sufficient mobility for the hosts. For example, the shellfish were not considered because the protective shells do not integrate with a means of locomotion. The intent is to find the convergence between biological systems and engineered armours to be able to enhance survivability in future conflict.

2. Background: ballistic armour

As has historically been the case, the higher the threat level, the greater the weight and bulk necessary in the armour to defeat it. Due to the ever-expanding range of threats, many countries and organizations have developed standards to benchmark protection levels. In the United States, the National Institute of Justice (NIJ) maintains the most commonly used standard for ballistic resistance of body armour, 0101. The most recent version of the NIJ standard, 0101.06, comprises five different protection levels evaluated against the threats laid out in table 1:

Table 1. Protection levels defined by NIJ 0101.06 [13].

| Armor Classification | Threat | Threat mass | Test velocity |

|---|---|---|---|

| Type IIA | 9 mm full metal jacketed round nose | 8.0 g (124 g) | 373 m s−1 (1225 ft s−1) |

| .40 smith & wesson full metal jacketed | 11.7 g (180 g) | 352 m s−1 (1155 ft s−1) | |

| Type II | 9 mm full metal jacketed round nose | 8.0 g (124 g) | 398 m s−1 (1305 ft s−1 |

| .357 magnum jacketed soft point | 10.2 g (158 g) | 436 m s−1 (1430 ft s−1) | |

| Type IIIA | .357 SIG full metal jacketed flat nose | 8.1 g (125 g) | 448 m s−1 (1470 ft s−1) |

| .44 magnum semi jacketed hollow point | 15.6 g (240 g) | 436 m s−1 (1430 ft s−1) | |

| Type III | 7.62 NATO full metal jacketed (M80 ball) | 9.6 g (147 g) | 847 m s−1 (2780 ft s−1) |

| Type IV | .30 calibre M2 armor piercing | 10.8 g (166 g) | 878 m s−1 (2880 ft s−1) |

Types IIA through IIIA comprise the handgun protection levels while levels III and IV are rifle rated armours as shown by the increased test velocities. Each successive level represents a greater impact energy (either through increasing projectile mass, velocity, or both) that the armour system must mitigate to successfully defeat the threat. Successful defeat is usually defined by two metrics: backface deformation and resistance to penetration (RTP). RTP can quite simply be defined as the ability of the armour to stop the incoming projectile before rear surface of the armour is penetrated and the projectile contacts the wearer. Backface signature or deformation (BFS or BFD) is a measure of the impact force applied to the user during the successful defeat of the projectile. Behind armour trauma can be as fatal as the projectile itself so most standards specify a maximum allowable deformation measured in clay or ballistic gel during testing. For example, to successfully pass the NIJ standard at any level, the armour must not only stop the specified threat from penetrating at the specified velocity, but also must have a maximum BFS depth of 44 mm or less [13]. The clay used in this test protocol captures the transient deformation of the armour and therefore the maximum deflection at any point during the ballistic event can be measured. Therefore, increasing impact energies require increasingly sturdy armour designs to be successful. Modern soft armour is capable of attaining up to the IIIA level of protection. To stop the rifle threats, Levels III and IV armours currently require hard armour designs.

Defeating a ballistic threat can most simply be described through an energy balance. The input of energy into the system by the threat must be absorbed or dissipated in the armour and/or the wearer in full. Therefore, in a successful RTP test, the equation can be written simply as follows:

where  is the energy of the penetrating threat (kinetic energy in the case of ballistic protection),

is the energy of the penetrating threat (kinetic energy in the case of ballistic protection),  is the energy absorbed by the armor system, and

is the energy absorbed by the armor system, and  is the energy per unit area transmitted to the wearer multiplied by A, the area the impact is dissipated over. Measurement of the BFS is intended to estimate the

is the energy per unit area transmitted to the wearer multiplied by A, the area the impact is dissipated over. Measurement of the BFS is intended to estimate the  as a way to quantify the likely behind armor trauma. In some cases, measurement of the volume of the penetration into the witness clay has been used as a more accurate measure of energy imparted to the body [14] but this is not yet an industry standard. Energy can be dissipated by the armour through absorption via elastic and in-elastic deformation, or through distribution by de-localizing the impact energy. Both methods may result in a deformation of the same volume, however, direct absorption without distribution will result in a much higher BFS measurement. This high

as a way to quantify the likely behind armor trauma. In some cases, measurement of the volume of the penetration into the witness clay has been used as a more accurate measure of energy imparted to the body [14] but this is not yet an industry standard. Energy can be dissipated by the armour through absorption via elastic and in-elastic deformation, or through distribution by de-localizing the impact energy. Both methods may result in a deformation of the same volume, however, direct absorption without distribution will result in a much higher BFS measurement. This high  due to the localized impacting energy can have a much more damaging effect on the wearer through behind-armor blunt trauma (BABT). Therefore, a common theme in the armor discussion to follow will be how the energy is transmitted to the user as this plays a large role in the survivability of the event.

due to the localized impacting energy can have a much more damaging effect on the wearer through behind-armor blunt trauma (BABT). Therefore, a common theme in the armor discussion to follow will be how the energy is transmitted to the user as this plays a large role in the survivability of the event.

The RTP tests used by the NIJ standard are also sometimes known as V0 tests, that is a test velocity at which the probability of a complete penetration of the armour is zero. Of course, a true probability of zero penetration is difficult, if not impossible, to find through reasonable testing so many standards use a confidence interval to set the sample test size. Another common metric for testing is the V50, or the velocity at which the specified threat would be expected to completely penetrate the armour 50% of the time. The most common method for evaluating this velocity is to increase the striking velocity with each successful defeat until an armour sample fails. Then the velocity is dropped until the armour successfully defeats the threat. This goes back and forth until all test samples are consumed. The average of an equal number of partial penetration and complete penetrations is the V50 [15]. This test is often used as a metric to compare armours against each other. In both V0 and V50 testing, a single armour panel may need to withstand between one and six ballistic impacts at various locations. The multi-hit performance may also be a required metric for an armour design.

Figure 2 shows relative trade-offs between the two different types of modern ballistic armour. Soft armour is much more compliant and lightweight than hard armour but has lower energy absorption potential. As will be discussed in more detail below, soft armour can meet the requirements of the first three protection levels but hard armour is required for the rifle threats. Hard armour offers much higher levels of ballistic protection but, as the name suggests, is completely rigid and therefore offers no flexibility. A desired armour system would combine the benefits of both types of armour into a flexible, protective package that could cover the majority of the body. As discussed, armour must balance weight and flexibility along with the ballistic metrics discussed above. Both styles of modern ballistic armours use monolithic constructions to provide consistent performance over the surface.

Figure 2. (a) Trade-offs between different types of NIJ 0101.06 armours. Currently no system available on the market strikes a balance between ballistic protection and flexibility. (b) Bending stiffness as a function of the plate thickness. To minimize the transmission of energy into the wearer's body, thickness should be maximized.

Download figure:

Standard image High-resolution imageTherefore, besides the composition, armour flexibility is related to a cubic factor of the thickness. From equation (1),  is proportional to h while A is proportional to

is proportional to h while A is proportional to  . Solving for

. Solving for  demonstrates quite simply that minimization can be accomplished by maximizing h.

demonstrates quite simply that minimization can be accomplished by maximizing h.

Conversely, flexibility can be described through the curvature defined as  where r is the radius of curvature. The resistance to bending can further be measured by the bending stiffness:

where r is the radius of curvature. The resistance to bending can further be measured by the bending stiffness:

where E is Young's Modulus, and h is the thickness of the structure. In this cause, resistance can be minimized (flexibility maximized) by minimizing the thickness. With monolithic structures, these two design goals become mutually exclusive. Both structures have desirable behaviours but no modern design has been able to take advantage of both aspects. With this understanding, a look at biological analogues can demonstrate where the industry is currently and where there is room for advancement.

As mentioned, natural protective structures have evolved for a different level of protection that what is necessary for ballistic protective armors. Similarly, modern engineering materials are also generally more capable then their biological counterparts. For example, a piranha bite force of 200  could be considered as a reasonable threat for a scaled skin [16]. Conversely, a 9 mm threat for NIJ Type II armor would impart over 1000

could be considered as a reasonable threat for a scaled skin [16]. Conversely, a 9 mm threat for NIJ Type II armor would impart over 1000  , not to mention the more substantial threats of the higher protection levels. Typical threat velocities in nature for some of the different protective structures described in this review are laid out in table 2 below.

, not to mention the more substantial threats of the higher protection levels. Typical threat velocities in nature for some of the different protective structures described in this review are laid out in table 2 below.

3. Soft armours: natural and engineered designs

3.1. Dermal armour

Mammalian skin provides protection against tearing and puncture in a soft, flexible package. As will be discussed in the following sections, it has a similar composition and protection characteristics as soft armour packages. In particular, the dermal shields developed by large herbivores are of interest as they have developed over time using similar defeat mechanisms. Jarman hypothesized that these mammals developed areas of markedly thickened skin as shields against blows received during intraspecific combat [20, 21] based on thickness variations noted by Cave and Allbrook [22]. This idea is supported by the earlier work of Geist on skin thickness variations in mountain goats [23]. Beyond localized dermal thickening, these areas also possess increased mechanical properties that cannot be attributed to thickness alone. Shadwick et al demonstrated that the dorsolateral skin of the white rhinoceros (Ceratotherium simum) has additional structural and mechanical specializations to make it a more effective shield beyond just the increased thickness [24]. White rhinoceroses are regarded as the third largest species of living terrestrial mammal [25] with incredibly dense, protective skin that is colloquially known for being impervious to all but high-powered rifles. This makes it a perfect natural analogue to the soft armour used in handgun protection.

The skin of a rhinoceros has a structure and material composition similar to most mammals. The epidermis is the outer most layer of the skin and is only about 1 mm in thickness [22]. The underlying dermis however, is impressively thick reaching 18–25 mm in areas and is responsible for providing the brunt of the protection characteristics [22, 24]. Comparatively, human skin typically ranges from 1 to 2 mm in total thickness but still provides limited protection from puncture [26–28]. The dermal structure is then attached to the structures beneath via non-resistant superficial fascia [22]. The primary components of typical mammalian dermis are water and collagenous fibres which constitute 70%–80% of the dry tissue mass [29]. The white rhinoceros comes in slightly higher than this at ~85% collagenous fibres which represent 33.2% of wet tissue mass with 60.9% water content in the skin [24]. The primary component of typical mammalian dermis is collagenous fibres constituting 70%–80% of the dry tissue mass [29] and the white rhinoceros comes in slightly higher than this at ~85% [24]. However, it is the highly ordered nature of the rhinoceros' dermis that distinguishes it from its peers. Like ballistic fabrics, the collagen fibres are relatively straight and arranged almost parallel to one another with a high degree of cross-linking. Unlike the ballistic fabrics that will be discussed for soft armour, the crosslinking in mammalian skin occurs in both the lateral and transverse directions. In typical mammalian skin, the collagen fibres are generally much more disorganized representing a feltwork mat [24]. The highly cross-linked collagen molecules and closely packed fibres give the skin relatively isotropic tensile properties orthogonal to the body long axis. The fibres also appear to be well-connected internally as tensile failure requires rather large stresses with fibre rupture being the preferred failure mechanism over fibre 'pull-out'. Compressive failure also requires very high stress levels which is believed to be due to the retention of interstitial water within the fibre network and generating tension perpendicular to the compressive force [24]. As skin samples are pulled in tension, the fibres become increasingly organized in a parallel manner resulting in a J-shaped stress–strain curve [30]. Figure 3 demonstrates this progression of failure through the dermis during a blunt impact event. As skin never evolved to protect against the penetrating power of a ballistic projectile, this figure is designed to demonstrate the force dissipation mechanisms against a realistic threat.

Figure 3. (a) Cross-sectional schematic of mammalian dermal structure. Relative thicknesses of component layers vary with species and function. (b) Deformation map of dermal response to an impact by a blunt threat: (i) the dermal structure prior to impact, (ii) upon initial contact, dermis begins to deform through compression along with orienting of the tangled collagen fibres, (iii) collagen fibres align and begin to elongate until finally, (iv) fibres begin to fail and the dermis begins to tear.

Download figure:

Standard image High-resolution imageWhile no studies have been conducted on ballistic impact resistance of dermal armours, much can be inferred from the mechanical properties in quasi-static testing and observations in nature. The dermal armour of the rhinoceros is thought to have developed as a defensive mechanism for resisting blows from the horns of conspecifics [22]. The tensile strength, work to fracture, and elastic modulus are all relatively high in relation to other mammalian skins which, coupled with the extreme thickness, enhance the tissue's RTP or tearing by a horn in combat [24, 31]. The flexibility of skin is great for motion but it limits its ability as a defensive structure. In an impact event, high compressive forces are placed on the strikeface but the successive layers are placed in tension. The high flexibility localizes the deformation to the area directly around the impact site creating a deep, narrow BFS. This can often correlate with what are known as backface signature injuries and can be defined as open penetrating lacerations due to blunt trauma although the projectile did not penetrate. This differs from BABT which is historical moderate to severe bruising and broken bones as the energy is distributed over a larger area [32]. In essence, the difference in injury pattern can be attributed to the difference in energy density [32].

Very little, if any, work has been done to model rhinoceros skin mechanical behaviour in literature however, given the similarities to the skin of other mammals (including humans), there is a plethora of available works that could be applied. Many early studies looked to linearize the stress–strain relationship of skin in numerical models which fails to accurately capture the J-shape of the curve due to collagen fibre orientation. While this may be sufficient for highly dense, oriented samples like rhinoceros' dermis, it fails to capture the full complexities of the mechanical behaviour. Some of the earliest work to develop constitutive equations for mammalian skin was performed by Lanir and Fung based on experimental data in observations of rabbit abdominal skin [33, 34]. These relationships, however, were dependent on preconditioning of the skin sample and required different equations for loading and unloading. Ridge and Wright looked to develop a relationship between the orientation and involvement of collagen fibres in a tension test with the mechanical performance of the dermis [30]. The relationships developed by Tong and Fung in [35] defined a 'pseudo strain potential' for the skin samples to begin to derive the stresses acting on the material in three dimensions. Sherman et al developed a constitutive model based on the organization of collagen fibrils in rabbit skin [36]. Hendriks et al took this one step further by developing a finite element model to describe the non-linear behaviour [37]. Samples used for these earlier studies were prepared from harvested tissues, not in vivo, and therefore may not fully represent the 'in-use' state. More recent experiments have analysed the mechanical properties of human skin in vivo using suction and ultrasound. The methods are described in [27, 38] and provide a more accurate representation due to internal tension, hydration, and vascularization of living samples.

Dermal armours offer an interesting natural analogue to soft body armours due to their similar fibrous composition and dependency on orientation for strength. Rhinoceros skin is an extreme example of the protection capabilities of skin but is so dense and thick that it is nearly inflexible itself. This demonstrates the limitations of soft armour packages where the bulk begins to outweigh the protective advantage. Even though dermal shielding is flexible (in most cases), it can be limiting in mobility and therefore is generally not found around joints or other areas requiring a high degree of flexion. Stiffness and areal density increase rapidly with increased thickness but energy absorption potential decreases much more slowly. Other mammals have less imposing dermal shielding but the principles and structure remain the same. Again, the weight versus protection trade-off must be made for animals less massive than the rhinoceros. Therefore, as with soft armour, different structures are needed to reach higher protection levels while maintaining a reasonable amount of encumberment. Modern implementations of soft armour may still be utilized around joints but as protection increases, increasing burden is put on the user limiting the full range of motion.

3.2. Soft engineered armour

Soft armours are generally composed of layers of synthetic or natural fabrics. Similar to the collagen fibres in dermal armours, high tenacity fibres do the bulk of the work in energy dissipation. Ballistic fabrics are most commonly made from woven yarns constructed in a 2D plain weave pattern [39]. If the fabric is composed of yarns with a tenacity of greater than 15 g/denier and modulus of 44–176.4 GPa, the fabric is considered to be a high performance fabric suitable for ballistic applications [39, 40]. Tenacity is defined as the ultimate breaking strength of the fibre or yarn divided by the denier, or linear mass density, of the fabric. Some of the most common fabrics in use today include para-aramids such as Kevlar® (DuPont) and Twaron® (Teijin), ultra-high molecular weight polyethylene (UHMWPE) such as Spectra® (Honeywell) and Dyneema® (DSM), and poly-benzobis-oxazole (PBO) such as Zylon® (Toyobo) [41]. Many works have also looked at spider silk as a biological replacement for engineered ballistic fibres due to their strength-to-weight ratio and elongation at failure [42–45]. During a projectile impact, the projectile is caught in the fibres and the kinetic energy is absorbed through fibre interactions and failure. Breaking down the simple energy balance from equation (1),  can be further described through

can be further described through

Where ETF is the energy absorbed in tensile failure of the yarn and EED is the energy absorbed in elastic deformation [46]. This process is shown graphically in figure 4.

Figure 4. (a) General construction of soft armour packages: ballistic fabrics are layered together and may be quilt-stitched to enhance transverse fibre interaction and localize deformation. (b) Steps of the fibre failure process during a ballistic impact: (i) cross-section of a single fibre before impact, (ii) initial impact, fibre begins to elongate, (iii) deformation increases to maximum strain of the material, and (iv) fibre rupture and penetration of the fabric [47].

Download figure:

Standard image High-resolution imageThe elastic deformation term can be thought of as a combination of the elastic deformation of the yarns and fibres along with the deformation of the fabric. The fabric deformation includes frictional absorption mechanisms like inter-yarn friction, fabric projectile friction, and interactions between fabric layers [39, 48]. It has been shown that the inter-yarn friction plays a critical role in energy dissipated in frictional work at the yarn-to-yarn junctions [49–51]. This affects the stiffness of the yarn in the tensile direction and the fabric in the transverse direction which, in turn, affects the performance of the material [52]. The inter-yarn friction can be described by the static frictional coefficient between the yarns while yarn-projectile friction can be better described by the coefficient of kinetic friction [53]. This highlights the importance of the weave or fabric structure in the energy absorption of the overall system. Manufacturers also may stitch soft armour packages in the transverse direction to enhance these frictional forces while maintaining flexibility. The weave of the fabric provides the similar interactions as the lateral crosslinking in mammalian dermis while the quilt-stitching replicates at least a portion of the transverse linkages. In fact, quilt-stitching was shown to increase the energy absorption in fragment impacts 14%–22% over non-quilted armours [54].

The other major energy absorption mechanism is through tensile failure of the yarns. Some ballistic fabrics, such as para-aramids, have been shown to exhibit strong strain-rate dependencies [55, 56]. It was found that the strain at failure decreased with increasing strain rate in Twaron® fabrics. This limits the energy that can be absorbed in fibre elongation and causes fibre failure in the brittle mode [39]. However, UHMWPE fibres have not be shown to demonstrate a strain-rate dependency which may lead to increased energy absorption [57]. While fibre elongation is an important mechanism for absorbing energy, it needs to be balanced in ballistic testing to limit back deflection [14]. As discussed above, this back deflection transmits energy into the body of the wearer causing BABT which can be potentially life-threatening. Like dermal armours, the soft nature of fabric armour localizes the damage creating sharp BFS deformations. Localized damage means that the remainder of the armour is likely undamaged and can withstand multiple impacts, but the total energy absorbed by the armour is limited.

The multiple energy absorption mechanisms at work highlight some of the difficulties in numerically modelling performance under high energy, ballistic impact loading. Given the time and expense required for ballistic testing, several groups have made attempts at modelling these mechanisms to predict ballistic results. Cunniff utilized a regression analysis of fragment simulating projectile (FSP) impacts on ballistic fabrics to provide an approximation of required areal densities to defeat specified threats [58]. Morye et al attempted to predict a ballistic limit, or V0, value from material characteristics and high-speed photography of the deformed area and cone velocity [46]. Leigh et al developed a 2D model for calculating the V50 performance of a membrane with provisions to scale the system up to the multi-ply systems used in armour vests [59]. Mamivand and Liaghat studied the effect of spacing between layers of ballistic fabrics through a numerical model and demonstrated that increased spacing decreased the ballistic limit up until a layer decoupling threshold [60]. Beyond the layer decoupling threshold, each ply behaved essentially independently deriving no support from adjacent layers. This understanding feeds into explaining the advantage gained by consolidating fabric system into semi-rigid armours that will be discussed later on. This is by no means a comprehensive list of the numerical models developed for soft armour systems but is intended to provide a general sense of the available literature.

In recent years, an area of research interest has been on increasing the ballistic performance of soft armour systems through impregnating fabrics to give non-Newtonian impact responses. The most well-known example is the work conducted at the University of Delaware on impregnating woven Kevlar® fabric with shear-thickening fluid (STF) [50]. During an impact, the colloidal suspension stiffens, imparting greater ballistic resistance characteristics than the neat fabric. It was shown that the addition of the STF raised the ballistic resistance of the fabric to that of an equivalent areal density of neat fabric albeit in a thinner and more flexible package [50]. Other works have shown that the increase in ballistic performance of this system is due to an increase in the inter-yarn and projectile-fabric frictional forces [61]. Conversely, the addition of lubricants such as PDMS has been shown to decrease the ballistic performance of the fabric lending credence to the above approach [52]. While this approach has demonstrated improved ballistic resistance, a commercially available armour has yet to be brought to market. This is likely due to the fact that this technology has yet to demonstrate an improvement in areal density over similarly performing systems. In fact, some implementations were over twice the weight of comparable all-fabric systems [39]. What is interesting however, is the non-linear response this system provides by offering some advantages of a hard system with the flexibility of a soft armour system.

Fully flexible armours are advantageous because they are inherently mobile and flexible. Therefore, they can be utilized around joints without undue encumberment, provided the thickness is reasonable in relation to the angles of motion. However, the drawback is the limited ballistic protection they can provide. Unfortunately, materials have yet to be discovered that can provide enough energy absorption potential to defeat rifle threats in a soft armour package without a thickness rendering it wholly unusable. As shown with dermal armour for rhinoceros, providing high levels of protection results in a package that is nearly inflexible and extremely heavy. To achieve maximum protection, the rhinoceros dermis becomes almost solid with heavy crosslinking between collagen fibres. This type of protection would add tremendous aerobic and heat strain to end users which has been shown to dramatically reduce soldier effectiveness [62–64]. Therefore, new types of construction are necessary to lend additional protection to soldiers while remaining functional.

4. Rigid armours: natural and engineered designs

4.1. Insect exoskeletons

The most common natural 'hard armour' is the exoskeletal system of arthropods, the largest animal phylum. The exoskeleton serves multiple purposes besides lending protection to the soft body inside. It also provides support, giving the insect shape and a means of locomotion, along with environmental protection [65, 66]. The exoskeleton, also known as the cuticle, can be broken into two primary components; the external layer, the epicuticle, and the main structural portion, the procuticle. The epicuticle is usually ~1–2 µm thick and is the main waterproofing barrier [65–67]. The procuticle is of the most interest in this research as it provides the bulk of the protective characteristics. This portion can be split into two additional sections: the outer exocuticle and inner endocuticle. The endocuticle makes up about 90% by volume of the exoskeleton [66]. The rigid fibrous composite nature of the cuticle makes it an excellent analogue to the rigid fibre-reinforced polymer matric composite armours in the following sections. As most adult insects fly, this construction provides an efficient, lightweight, yet protective structure.

The strength and toughness of the exoskeleton is due to its hierarchical structure. The natural composite is composed of highly mineralized chitin fibres in a protein matrix [66]. The cuticle is secreted by a single layer of epidermal cells covering the entirety of the exterior surface of the insect [68]. In locusts, the cuticle is deposited in layers of parallel fibres by day, and by night, fibres are deposited in a helical arrangement forming a Bouligand arrangement [65, 69]. This Bouligand structure is characteristic of fibrous arrangements in other natural structures such as collagen in bone and cellulose in plant cell walls [66, 70]. This plywood type structure imparts strength and stiffness into the cuticle. The mechanical properties are due to the extent of the interaction between the chitin fibres and the protein matrix [68]. Chitin, like cellulose, is a nearly completely acetylated polysaccharide forming straight, ribbon-like chains. These chains are arranged in a crystalline manner with a large degree of inter-chain H-bonding making the structure stiff and stable [71]. For load bearing portions, there is often a high degree of bio-mineralization of the structure for reinforcement. For example, the shell of the American lobster incorporates various amounts of amorphous and crystalline calcium carbonate depending on the portion of the cuticle [72–74]. Another example of this is the heavily armoured, club-like dactyl of stomatopods. These marine crustaceans use this appendage as a hammer capable of inflicting considerable damage on prey such as mollusk shells, small fish, and crab exoskeletons [19, 75]. Calcium phosphate concentration decreases sharply from the impact surface of the dactyl creating an exceptionally hard exterior with decreasing modulus through thickness [19]. Another hardening mechanism is the sclerotization of the cuticle. Sclerotin is formed by crosslinking between protein molecules in a form of phenolic tanning [71, 76]. Crosslinking occurs by reaction with quinones produced by the enzymatic oxidation of phenols creating a macromolecule insoluble in all reagents except those that degrade the material [76]. The result is a hard, toughened exterior for protection from the environment and physical damage. As the constituent materials are relatively weak, it is the hierarchical structure that is of most interest for the protection that the final system offers [66].

Due to the composite nature of the cuticle, mechanical properties and failure are due in large part to the strength of the chitin fibres. Many studies have investigated the mechanical properties of different arthropod cuticles and found results to vary greatly depending on the hydration state of the chitin fibres [66, 68, 77–79]. Unsurprisingly, dry chitin was found to have a breaking stress of nearly twice that of wet chitin but was far more brittle. Wet chitin had a much higher elastic modulus and nearly twice the strain to failure than in the dry state, though very little of the strain is plastic in either state. The work of fracture, or toughness, is also nearly ten-times higher in the natural wet state [66]. The real toughness of the cuticle, however, is due to the cross-ply Bouligand arrangement of fibres. A crack cannot propagate in a straight path through this twisted structure which allows much more energy to be consumed in crack elongation [80]. With stress, the rigid mineralized components will fracture but, the chitin fibres can absorb moderate amounts of strain to hold the structure together. This allows the structure to maintain integrity and self-heal with time [80].

During fracture, failure occurs first at the boundary layer between the exocuticle and endocuticle. Generally, the layers in the exocuticle are stacked on the order of three-times more densely than the endocuticle making it stiffer [66]. This type of discontinuity, among others, is likely the cause for preferential fracture as the different zones will have different energy absorption characteristics. The progression of failure under blunt impact loading is shown in figure 5. Again, this figure is designed to show the failure mechanisms at play when a cuticle is impacted by a typical, natural threat. Failure within each portion of the cuticle is analogous to fibre reinforced composites. The mechanical response is highly anisotropic with loading in-plane versus transverse directions as the high modulus fibres dominate the response. Unlike man-made composite materials however, fibre direction can change dramatically between layers in the laminate to allow for preferential response characteristics [68]. Additionally, an asymmetrical layup in the transverse direction can put the outer, stiffer layer in compression which allows for larger deformations and elastic energy storage before failure. The more compliant inner layer also increases toughness in mode I and III fracture [68, 81]. As with ballistic hard armour structures, the harder exterior surface provides protection from the initial penetrating blow and the inner structure provides the bulk of the energy absorption through deformation.

Figure 5. (a) Cross-sectional view of the cuticle structure with the constituent layers and a magnified view of the Bouligand arrangement, (b) deformation map of the response of the cuticle to a blunted impactor: (i) the layered structure prior to impact, (ii) initial impact cause cracking to start in the layered composite. The Bouligand structure arrests crack propagation in the transverse direction and the cracks preferentially follow the helical structure. (iii) Cracking continues through the subsequent layers, one layer at a time until, (iv) the full cuticle structure is fractured and the threat can penetrate.

Download figure:

Standard image High-resolution imageAnother point of interest on arthropod exoskeletons is how they provide protection without restricting motion. Looking at the exoskeleton as a system of defence rather than just a defensive structure can provide ideas of how to offer the most amount of protection without sacrificing freedom of movement. Unfortunately, there currently is not a large amount of information available on the structure and materials that make up the joints of the exoskeleton [68]. There are several different types of joints/attachments commonly seen in nature and Gorb et al provides an overview of each in [82]. However, the concept of utilizing different types of protection for different areas based on functional need is an interesting one for armour systems design and something that will be returned to later on.

4.2. Turtle carapace

Hard armour plates can easily be likened to the hard dorsal shells of turtles' due to their high level of protection and restriction on movement. Turtles are a part of the Testudine (or Chelonii) order of the Reptilia class and are thought to have been around for ~200 million years [83]. The turtle shell is a novel anatomical feature to the Testudine order distinguishing it from all others in the Reptilia class. No intermediate forms of this evolutionary change have been found in the fossil record so the mechanism for the development of the shell is still controversial [84]. However, it is believed to have developed as a defensive structure to protect against extreme mechanical forces including sharp, high strain-rate attacks by alligators [85]. Besides protection, the shell is also used as a pH buffer and reservoir for water and wastes [84].

The shell is a bony organ and composed of two main sections: the carapace on the dorsal side and the plastron on the ventral. The carapace utilizes multiple structural elements in a hierarchical fashion to provide penetration resistance and impact protection. The outer surface of the shell is covered by keratinous epidermal scales known as scutes [83]. These scales add strength to the shell by covering the overlap of the bony plates. The scutes are primarily made-up of β-pleated sheet keratin and are attached to the bone through the dermis [83]. The bony portion of the carapace is in part formed by the vertebrae with ribs emanating laterally and fused in dermal bone to create the shell structure [84, 86]. The bones of the carapace are similar to other bony tissues in composition with ~90% collagen helices and hydroxyapatite nanocrystals [87]. The symmetric, sandwich structure of the bone possesses a graded density that can be decomposed into three distinct sub-regions. The exterior dorsal cortex is made up of mineralized exocortical bone creating a strong stuff surface [83, 88, 89]. The interior of the carapace is composed of a matrix highly porous trabecular bone providing structural support and impact dampening [88]. At a porosity of almost 60%, the matrix keeps the carapace remarkably low-weight to aid in swimming and manoeuvring [89]. The interior surface of the carapace is the ventral cortex of similar composition as the dorsal cortex on the far side. However, the cortices differ in fibrillar structure and orientation. Much like the arthropod cuticle described above, the dorsal cortex has a densely packed, interwoven fibrous array to limit crack propagation [83, 90]. The ventral cortex is far more organized with perpendicular fibres layers. This arrangement is advantageous in stabilizing the entire structure under load by mitigating the effects of unequal torsional effects on the carapace [83]. In total, the sandwich design provides an effective impact resistant protection.

Like ballistic armours, for the carapace to perform its defensive function adequately, it must resist compressive and penetrating loads. The composite nature of the carapace lends itself well to mitigating impact forces with hard external layers and foam-like structure to absorb the force. In compression testing, the carapace demonstrates initial linear elastic deformation due to cell wall bending at small strains. After this, perfectly inelastic densification occurs as cell walls buckle. Once densification has occurred, another section of linear deformation occurs resulting in a rapid increase of compressive stresses [89]. The non-linear performance seen with the carapace is also typical of what is seen with man-made foams [91]. This progression of failure is shown in figure 6. In fact, the matrix layer has a high elasticity index allowing it to recover up to 91% of its deformation after an impact [88]. The highly dense third layer provides structural support and protection to the organs with the matrix layers to provide shock absorption. This combination allows for high energy impacts to be absorbed and distributed over a larger area to reduce damage to the relatively soft and fragile turtle inside.

Figure 6. (a) Cross-sectional view of the structure of a turtle's carapace. The cortices are far denser than the porous trabecular bone interior section. (b) Deformation map of the carapace response to a blunt impactor: (i) the carapace structure prior to impact, (ii) initial impact causes deformation of the dorsal cortex until cracking begins around the impact site, (iii) deformation and fracture continues in the dorsal cortex causing compression of the spongy trabecular bone until, (iv) the carapace is fully densified and stress is imparted into the denser ventral cortex.

Download figure:

Standard image High-resolution imageResearch and modelling of turtle shells has generally followed one of two paths. The first, has been to gather data on the component elements of the carapace through compression and indentation to build numerical models of the constituents [88, 89, 91, 92]. The second, has been to model the shell as a system through finite element analysis to simulate the stress conditions in various compressive loadings [93–96]. One study [97], even evaluated complete shells with euthanized turtles inside against compressive and point loads to compare the strength and failure mechanisms for different turtle species. Analysis of the constituent materials and layers is important, but understanding how the armour works for protection requires analysis of the system. Terrestrial turtles have evolved with taller, more domed shells for increased energy absorption as opposed to aquatic turtles [94, 97]. Aquatic turtles living in higher flow regimes are built more streamlined with smaller, weaker shells to use speed and mobility to their advantage. Even with the various levels of protection between different species, all turtles use the same functionally graded material structure of the carapace to blunt a predator's attack and distribute the energy input to their soft tissue [91, 98].

The hierarchical structure of a turtle carapace is designed to provide protection from impacts. With a highly dense exterior component to mitigate impact and a softer supporting structure for shock absorption, the carapace can withstand relatively large applied loads. While a carapace would be unlikely to perform well in a ballistic event, the design of the structure and mechanisms for energy absorption echo the intent of man-made armours. The interior foam-like structure absorbs and dissipates the impact energy as a ballistic protective armour should to mitigate BFS. As will be discussed in the hard armour section below, the highly dense and rigid exterior plays an important role in blunting the initial contact of the incoming threat. Also, similar to hard armour protection, the carapace is bulky, heavy and cumbersome. Again, a much higher level of energy absorption can be obtained but the cost is rigidity. As mentioned, different species balance the trade-offs to be more effective in their environments. In some cases, speed and agility may be preferred for hunting and evasion rather than maximizing protection. But for slow moving terrestrial turtles, being able to fully retract into their shells if necessary, mobility is less of a concern. As an analogue for the modern soldier, mobility is not optional and the ability to escape and evade is critical to survival on the battlefield.

4.3. Man-made hard armour

As mentioned above, hard armour is utilized today when it is necessary to defeat rifle threats (NIJ Level III and above). Depending on the intended threat class, designers may employ plates made from solely polymer matrix composites or may use hard ceramic cores. Semi-rigid armour plates and combat helmets are made from fibre reinforced polymer matrix composites based on fibres like those used in soft armour. The difference here is the addition of a resin matrix to bond layers together in the transverse direction. The resin matrix constrains the yarns of the fabric so that the projectile must engage and fracture more fibres directly to penetrate the material. Additionally, the resin enhances the frictional forces between yarns and plies so the composite has more energy absorption potential than similar soft armours [51, 99, 100]. The stiffer the resin used, the greater the yarn confinement and generally the greater the absorption potential of the laminate. However, fibres must still be able to move and stretch with an impact as over confinement can make them more likely to fail in transverse shear before any elongation can occur, diminishing the ballistic performance [99]. Additionally, an increased through-thickness elastic modulus can have a detrimental effect on the BFS during an impact leading to increased BABT [101, 102]. Laminate structures have two primary failure mechanisms that dictate the amount of energy absorbed in the failure: ply delamination and plug-punch out [47]. The delamination mechanism has been found to resemble the 'generator strip' phenomenon where the projectile impact pushes a strip of the first lamina towards the rear of the structure, which in turn produces shear cracks in the resin matrix parallel to the fibres and applies a transverse load to the successive lamina causing delamination [103]. This failure mode absorbs the most energy as fibres are elastically and plastically deformed while consuming energy in surface formation of cracks in the resin matrix. The plug-punch out failure is more commonly seen in thin laminates as the projectile shears straight through the structure without the narrow strip rear-ward displacement seen in delamination. This often occurs when the armour is overmatched by the impact energy and the failure occurs before much fibre elongation can occur. In fact, the kinetic energy for full perforation of thin composite laminates has been found to be dependent on thickness similarly to ductile monolithic materials [99].

While the addition of a resin-matrix improves ballistic performance, military-grade armour systems rely on a rigid core to provide enhanced protection levels. As mentioned above, this core is usually made from ceramics such as silicon carbide, aluminium oxide (alumina), and boron carbide due to their high strength to weight ratio. Ceramics are characterized by having extreme compressive strength while being relatively weak in tension. These ceramic options vary widely in performance versus weight but this review will focus only on the role of the ceramic during the impact event rather than the benefits of a specific type. The role of the core component is to plastically deform, fracture, or deflect the projectile, making them crucial in the defeat of high-velocity rifle and AP threats. These plates are generally constructed as a thin ceramic layer backed by a ductile metal or fabric-based composite [39, 104, 105]; fibre reinforced matrix composite being the most common in personal armour due to weight constraints. When the projectile strikes the armour plate, the plate remains at zero velocity for fractions of a second as the projectile contacts the ceramic. During this time, known as the dwell time, the projectile begins to plastically deform and compressive shock waves propagate from the point of impact through the armour [106]. Due to the mechanical impedance mismatch of the different material constituents of the armour backer, the stress waves are partially reflected towards the strikeface as tensile waves. These waves initiate the formation of cracks starting from the backside of the ceramic because of the low threshold for tension in ceramics. The cracks propagate through the ceramic in a conical shape until reaching full thickness and the projectile can penetrate the tile [39]. The longer this dwell time, the greater the effectiveness of the ceramic tile. As the projectile passes through the ceramic tile, pulverized fragments of the ceramic flow past it in the opposite direction further eroding the threat [106]. Restraining the ceramic with thin layers of fiberglass or carbon fibre has been shown to enhance the RTP of the tile and can increase the effectiveness up to 25% with only a 2.5% addition to areal density [107]. The added confinement of the ceramic channels the pulverized fragments into the path of the projectile and keeps the now fractured ceramic in place for subsequent impacts. The role of the backer component is to then catch or stop the remaining projectile and ceramic fragments through the energy absorption mechanisms discussed above. The general torso plate construction and response to ballistic impact is detailed in figure 7.

Figure 7. (a) Cross-section of a typical hard armour plate. The ceramic core is used to break the incoming projectile and the backer 'catches' the fragments. A cushion layer on the strikeface may be used to protect the ceramic from blunt impacts, improving the durability. Similarly, foam or other cushioning materials may be used against the body to distribute the force of the impact and reduce the backface signature. (b) Steps in the ballistic defeat of a hard armour plate: (i) before impact, (ii) dwell of the projectile on the ceramic plate. Crack propagation begins from the backside, (iii) ceramic fractures and begins to deform the composite backer, (iv) the ceramic is destroyed and fragments are ejected back along the projectile's path while backer deformation increases, and (v) the composite backer is stretched until eventual fibre rupture/pull-out and the system is penetrated.

Download figure:

Standard image High-resolution imageAs with soft armour systems, there have been several efforts to model ballistic interactions with hard armour. Ceramic-based armours have been exceptionally difficult to accurately model due to the complex defeat mechanisms. Gower et al was able to model FSP interactions on laminated Kevlar® targets but had difficulty predicting backface signature with hemispherical projectiles due to the dominant delamination mechanism [101]. Chocron and Galvez presented a simple 1D, fully analytical model of the interaction with a ceramic/composite-backed armour system to calculate residual projectile velocity and mass, along with the strain history of the backing composite material [108]. Shokrieh and Javadpour further developed this model via finite element methods to predict the ballistic limit of an armour system. The authors utilized the mechanical properties of Kevlar® under different strain rates in their model to improve the accuracy of their results [105]. Cortés et al created a macroscopic model for the pulverized ceramic ahead of the projectile to obtain a detailed picture of the penetration process [109]. Bürger et al developed an FEA model of an armour-piercing projectile impact on a ceramic/composite armour with special attention paid to the delamination between the backer and strikeface during the defeat [110]. Due to the multitude of deformation processes occurring during impact, including large strains and fracture, the most effective modelling techniques rely on mesh-free FE analyses. One method, smooth particle hydrodynamics, borrowed from fluid dynamics appears to show the most promise in predicting ballistic results. An overview of the method and it's applications is presented in [111]. Lee and Yoo found good correlation between ballistic experiments and armour tiles designed with metal backing plates using this method [112]. In total, these models present a detailed depiction of the defeat process in hard armour but so far have not been accurate enough to replace physical ballistic experiments.

While a hard armour plate provides substantially higher protection from ballistic threats, the stiffness, thickness, and weight takes a toll on the user. As described in the defeat mechanisms, this type of architecture must be rigid and therefore mobility will be inherently reduced. Soldiers use a set of plates in an attempt to cover all the vital organs in the torso but there are gaps in coverage to maintain mobility. The thickness of commercially available armour exacerbates this issue. Military level torso plates are usually about an inch thick; lower performing systems may be thinner. These factors combined with the system weight has been shown to have a severely negative effect on users. One study showed that a standard law enforcement kit decreased mean performance by 13%–42% in mobility tasks [63]. This study used stab resistant armour (similar composition to soft armour) and other standard accessories but the results are still valid in terms of the physiological effect. Another study noted significant pulmonary function deterioration and increased mean skin temperature in exercise tasks while wearing typical military hard armour plates [113]. Even more concerning is a study that showed that soldier vigilance was diminished while carrying a heavy load while standing or walking [114]. As armour is just a part of a soldier or law enforcement officers load, it is readily apparent that weight and restriction of movement are very important factors in new armour design due to the potentially severe impacts it can have on the user.

5. Bioinspired alternative: compound armours

Armadillos, pill-bugs, many reptiles, and fish all utilize various manners of overlapping hard plates to provide the protection they need (examples shown in figure 8). Scales are the most common among these and present a novel method of protection that combines many of the benefits of most the hard and soft protective systems described above. They are of unique interest in armour development because of their inherent flexibility while maintaining a high level of protection. Fish skin, specifically the leptoid scales found on higher-order bony fish, is the most well studied implementation of scaled structures. It has received increasing attention because of its nonlinear response in bending. Fish skin is composed of a highly elastic dermis on one side and stiff, imbricated scales on the other. The scales are generally composed of similar materials as bone and teeth such as type I collagen fibres, often arranged in a Bouligand pattern, with calcium-deficient hydroxyapatite [65, 115–117]. These materials give the individual scales a relatively high modulus of ~2.2GPa and tensile strength ~90 MPa [118]. The quasi-periodic arrangement of scales can be characterized by scale shape, size and overlapping distance. While scale size will vary considerably between species of fish, normalized overlap distance has been shown to be remarkably consistent [119]. In the following sections, an overview of the current research into scale interactions and modelling approaches will be reviewed along with the applicability for future armour development.

Figure 8. Examples of scaled armours seen in nature: (a) fish, (b) pangolins (©Tusk, 'Pangolin' used under public license, via Flickr), (c) pill bugs (©Ryaninc, 'Pill bug' used under public license, via Flickr), (d) snakes, and (e) armadillos.

Download figure:

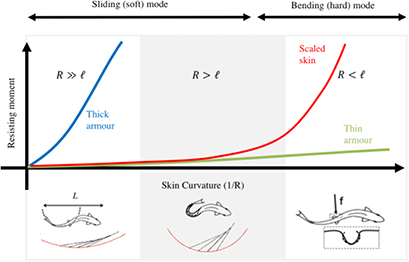

Standard image High-resolution imageAs mentioned above, the asymmetrical composition of fish-skin gives rise to its unique mechanical properties. These properties are characterized by a highly anisotropic response in bending due to the scale to scale interactions. Vernerey and Barthelat demonstrated this with a simple pinch test of fish-skin. Bending in the direction of the scales (scales on the inside) showed significant scale rotation and increasing bending resistance while convex bending showed no stiffening [119]. The stiffening response can be described via a simple 1D model relating stiffness to radius of curvature. Figure 9, below, introduces the setup for this model:

Figure 9. Fish-skin compared with 1D representation for modelling purposes. On the left, skin and model show are in the undeformed state while on the right, the skin and model is bent showing the scale rotation and scale bending [119]. (a) and (b) Adapted with permission from [123]. © 2015, American Chemical Society. (c) and (d) Adapted from [119], © 2014, with permission from Elsevier.

Download figure:

Standard image High-resolution imageFor a full derivation of this model, the reader is directed toward [119] but suffice it to say that the total curvature can be decomposed into a component driven by scale rotation and a component driven by scale bending for small to moderate scale bending. In turn, this can be written to expand on the energy balance for ballistic defeat in Equation (1):

where EB is the elastic energy due to scale bending, ER is the energy associated with scale rotation,  and

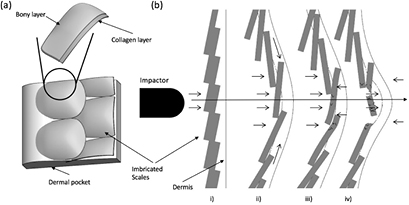

and  are the elastic and plastic energies of scale deformation, respectively. Scale bending is driven by scale stiffness while scale rotation is driven by the stiffness of the dermal pocket [119]. Which of these two behaviours dominate the response of the system depends on the relative stiffness of the dermal pocket to the scales [120]. If the dermal pocket is sufficiently stiff, then scale bending must dominate once the scales in engage. However, if the pocket is softer, than it can stretch and scales can slide past each other and rotate before bending. The effects of scale contact were further explored in [121] through an investigation of the frictional effects of scale engagement. It was found that frictional effects gave rise to two different scale locking behaviours. Above a certain critical value for the frictional coefficient, so-called static frictional lock could arrest post-engagement motion almost immediately. More commonly, kinetic frictional lock was responsible for increased bending resistance as curvature increased until reaching a maximum curvature value [121]. These factors combine to create the J-shaped response in bending that makes this structure appear promising for impact mitigation.

are the elastic and plastic energies of scale deformation, respectively. Scale bending is driven by scale stiffness while scale rotation is driven by the stiffness of the dermal pocket [119]. Which of these two behaviours dominate the response of the system depends on the relative stiffness of the dermal pocket to the scales [120]. If the dermal pocket is sufficiently stiff, then scale bending must dominate once the scales in engage. However, if the pocket is softer, than it can stretch and scales can slide past each other and rotate before bending. The effects of scale contact were further explored in [121] through an investigation of the frictional effects of scale engagement. It was found that frictional effects gave rise to two different scale locking behaviours. Above a certain critical value for the frictional coefficient, so-called static frictional lock could arrest post-engagement motion almost immediately. More commonly, kinetic frictional lock was responsible for increased bending resistance as curvature increased until reaching a maximum curvature value [121]. These factors combine to create the J-shaped response in bending that makes this structure appear promising for impact mitigation.

The kinematics of the scaled system can be mapped as a function of scale angle and substrate rotation angle. When the response is dominated by scale rotation, three distinct mechanical regimes can be identified from this as linear, non-linear and rigid behaviour [122]. Three distinct mechanical response regimes can be identified from this as linear, non-linear and rigid behaviour [122]. When substrate rotation is sufficiently small or the overlap ratio is below a critical value, there is essentially no scale engagement and the system can be described via linear elastic behaviour. As scales begin to slide against each other, nonlinear behaviour becomes dominant due to the frictional effects described above. Eventually, frictional effects take over entirely and the system becomes locked in the rigid phase [122]. When the response is dominated by scale bending, these same three regimes can be identified but the driving factor is scale stiffness rather than frictional forces. These three phases of kinematics allow scaled structures to have the seemingly contradictory properties of flexibility and penetration resistance that make them intriguing for armour development.

Penetration resistance is a crucial attribute in a defensive structure for obvious reasons. The anisotropic response of the scale interactions lends itself well to out-of-plane deformation resistance. Funk et al constructed an artificial fish-skin and found that in bending tests the scales showed little resistance to small curvatures but stiffened significantly with large bending moments. Further testing showed ~7 times greater penetration resistance with the artificial skin attached to a foam substrate than the substrate on its own [123]. Rudykh et al showed that a scaled surface could increase penetration resistance by up to 40 times while flexibility decreased less than 5 times [124]. It was found here that different deformation resistance mechanisms governed flexibility and penetration resistance. As discussed above in kinematic frictional locking, flexibility was shown to be driven by inner-matrix shear forces. Penetration resistance however was shown to depend on localized scale bending [124]. Furthermore, these responses can be tailored by changing scale size, overlap distance, and scale stiffness [125]. Therefore, a fish may have evolved with a scale structure such that the scales lock against each other before soft tissue damage occurs. Similarly, a ballistic structure could be designed to lock before a small ballistic penetrator can reach a certain depth.

Another factor that makes scales highly desirable in a defensive structure is the ability to distribute the force of penetration or impact loads over a larger surface area and limit  . The scale overlap allows for the transfer of load to adjacent scales which helps to distribute the force and limit the depth of penetration or BFS [123]. Impacting isolated scales can cause 'sinking' into the much softer, underlying skin but when the scales can interact, the force can be distributed [126]. Browning et al demonstrated that the back deflection of the scaled surface was dependent on the density of the scale arrangement and therefore could be tailored to mitigate blunt trauma [127]. However, in this case, the structure bending response was dominated by scale bending as the sample design limited scale sliding resulting in a nearly linear stress–strain response. Figures 10 and 11 illustrate how scales can distribute the loading of an impact to mitigate trauma. While the load is distributed over a larger surface area, damage to the structure is still relatively localized to the armour because cracks cannot propagate between adjacent scales. Therefore, unlike monolithic structures, each impact on a scaled structure would behave like an undamaged panel as long as impacts were not on directly adjacent scales. Fish-skin presents a defensive structure unlike those currently available for ballistic protection because it aims to balance of mobility and protection. The imbricated structure allows for the benefits of both types of armour to be incorporated into a single system. Currently, there is no well-accepted in-between for man-made ballistic armours; simply hard or soft packages. In natural defensive structures, scales utilize the best parts of the hard and soft protective systems to create protection that supports motion [128]. The additional energy absorption mechanisms and ability to distribute loading are large factors in the appeal of scales for future armour systems.

. The scale overlap allows for the transfer of load to adjacent scales which helps to distribute the force and limit the depth of penetration or BFS [123]. Impacting isolated scales can cause 'sinking' into the much softer, underlying skin but when the scales can interact, the force can be distributed [126]. Browning et al demonstrated that the back deflection of the scaled surface was dependent on the density of the scale arrangement and therefore could be tailored to mitigate blunt trauma [127]. However, in this case, the structure bending response was dominated by scale bending as the sample design limited scale sliding resulting in a nearly linear stress–strain response. Figures 10 and 11 illustrate how scales can distribute the loading of an impact to mitigate trauma. While the load is distributed over a larger surface area, damage to the structure is still relatively localized to the armour because cracks cannot propagate between adjacent scales. Therefore, unlike monolithic structures, each impact on a scaled structure would behave like an undamaged panel as long as impacts were not on directly adjacent scales. Fish-skin presents a defensive structure unlike those currently available for ballistic protection because it aims to balance of mobility and protection. The imbricated structure allows for the benefits of both types of armour to be incorporated into a single system. Currently, there is no well-accepted in-between for man-made ballistic armours; simply hard or soft packages. In natural defensive structures, scales utilize the best parts of the hard and soft protective systems to create protection that supports motion [128]. The additional energy absorption mechanisms and ability to distribute loading are large factors in the appeal of scales for future armour systems.

Figure 10. (a) Cross-section of scale arrangement and scale composition. The top bony layer is highly mineralized similar to the epicuticle or teeth. The collagen layer has a similar Bouligand type arrangement as the exocuticle for crack-mitigation. (b) Map of deformation steps when impacted by a blunted projectile: (i) undeformed scale arrangement, (ii) scales lock against each other while underlying dermal layer elongates, (iii) scales begin to bend and crack until, (iv) scales are fractured and deformation becomes increasingly localized at impact point.

Download figure:

Standard image High-resolution imageFigure 11. Response curve of scaled structure in bending. As the radius of curvature changes with respect to the scale length, the material bending stiffness changes. The non-linear response of the complete structure utilizes the positive attributes of both hard and soft, thick and thin, by offering a range of flexibility until the scales lock against each other and behave as a rigid structure. This also protects the skin, muscles and skeletal system by preventing hyperflexion [120]. Adapted from [119], © 2014, with permission from Elsevier.

Download figure:

Standard image High-resolution image5.1. Man-made compound armours

While there is no well-accepted armour on the market that takes advantage of the structural advantages of scales, some companies have tried. The most well-known system to try this was Dragon Skin developed by Pinnacle Armor. Dragon Skin utilized overlapping ceramic discs to create a 'scaled' strikeface backed by neat Kevlar® fibres, shown in figure 12 [129]. This was the subject of intense controversy between the US Army and Pinnacle Armor due to their ballistic claims following its release in the early 2000s. A consequence of this is that there is a lack of reliable information as to its true ballistic performance. What is known however, is that the modular strikeface offered an improvement in multi-hit performance due to the restriction of ceramic fracture propagation to individual tiles but the cost of this performance was increased system weight. One belief is that each scale needed to be thicker than the ceramic component of a monolithic plate of the same performance because the scale geometry did not allow for proper support of the ceramic which limited the dwell time and thus the ballistic effectiveness. This coupled with scale overlap is commonly blamed for the increase in weight. Additionally, there was not a substantial increase in flexibility due to the bulk of the system. However, this remains an area of interest because of the severe effect body armour can have on a soldier's effectiveness. While Dragon Skin used a 'scaled' strikeface, it did not truly replicate the interactions of scales in nature. For example, this bio-inspired structure lacks an analogue to the dermal pocket which controls scale rotation. Ceramic scales would have no ability to bend before breaking so this mechanism cannot be used to enhance energy absorption. Therefore, to gain a benefit from the scaled structure, scale sliding and rotation must activate. Without a dermal pocket analogue, these factors also may not be in play. With a greater understanding of how this protection is accomplished in nature, it may be possible to realize an armour system that can outperform the current standards without an added weight.

Figure 12. Cross-sectional view of Dragon skin body armour showing imbricated ceramic discs [128].

Download figure:

Standard image High-resolution image5.2. Future of compound armour systems