Abstract

Spin-coated perovskite solar cells from sol–gels result in high processing costs because of the need for high temperatures. Here, we report a low-temperature spin-coating route to fabricate planar heterojunction perovskite solar cells using chemical bath deposition of compact-TiOx layers. Comparison of the solar cell properties of compact-TiOx and compact-TiO2 layers show that the power conversion efficiency of the planar heterojunction perovskite solar cell fabricated by the low-temperature, compact-TiOx route is comparable to that of conventional TiO2. The chemical bath deposition method requires heating to 150 °C only to form amorphous compact-TiOx films compared with the 450 °C required for crystalline anatase compact-TiO2 films.

Export citation and abstract BibTeX RIS

1. Introduction

Organometallic halide perovskite solar cells have recently emerged as promising cost-effective and highly efficient nanostructured solar cells.1,2) The first perovskite solar cell with a power conversion efficiency (PCE) of 3.81% was reported in 2009 by Kojima et al.3) Currently, typical PCE values of perovskite solar cells are over 20%4) — far higher than that of organic thin-film solar cells. Perovskite solar cells are classified into two types: i) spin-coated perovskites based on dye-sensitized solar cells, with compact-TiO2 and mesoporous TiO2 layers,5–15) and ii) vapor-deposited perovskite solar cells based on small molecule organic solar cells, with compact-TiO2 layers having PCE of over 15%.16,17) Liu et al. first reported17) the co-evaporation method for depositing the perovskite layer — termed the planar heterojunction (PHJ) perovskite solar cell. Both the spin-coated and vapor-deposited PHJ perovskite solar cells consist of an approximately 40-nm-thick compact-TiO2 layer on the transparent conducting oxide substrate. Generally, the spin-coated compact-TiO2 layer is deposited from an acidic solution of titanium isopropoxide in ethanol and heated to 500 °C for approximately 30 min.17) Such sol–gel methods require excessive thermal treatment resulting in high processing costs for commercial applications.

The chemical bath deposition (CBD) method has previously been reported in the development of the electron collection layers for inverted polymer solar cells.18) Here, we apply the CBD method to vapor-deposited PHJ perovskite solar cells. We report the synthesis of a compact-TiOx layer by CBD via a low-temperature route at 150 °C.

2. Experimental methods

Figure 1 depicts the schematic structure of the device. The transparent conducting indium tin oxide (ITO) and F-doped tin oxide (FTO) were treated with oxygen plasma for 20 min. The compact-TiOx layer was deposited in an aqueous solution of titanium(IV) oxysulfate (TiOSO4) and hydrogen peroxide (H2O2) for 16 min in an oil bath at 80 °C. An amorphous film was produced after heating to 150 °C for 1 h on a hot plate. By the CBD method, a 30-nm-thick crystalline anatase TiO2 film was produced after heating for 1 h at 450 °C.19,20) To obtain thicker (60 and 90 nm) TiOx films, the deposition cycle was repeated (two and three times, respectively). Rather than co-evaporation, the perovskite layer was formed by sequential deposition and evaporation of lead iodide (PbI2) and methylamine iodide (MAI, CH3NH3I). PbI2 was dehydrated under vacuum at 450 °C for 3 h and MAI was synthesized in our own laboratory. The thicknesses of the PbI2 and MAI layers were 80 and 500 nm, respectively. To remove residual MAI, the perovskite layer was washed in 2-propanol and heated to 70 °C for 30 min on a hot plate. This process was repeated until a 200-nm-thick CH3NH3PbI3 film was obtained. The hole transport layer was spin-coated at 4000 rpm for 30 s from a solution of 2,2',7,7'-tetrakis(N,N-di-p-methoxyphenylamine)-9,9'spirobifluorene (spiro-OMeTAD) in chlorobenzene (0.058 M) containing 4-tert-butylpyridine (0.19 M), lithium bis(trifluuoromethylsulfonyl)imide (0.031 M), and tris[2-(1H-pyrazol-1-y1)-4-tert-butylpyridine]cobalt(III) tris[bis(trifluoromethysulfonyl)imide] (5.6 × 10−3 M).21,22) Finally, a 100-nm-thick gold layer acting as the uppermost electrode was deposited onto the hole transport layer. The resulting active device area was 4 mm2. All film thicknesses were measured using a Microfigure measurement instrument (Kosaka Laboratory Surcorder ET 200). The current density versus voltage (J–V) characteristics of the cells were measured under simulated AM 1.5G solar illumination (Keithley 2401 SourceMeter). An atomic force microscope (AFM; SII SPI 3800N) was used to investigate the morphology of the surface of the solar cells.

Fig. 1. Schematic of structure of the PHJ perovskite solar cell.

Download figure:

Standard image High-resolution image3. Results and discussion

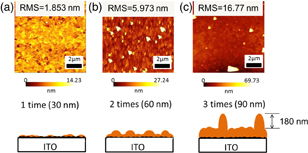

PHJ perovskite solar cells were synthesized with 30-, 60-, and 90-nm-thick amorphous compact-TiOx layers to determine the effect of layer thickness. The J–V characteristics at scan speeds of 0.01 V/s are presented in Fig. 2. The parameters of forward scan measurements — from the negative bias side to the opposing positive bias side — under AM 1.5G simulated solar light are listed in Table I. All perovskite solar cells based on the CBD compact-TiOx layer were active as solar cells. The 60-nm-thick compact-TiOx layer PHJ perovskite solar cell had the highest PCE of 4.09%, whereas the 90-nm-thick compact-TiOx layer solar cell displayed the lowest conversion efficiency (2.90%). Figures 3(a) to 3(c) show AFM images of the compact-TiOx films. The surface is significantly rougher on the 90-nm-thick compact-TiOx film, having a root mean square (RMS) value of over 15 nm. This film presented an abundance of surface islands with heights on the order of 180 nm. The 200-nm-thick perovskite layer is deposited onto these TiOx surface islands, and this result in either short-circuiting or a low PCE value. In the 30- and 60-nm-thick TiOx films, the surface islands are 30 and 70 nm high, respectively, with RMS values of 1.8 and 5.8 nm. Figures 3(d) to 3(f) show cross-sectional illustrations of the 30, 60, and 90 nm layer thicknesses of the compact-TiOx films present on the transparent conducting ITO. The high efficiency of the perovskite solar cell having a 60 nm compact-TiOx coating is considered to arise from the increase in the contact surface area owing to the complete coverage of the ITO surface by the compact-TiOx film as a result of using the CBD method.

Fig. 2. J–V characteristics of the 30-, 60-, and 90-nm-thick compact-TiOx PHJ perovskite solar cells.

Download figure:

Standard image High-resolution imageTable I. Solar cells parameters calculated from J–V curves measured by forward scanning.

| TiOx operation times (thickness) | Jsc (mA/cm2) | Voc (V) | FF | PCE (%) |

|---|---|---|---|---|

| 1 (30 nm) | 9.58 | 0.91 | 0.40 | 3.45 |

| 2 (60 nm) | 8.03 | 0.94 | 0.54 | 4.09 |

| 3 (90 nm) | 10.2 | 0.82 | 0.35 | 2.90 |

Fig. 3. AFM images of (a) 30-nm-thick compact-TiOx on ITO, (b) 60-nm-thick compact-TiOx on ITO, and (c) 90-nm-thick compact-TiOx on ITO. Cross-sectional illustrations of each film are given below the images. RMS: Root mean square.

Download figure:

Standard image High-resolution imageThe J–V characteristics of the PHJ perovskite solar cells were investigated. Forward and backward scans are detailed in Figs. 4(a) and 4(b), and the corresponding forward scan solar cell parameters are listed in Table II. The backward scan means scanning from the positive-bias side to the negative-bias side. The J–V characteristics of PHJ perovskite solar cells for the amorphous compact-TiOx layer are comparable to those of the analogous anatase cell, with both displaying low hysteresis. The results indicate that the electrical properties of the compact-TiOx layer solar cell are almost identical to those of conventional compact-TiO2 layer cells.

Download figure:

Standard image High-resolution imageFig. 4. J–V characteristics of (a) amorphous compact-TiOx and (b) crystalline anatase compact-TiO2 PHJ perovskite solar cells.

Download figure:

Standard image High-resolution imageTable II. Solar cell parameters calculated from J–V curves measured by forward scanning.

| Jsc (mA/cm2) | Voc (V) | FF | PCE (%) | |

|---|---|---|---|---|

| ITO/TiOx | 8.03 | 0.94 | 0.54 | 4.09 |

| FTO/TiO2 | 11.2 | 0.88 | 0.54 | 5.28 |

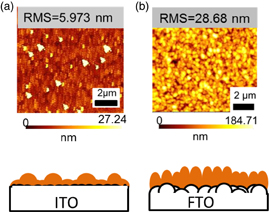

The relationship between solar cell performance and the low hysteresis in the PHJ perovskite amorphous and anatase solar cells is discussed. The AFM images shown in Figs. 5(a) and 5(b) reveal compact layer surfaces, with dense and uniform 100-nm-high TiO2 islands and 70-nm-high TiOx islands on their respective surfaces. There are numerous literature reports on mesoporous TiO2 and the effect on hysteresis as a function of the layer material.23–25) Snaith et al.24) reported that using a mesoporous TiO2 layer reduced the hysteresis on perovskite solar cells. Hence, we infer that with the low hysteresis produced in our solar cells, the 100-nm-high TiO2 and the 70-nm-high TiOx surface islands produce effects similar to those of the mesoporous-TiO2 material reported by Snaith et al. Island density observations revealed dense relined TiO2 islands and non-dense relined TiOx islands. The dense relined TiO2 islands on the compact-TiO2 films are generated because of the surface roughness of the FTO substrate, as RMS values of over 20 nm provide ample nucleation sights for larger islands to grow. The area of contact at the compact-TiO2 layer-perovskite interface was compared with that of the TiOx analogue; the anatase-based solar cells had increased surface area because of the high number of islands. The increased contact area influences the efficiency of electron collection, and therefore, circuit current is shorter for the PHJ perovskite solar cells containing compact-TiO2 layers that for cells with the amorphous TiOx materials.

Fig. 5. AFM images of (a) compact-TiOx (amorphous) on ITO and (b) compact-TiO2 (anatase) on FTO. Cross-sectional illustrations of each film are given below the images.

Download figure:

Standard image High-resolution image4. Conclusions

We reported herein the successful design of PHJ perovskite solar cells based on low-temperature compact-TiOx layers fabricated by the CBD method. All compact-TiOx perovskite solar cells, regardless of their layer thickness, were active as solar cells even compare with conventional compact-TiO2 anatase materials. The PHJ perovskite solar cell with a TiOx layer of 60 nm performed the most efficiently of the three materials, obtaining a PCE of 4.09%. This result is almost identical to that for the crystalline anatase perovskite, which possesses an efficiency of 5.28%. Furthermore, we concluded that the hysteresis is influenced by the surface structure of compact-TiOx and -TiO2 layers produced by the CBD method.

Acknowledgment

This work was supported by the Precursory Research for Embryonic Science and Technology (PRESTO) program from the Japan Science and Technology Agency (JST).