Abstract

We report that the dynamic levitation force of bulk high temperature superconductors (HTS) in motion attenuates when exposed to an inhomogeneous magnetic field. This phenomenon has significant potential implications for the long-term stability and running performance of HTS in maglev applications. In order to suppress the attenuation of the levitation force associated with fluctuations in magnetic field, we compare the dynamic levitation performance of single grain Y–Ba–Cu–O (YBCO) and Gd–Ba–Cu–O (GdBCO) bulk superconductors with relatively high critical current densities. A bespoke HTS maglev dynamic measurement system (SCML-03) incorporating a rotating circular permanent magnet guideway was employed to simulate the movement of HTS in a varying magnetic field at different frequencies (i.e. speed of rotation). The attenuation of the levitation force during dynamic operation, which is key parameter for effective maglev operation, has been evaluated experimentally. It is found that GdBCO bulk superconductors that exhibit superior levitation force properties are more able to resist the attenuation of levitation force compared with YBCO bulk materials under the same operating conditions. This investigation indicates clearly that GdBCO bulk superconductors can play an important role in suppressing attenuation of the levitation force, therefore improving the long-term levitation performance under dynamic operating conditions. This result is potentially significant in the design and application of HTS in maglev systems.

Export citation and abstract BibTeX RIS

Original content from this work may be used under the terms of the Creative Commons Attribution 3.0 licence. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

1. Introduction

The performance and efficiency of rail-based transport, which forms a critical part of the global social and industrial infrastructure, is under constant development around the world. An emerging type of magnetic levitation technology (maglev) based on high temperature superconductor (HTS) materials has the advantages of stable passive levitation, low energy consumption, low noise, potentially high-speed and pollution-free operation. As a result, HTS maglev is being investigated actively by rail transit companies and organizations in many countries around the world [1–5].

Large single grain Y–Ba–Cu–O (YBCO) bulk superconductors exhibit good field generating and superconducting properties at liquid nitrogen temperatures (77 K) and can be manufactured routinely by established fabrication techniques. As a result, these materials have been employed in virtually all of the HTS maglev vehicles (manned and unmanned) developed to date, including the first manned HTS maglev test vehicle constructed at Southwest Jiaotong University, China in 2000 [6], the first evacuated tube HTS maglev vehicle test system established subsequently in 2014 [2, 3] and the full-scale 200 m long HTS maglev vehicle operational line at the Federal University of Rio de Janeiro, Brazil in 2014 [7]. A number of significant developments have emerged from the numerous fundamental studies of HTS maglev employing YBCO bulk superconductors [1, 8, 9]. In recent years, Gd–Ba–Cu–O (GdBCO) bulk superconductors have been developed with superior superconducting and mechanical properties compared to YBCO, and these materials are playing an increasingly important role in a variety of engineering applications that require higher and more stable sources of passive magnetic field [10]. In 2014, Durrell et al reported a trapped magnetic field of magnitude 17.6 T in an assembled stack of two GdBCO bulk superconductors, each 24.15 mm in diameter and 15 mm high and reinforced with shrink-fit steel [11]. This result exceeds the record field achieved in YBCO bulk superconductors, which had stood previously for more than a decade. Significantly, GdBCO bulk superconductors exhibit the so-called second peak effect in the variation of critical current density with increasing applied magnetic field, which leads directly to superior in-field, flux trapping performance compared to YBCO [12].

The dynamic interaction between bulk superconductors and permanent magnet guideways (PMGs) in HTS maglev systems is analogous to the wheel-rail interaction in conventional high-speed railway systems. Many designs of PMG arrays have been investigated for the optimization of levitation force, guidance force, levitation stiffness and other key parameters in the development of HTS maglev [13]. Moreover, from the perspective of superconducting materials, it is important to clarify the effects of superconducting properties on maglev performance, to verify, for example, whether the use of GdBCO bulk superconductors with higher critical current density and better flux trapping performance than YBCO would improve the levitation performance of the HTS maglev system overall, as expected.

Levitation force is one of the most important performance indicators in the design of a HTS maglev vehicle, and under long-term running conditions, in particular. The levitation force and its attenuation in systems incorporating bulk superconductors when exposed to a changing external magnetic field have been investigated in previous studies [14]. In these, the levitation force measured under dynamic conditions was found to attenuate slowly initially and to reach a plateau gradually with increasing time. This behavior has been attributed to the AC component associated with the intrinsic non-uniformity of the magnetic field generated by the rotating PMG [14–17]. However, most of the studies to date have been performed only on YBCO bulk superconductors, so it is essential to compare the levitation performance of other emerging superconducting materials with this benchmark.

In this paper, we report an investigation of the static and dynamic levitation behavior of GdBCO and YBCO bulk superconductors with the same dimensions by carrying out experiments on a HTS maglev dynamic measurement system (SCML-03) that has a rotatable circular PMG. A detailed comparison of the static levitation force between the two different bulk superconductors is presented. In addition, the attenuation of levitation force in both types of materials produced by an AC magnetic field generated by the moving an inhomogeneous PMG is analyzed rigorously. In particular, the levitation force performance of the GdBCO and YBCO bulk superconductors were compared under several different operating conditions by adjusting the rotating speed of the circular PMG. We discuss the potential of the GdBCO bulk superconductors for application in the HTS maglev systems and identify that further studies are required. The results of this study are potentially significant for the development of high field engineering applications, and especially for the future design of HTS maglev.

2. Experiment

2.1. Experimental arrangement

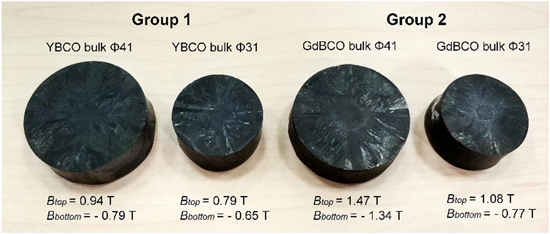

Four cylindrical single grain HTS bulk samples fabricated by top-seeded melt-growth from the bulk superconductivity group at the University of Cambridge [18] were divided into two groups, as shown in figure 1. Group 1 was composed of two YBCO bulk superconductors, of which one bulk had a diameter of 41 mm and a thickness of 15 mm, and the other had a diameter of 31 mm and thickness of 15 mm. Group 2 was composed of two Ag-containing GdBCO bulk superconductors of the same size as those in group 1. The GdBCO bulk superconductors studied here exhibit enhanced flux trapping capability compared to the YBCO based on measurements at 77 K (liquid nitrogen temperature). The peak trapped field of the 41 mm diameter YBCO and GdBCO bulk samples are 0.94 T, 1.47 T on the top surface (Btop) and –0.79 T and –1.34 T on the bottom surfaces (Bbottom), respectively; and Btop for the 31 mm diameter samples are 0.79 T and 1.08 T, and Bbottom are –0.65 T and –0.77 T. The levitation performance of the samples was compared within the two groups. The reason why we did not measure the levitation forces of single HTS bulk samples directly was the difference of the levitation forces generated by one HTS bulk sample was not obvious enough.

Figure 1. HTS bulk samples studied in this investigation.

Download figure:

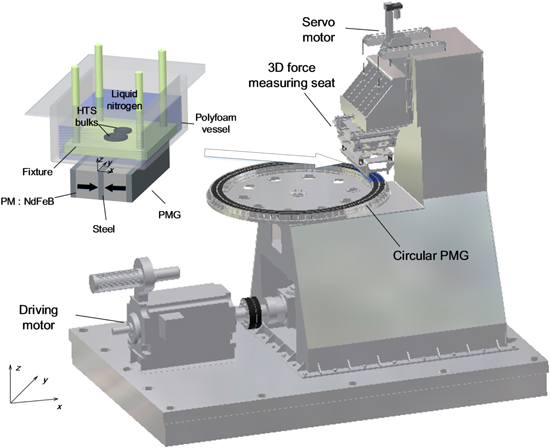

Standard image High-resolution imageThe samples in each group of two cylindrical bulk superconductors were mounted in a sample holder (shown in the inset of figure 2), which was connected directly and rigidly to the force sensors on a HTS maglev dynamic measurement system (SCML-03) developed in-house [19], as shown schematically in figure 2. The orthogonal growth sector facets of the bulk superconductors were arranged to be parallel or perpendicular to the direction of the PMG tangential velocity, as shown in figure 3. It has been found previously that the levitation force can be improved and the decay of the levitation force suppressed in this arrangement [20].

Figure 2. Schematic diagram of the HTS maglev dynamic measurement system (SCML-03) used in this study and the arrangement of bulk superconductors in the sample holder above the PMG.

Download figure:

Standard image High-resolution imageFigure 3. Schematic diagram illustrating the orientation of the bulk superconductor growth facet boundaries.

Download figure:

Standard image High-resolution imageThe SCML-03 apparatus consists of a circular NdFeB PMG of diameter 1.5 m spinning at a speed of up to 1200 rpm to simulate a maximum linear velocity of about 300 km h−1. The magnetic field along the direction of relative movement in this arrangement is not homogeneous due to the limited accuracy of processing and assembling the PMG. As a result, the magnetic flux varies typically by up to 32 mT at a height of 15 mm above the rotating PMG [14, 19].

A poly-foam cryostat filled with liquid nitrogen for cooling the HTS bulk samples was fixed on a plate independently of the force sensors but connected to the SCML-03 apparatus. The sample holder containing the bulk superconductors was positioned within the cryostat and there was a small gap between the bottom of the vessel and the sample holder, so that the continuous evaporation of liquid nitrogen during the experimental procedure, and hence the associated change in weight, did not affect the measured levitation force.

2.2. Experimental procedure

Firstly, the cooling height (CH) gap between the PMG and bulk superconductors was set to be 60 mm, and liquid nitrogen was poured into the cryostat to completely submerge the samples. This condition was maintained for ten minutes to ensure that the HTS bulk samples transformed fully from the normal state to the superconducting state to achieve maximum, stable levitation performance. The air gap was reduced slowly following the cooling process from the CH at a rate of 1 mm s−1 to the working height (WH), which was predetermined to be 15 mm. This static condition was then maintained for 5 min to allow for flux creep in the bulk samples and any associated relaxation of force. The driving motor of the SCML-03 was started and the PMG, positioned immediately beneath the HTS bulk samples, accelerated gradually to the preset, target rotation speed. The circular PMG was kept running at a stable speed for ten minutes under these conditions. Finally, the rotation speed of the PMG was slowed to zero gradually by adjusting the power input to the motor. The levitation force was recorded automatically by the measurement devices throughout the experiment. The rotation speeds of the circular PMG employed in this experiment were 60 rpm, 120 rpm, 240 rpm, 360 rpm and 480 rpm, corresponding to linear speeds of approximately 15 km h−1, 30 km h−1, 60 km h−1, 90 km h−1 and 120 km h−1, respectively.

A comprehensive test process was performed at each different experimental speed during cooling of the HTS bulk samples, movement of the samples to the WH, starting and stopping the motor and moving the samples for post-test quenching. The rigorous test procedure avoids the effects of re-magnetization of the HTS bulk samples on the measured levitation force to increase the accuracy of the measurements. The maximum magnetic flux density in the vertical direction above the PMG, Bmax, had been determined previously, as reported elsewhere [14]. The location of the PMG below the bulk superconductors, which were positioned at Bmax, was the same at the beginning and the end of each test. The sample holder was attached rigidly to the SCML-03 to avoid any displacement during the test. This procedure enabled the YBCO and GdBCO bulk superconductors to be studied systematically group-by-group with minimum measurement errors.

3. Results and discussion

3.1. Levitation force relaxation and static levitation force

The static levitation force in maglev or other systems provides critical information about the maximum load capacity and, as a result, is a key operating parameter for practical applications. All references to the static levitation force in the present work represent the residual levitation force after flux creep and force relaxation. The bulk superconductors in this study were maintained 15 mm above the PMG for 5 min before the PMG started to rotate to allow for such relaxation and to enable the levitation force to stabilize. The static levitation force and force relaxation process for the two kinds of bulk superconductors (i.e. prior to the dynamic tests) were compared by performing two sets of levitation force measurements as a function of time, as shown in figure 4.

Figure 4. Levitation forces of YBCO and GdBCO bulk superconductors prior to dynamic operation.

Download figure:

Standard image High-resolution imageThe ascending part of the curve, between 75 and 125 s in figure 4, indicates the levitation force increases as the cooled HTS bulks descends close to the static PMG. The bulk superconductors were positioned at the WH position after 125 s, 15 mm above the PMG, at which point the levitation force attained its maximum value. It can be seen that the maximum levitation force observed for the GdBCO bulk superconductors is significantly greater than that observed for YBCO bulk superconductors, and this increase in levitation force performance is constant with time, which suggests a similar relaxation mechanism for the two different materials.

Five sets of tests for five different rotational speeds were performed for each group of HTS bulk samples, generating ten sets of results in total. Tables 1 and 2 list the initial conditions of the levitation force of the two kinds of bulk superconductors prior to the dynamic tests. The initial test conditions were slightly different for each experiment set due to the fluctuation in magnetic field above the PMG and a slight misalignment between the crystallographic symmetry of the bulk samples and the manual operation of the PMG.

Table 1. Levitation force data for GdBCO bulk superconductors prior to dynamic operation.

| GdBCO bulk superconductors | Test 1 | Test 2 | Test 3 | Test 4 | Test 5 | Average value |

|---|---|---|---|---|---|---|

| Maximum levitation force (N) | 75.8 | 76.8 | 76.1 | 77.4 | 77.5 | 76.7 |

| Static levitation force (N) | 72.9 | 74.1 | 73.6 | 74.5 | 74.6 | 73.9 |

| Reduction (N) | 2.9 | 2.7 | 2.5 | 2.9 | 2.9 | 2.8 |

| Reduction rate | 3.8% | 3.5% | 3.3% | 3.7% | 3.5% | 3.7% |

Table 2. Levitation force data of YBCO bulk superconductors prior to dynamic operation.

| YBCO bulk superconductors | Test 1 | Test 2 | Test 3 | Test 4 | Test 5 | Average value |

|---|---|---|---|---|---|---|

| Maximum levitation force (N) | 72.2 | 71.8 | 71.2 | 72 | 72.5 | 71.9 |

| Static levitation force (N) | 69 | 68.6 | 68.4 | 69.4 | 69.2 | 68.9 |

| Reduction (N) | 3.2 | 3.2 | 2.8 | 2.6 | 3.3 | 3 |

| Reduction rate | 4.4% | 4.5% | 3.9% | 3.6% | 4.5% | 4.2% |

The average maximal levitation force relaxation for the GdBCO bulk superconductors is 76.7 N, as shown in table 1. The average levitation force after relaxation for these samples is 73.9 N, with an observed reduction in force of 2.8 N and a rate of decay of 3.7%. The corresponding values for the YBCO bulk superconductors are 71.9 N, 68.9 N, 3 N and 4.2%, respectively, as listed in table 2. The static levitation performance is evaluated principally by the magnitude of levitation force after relaxation. It can be concluded by comparing the average levitation force after relaxation that the static levitation force of GdBCO bulk superconductors is significantly better than that of YBCO, with an observed stable, incremental improvement of more than 7%.

The difference in levitation force of the two kinds of bulk superconductors employed in this study can be interpreted from equations (1) and (2) according to the trapped field (Btrap) of the single grain bulk superconductor [21] and the Lorentz formula, respectively:

where A is a geometrical constant, μ0 is the permeability of free space, Jc is the critical current density of the bulk HTS and R is the radius of the fully magnetized bulk superconductor, FLev is the levitation force between the bulk HTS and the PMG, J is the internal current density of the bulk HTS, BPMG-x is the magnetic flux density of the applied external field along the x axis, and dv is the incremental volume of the bulk sample.

Equation (1) is used widely and qualitatively to describe the relation between the trapped field and Jc in fully magnetized, cylindrical bulk superconductors, which corresponds exactly to the conditions of the trapped field measurements. Thus, the GdBCO bulk superconductors with greater Btrap, as shown in figure 1, has a higher volume (or average) Jc compared with the YBCO bulk superconductors of the same size according to equation (1). This is the main reason why GdBCO bulk superconductors have a better levitation force performance than YBCO under the same magnetic field according to equation (2).

The above analysis and comparison of the data indicates clearly that the levitation force attenuation rates are similar for both types of bulk superconductors, but that the levitation force for GdBCO is higher than that of YBCO under the same operating conditions. This raises two points of discussion. Firstly, the PMG in this study is constituted of two rows of 40 mm wide and 50 mm high permanent magnets arranged in polar opposition. As a result, the magnetic flux density and gradient of this arrangement is much lower than that of the Halbach-type PMG used typically in practical maglev applications [3]. It can be anticipated, therefore, that the enhancement in levitation force for GdBCO bulk superconductors will be even greater with a better, more practically representative PMG system. Secondly, although the incremental improvement in levitation force performance of around 7% observed for two HTS bulk samples may not appear to be large, the associated improvement in levitation performance of HTS maglev systems based on GdBCO may yield real benefits in actual system performance.

3.2. Levitation force performance under dynamic operation

The circular PMG was accelerated gradually after allowing for flux creep and force relaxation to the desired rotation speed, and maintained for a period of about 12 min. The rotation speed of the PMG was then decreased and Bmax position of the PMG maintained under the samples for three minutes. The fluctuation of magnetic field and internal energy loss within the bulk superconductors during this process causes the levitation force to oscillate and attenuate, as reported previously [14].

Figure 5 compares the levitation forces of the two kinds of bulk superconductors under dynamic operation at a rotation speed of 60 rpm. The high volume of the test data at the sampling frequency of 1 kHz necessitated the use of an adjacent averaging method in which one thousand points were smoothed to generate a single point to enable a more precise and intuitive analysis. The gray-shaded background in figure 5 indicates the range of the original data associated with the inhomogeneity of the magnetic field, but not with any intrinsic vibration or disturbance of the system. It can be seen that the levitation force goes through an abrupt decline and ascent when the Bmax position of the PMG is distant from and close to the bulk superconductors during acceleration and deceleration stages.

Figure 5. (a) Levitation force of GdBCO and (b) YBCO bulk superconductors during dynamic operation with a PMG rotation speed of 60 rpm.

Download figure:

Standard image High-resolution imageIt has been established in a previous study that the levitation force attenuation associated with the varying magnetic field of the PMG system is unrecoverable [22], which is why it is essential to study the attenuation conditions of levitation force before and after dynamic operation. It can be seen by comparing figures 5(a) and (b) that the general trends of the smoothed red and blue curves are similar, and are effectively parallel, which indicates the basic mechanism of generating the levitation performance for GdBCO and YBCO bulk superconductors is essentially the same. The static levitation force for GdBCO bulk superconductors, shown in figure 5(a), is 72.9 N and the steady levitation force is 68.5 N with a force attenuation of 4.4 N, corresponding to an attenuation rate of 6%. The levitation force for YBCO bulk superconductors similarly exhibits attenuation, with a steady-state levitation force 64.8 N, which is 4.2 N less than the static levitation force of 69.0 N before rotation of the PMG with an attenuation rate of 6.1%. A preliminary conclusion drawn from these results, therefore, is that the levitation force attenuation of GdBCO bulk superconductors is, at last, comparable to YBCO under conditions of relatively low speed.

Figure 6 shows the levitation performance of GdBCO and YBCO bulk superconductors under typical dynamic operation with a moderate rotation speed of 240 rpm. The same method as that used for the lower speed tests described above was used to analyze these data. The static, steady levitation force of GdBCO was observed to be 73.6 and 68.7 N after 240 rpm-rotation dynamic operation, with a force attenuation of 5.2 N at a rate of 6.7%. The static levitation force for YBCO was observed to be 68.4 N, and the equivalent steady levitation dynamic force to be 63.5 N with an attenuation rate of 7.2%. As a result, there is a decay of levitation force attenuation of about 0.5% between GdBCO and YBCO bulk superconductor under dynamic operation at a rotation speed 240 rpm. Several additional sets of tests were performed at different rotational speeds to understand further the differences between the levitation force attenuation for the two types of bulk superconductors investigated. The test data for these additional measurements are shown in tables 3 and 4.

Figure 6. (a) Levitation force of GdBCO and (b) YBCO bulk superconductors during dynamic operation with a PMG rotation speed of 240 rpm.

Download figure:

Standard image High-resolution imageTable 3. Levitation force data for GdBCO bulk superconductors before and after dynamic operation.

| GdBCO bulk superconductors | 60 rpm | 120 rpm | 240 rpm | 360 rpm | 480 rpm |

|---|---|---|---|---|---|

| Static levitation force (N) | 72.9 | 74.1 | 73.6 | 74.5 | 74.6 |

| Steady levitation force (N) | 68.5 | 69.3 | 68.7 | 69.3 | 69.2 |

| Levitation force attenuation (N) | 4.4 | 4.8 | 4.9 | 5.2 | 5.4 |

| Attenuation rate | 6.0% | 6.5% | 6.7% | 7.0% | 7.2% |

Table 4. Levitation force data for YBCO bulk superconductors before and after dynamic operation.

| YBCO bulk superconductors | 60 rpm | 120 rpm | 240 rpm | 360 rpm | 480 rpm |

|---|---|---|---|---|---|

| Static levitation force (N) | 69.0 | 68.6 | 68.4 | 69.4 | 69.2 |

| Steady levitation force (N) | 64.8 | 63.9 | 63.5 | 64.0 | 63.5 |

| Levitation force attenuation (N) | 4.2 | 4.7 | 4.9 | 5.4 | 5.7 |

| Attenuation rate | 6.1% | 6.9% | 7.2% | 7.8% | 8.2% |

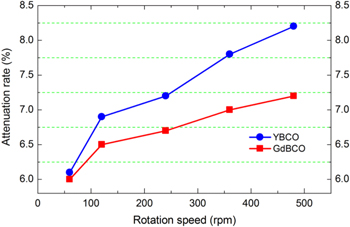

It can be seen from tables 3 and 4 that the levitation force attenuation rates for both GdBCO and YBCO bulk superconductors increase with the increase of PMG rotation speed, which is consistent with the results of previous studies. Essentially, higher rotation speeds are associated with more rapid fluctuations in magnetic flux and an increase in attenuation in the measured levitation force. However, there is a limit to the extent of the observed attenuation as the levitation force reaches a dynamic equilibrium under conditions of steady speed. The superiority of GdBCO bulk superconductors for resisting levitation force attenuation as the speed increases is illustrated by comparing the final two rows in tables 3 and 4. In order to give a visual representation of the phenomenon, figure 7 shows the levitation force attenuation under five dynamic operational conditions with different rotation speeds. On one hand, the attenuation rate curves of both YBCO and GdBCO bulk superconductors increases as the rotation speed increases, although the GdBCO curve is always below that of YBCO. On the other hand, however, the gap between the two curves increases with increasing rotational speed, which indicates that the GdBCO bulk superconductors may have greater potential for application under dynamic operation, and particularly at high speeds.

Figure 7. Attenuation rates of GdBCO and YBCO bulk superconductors under dynamic operation with different PMG rotation speeds.

Download figure:

Standard image High-resolution imageThe attenuation of levitation force under dynamic operating conditions is thought to be caused, at least in part, by internal AC energy loss within the bulk superconductors, which originates mainly from hysteresis effects (eddy current loss is much less significant in bulk HTS) [23, 24]. As a result, hysteresis loss should account for the substantive energy losses under the experimental conditions employed in this study. In the case of hysteresis losses due to the effects of pinning, the energy loss according to the Bean model can be written as equation (3) [25]:

where W is hysteresis loss during one period, Hac corresponds to the amplitude of alternating magnetic field and r is the penetration depth in the radial direction of the bulk superconductor. In this study, the applied magnetic field is not of sufficient magnitude to penetrate the bulk superconductor completely. As a result, the penetration depth r in the two types of bulk superconductor is small and, therefore, assumed to be the same. Hence, the magnitude of Jc induced in the samples is likely to have a major effect on the hysteresis loss. According to the trapped field data, the GdBCO bulk superconductors employed in this study exhibit higher Jc. In this case, the levitation force attenuation of GdBCO bulk superconductors is consistently less than that of the YBCO bulk superconductors in each test.

The observed rise in attenuation rates rise with increasing rotation speed for both types of bulk superconductor can be explained by thermal effects associated with the AC losses. The frequency of the varying external field increases as the rotation speed of the PMG increases. Dynamic equilibrium in the bulk HTS in the varying magnetic field, however, is established as flux enters and leaves the bulk material, during which heat is generated [22]. The amount of heat generated increases with increasing rotational speed before dynamic equilibrium is reached [26]. The heat generated internally within the bulk superconductors, therefore, has a direct impact on Jc, according to equation (4) [27]:

where, Tc is the critical temperature of the bulk superconductor. Based on this theory, the increment in temperature T caused by the heat generated during the process before dynamic equilibrium is established can decrease Jc. It can be concluded, therefore, that the higher the rotation speed, the higher the increment in T, the lower the Jc, the smaller the levitation force and the greater the attenuation rate.

A superconductor with higher Jc and greater flux trapping performance will have better resistance to levitation force attenuation as the frequency of the varying magnetic field increases under dynamic operation [16]. In addition, the presence of Ag within the GdBCO bulk superconductor microstructure aids the internal release of heat and, hence, this material is more able to respond to a varying magnetic field than YBCO (which does not contain silver). This could be effective in suppressing any rise in temperature, and therefore reduce the attenuation of Jc and, hence, the levitation force. The higher Jc and the presence of Ag in the GdBCO bulk superconductors employed in this study could explain the observed increasing difference in attenuation rates of the two types of bulk superconductors as the PMG rotation speed increases. This difference in performance may reasonably be anticipated to stabilize at sufficiently high frequencies [14].

4. Conclusions

The fundamental levitation characteristics, including levitation force and levitation force attenuation, of both GdBCO and YBCO bulk superconductors of the same sample dimensions were investigated experimentally above a bespoke, spinning PMG with controllable rotational speeds. The observed characteristics and time-dependent levitation force of the two types of bulk superconductors investigated were consistent, in general, with the results of previous research. However, under the same experimental conditions, analysis of the levitation force and levitation force attenuation indicates that GdBCO bulk superconductors exhibit enhanced static levitation force and levitation force attenuation performance than YBCO. The average static levitation forces of GdBCO and YBCO bulk superconductors are 73.9 N and 68.9 N, respectively, under the same experimental conditions (in which the CH above the PMG was 60 mm and the WH was 15 mm). The observed improvement in performance of more than 7% is considered to be significant for developing practical engineering applications that incorporate bulk superconductors, such as maglev. The levitation force attenuation of GdBCO bulk superconductors was observed consistently to be lower than that observed for YBCO under conditions of dynamic operation for a relatively wide range of PMG rotation speeds. This phenomenon becomes more pronounced for higher speeds of rotation. The levitation force attenuation rates for GdBCO and YBCO bulk superconductors at a rotation speed of 480 rpm (120 km h−1) are 7.2% and 8.2%, respectively. These results imply that the HTS maglev system with on-board GdBCO bulk superconductors will have a greater loading capacity and better operational performance for long-running operation than that with YBCO bulk superconductors. Future studies will explore further the potential of GdBCO bulk superconductors for HTS maglev applications by investigating the levitation force generated by larger arrays of GdBCO HTS bulk materials and the use of applied PMGs with stronger magnetic field intensities and higher magnetic field gradients under dynamic operation at higher relative rotational speeds.

Acknowledgments

The maglev study was supported partially by the National Natural Science Foundation of China (51375404), the Sichuan Youth Science and Technology Fund (2016JQ0039), the Fundamental Research Funds for the Central Universities (2682017ZT05 and 2682017ZDPY05) and the State Key Laboratory of Traction Power at Southwest Jiaotong University (2016 TPL_T01, TPL1709 and 2018TPL_T06). The processing of bulk HTS materials was supported partially by the Engineering and Physical Sciences Research Council in UK (grant number: EP/P00962X/1).