Abstract

Recent studies indicated the electrorhological (ER) effect of the ER fluids with flower-like particles were more significant than those with traditional sphere particles, but whether the special morphology can enhance the properties of magnetorheological (MR) fluids remains unclear. To address the issue, flower-like cobalt particles (FCP) and sphere cobalt particles (SCP) were synthesized, and the properties of the two kinds of MR fluids with the two kinds of particles were compared. Particle characterization results indicate the two kinds of particles have significant difference in morphology, but little difference in crystal structure, particle size, and magnetic properties. The FCP based MR fluids (FCP-MRFs) present higher zero-field viscosity, higher field-induced yield stress, higher storage modulus and better sedimentation stability than the SCP based samples (SCP-MRFs). The high performance of the FCP-MRF can be attributed to the special morphology of the flower-like particles.

Export citation and abstract BibTeX RIS

1. Introduction

Magnetorheological (MR) fluids are suspensions composed of micron-sized magnetizable particles dispersed in a non-magnetizable carrier fluid, usually mineral or silicon oil [1–3]. Under the presence of magnetic fields, the viscosity of MR fluids changes rapidly. As a result, they transfer from liquid state with free flow to semi-solid state with controllable yield stress, which is reversible. Since Rabinow firstly discovered the MR effect in 1948, many achievements have been made on preparation and applications of MR fluids [4–6]. Nowadays, commercially available MR fluids based on carbonyl iron particles exhibit large magnetic field-induced yield stress of more than 100 kPa [7, 8]. As an excellent smart material, MR fluids have been successfully applied as clutches, dampers, actuators, human muscle simulators in various fields [9–15].

The MR effect is mainly attributed to the field-induced magnetization of the dispersing particles. When a magnetic field is applied, the magnetized particles attract one anther along the field direction and form chains or even columns. As a result, the suspension cannot flow until the applying shear stress reaches a critical value, which is defined as the yield stress. Obviously, the magnetizable particles play the dominate role for the MR effect. The influence of particles composition, size, volume fraction on MR properties have been fully studied in previous studies. However, the effect of particle morphology on properties of MR fluids was seldom investigated. The major reason was the morphology of carbonyl iron particles, which is the best candidate to prepare MR fluids due to their high magnetic permeability and high saturation magnetization, was difficult to control. In most of previous studies, the carbonyl iron particles used as the dispersing phase had sphere morphology. Consequently, a number of theoretical models were established based on the assumption that the particles have sphere shape.

In 2008, Bell et al prepared a MR fluid submicron diameter iron micro-wires [16]. The MR performance and the sedimentation stability of the new MR fluids were better than those with the sphere particles. In 2011, Li et al established a yield stress model for MR fluids using rod particles, which can be used to explain the excellent MR properties of the MR fluids with rod particles or micro-wires [17]. Those studies indicated much attention should be paid on the effect of particle morphology on properties of MR fluids. In fact, several studies have been conducted on their electrorheological (ER) counterparts, electrorheological fluids. Besides rod-like particles, bionic cactus-like particles and chrysanthemum-like particles were used to prepare new ER fluids with better ER performance [18–21]. Those studies inspired us to develop high performance MR fluids by using special morphology particles as the dispersing phase.

Although iron particles are the best candidate to prepare MR fluids, it is difficult to synthesis iron particles with different morphologies. Cobalt is also a ferromagnetic material with high saturation magnetization. Compared with iron particles, the morphology of cobalt particles can be easily controlled [22–26]. In this study, sphere and flower-like cobalt particles (FCP) were synthesized and used to prepare two different MR fluids. They were used to investigate the effect of particle morphology on properties of MR fluids.

2. Experimental

2.1. Preparation of cobalt particles

FCP were synthesized by a solvothemal method. All chemicals were of analytical grad and used without further purification. In a typical procedure, 8 mmol of CoCl2 · 6H2O and 30 mmol of NaOH were separately dissolved into 40 ml of 1,3-propanediol under magnetic stirring until two homogeneously solutions were formed. Subsequently, the two solutions were mixed together at room temperature and stirred for 30 min. The mixture was transferred into a 100 mL Teflon-lined stainless steel autoclave, sealed and maintained at 200 °C for 10 h. After cooling to room temperature naturally, precipitates were obtained. They were thoroughly washed with ethanol and deionized water several times, and then dried at 60 °C for 12 h to obtain the final products. Sphere cobalt particles (SCP) were synthesized through a similar process [26]. The only difference with respect to the synthesis route of the FCP was that ethylene glycol were used to replace 1,3-propanediol.

2.2. Preparation of cobalt particles based MR fluid

Silicon oil with a dynamic viscosity of 0.5 Pa s was used as the carrier liquid. SCP and FCP were mixed with silicone oil to prepare two different kinds of MR fluids, respectively. They are named as SCP-MRF and FCP-MRF for short in the following text. For rheological measurements, the concentration of the two MR fluids was 12% by effective volume, while for sedimentation tests, the effective particle volume fraction was 3%. Those concentrations were consistent with our previous studies [22].

2.3. Characterization of cobalt particles and evaluation of MR fluids

The structures of the particles were identified by means of x-ray diffraction (XRD) with an Empyrean x-ray diffractometer (PANalytical, Netherland) with Cu Kα radiation (λ = 1.5418 Å) at a scan rate of 0.04 s−1. Their morphologies were investigated by a scanning electron microscopy (SEM, QUANTA 450, America). Magnetic measurements were carried out using a JDM-13T vibrating sample magnetometer.

The magnetorheological properties of MR fluids were measured by a Physica MCR301 rheometer (Anton Paar, Austria) fitted with a magneto-rheological module (MRD180), which can apply different magnetic fields on the parallel-plates system by changing direct current. The diameter and the gap of the parallel-plate system were 20 mm and 1 mm, respectively. The viscosity–shear rate curves at zero field and the shear stress–shear rate curves at different magnetic fields were measured by applying logarithmically increasing shear rate from 0.01 to 100 s−1. Bingham model was used to fit the experimental data. The vertical intercept of each fitting curve was considered as the yield stress under the corresponding field. To find the linear viscoelastic (LVE) region of the two MR fluids, strain amplitude sweep (0.001%–50%) measurements were carried out at a constant angular frequency 10 rad s−1 and different magnetic fields (0, 82, 142, 186, 220 and 250 kA m−1). Besides, at fixed angular frequency (10 rad s−1 and fixed strain amplitude (0.01%), magnetic field sweeps were carried out. The shear stress amplitude, storage modulus and loss modulus were obtained in those oscillatory tests. All the samples were measured at 25 °C.

The sedimentation experiments were carried out at room temperature by using cuvettes. The sedimentation ratio, defined by the height percentage of the particle-rich phase relative to the total suspension height, was used to evaluate the sedimentation stability of the MR fluids.

3. Results and discussion

3.1. Morphological and structural characteristics of cobalt particles

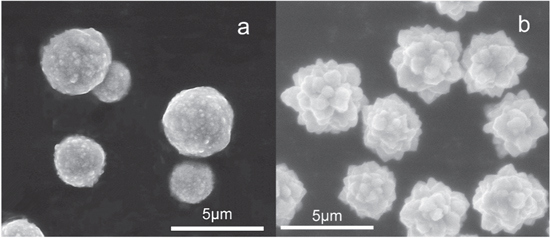

The SEM images of the SCP and the FCP particles are shown in figure 1. The obtained sphere particles present uniform diameters (2–5 μm), as shown in figure 1(a). The FCP present comparable particle size with the sphere particles (figure 1(b)). Previous studies indicated the performance of the MR fluids with carbonyl iron particles in this particle size range was excellent.

Figure 1. SEM image of (a) sphere cobalt particles and (b) flower-like cobalt particles.

Download figure:

Standard image High-resolution imageThe XRD pattern of the two kinds of cobalt particles is shown in figure 2. As is known, there are only two crystal structures for elemental cobalt: hexagonal close packed (hcp) and face centered cubic (fcc). In spite of the low degree of crystallinity, all the diffraction peaks observed for the sphere particles and flower-like particles can be indexed as cobalt with mixed structures of both fcc-cobalt (JCPDS 15-0806) and hcp-cobalt (JCPDS 05-0727). No obvious peaks resulted from impurities of cobalt oxides or hydroxides are observed, indicating that the structures obtained by the synthetic route consist of a pure cobalt.

Figure 2. XRD pattern of sphere cobalt particles and flower-like cobalt particles.

Download figure:

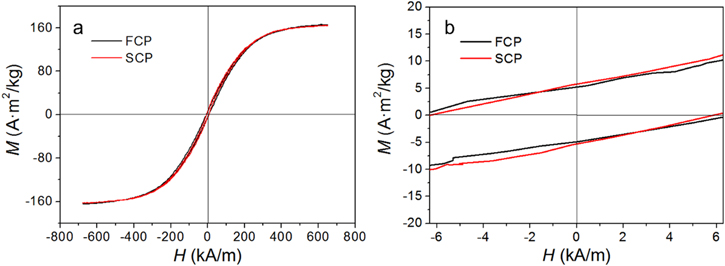

Standard image High-resolution imageFigure 3 shows the magnetic hysteresis loops of the FCP and the SCP at 300 K. There is little difference between the two magnetic hysteresis loops. The saturation magnetization (Ms) of the flower-like particles and the sphere particles are 165 A m2 kg−1 and 163 A m2 kg−1, respectively. Meanwhile, the two kinds of particles show similar coercivity and residual magnetization. Their comparable particle size is responsible for the similar magnetic performance.

Figure 3. Magnetic hysteresis loop of sphere cobalt particles and flower-like cobalt particles. (a) Entirety, (b) portion.

Download figure:

Standard image High-resolution image3.2. Rheological properties of cobalt particles-based MR fluids

Figure 4 presents the flow curves at zero field for the two MR fluids containing 12% flower-like particles and sphere particles by volume fraction, respectively. Due to the shear-thinning effect, the viscosities of the two fluids decrease with increasing shear rate. At low shear rate levels, the FCP-MRF presents much higher viscosity than the SCP-MRF. The possible reason is that the petals of flower-like particles keep them from severe aggregation. In another words, the aggregation of the sphere particles in the silicon oil is severer than that of the flower-like particles. As a result, the sphere particles present larger apparent particle size than the flow-like particles in the suspensions. Previous studies proved that the apparent viscosity of a suspension increases with decreasing apparent particle size [27–29]. Interestingly, at high shear rate, there is little difference on viscosity between the two fluids. It indicates the influence of the particle morphology on the viscosity of the MR fluids can be ignored at high shear rate levels. The possible reason is that the particles aggregation is completely decomposed at high shear rate without respect to the particle morphology, in which case the true particle size plays the dominate role on the viscosity of the MR fluids [28].

Figure 4. Dependence of viscosity of FCP-MRF and SCP-MRF on shear rate.

Download figure:

Standard image High-resolution imageFigure 5 shows shear stress as a function of shear rate for FCP-MRF and SCP-MRF under different magnetic field strengths (0, 82, 142, 186, 220 and 250 kA m−1). The two MRFs present Bingham behavior. The fitting curves based on the Bingham model agree with the experimental data. The vertical intercept of each fitting curve is used to represent the yield stress under the corresponding magnetic field. Then the dependence of the yield stress of the two MRFs on magnetic field is obtained, as shown in figure 6. Their yield stress increases with increasing magnetic field strength, indicating significant MR effect. That is caused by the formation of chain-like or even robust columns due to the interaction among the adjacent magnetic particles. The yield stress of FCP-MRF is higher than that of SCP-MRF in all magnetic field strength, and the difference between them gets wider with increasing magnetic field strength. It indicates that using the flower-like particles as the dispersing phase can improve the field-induced yield stress of MRFs. This behavior relates with the higher friction between the flower-like particles with respect to the sphere particles. The friction could lead to wear and possible degradation of the performance of MR fluids. Each MR fluid was tested 10 times, and no significant changes were observed on their performance. The flower-like particles was observed by SEM before and after the tests (figure S1), and they present little change in morphology. However, the evaluation of its service life still needs more experiments.

Figure 5. Shear stress versus shear rate curves: (a) FCP-MRF, (b) SCP-MRF.

Download figure:

Standard image High-resolution imageFigure 6. Dependence of yield stress of FCP-MRF and SCP-MRF on magnetic field.

Download figure:

Standard image High-resolution image3.3. Dynamic viscoelasticity of cobalt particles-based MR fluids

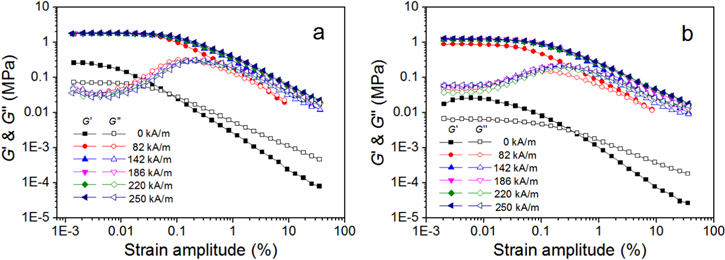

Figure 7 shows the dependence of the dynamic shear moduli of FCP-MRF and SCP-MRF, including storage modulus G' and loss modulus G'', on strain amplitude at a constant angular frequency of 10 rad s−1. In absence of a magnetic field, their storage modulus and loss modulus decrease with increasing strain amplitude, and the storage modulus become lower than the loss modulus when the strain amplitude exceeds a small value, indicating a liquid-like state. By applying a magnetic field, their storage modulus keeps unchanged at low strain amplitude and then decreases with increasing strain when it reaches a critical value, while the loss modulus initially increases and then decreases. Below the critical strain amplitude, the MR fluids are considered in LVE region. When the strain amplitude exceeds the critical value, the chains or columns formed by the magnetized particles becomes unstable, and the MR fluids are in nonlinear viscoelastic region. Furthermore, the storage modulus is higher than the loss modulus at low strain amplitude levels, indicating a solid-like state. As the strain amplitude increases, the storage modulus is gradually lower than the loss modulus, corresponding to the process of transforming from solid-like state to liquid state. The reason is that the chain or column structures are destroyed at high strain amplitude. The strain amplitude that the loss modulus begin to exceeds the storage modulus shifts to right with increasing magnetic field, even though some points are not shown due to the limit range of the strain amplitude. It agrees with the positively relationship between the yield stress and the magnetic field, and indicates the chains or columns composed by the particles are more rigid under higher magnetic field.

Figure 7. Dependence of the dynamic shear moduli (storage modulus G' and loss modulus G'') of (a) FCP-MRF and (b) SCP-MRF on strain amplitude at a constant angular frequency of 10 rad s−1.

Download figure:

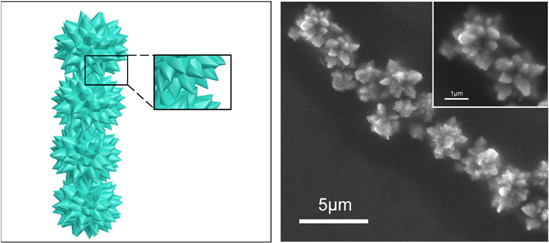

Standard image High-resolution imageFigure 8 shows the dependence of the storage modulus of the two MR fluids on magnetic field at 0.01% stain amplitude and 10 rad s−1 angular frequency. The storage modulus of the two MR fluids increases with increasing magnetic field, which is gently at low field, and dramatically at high field. It indicates the rigidity of the structures formed by the particles is enhanced with rising magnetic field. Interestingly, although the flower-like particles have similar magnetic properties and particle size with the sphere particles, the FCP-MRF presents higher storage modulus with respect to the SCP-MRF. At low field levels (<3 kA m−1), the particles can be considered randomly dispersed in the suspensions, the higher storage modulus for the FCP-MRF can be attributed to its higher viscosity. At high field levels (>3 kA m−1), the magnetized particles form ordered structures. In that case the storage modulus depends on the rigidity of the column structures. The petals of the flower-like particles provide additional mechanical lock effect between the adjacent particles (figure 9), which makes the rigidity of the ordered structure composed by the flower-like particles is stronger than that formed by the sphere particles. As a result, the FCP-MRF presents higher storage modulus than the SCP-MRF.

Figure 8. Dependence of the storage modulus of (a) FCP-MRF and (b) SCP-MRF on magnetic field at 0.01% stain amplitude and 10 rad s−1 angular frequency.

Download figure:

Standard image High-resolution imageFigure 9. Schematic illustration of the adjacent particles under magnetic field.

Download figure:

Standard image High-resolution image3.4. Sedimentation stability of cobalt particles-based MR fluids

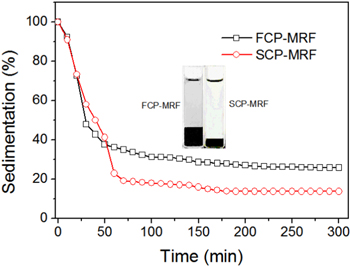

Figure 10 shows the sedimentation stability curves of the two kinds of MR fluids. The sphere particles and the flower-like particles settled down rapidly during the initial 50 min. Subsequently, the sedimentation velocity of the FCP-MRF became slow, and the sedimentation ratio gradually reached a stable value at 25%. By contrast, the SCP-MRF exhibited higher sedimentation velocity than the FCP-MRF until ∼80 min, and its sedimentation ratio slowly achieved a constant value at ∼10%. It indicates the MR fluid with the FCP presents better sedimentation stability than that with the SCP. The possible reason is that the special morphology of the flower-like particles keeps them from aggregation to large particles, and the petals makes them support each other and occupy more space, which can be illuminated as figure 11. Considering its low concentration, the sedimentation performance will be improved with increasing particle content [30].

Figure 10. Sedimentation curves of FCP-MRF and SCP-MRF. The inserted picture is the photograph of the two MR fluids after 300 min setting without any disturb.

Download figure:

Standard image High-resolution imageFigure 11. Schematic illustration of the state of the particles suspended in MRFs.

Download figure:

Standard image High-resolution image4. Conclusions

SCP and FCP were used as dispersing phase to study the effect of particle morphology on properties of MR fluids. The two kinds of particles have comparable size and magnetic properties. Compared with the MR fluids with sphere particles, flower-like particles-based MR fluids present higher field-induced yield stress. The possible reason is that the special morphology of the flower-like particles provides additional mechanical lock effect between adjacent particles, and enhances the rigidity of the ordered structure by applying magnetic field. In order to further demonstrate the effect of particle morphology on magnetorheological properties, a squeeze-shear mode test can be carried out in the future [31–34]. The special morphology is also responsible for the better sedimentation stability of the MR fluids with flower-like particles. Although the flower-like particles based MR fluids present better performance than the sphere particles based ones, the high cost of flower-like particles is the main obstacle for their applications. In this study, the cost of the flower-like particles was ∼30 dollars/g, while the cost of the sphere particles was ∼10 dollars/g. The high cost of the flower-like particles was mainly from 1,3-propanediol, which was used in the synthesis process.

Acknowledgments

This research is financial funded by the National Natural Science Foundation of China under the grant number of 51478088 and 51378093, and the International Science & Technology Cooperation Program of China under the grant number of 2014DFA70950.