Abstract

This paper describes a liquid-filled tunable lenticular lens for switching between two-dimensional (2D) and three-dimensional (3D) images in naked-eye 3D displays. Compared with previous 2D/3D switchable displays, this tunable lenticular lens that is directly attached to a smartphone display can project both a 2D image with the original resolution of the smartphone display and a 3D image with high brightness. This lens is simply composed of transparent poly(dimethylsiloxane) (PDMS) microchannels. While the thin top membrane on the microchannels is normally flat to transmit light without deflection for displaying 2D images, applying pressure to the microchannel deforms the membrane to acquire characteristics of lenticular lenses for 3D images. We successfully demonstrate the switching between the 2D and 3D modes. We believe that our lens can be applied as a part of a portable 2D/3D naked-eye 3D display.

Export citation and abstract BibTeX RIS

1. Introduction

Recently, three-dimensional (3D) displays have become popular in video contents industries such as 3D movies and 3D video games. In particular, naked-eye 3D displays have potential for becoming a standard of next-generation displays because they do not need glasses or other special equipment [1]. As naked-eye 3D displays have become widespread, a function that switches between two-dimensional (2D) and 3D images in a single display is highly required because of user requests or characteristics of content. Lenticular systems [2] and parallax barrier systems [3, 4] have been considered as candidates for 2D/3D switchable naked-eye 3D display systems. Compared with parallax barrier systems, lenticular systems facilitate high brightness because they do not need optical barriers that impair light transmission. However, typical lenticular lens systems cannot show 2D images with the original display resolutions because of their lens effects. Consequently, it is difficult to obtain 3D images with high brightness and 2D images with their original resolutions in a single lenticular display.

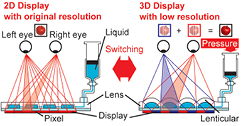

In this study, we propose a tunable lenticular lens system for 2D/3D switchable displays using the deformation of transparent elastic materials driven by liquid pressure (figure 1). This lens system is simply composed of PDMS-glass microchannels with a thin, deformable PDMS membrane at the top of the channel. When applying liquid pressure, the top membrane on the microchannels is deformed to form lens shapes. By controlling the shape of the liquid-filled tunable lenticular lens, we can obtain a naked-eye 3D display that switches between 2D images with their original resolution and 3D images with high brightness. Compared to previously reported tunable lenticular lenses based on liquid crystals [5–8] and electro-wetting [9], which suffer from optical aberrations [10–13], high driving voltage requirements [14, 15] and optical distortion [10–15], a liquid-filled tunable lens has advantages that overcome the above problems [16–21]. We apply this mechanism of liquid-filled lenses to a 2D/3D switchable display employing a tunable lenticular lens for the first time. Moreover, our tunable lenticular lens, when attached to the capacitance-type touch panel display does not disturb its touch panel function. In this study, we demonstrate a naked-eye 3D display that switches between 2D images with their original resolutions and 3D images with high brightness by applying this lens to an existing smart phone display.

Figure 1. Conceptual illustration of the liquid-filled tunable lenticular lens system for 2D/3D switchable displays. When pressure is applied, the thin top membrane of the microchannels becomes deformed to acquire the characteristics of lenticular lenses.

Download figure:

Standard image High-resolution image2. Design and fabrication

2.1. Design of the liquid-filled tunable lenticular lens

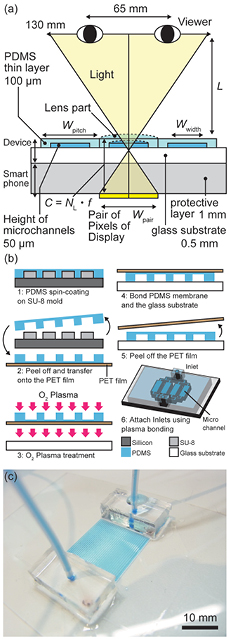

To design a naked-eye 3D display, the focal length and thickness of lenticular lenses are key factors. Figure 2(a) shows the construction of lenticular systems using a liquid-filled tunable lenticular lens. We designed a lens pitch (Wpitch), a lens width (Wwidth), and a lens length of 491 µm, 430 µm and 15 mm, respectively, by fitting to the width of a pair of pixels (Wpair) of a smartphone display (Galaxy S II LTE SC-03D, Samsung Electronics Co., Ltd, Korea). Note that we designed the lens pitches to contain two display pixels, which are a pair of pixels for the right eye and left eye. The whole area of the lenticular lens array is approximately 15 × 15 mm containing 32 thin rectangular lenses. When we fix the viewing distance as L, the focal length of the lenses (f) is calculated by

because the width of the pair of pixels for the right and left eye should be magnified to twice the distance between the eyes (we, 65 mm) when the images reach the viewer's eyes. Using equation (1), we calculated f as 1.13 mm by fixing L as 300 mm. By using f = 1.13 mm, the distance between centers of lenses and surfaces of pixels (C) should be designed to be 1.6 mm according to the equation

where the refractive index NL = 1.4 (refractive indexes of PDMS, water, and glasses are approximately 1.4, 1.3, and 1.5, respectively). Note that we ignore the effect of the thickness of the PDMS membrane for simplifying the calculation. Practically speaking, the thickness of the devices is 0.6 mm because there is a 1.0 mm-thick protective layer on the display pixels. The required radius of curvature of the lenses (R) is calculated as 450 µm using

Figure 2. (a) Design of the liquid-filled tunable lenticular lens. (b) Fabrication process of the liquid-filled tunable lenticular lens. This lens is simply composed of PDMS, a glass substrate, tubes, and syringes. (c) Image of the fabricated lenticular lens array.

Download figure:

Standard image High-resolution imageIn this system, we designed the thickness of the glass substrate as 0.5 mm, the thickness of the PDMS membrane as 100 µm, and the height of the microfluidics as 50 µm.

2.2. Fabrication of liquid-filled tunable lenticular lenses

We fabricated the liquid-filled tunable lenticular lens with simple soft lithography [22]. Figure 2(b) shows the fabrication process of the liquid-filled tunable lenticular lens. We spin-coated PDMS (Sylgard 184 Silicone Elastomer, Dow Corning) on a SU-8 mold (SU-8 Series; MicroChem Corp., MA) at 500 rpm for 10 sec and 1200 rpm for 30 sec to produce a PDMS membrane having microchannels. After heating the SU-8 mold at 100 °C for 30 min on the hot plate, we peeled-off the membrane and put onto a polyethylene terephthalate (PET) film. The membrane and a glass substrate (Matsunami glass Co. Ltd, Japan) were treated with O2 plasma. Subsequently, the membrane bonded to the substrate. Similarly, inlets for tubing were connected to the membrane. Note that we used PDMS at 10 : 1 ratio of the PDMS base and curing agent (Young's modules of PDMS is about 1.5 MPa) [23]. The stiffness of the PDMS membrane was appropriate to form the lens shape; when the PDMS was too stiff, the PDMS membrane did not deform, but when too soft, it was technically difficult to fabricate the device. Finally, deionized water was introduced to fill the PDMS microchannel. Air bubbles that were sometimes trapped in the microchannel completely disappeared when we applied pressure at approximately 30 kPa. Figure 2(c) shows the fabricated lenticular lens. We used a pressure-driven flow controller (MFCSTM, Fluigent S.A., France) to induce solution into microchannels and to control applied pressure.

3. Characteristics of lenses

3.1. Deformation of PDMS membranes

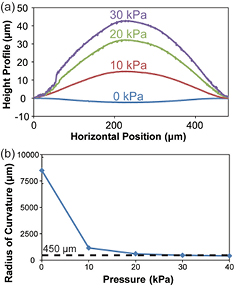

In order to determine whether the lens shape is sufficiently cylindrical or not, we measured profiles of the deformed membrane and examined the relationship between the applied pressure and the radius of curvature of the membrane. We used a laser interferometer (VK-X 200, Keyence Co., Ltd, Japan) and its analysis software (VK-X 200 Analysis Application, Keyence Co., Ltd) to measure the profiles of the membrane and the radius of curvature of the membrane. Figure 3(a) shows the height profiles of the membrane while varying the applied pressure from 0 to 30 kPa. The lens shape changed continuously depending on the applied pressure from 0 to 30 kPa. The delamination between the PDMS membrane and the glass layer occurred when we applied pressure more than 50 kPa. Note that air bubble did not occur by applying positive pressure or negative pressure. Figure 3(b) shows the relationship between the applied pressure and the radius of curvature of the membrane. These results indicate that when the applied pressure is 30 kPa, the radius of curvature reaches approximately the 450 µm that is required for 3D imaging.

Figure 3. Relationship between the deflection of the top membrane of the channel and the applied pressure: (a) Height profile of the deformed membrane when the applied pressure was 0, 10, 20, and 30 kPa; (b) Relation between the radius of curvature of deformed membrane and the applied pressure. When the applied pressure was 30 kPa, the membrane achieved radius of curvature of approximately 450 µm, which was large enough to show 3D images.

Download figure:

Standard image High-resolution image3.2. Focal length of liquid-filled tunable lenticular lenses

We also measured the focal length of the lens to confirm the focal length's variable range. The measurement method is shown in figure 4(a). A collimated light passed through the lens was focused into linear shapes at the focal point. We moved the camera position to measure the focal length. Figure 4(b) shows the relationship between the applied pressure and the focal length. The theoretical focal length was also calculated from the radius of curvature using equation (3). We confirmed that the device could change its focal length extensively (from 17 to 6 mm) by pressure-driven deformation. While we could not measure the focal length under 6 mm due to constraints of the experimental system, the measured values almost matched calculated values when the applied pressure was within the range 3–6 kPa. Hypothesizing that the focal length of the lenticular lenses matches theoretical calculation over the entire range of the applied pressure, we could estimate that the focal length can be reduced to 1 mm which is required for 3D imaging when the applied pressure is approximately 30 kPa.

Figure 4. Measurement of the focal length. (a) Experimental setup to measure the focal length of lenticular lenses. (b) Relationship between the focal length and applied pressure.

Download figure:

Standard image High-resolution image3.3. Optical characteristics' dependence on viewing angle

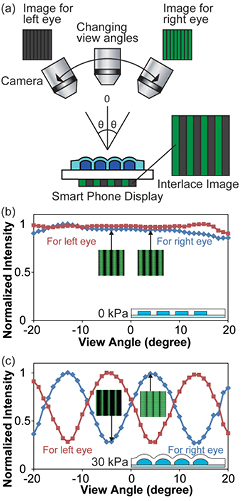

Next, we measured the optical characteristics' dependence on viewing angle. Figure 5(a) shows the method of measuring the view angle dependency of lenticular lenses. We placed the lens on the interlaced image composed of green line for a right eye and black line for a left eye, then observed the green light intensity from various angles (from −20° to 20°) to measure the angle-dependent light intensity for the right eye. After that, we swapped the position of the green lines and the black lines and observed light intensity in the same way to measure changes in light intensity for the left eye. In both cases, we performed this experiment when the membrane was flat and when it was deformed (applied pressure: 0 kPa and 30 kPa, respectively). Figures 5(b) and (c) show the relationship between the view angles and the normalized green light intensity when the membrane was flat and deformed, respectively. When the membrane was flat, the intensity from various angles was almost the same level, indicating that the light went through the membrane without reflection. When the membrane was deformed, peaks of green light intensity for the right eye and left eye were observed around 4°, indicating that the light was focused to those specific directions by the lens effect. These results show that this device has characteristics of lenticular lenses and enables on/off switching of its lens effect by controlling the applied pressure.

Figure 5. Measurement of the optical characteristics with respect to view angles. (a) Illustrated experimental setup for angle-dependent optical characteristics. (b, c) Normalized intensity of green light for various viewing angles when the membrane was flat (b) or deformed (c).

Download figure:

Standard image High-resolution image4. Applications

4.1. 2D/3D switchable naked-eye 3D display

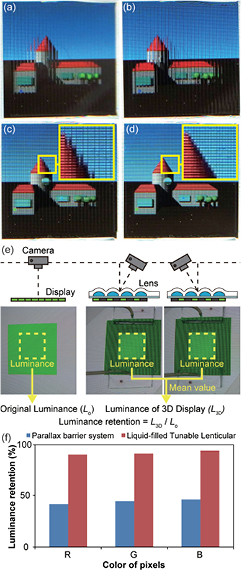

By applying our tunable lenticular lens to existing a smartphone display, our system achieves a 2D/3D switchable naked-eye 3D display. First we confirmed whether we could obtain 3D images through the lens. The interlaced image, which was composed of two different images for the right eye and the left eye, was displayed on a smartphone display. After putting the lens on an interlaced image, the membrane was deformed by applying pressure. When the applied pressure was 10 and 20 kPa, we could not obtain 3D images because the lens deformation was not enough. By applying pressure of 30 kPa, we deformed the membrane to successfully project two different images for the right eye and left eye depending on viewing angles at 4° (figures 6(a) and (b)). This means that our system can display parallax images which are processed as a 3D image in the human brain. Next, we determined whether we could display 2D images with their original resolutions through the device when the membrane was flat. The device was put on the smartphone display, which shows a 2D image with its original pixel resolution. While we obtained the distorted 2D image due to lens effects when the membrane was deformed, we could also observe the clear 2D image when the membrane was flat (figures 6(c) and (d)). This means that our system can display 2D image with original pixel resolution of the smartphone display.

Figure 6. The images through the tunable lenticular lenses attached on a Smart Phone display. (a, b) 3D images when the membrane is deformed; (a) is the image for the right eye and (b) is the image for the left eye. (c) Distorted 2D images through the lenses when the membrane is deformed; (d) Clear 2D image with original resolution of the display when the membrane is flat. (e) Method of measuring luminance retention. (f) Luminance retention of the display. The value of parallax barrier systems is cited from [4].

Download figure:

Standard image High-resolution image4.2. Luminance retention

Finally, we evaluated the luminance retention of the 3D display using our lens by comparing it to a parallax barrier system [4]. We calculated the luminance retention of displays by measuring the luminance of images of screens taken from the viewer's position using image processing software (ImageJ, Wayne Rasband) (figure 6(e)). First, we measured the luminance of the display without attaching our lens. We defined this luminance as the original luminance of the display (Lo). Then, we put our lens on the display and measured the luminance of the two images taken from the viewer's right eye and left eye positions. We defined the luminance of our 3D display (L3D) as the mean of these values of luminance. After that, we calculated the luminance retention by dividing L3D by Lo. Figure 6(f) shows the luminance retention of the display through our lenses. Although the maximum theoretical value of the luminance retention is 50% in parallax barrier systems [4], we succeeded in maintaining over 90% of luminance of the display.

5. Conclusion

In conclusion, we proposed a liquid-filled tunable lenticular lens whose focal length can be adjusted by liquid pressure-driven deformation. Optical characteristics of the tunable lenticular lenses were measured, and a 2D/3D image switchable naked-eye 3D display without luminance retention was demonstrated. Although the size of the lenticular lens array demonstrated here was 2.25 cm2 in area, we think that our device could be extended to larger displays if we can manipulate a larger volume of fluid to drive the lenses; our device requires 0.2 mm of liquid for a 10 cm2-area of lenticular lens array. To realize smaller lens apertures for high resolution displays, the thickness of the membrane and the bonding area between the PDMS and the glass layer could be key parameters to avoid the delamination of the PDMS and the glass layer. Once the both parameters can be optimized, smaller lens aperture, for example, ~100 µm of lens diameter, could be achieved. We believe that our tunable lenticular lens system could be applied to portable naked-eye 3D displays capable of 2D/3D switching and adjusting a viewing a space to viewer's position by combining with head tracking systems.

Acknowledgments

This work was partly supported by ERATO Takeuchi Biohybrid Innovation Project, JST, Japan.